Description

***Included with your LongMill MK2.5***

- All rails, gantries, fasteners, lead screws, and other hardware parts to make a complete LongMill

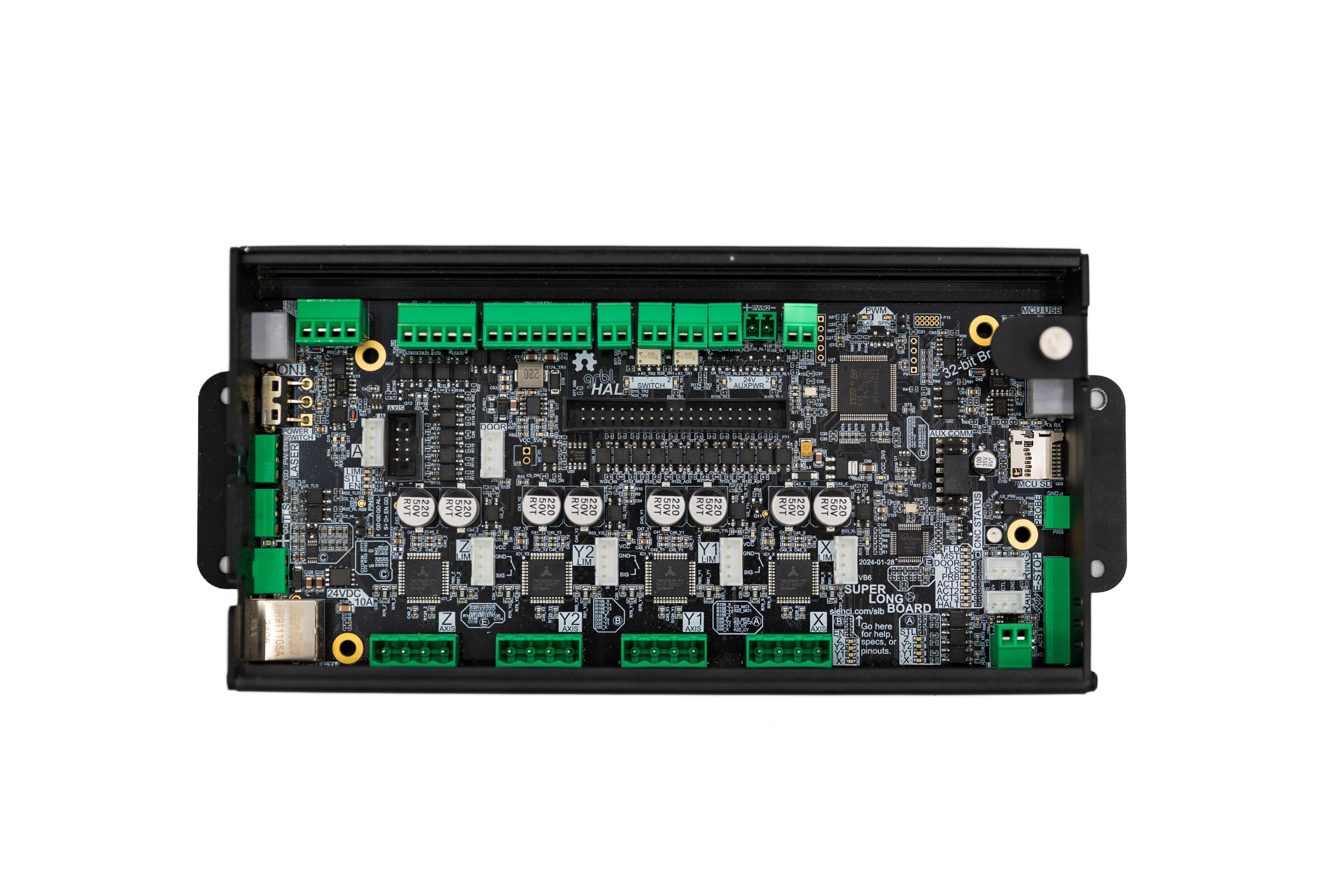

- All electronics, including power supply, controller, drivers, and motors; power to 110V/120V

- Welcome package

***Not included with your LongMill MK2.5***

Check out our recommended products tabs for an ideal set up, but note the following ARE NOT included with your order:

- Computer or laptop

- Router*

- End mills or bits

- Work surface (e.g. MDF sheet)

- Screw drivers, standard bits or drill for assembly

Please Note: Power supplies are 110V only, (North America). If you live in a country with 220V/240V power, our standard LongMill MK2 power adapter must use a transformer with a rating above 300 watts to convert your power to 110V/120V. Routers that we supply will be 110V only (North America). If you live in a country that uses a different voltage, please purchase a router in your region.

