Hey everyone, here’s our July production updates.

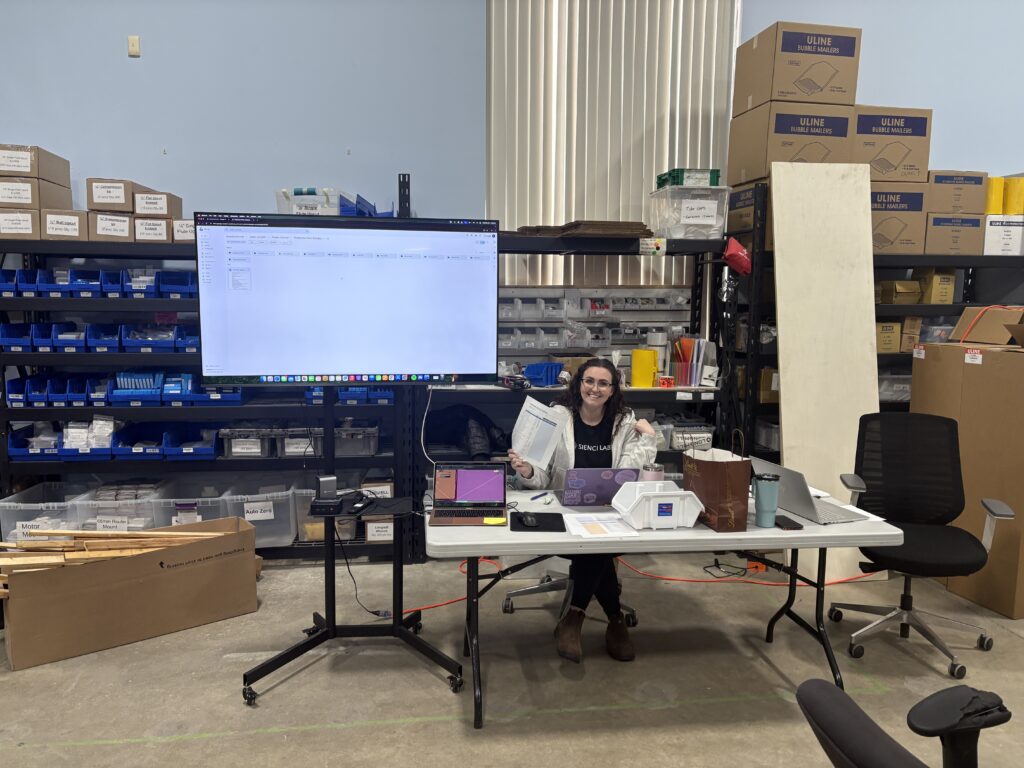

If you haven’t checked out our warehouse tour, make sure to check it out here:

Cost, quality, speed?

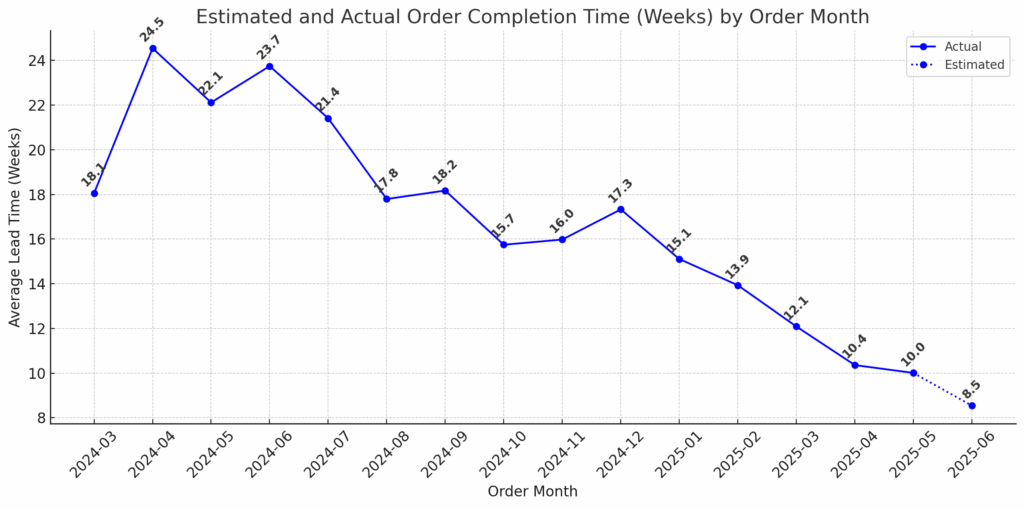

While the lead times for newly released products, especially the AltMill, tend to be a sticking point for many customers, our process is intentional to provide products at the lowest cost and the highest quality possible. Long lead times is temporary, as once we’ve establish and mature our production process, the average lead time drops significantly. To learn more, check out our article here.

