AS FEATURED ON 3DPC.co

http://3dpc.co/meet-3d-printings-big-brother-cnc-milling-3442/

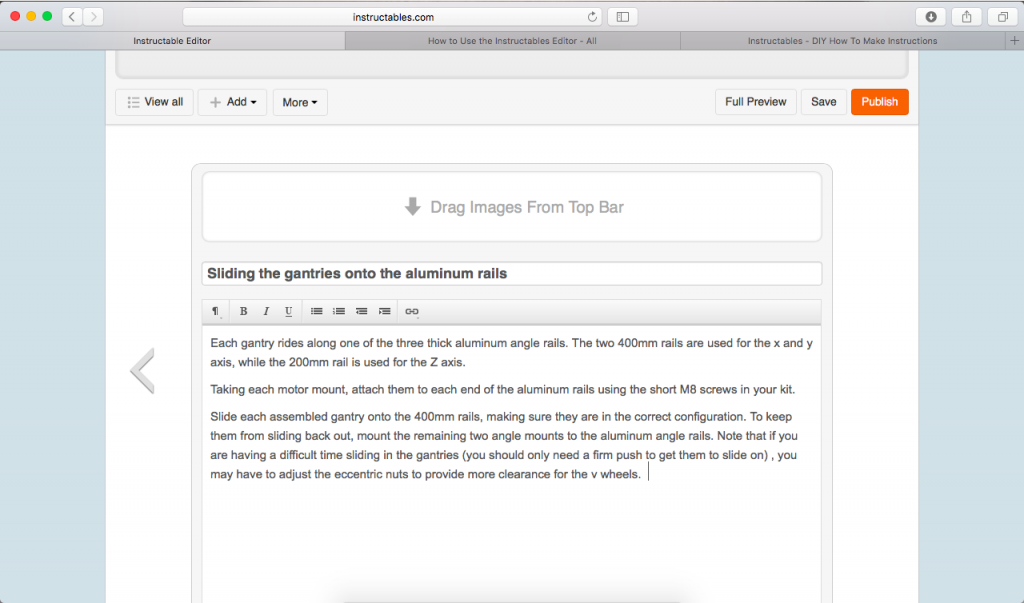

While CNC milling machines come in all shapes and sizes, there is one thing they all have in common: computer numerical control. Yes, CNC stands for computer numerical control. These machines implement mechanical and electrical systems to control a milling tool in three dimensional space. Unlike a 3D printer, which is a “additive†manufacturing process that involves stacking layers and layers of plastic, CNC milling is a “subtractive manufacturing process that starts from a base material and carves away at it until you are left with a finalized part.

These machines are used to manufacture everything from the furniture you’re sitting on to the injection molding forms that make up a huge number of the things you use every day. And since they can shape virtually any material, the applications are endless.

3D printing has gone from expensive industrial machines to affordable consumer machines that fit on your desktop. So why hasn’t the same happened with CNC milling machines?

Well, there are a few challenges in creating a device suitable for your home, but the biggest challenge has been creating the necessary mechanics to stand the enormous forces CNC machines need to handle. The robust linear motion systems needed to control these machines are expensive and complicated, and that shows on the price tag for current desktop CNC milling machines.

Sienci Labs, a group based in Waterloo, ON, have developed low cost, high performance linear motion systems to finally create the machines that you can afford to put on your desktop. And with partnerships with some of the most innovative CAM and CAD developers, they’ve created the fastest and easiest user experience in desktop CNC milling.

Meet the Sienci Mill One.

The Sienci Mill One is a $399 desktop CNC milling machine that creates 2D and 3D models from materials like wood, plastic, brass, aluminum, and foam.

Specifications:

Working area: 250mm x 200mm x 100mm

Working materials: Wood, foam, aluminum, brass, leather, PVC, acrylic, ABS, PCB boards, and more

Precision: The Sienci Mill One comes with anti backlash leadscrews with a thread pitch of 2mm/revolution, as well as stepper motors with a resolution of 200 steps/revolution. The Sienci Mill One can accurately reproduce details within 0.001″.

Speeds: Recommended speeds are between 250mm/min to 1500mm/min

Firmware: GRBL

Software:

While the Sienci Mill One can handle gcode generated by virtually all modern CAM software, we’ve partnered with Onshape to bring fun, fast, and free CAM and CAD programs to help you draw 3D models and create the code that controls the Sienci Mill One.

With CAM programs like Kiri:Moto, both beginner and advanced users can create gcode on their browser in mere minutes.

Try it out at www.onshape.com

Kickstarter:

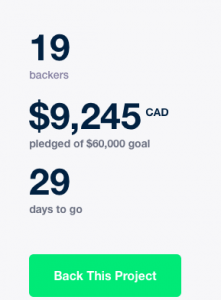

Sienci Labs is sold out of their first batch of machines and will be starting a Kickstarter in the middle of August!

Prices for the Kickstarter are:

$399: Sienci Mill One Kit*

$549: Sienci Mill One Assembled*

$139: 1-¼ HP Router Kit

*does not come with router

Sign up for the mailing list at:

https://sienci.com/kickstarter/