For routers, we recommend the Makita RT0700/RT0701. It’s reliable, powerful, speed-adjustable to a large range (10-30K RPM), and its uniform outer body allows for versatile z-axis mounting. We’ve been using the Makita on our CNC machines for years. The LongMill MK2 comes free as standard with a 65mm router mount, which is compatible with the Makita RT0700/RT0701 and most variations of this router design.

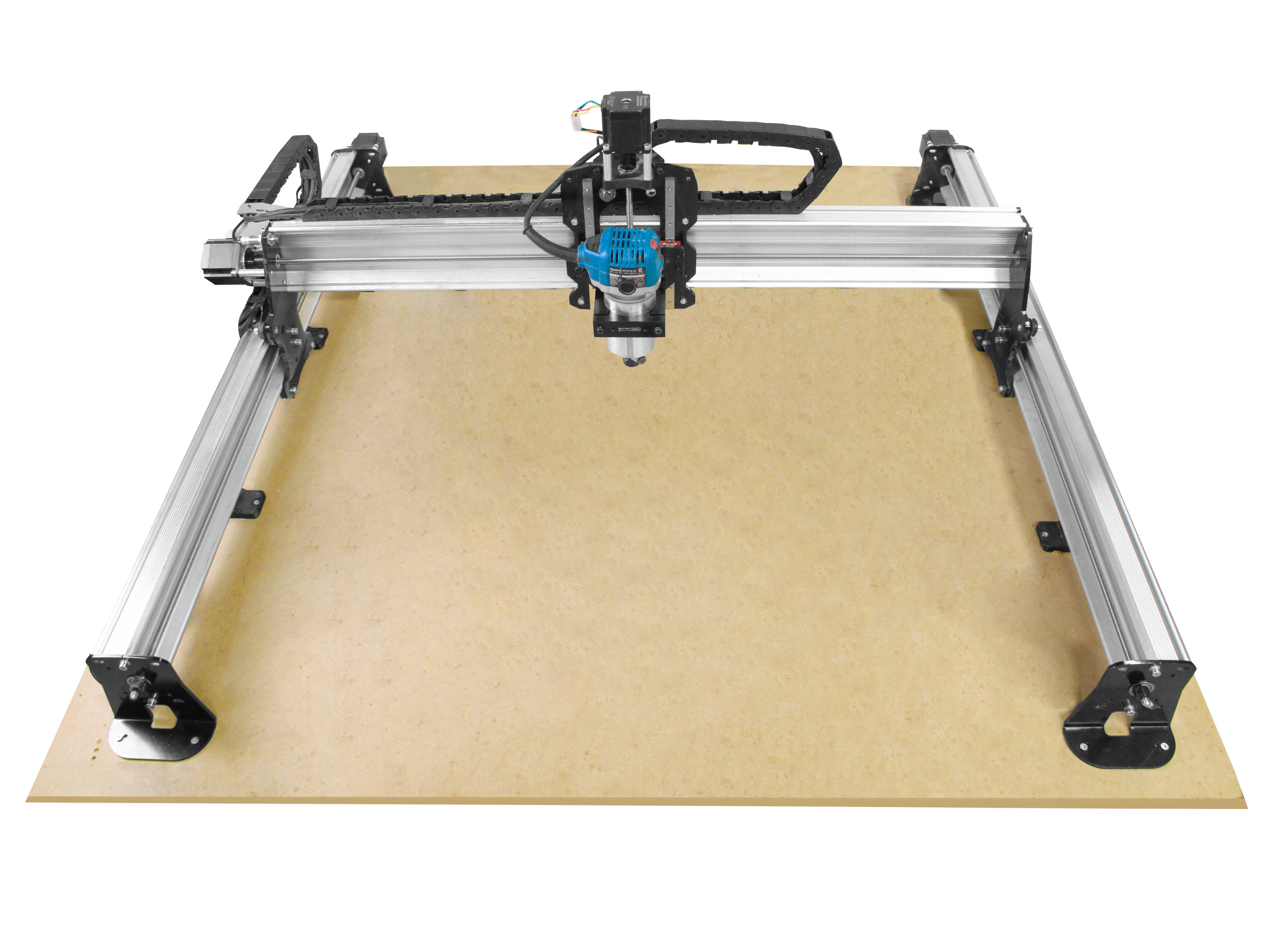

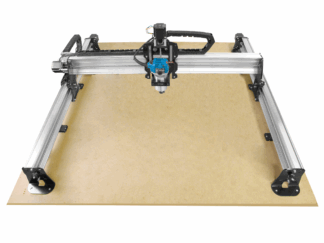

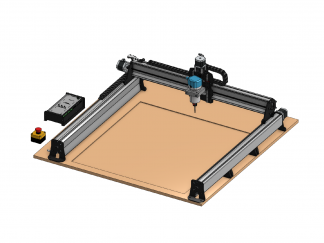

Some photos may contain items for illustrative purposes, such as routers, work surfaces, dust shoes or additional shelving. There may also be cosmetic differences between the machine in the photo and the production version of the LongMill.

We designed the LongMill to be the best hobby CNC router in its class, offering rigidity, and reliability. With large extruded aluminum rails, fully supported Y-axes, 1/4″ steel gantries on all axes, high power NEMA 23 motors, and high precision MG-12 type linear guides on the Z-axis, the LongMill MK2 is the most powerful CNC router in its class at its price point.