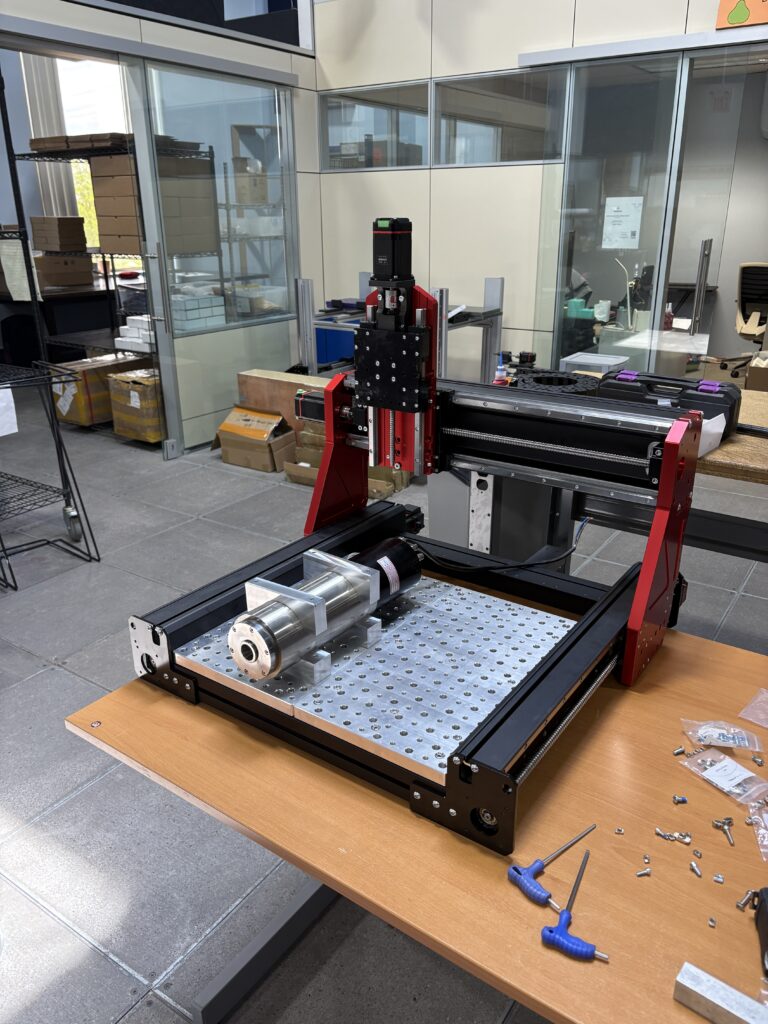

AltMill 2×4 and 4×4

AltMills continue to ship to clear out the remaining materials from Batch 4. We are now waiting on some of our Batch 5 parts to arrive which are needed to continue shipping in July. Based on current shipment tracking data, we are expecting parts to arrive July 9th, but still have a chance to be delayed. Due to this uncertainty, plus time to destuff and sort parts, after Batch 4 is complete, there is a chance that machines will start shipping in August.

While we continue to wait for our next batch of parts, our team is continuing to pre-pack and assemble parts on hand so that we can ship remaining orders in the queue rapidly as soon as we have everything ready to ship. This means that the first few weeks of July won’t have much shipping out but as soon as the new parts arrive, we’ll be aiming to ship around a hundred AltMills per week.

