Description

***Included with your AltMill MK2 4×4***

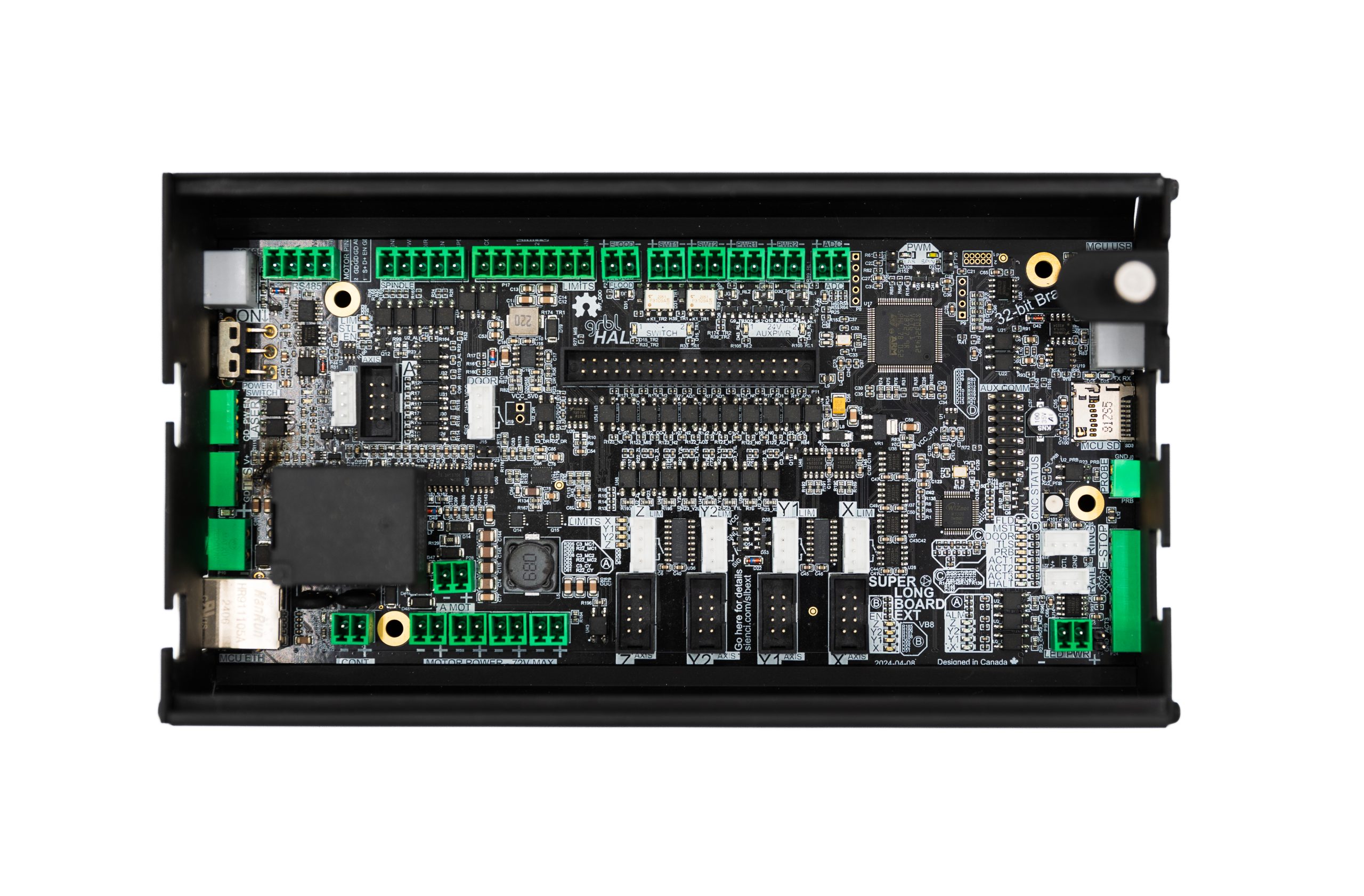

- SLB-EXT controller and emergency stop

- 48 Volt Power Supply

- Partially pre-assembled rigid frame

- Inductive sensors for homing

- Sturdy metal legs with the ability to add 4ft wide shelving underneath

- Welcome package

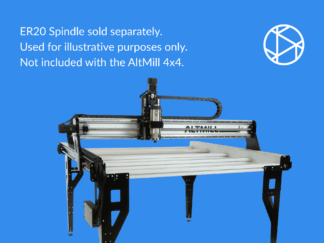

***Not included with your AltMill MK2 4×4***

Check out our recommended products tabs for an ideal set up, but note the following ARE NOT included with your order:

- Computer or laptop

- Spindle

- End mills or bits

- T-tracks

- Waste board (e.g. MDF 2ft x 4ft sheet)

- Set of metric Allen keys, standard bits or drill for assembly

***Some photos may contain items for illustrative purposes, such as spindles, caster wheels, t-tracks, or additional shelving. There may also be cosmetic differences between the machine in the photo and the production version of the AltMill.

Lead times

This product has a potentially long waitlist, relative to demand and seasonality. For more info on expected shipping and delivery times, please see our Order Status page.