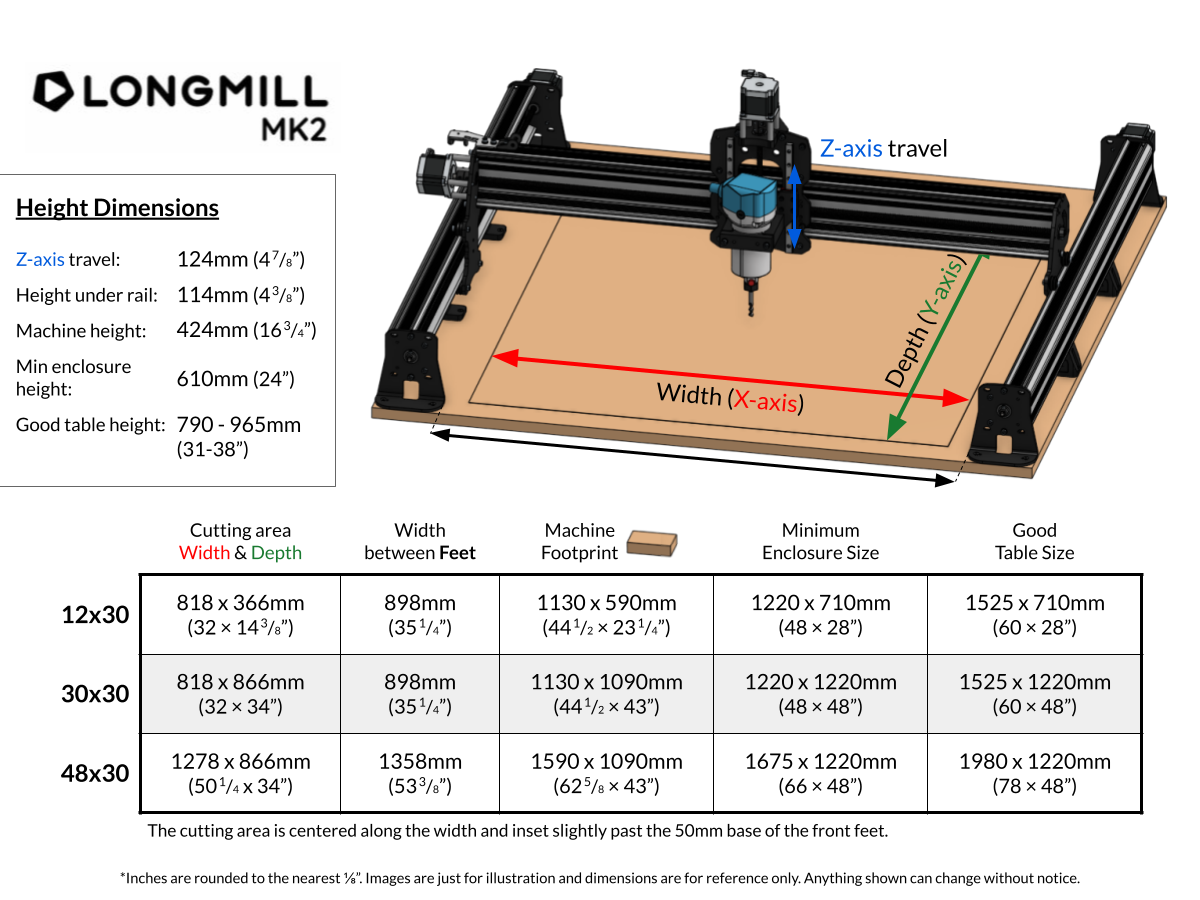

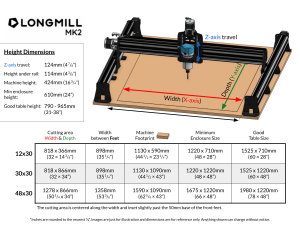

Measurements & Specifications

Specifications

If you’re looking to properly size a space to put your machine or are making a dedicated table, ensure that you leave enough room for the LongMills control box and any other peripherals that you might be using like a laptop, monitor, keyboard, etc. The control box is roughly 150mm x 280mm, has holes so that it can be easily screwed or mounted to any surface, and has a USB port on its left side which allows you to connect your computer to control the machine.

FAQs

Choosing an LongMIll vs an AltMill

https://youtu.be/7-sgkZQwWMk

What materials can it cut?

The LongMill is primarily designed for cutting wood but is capable of cutting foam, plastic, and soft metals such as aluminum and brass.

Where can I buy end mills and other tooling?

End mills and bits are available on sale on our website as well as online such as Amazon and Ebay, or at your local hardware store such as Home Depot or Lee Valley.

What software can you use with the LongMill?

The LongMill is compatible with dozens of free and paid CAM software. The LongMill is compatible with standard G-code. You can check out our resources page at www.sienci.com/resources and look under the software tab. We’ll be hosting webinars and creating additional resource videos to help you learn to design and program your CNC machine.

What system requirements are there?

You can run your machine off virtually any modern laptop made in the last 5 years running Windows, Mac OS, and Linux. We’ve tested our machine with Intel Celeron and AMD Phenom processors with less than 2GB of RAM with no issues (although it is a bit slow). For any other downloadable CAD or CAM programs that don’t run on the cloud, please check with the software creator for minimum system requirements.

What spindles or routers can I use?

While we recommend the Makita RT0701/RT0700, you can also use other trim/palm style routers. You will be able to let us know what tool you want to use and we will send you the appropriate mount.