We are expecting to have a strong shot at significantly reducing our lead times, because when the final parts for Batch 5 arrive, we will have more materials on hand than machines currently sold. However, we do expect demand to pick up further as from August we’ll be entering into our busy season.

grblHAL merge

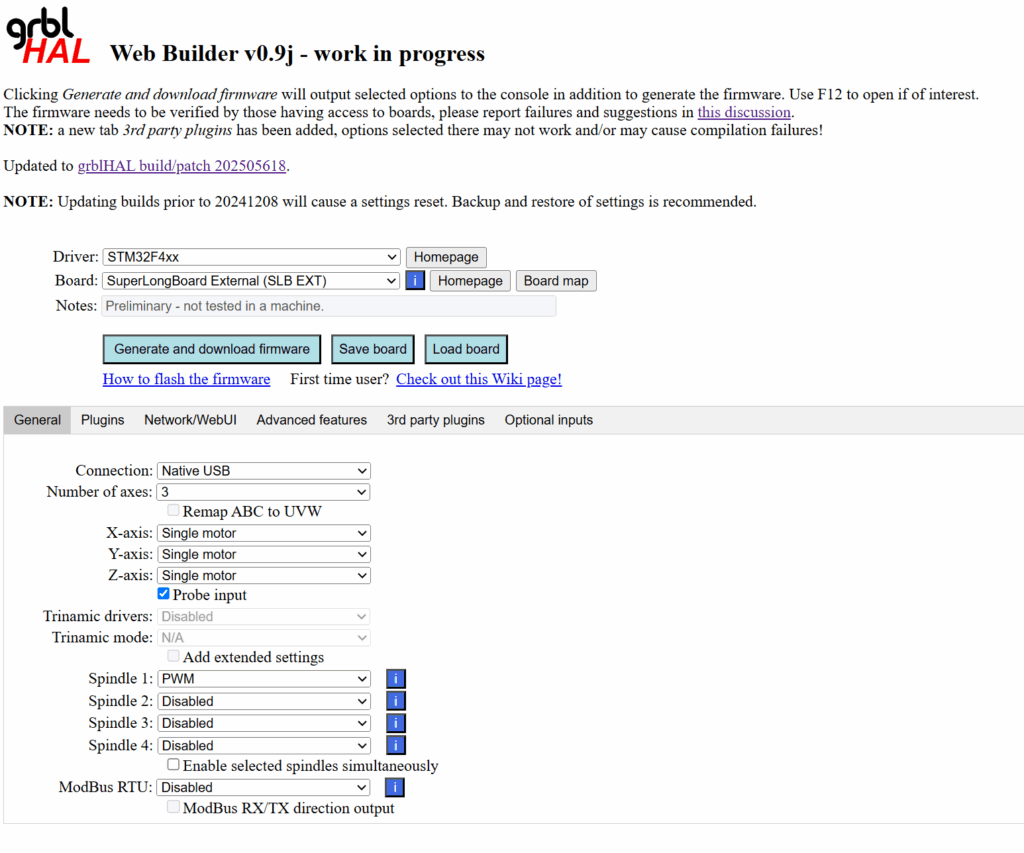

For current and upcoming CNC users with the SLB or SLB-EXT, our team is currently working on a grblHAL merge. As of current, the AltMill is using a modified version of grblHAL that branched off into it’s own version a little more than a year ago, with machine specific features and modifications. This code merge is intended to merge all of the features we’ve developed, plus all of the new features and support in the latest main version of grblHAL together. Our goal in the future is to allow new versions of grblHAL compatible directly with the boards and users will be able to update using the web builder for different use and configurations of SLB or SLB-EXT.

Once this merge is complete, we should see some smaller improvements, such as the handling of various alarms and motion planning, as well as integrating better support for toolchanger workflow.

gSender 1.5.0

A new, overhauled version of gSender is now out, with improvements to the user interface and new features.

