Andy Lee’s Enterprise Co-op term is coming to an end this month, but he and his co-founders at Sienci Labs are busier than ever with the launch of their Kickstarter campaign. The campaign aims to bring the Sienci Mill One, an affordable and user-friendly desktop CNC milling machine, into the hands of creative makers across the world.

Over the course of the term, the Sienci Mill One has undergone eight iterations of design, with continuous improvements for performance, affordability, and ease-of-use. In this blog, Andy describes how getting outside the building and talking to customers has helped the team create a better product — one that people can’t wait to use!

When my co-founders and I started Sienci Labs, we began with the purpose of making mechanical systems in rapid prototyping and fabrication tools (such as 3D printers, laser cutters, and CNC milling machines) more affordable and easier to use in consumer applications. Over time, the team decided to create our own machines using the systems that we had developed. As a proof of concept and first product, we developed a desktop sized CNC milling machine.

During our Enterprise Co-op term, we headed out the door with our early prototype machines to answer the two questions that all startups need to ask themselves: “Who are our customers?” and “what do they want to buy?”

Find your customers where they hang out

At first, we planned to market the product to low budget makers, hobbyists, and artists who want to turn their digital 3D models into real objects in materials like wood, plastic, and metal at a touch of a button. Events like Hamilton Maker Faire and Toronto Maker Festival put us in front of hundreds of interested people in our target demographic and helped us to develop customer archetypes and figure out what type of people needed our products.

At these events, we showed off our newly-developed desktop CNC machine to people who do everything from leatherworking, to electronics, to 3D printing, and woodworking. The purpose was to connect directly to our target market and get their thoughts and feedback as well as garner interest in the company.

Our initial method of testing customer interest was to mill examples of some of the things our customers were looking for. Whether it was Teflon sensor holders or model cars, we were able to focus on the features that were key in making what they needed.

Be flexible to feedback

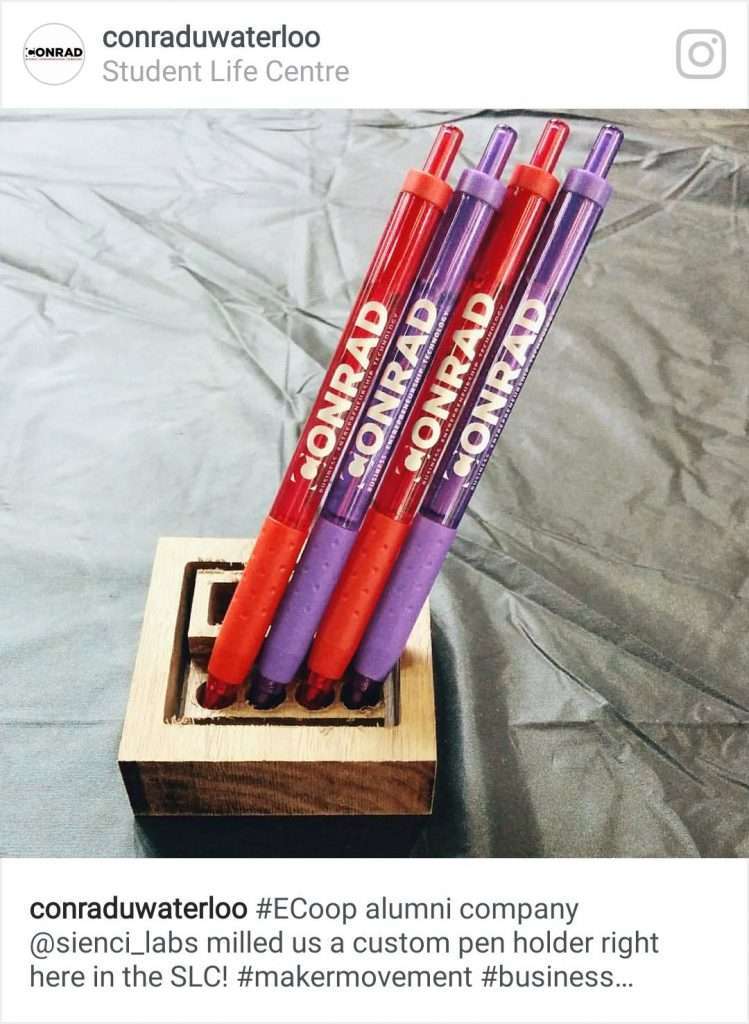

After several of these events, we discovered that our users were mostly small businesses who wanted to make custom parts for themselves to save substantial amounts of money, or wanted to create products to sell.

While we had initially believed that makers and hobbyists would purchase this machine for personal use, we discovered that businesses and organizations were more willing to put the money down to get one of our machines. This is not to say there weren’t a lot of makers and hobbyists who were interested, but we realized that marketing to small businesses would yield the most traction.

Solve customers’ problems

With all of the people wanting to purchase and distribute the Sienci Mill One, we knew that we had figured out who our customers would be and that what we had created fit their needs.

If you’re starting a business, go out and see what people want to pay for! Ask them what they need. Help them solve their problems, and create something new that can make their lives better. Keep iterating!

Check out Sienci Labs’ Kickstarter campaign, and keep up with them through their mailing list!

![]()