Will there be 4th or 5th axis support?

In the immediate future, there will not be 4th or 5th axis support for the LongMill. If you would like to implement an additional axis to your machine, we encourage users to try creating their own and sharing it with the community!

Warranty

The LongMill has a 90 day warranty once it arrives at your door.

We want you to have a great experience with your machine, so if any parts are found to be missing or damaged, please email us. We will ensure that you receive the support you need to restore your LongMill to operating condition or provide a full or partial refund.

You may cancel an order if it has not shipped yet, please contact us if you wish to do so. We do not offer returns for LongMills that have already shipped.

General Warranty and Limits of Service:

Effective March 4, 2019

Throughout this policy the words “we”, “us” and “our”, or “Sienci Labs” will be used to refer to Sienci Labs Inc. herein and “LongMill” or “machine” will refer to Sienci Labs’ Sienci LongMill 12×12, Sienci LongMill 12×30 and Sienci LongMill 30×30. Additionally, the words “you”, “your”, “user”, and “operator” will refer to the original purchaser/customer, user, or viewer of any of the products or media provided by or through Sienci Labs.

Sienci Labs Inc. (the “Company”) grants the LongMill (the “Product”) a standard warranty within Canada and the US to the original customer to be free from missing parts, defects in material, and defects in workmanship for a period of ninety (90) days from the date of receipt by the original purchaser. Sienci Labs Inc. will ensure that the appropriate support is provided to the original customer to restore the LongMill to operational condition or provide a full or partial refund under the sole discretion of the Company.

This warranty does not cover damage due to improper use or assembly, lack of maintenance, normal wear and tear, or modifications to the LongMill which are not produced or authorized by the Company. Consumables such as cutting tools and sample or stock materials which may have come with your LongMill are not included in this warranty.