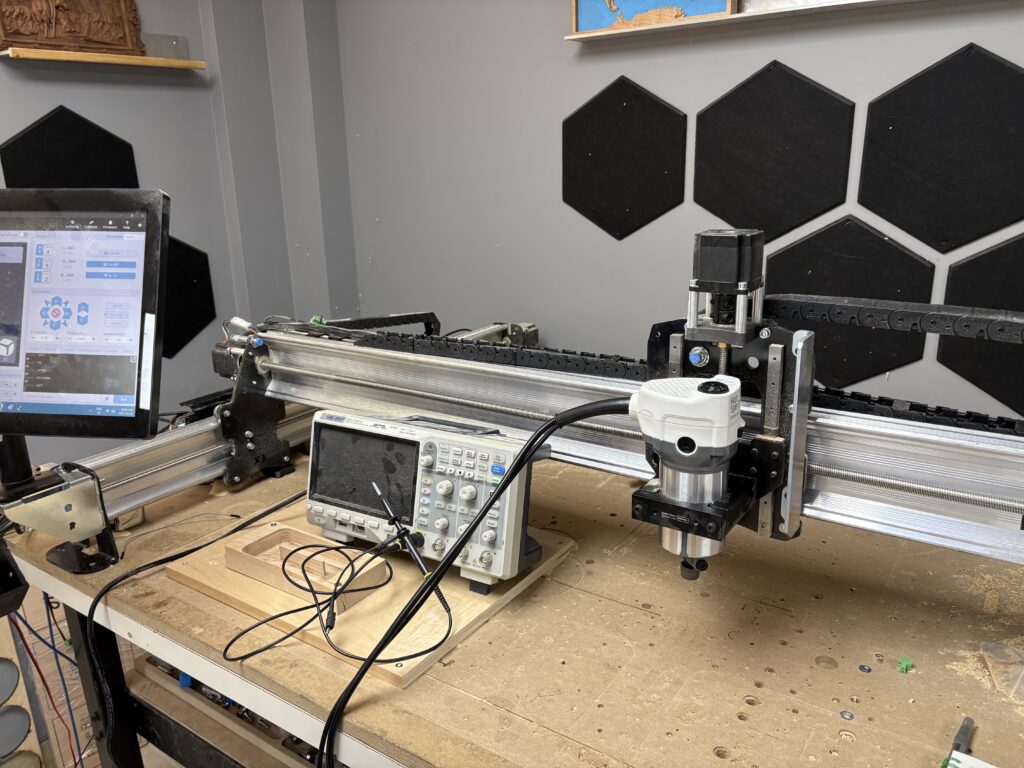

AltMill 4×8

Development continues to move forward with the AltMill. As we alluded to in the previous update, our main development challenges currently revolve around improving the accuracy of the Y-axis system. After additional testing with several different gearboxes, we’re happy to announce that we’ve had acceptable results for the latest batch of gearboxes. We are currently working on improving the placement of the additional components to optimize for space efficiency.

For this month, we are expecting to complete a first stage full size prototype with incoming set of rails and additional parts. A couple of things in progress include:

- An “eloquent” way for joining rails together accurately.

- Continued design on improving the positioning of the gearbox.

- Long term wear testing.

