You know when you’ve just ordered a lot of parts when the weight of the package that’s going to show up at your door is nearly 360KG (about 800lbs for the Americans). We finally completed negotiations with one of our major suppliers in China and have a lot of things coming our way soon. There are a couple minor things we still need to get, but since they are fairly low value items, I feel like a weight has been lifted off my back.

What’s left to order are USB cables, clamps, and eccentric nuts. So a little bit of online shopping to do.

According to our aluminum supplier, the aluminum angle should have arrived at the machining facilities yesterday and should be ready to be picked up in one or two weeks. I will check in later and see how things are going with that.

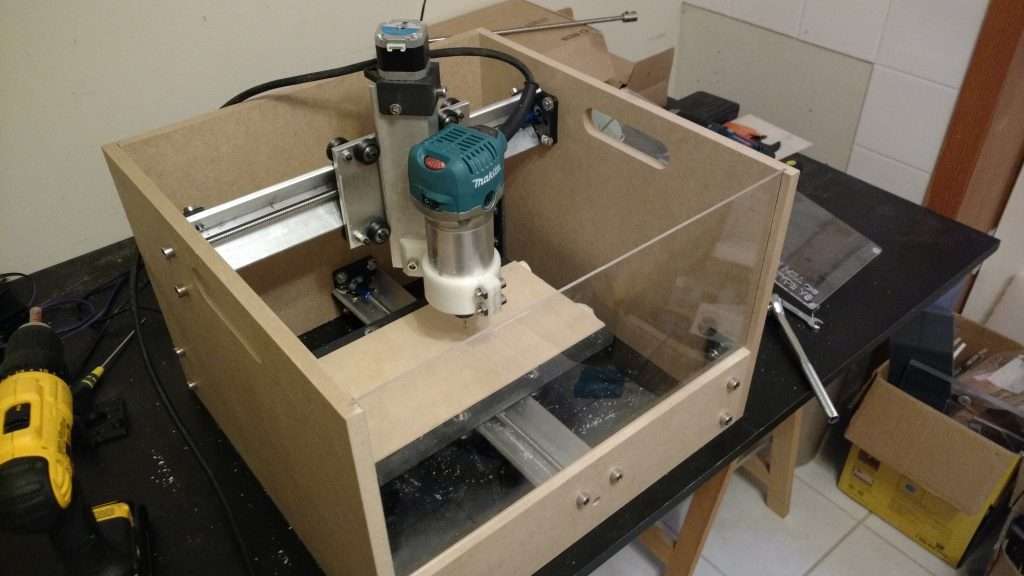

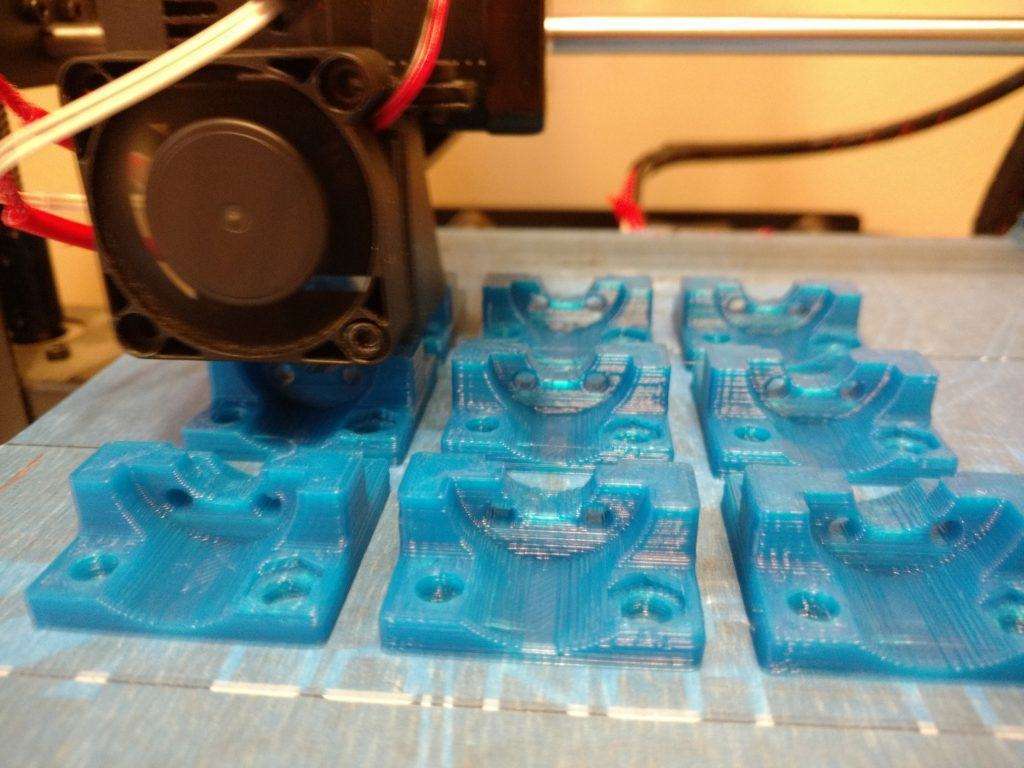

In terms of the 3D printed parts that are used in the Sienci Mill One, we have decided to purchase two new 3d printers (Maker Select V2’s) to print out the parts, and also work with Andrew Netherton from Netherton Solutions (Hi Andrew, I know you’re reading this blog!) with his Makerbot. Andrew is one of our backers, and it’s pretty cool to have him on board to help us. We’re figuring out the most optimal settings to get the best parts out of his 3D printer, but we should be churning out new parts soon!

So in total, that’s five 3D printers that will be chugging away. A sixth when Chris’s Cetus printer that he backed on Kickstarter shows up (estimated delivery date is November, but who knows what the actual delivery date will be). Nevertheless, we should be able to make the parts fairly quickly, and keep up continuous manufacturing after the Kickstarter batch of machines have been made.

The parts we have already received, Chris and I have been using our spare time to count them out and throw them into baggies, and organize our stock. We will continue to do so as things arrive, and once we have enough items, we can purchase boxes and other packing materials so start assembling the kits.

To finish up, I wanted to mention that our friends at Waterloop: The Canadian SpaceX Hyperloop Competition Team have launched a Kickstarter to help fund the development of a super high speed train system. Check it out, and show them some love!