This warranty will become void if the operator does not follow the Safety Warnings and Guidelines, uses the Product for illegal purposes, intentionally causes damage to the Product, or transfers the Product to another owner.

The original customer must contact Sienci Labs Inc. within ninety (90) days of receiving their order to make a warranty claim to be eligible for warranty service. Proof of purchase, tracking number, email address, or other material will be used to confirm the original purchasing date and the identity of the original customer. If damage was due to shipping, original packaging materials must be kept in the original received condition. Photos, videos, written descriptions, and other items may be requested to assess and validate a warranty claim. In the case Sienci Labs Inc. requires the original parts to be returned, the customer is solely responsible for packing all items securely. Damage incurred during return shipping will not be covered by the warranty. A method of payment such as a credit card may be requested by Sienci Labs Inc. to cover shipping costs or damaged items if Products are not eligible for warranty service.

Only logged in customers who have purchased this product may leave a review.

Jack D. (verified owner) –

Machine is great. Still learning, but made 2 simple projects and one more complex and happy with the performance. Some pre-assembly ( putting small parts together so they could still ship in one box) would be even better. Putting it together was a bear with too many steps.

Doug Moore (verified owner) –

Nice solid unit, intuitive to assemble, great online video support. Great interactive community, wrought full of advice and ideas for your table, spoil board and hold-down options.

Peter Dunshie (verified owner) –

easy to setup and run

Ville (verified owner) –

Really nice machine.

LARRY ROBINSON (verified owner) –

I have enjoyed playing with the Longmill, I am a CNC machinist on large Mills and Lathes and really just wanted something at home to display some methods to teach others some Gcode related things plus have another tool in the shop for useful things. I have been happy with it so far, I honestly can say I absolutely hate the fact that G Sender doesn’t have Gcode on the screen like UGS does so I think it’s dangerous not to be able to look at and edit as needed. But I am using the latest version of Gsender Edge trying to force myself to like it. The rigidity of this machine is pretty good, Maybe the Z lifter could use some beefing up but in this price market it’s everything and more that I would expect honestly. Happy with it.

Darin Bosell (verified owner) –

This machine is awesome, easy to build and use. I did have to use some shims for the router block. I think the gantry was bent during shipping.

David Stokely (verified owner) –

I am having so much fun with my LongMill Benchtop CNC MK2. My mind is continually coming up with new possibilities of things I can do on it. I absolutely love it.

Steven Ray (verified owner) –

I love it. It’s an amazing machine. For the price and quality, you can’t beat the value. It arrived on time and in great condition. The two packages were packed very well. The only thing missing where nylon washers but one video said they were not necessary. Assembly and set-up was not difficult at all. The online videos were easy to follow if I had issues with the written instructions. Just took my time. The detail on the carves is incredible. The photo carving blew my mind. Very happy with this machine.

Louis Carusone (verified owner) –

Being a new with CNC, CAD/CAM, Routers, Youtubing and such I have had a lot of things to learn. It is like the chicken and egg question as where to go first. As far as assembly I believe with the viewing the assembly videos and the instruction manual this was a very good experience. I have had a couple of reasons to interface with customer service and it was a very good experience. I have had the machine for only a little over a month but have been able to do a tuning project, surface the spoil board, create to signs, and put T Slots in the spoil board for holding. I think more priority should be put on tuning as this is where I have had most of my problems so far.

Marwin M. (verified owner) –

It interrupts in the middle of the program randomly and has damaged a lot of my plywood, which I can’t just afford. I set up a hand full of cnc machines before.

Joe Hoffmann (verified owner) –

This is a great Machine for the price. I have had it up and running for about a month and I have no complaints on it.

Jorge Lopez (verified owner) –

I can’t get it started

Peter Granata (verified owner) –

I have now completed a few projects with this machine (MK2), It performs as expected. Assembly was pretty simple with the follow along videos and instruction. I like that I know how the machine works for the bottom up from doing so.

Customer service was excellent when I found I was missing a few screws. You can these guys are passionate about their product and development

Dana Vandiver (verified owner) –

Setup was long but well documented and easy to understand. Works great. Still in my learning curve.

Jack Conrad (verified owner) –

In general very pleased that I purchased, except the dust shoe, needs work, clear plastic, and lights would be nice.