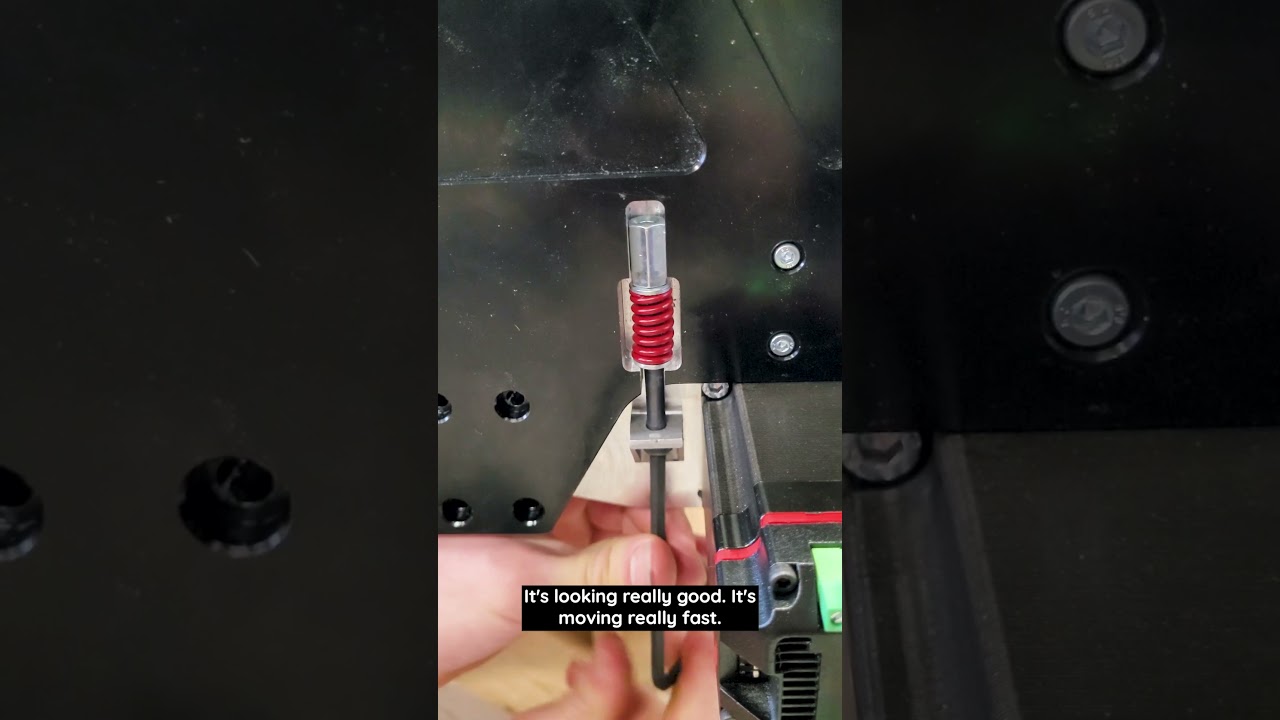

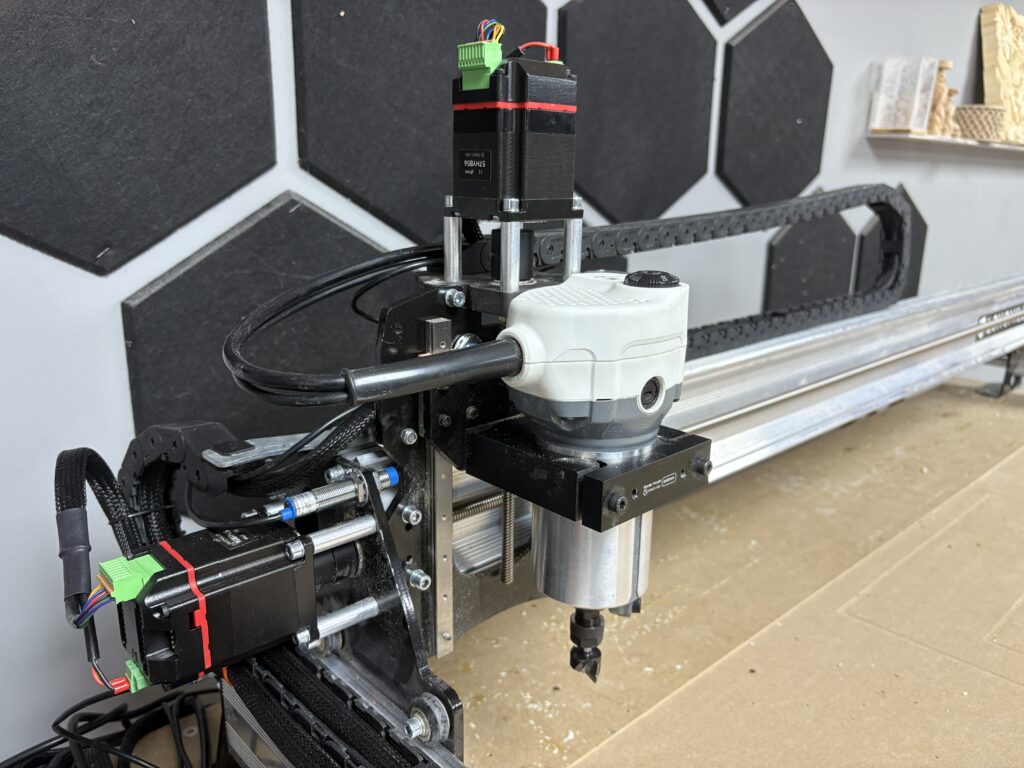

Automatic Tool Changer

Toolchanger development is moving along well. Some of the main development done in the past month focuses on improvements to the design of the pneumatic systems:

- Testing with using different air compressors commonly available to the general public

- Changes to the manifold to improve compactness

- Testing of overall reliability (over +700 tool changes completed so far)

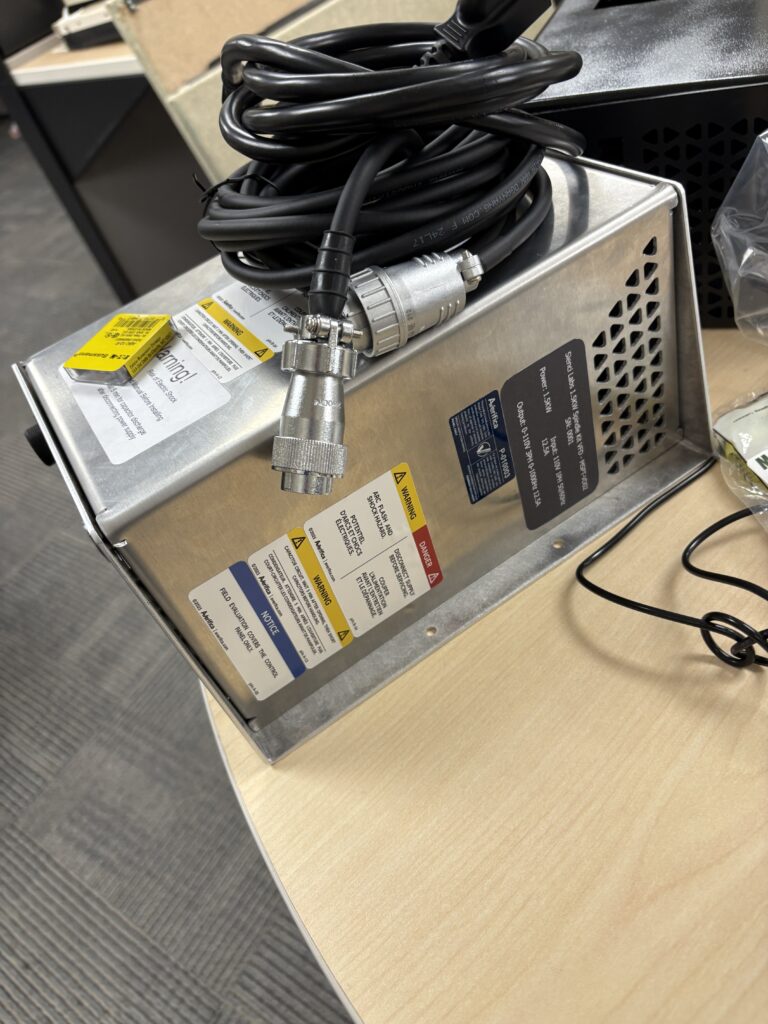

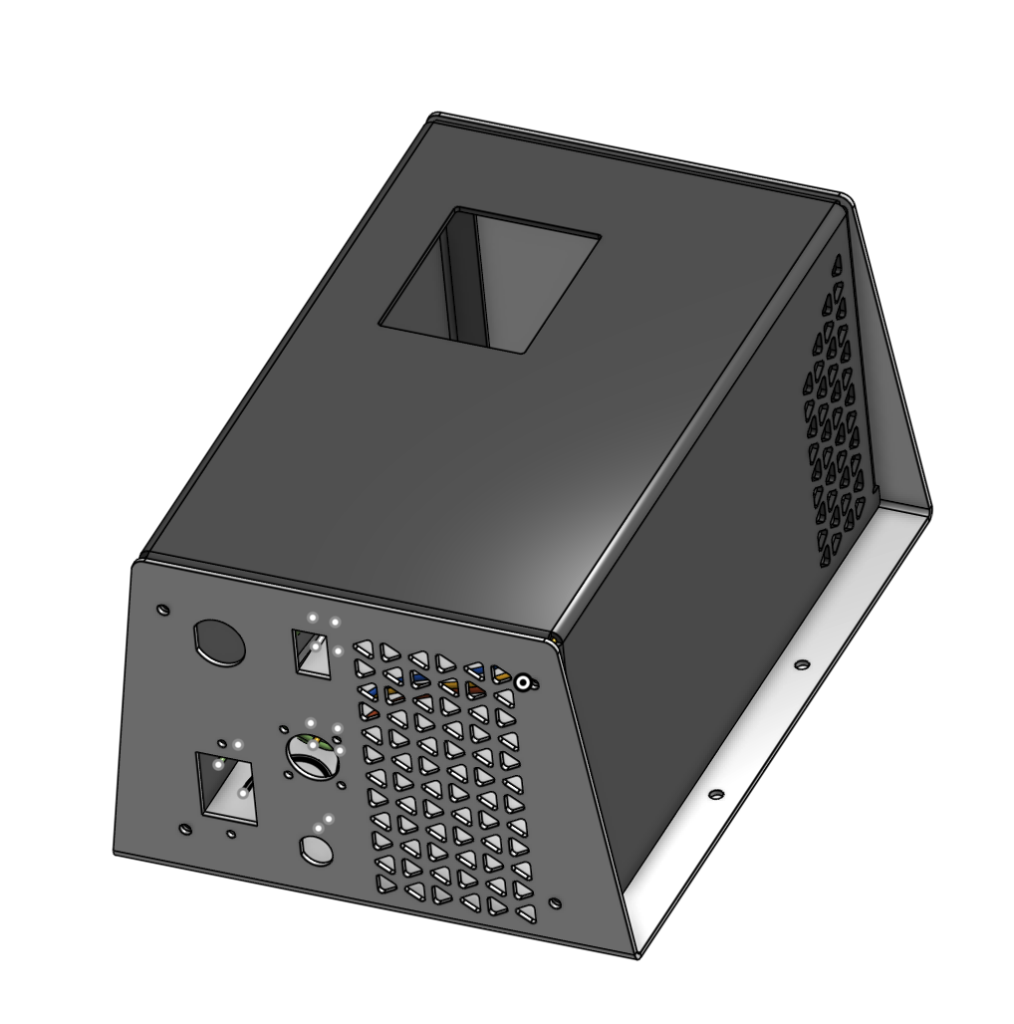

Certified VFDs

As we talked about in some of our previous updates, we’ve been working on building