I know that a lot of you guys have been waiting patiently to order the new Sienci Mill One. We wanted to make sure that going forward, we could produce machine kits at a reliable pace. We’ve held off on taking these new orders until we’ve established our supply chain and fully understand what lead times we can expect from our suppliers and manufacturers. Also, we’ve been fiddling around with a variety of e-commerce platforms to set up an efficient method for our customers to order their machines, and are establishing more resources for assembling and using the Sienci Mill One.

Now the time has come…

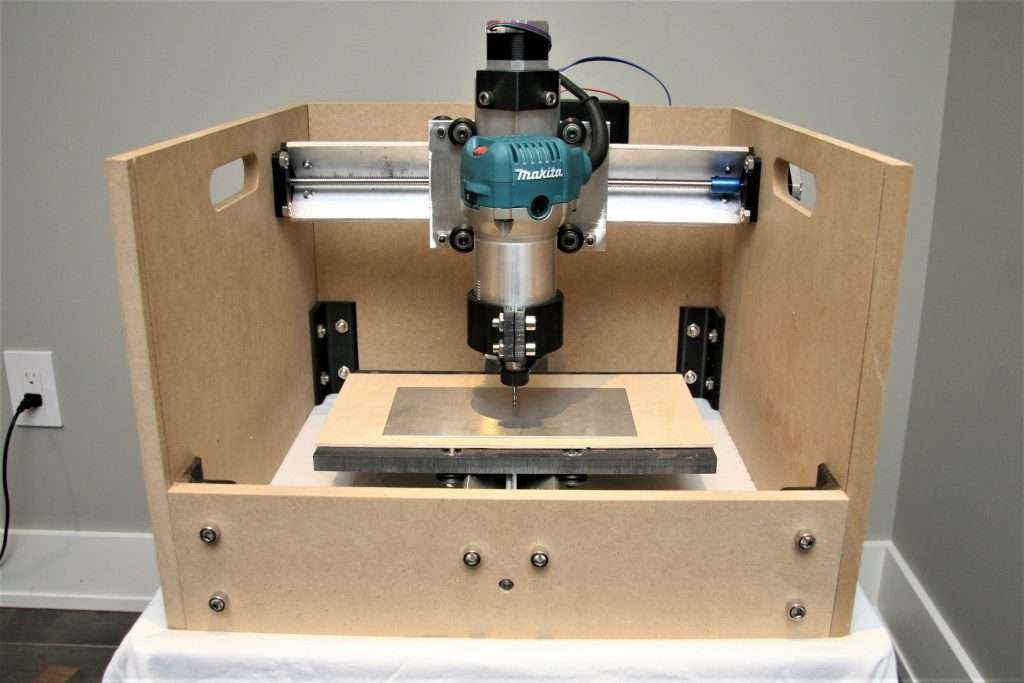

Within the next week or two, Sienci Labs will be taking new orders for the Sienci Mill One. We will be offering the complete Sienci Mill One Kit (without a router) to our customers in the US and Canada for $499USD (plus shipping). Those who have signed up for our waiting list will have early access to these kits for one week and will receive a passcode which will allow them access to the ordering page.

At the current moment, we will not be offering routers to go with the Sienci Mill One because we are not able to offer prices that are competitive to what you can find from other retailers until we can purchase over 100 routers at a time. Routers can be purchased online or at hardware stores (such as Home Depot or Amazon). The Makita RT0701C and Ridgid R24012 will be supported for the Sienci Mill One, but if you have another router or tool you would like to use, please contact us about a custom solution.

The estimated lead time for the second batch of kits will be 6-8 weeks and machine delivery will vary based on shipping location. Kits which were ordered through Kickstarter will be given priority, and newly ordered kits will be shipped in order of which they are placed. We will continue to update our customers about our progress and any delays on our blog and social media pages (Facebook and Twitter) and keep our inventory list updated (inventory).

If you have any questions or concerns, please email us at hi@sienci.com and we’d be happy to help you out!