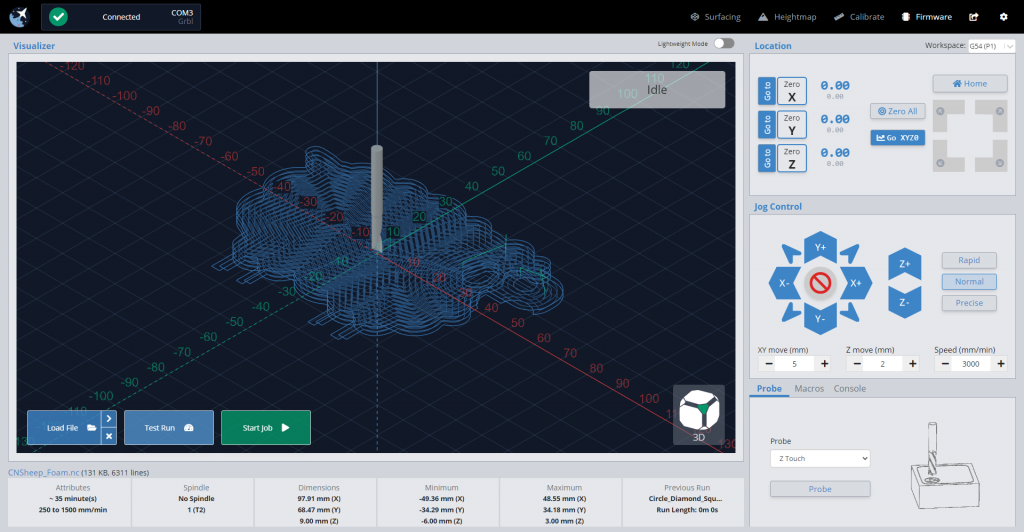

Your CNC dashboard

- It’s Free!

- Supports grbl and grblHAL CNCs

- Connect over USB or Ethernet

- Wireless control from a second device through a browser

- Quickly position your CNC in all axes

- Set zero manually or using a touch plate to locate your cutting job

- Preview g-code with 3D visualization and other information

- Run cutting jobs with active feedback and overrides

- Leverage keymaps for full-keyboard control or use a joystick

- and much more!

Why choose gSender?

- Designed to be clean and easy to use no matter your previous CNC experience

- Brings new features to the table for easier CNC calibration, surfacing, tool changing, firmware control, and more

- Streamlined code-base and optional ‘Lightweight mode’ means larger cutting jobs run more reliably

- Presets support many GRBL-based machines and works out-of-the-box on the LongMill and AltMill CNCs

Downloads

Having trouble with most recent version of gSender? Click here to find the previous one that worked for you.

Development is still ongoing, providing feedback will help us continue to improve it.

Interested in trying some bleeding-edge features? Try gSender Edge – our test playground for the future of gSender (download page)

Full Feature List

- GRBL controllers supported

- Smart machine connection

- 3-axis digital readout (DRO) with manual value entry

- All-directional jogging with XY diagonals, jog presets, and incremental/continuous single-button handling

- Zero-setting and gotos (independent and combined)

- Probing in any direction plus safe continuity detection ensures no broken cutting tools

- Full imperial/metric compatibility

- Responsive screen design and workspace customizations including visualizer light and dark theme

- 3D toolpath visualization (no machine connection required)

- File insight on load (feed range, spindle range, tools used, estimated cutting time, and overall, max, and min dimensions)

- Feed override and active job status indicators

- Fully exposed keyboard shortcuts for external keyboard/keypad control

- Joystick support built-in for a variety of controllers

- Safe height movements – accommodates machines with or without endstops

- Homing cycle and quick-movement locations available for machines with homing hardware

- Full spindle/laser support via manual control widgets, active alerting, and live overrides

- Full mist/flood coolant support via manual control widgets and active alerting

- Macros buttons (rearrangeable) with enhanced macro variables and individually assignable keyboard shortcuts

- Lightweight mode reduces processing intensity on less powerful hardware or when running larger files

- Easy workspace swapping for more advanced jigging or alignment work

- Optional automatic handling for common error throwing g-code

- Firmware tool for easier GRBL EEPROM changes, loading defaults, and GRBL flashing

- Surfacing tool auto-generates surfacing g-code based on machine cutting area and other preferences, ready to execute

- Calibration tool for axis alignment – a step by step process to make sure your CNC is square

- Movement tuning tool for calibrating motor axis movements

- Tool change functionality – pause, ignore, or run code blocks on M6 commands

- Start-from-line functionality to resume jobs part-way through in case of failure of abort

- Outline functionality indicates the rough bounds of the job before cutting

- Customizable g-code injection at job start & end

- Tooltips for data entry points

- Alarm warning explanations to better contextualize CNC errors

- Sleep management to keep PC awake during g-code sending

- Pre-built machine profiles, including:

- LongMill

- AltMill

- Shapeoko

- X-Carve

- OpenBuilds CNCs

- Ooznest WorkBee

- Nomad

- Carvey

- RatRig

- 3018 CNC & PROVer

- Bulk-Man 3D

- FoxAlien

- SainSmart/Genmitsu

- YoraHome

- Two Trees

- BobsCNC

- CNC4Newbie

- MillRight

- Onefinity (running grbl-based controller)

- Mill One, and more…