a certified version of the H100 VFD, since they are not certified for sale within Ontario. Since we have completed the certification, we are now waiting on parts to arrive to start shipping replacements to customers in Ontario new VFDs if they have opted in. We are expecting these to arrive mid to end of July.

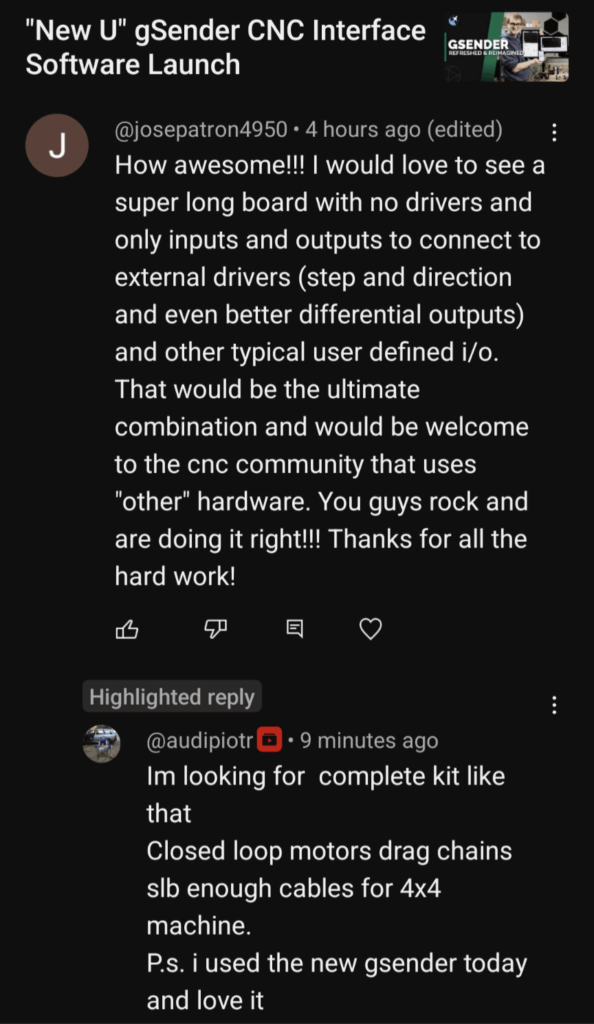

Close Loop Stepper Motor and SLB-EXT Kit?