Jeff Denney (verified owner) –

This machine is quite a step up from the belt driven open stepper one I had for 7 years. Definitely faster, smoother, easier to set up. Assembly instructions and videos were good enough to get a mechanically competitent person to complete assembly. However a novice may have some difficulty. I was a little let down at lack of a spoil board and that may be a challenge for a novice as well. Build quality is very good. I would be interested to being a beta partner to help continously improve this platform and supporting materials.

MAXIME BELANGER (verified owner) –

I upgraded to the Altmill 4×4 from a Longmill and the difference is night and day. The Altmill is fast, reliable, and honestly, for the price, nothing else touches it in terms of build quality. I had a little issue with my SLB and they sent a replacement board the next day.

SERGIO Arreola (verified owner) –

Great product, value and service. Thanks!

Kyle C. (verified owner) –

The build quality is great. Going from a homemade machine to the 4×4 was a huge improvement. The repeatability alone is amazing.

Taitum L. (verified owner) –

Overall very happy with the machine. Set up of the actually gantry was a breeze. I did stumble into hiccups with my spindle. I chose to do a 3rd party ATC set up with a 800hz spindle. And I notice either gsender or the SLB don’t have a lot of support for 3rd party spindles, at least not with modbus anyway. That being said, I knew going in doing a 3rd party spindle, especially ATC would have its challenges, im not blaming Scienci labs for that. Just that it would have been nice to have a little more support for 3rd party. That being said, I fixed my issues with pwm control and the machine is looking like it’s going to be pretty sweet. (Haven’t actually finished it yet so haven’t really given it a proper test)

Travis S. (verified owner) –

Has been great so far. Setup instructions were good and got me running as quickly as feasible.

David Kelly (verified owner) –

SLB appears dead on arrival. Do I need to buy another one?

James Carmody (verified owner) –

Very good CNC, my 3rd machine and I am more than happy I spent the extra money and went away from the budget model CNC’s and went for a top-level machine. It is definitely worth the extra money. Well built, solid machine with clear instructions on how to put it together. There is also a lot of information online to help out with potential issues when getting started with the machine. I live in Australia and the machine was shipped here a lot quicker than I was expecting and hassle free. My only negative point so far would be that I have some small corrosion spots on the X & Y ball screws and on the X axis linear guides where the Z axis guide blocks slide along. to be fair I live in a coastal area, so I was expecting to have to deal with some surface corrosion. it doesn’t affect the machines performance or accuracy it’s just an extra step in the maintenance/cleaning of the machine that I have to perform all my other tools/equipment suffer the same issue. To anyone outside of Canada/North America I Strongly believe this machine is worth the extra effort with regards to import duties and/or taxes and sorting out a power supply if your countries voltage is different to 110VAC. Everything from the G-Sender software to machine assembly/use is very user friendly with a host of information online on the Sienci website.

John Yount (verified owner) –

Good experience overall. Easy to find and follow instructions. YouTube videos were very helpful and plentiful.

My only suggestion for improvement is to include tramming in your basic info more prominently. Using the off axis screw on the x axis mount for tramming the Y direction was not successful. I ended up using the old school method of sheets of paper in the spindle mounting bolts. The off axis screw worked great for the x axis tram (one of 4 spindle mounting bolts.)

This is a sideways compliment. When I inserted the bolt into the x axis mount to try to tilt the spindle front to back( I was raising the front) all it did was lift the entire x axis beam on the right side. The thing was so rigid and stiff that I couldn’t make it tilt. Great idea on paper but I couldn’t make it work. The thing is just built too well.

I had a little experience with a desktop Foxalien CNC and Easel free version.

I’ve been cutting out French Cleat hangers, playing with some signs, made a great spoil board and work holding setup, carved some of the clip art provided with a Vcarve and I’ve been very impressed with the quality of the machine. I’ve only touched on the speeds. Nothing over 120 inches per minute so far. I’ll increase that with more testing of bits and materials. It’s just so much faster and more accurate than my little desktop CNC that I haven’t needed to push it faster yet.

If you had a way to upload images I would send you a picture of the spoil board and overhead dust collection arm. Both are hybrids of many versions I’ve seen. I’m settling in on 3d printed clips for work holding and anchoring them to the t track. I’ve hit them several times but the machine just trims them and keeps going.

It was a lot to assemble. I did do it solo. Except for flipping the base over to mount the front legs. I used 2 bench jacks to support and lift the x axis beam. That is my first use of the jacks and it was so cool to be able to safely and securely lift it. I would have had to have a helper otherwise. You did a great job with the sturdiness and rigidity. The size and weight can’t really be sacrificed. That’s another sideways compliment.

I am genuinely impressed with the machine and the value.

Do you have a database of your bits for Vcarve? I’ve had to make up a few including the surfacing but for the spoil board. If you have it I haven’t found it yet.

Andrei Apanasevich (verified owner) –

Very good machine, compact and strong, easy assembly

Richard Perdue (verified owner) –

Great machine it took about 6 hours to set up but I was ready and had my area cleaned out and my MDF was already cut. I did watch all of the assembly videos and reviewed the step by step instructions several times before the machine arrived. I love it!

John Boyd (verified owner) –

easy to use using easal pro getting use to the software is taking time. so far just need to use it more otherwise love it.

Micah Penman (verified owner) –

Amazing CNC!!

Cory (verified owner) –

Great Machine, I am so happy with my choice after all the research. One of best machines out there.

Chris Harrison (verified owner) –

fair price