It’s been a pretty popular request, but perhaps an even more popular request recently for us to release the SLB-EXT and close loop stepper motors to the public. We primarily haven’t up to this point simply because we’re trying to hold onto them so that we don’t run out of them for the AltMill production.

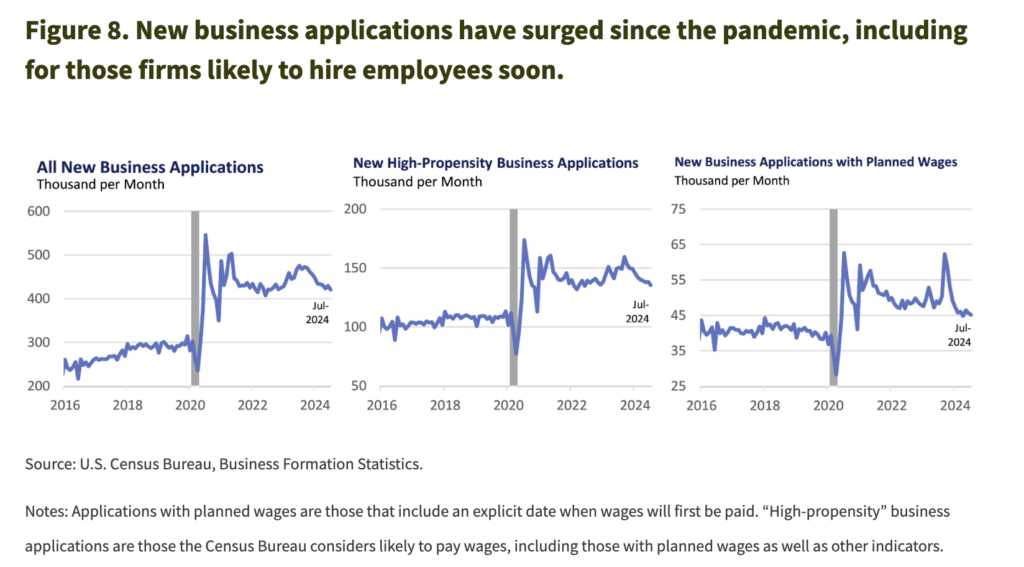

I believe there are a couple of other factors playing into seeing some additional demand for this solution to be launched, which include:

- Closure of OpenBuilds, which provided the popular “BlackBox” series of controllers

- Production uncertainties around third party controller supply availability for some OEM manufacturers

- Increasing popularity in grblHAL platform, DIY builds, and growth in new hobby CNC manufacturers

What are some things folks may expect to see with a kit like this?

- Ability to retrofit close loop stepper motors to the LongMill family of machines*

- Ability to retrofit close loop stepper motors to many, if not most hobby CNC machines on the market

- A simplified option for DIY builders

- The ability for other CNC manufacturers like us to use the same electronics platform across many different types of machines

And why would a kit like this be the ideal solution for these people?

- The kit is already tested and proven on the AltMill CNC as they share the same components.

- At an expected price point of around $500USD, one of the least, if not the least expensive complete kit of it’s type.

- Compatibility with other accessories in our ecosystem, including gSender, gControl, AutoZero touch plate, and more

- Open source, which means that companies and individuals can reproduce and modify source code and designs to fit their needs, regardless of whether Sienci Labs continues to exist or not.

So what’s next?

- As of current, we are knee deep in sourcing for Batch 6 AltMill. A survey to determine demand would help us understand how many additional components we should order to support upcoming demand.

- We need to determine what sort of resources and documentation to provide to allow users to retrofit the kit to their own machines.

- We need to see what type of machines people are looking to retrofit, so that we can have proper wire and cable lengths on hand.

If you want to help, please feel free to answer the survey below!