Ben Warner (verified owner) –

I have really enjoyed using my Longmill CNC so far and look forward to making lots of awesome projects with it in the future! It was pretty easy to put together and learn to use

robert jolly (verified owner) –

price for this machine is great had it up and running very quickly the only thing i sww so far is gsender on the z axis it should also go to zero when zeroing machine if you stop a program u must raise ths z axis manually before returning it to home position

Mike G. (verified owner) –

Sienci makes awesome CNC machines, but what makes them even better is the community that comes with your purchase! Any problem you have, the community is there, and someone will have the answer if not the folks at Sienci will. It doesn’t matter if you know anything about cncs , the program and machines are super user-friendly . Assembly can be frustrating, but any problem you have they are more then happy to help.

Awesome work guys I’m glad I purchased my cnc from sienci

Brian N. (verified owner) –

Alot of issues with USB, once I switched to a heralded USB problems went away and works beautifully

John H. (verified owner) –

I’ve owned the Longmill MK2 48×30 for approximately 1 month now. I’m very satisfied with the machine. I do look forward to seeing improvements on the backlash blocks. Overall , I’m extremely happy with my purchase from sienci labs and I plan on doing more business with them in the future.

Alan C. (verified owner) –

As this is our first CNC for our business we had a lot of concern regarding which machine / manufacturer to purchase. After looking at many of the other benchtop machines on the market we opted for the Sienci Longmill MK2 48×30.

I cannot really put into words how pleased we are with not only the machine itself but the incredible support from both Sienci as a manufacturer but also the greater Sienci community of owners. Absolutely the best customer service and advise!

Assembling the 48×30 took about 7-8 hours, including tuning the machine. Since that we have used the machine for approximately 90 different projects, approx. 8 hours of usage. This machine has absolutely sped up our process (small manufacturing business) and increased our quality, this is hands-down one of the best investments for our company.

We primarily cut sheet goods (Baltic birch), the intuitive Feeds and Speeds charts from Sienci are a breeze, coupled with the Carveco software we have blazing fast speeds on project setup and execution. We have yet to have an issue with the machine, the recommended routine maintenance is simple and easy which accounts for very little lost production time.

We honestly couldn’t be happier… well we could be if I could cut 60″ wide but hey, someday!

Rick Moore (verified owner) –

During assembly the X axis lead screw would not thread through any of the anti backlash blocks. Turns out the screw was mis-threaded. I paid for a new screw and blocks plus shipping for something that should have worked from the start. Then after finally getting it assembled the screw kept coming out of the coupler no matter how tight I tightened the screw. Once again I ordered some new couplers for fear of over tightening the screw to get it to stay on. It still would not stay in no matter how hard I tightened. At this point I submitted a contact support form with info about the screw and never heard back. I finally gave up and epoxied the screw to the coupler to get it to stay. Not happy I had to pay extra to try and get it to work and horrible customer support.

Kevin Philpott (verified owner) –

I owned an entry level 3018 cnc for a couple of years. During that time I did extensive research into which cnc I really wanted to upgrade to. One that I wouldn’t grow out of quickly. The longmill MK2 48″x30″ checked all the boxes. Since I first hit the power on button, I knew I had made the right choice. It took a bit of getting used to, but once I had the cnc dialed in, the abilty to make what I want is now possible. That’s what the Longmill is…possibilities… It’s up to my learning and skill to now design and make whatever it is that I can imagine. When my order first arrived, I had my table built, I recommed a full size sheet of 3/4 MDF… the assembly instructions were very accurate and easy to follow. The hardest part was the wiring… but I got it…My only regret was not purchasing the t-tracks… I’m very happy with the dust collector, auto zero touch plate, and homing switches. I have been making some signs, tablet stands, and I am really getting into design using 3d models. (stl learning how….) looking forward to adding some 3d carving to small furniture projects… Would I buy the longmill if I had my time back? Yes!!! Time and time again, it’s worth every dollar.

Kelvyn Savage (verified owner) –

I think this is a great machine, and a good upgrade for me from a cheap China one. I have only done one small project so far and it was very fast compared to my old machine. The dust boot is also fantastic as well as the auto touch block. My next project will be to make some new hold downs. Your assembly instructions and video series is great. I watched them all before and during assembly and these made assembly very easy.

However there were a few issues I did run into .

1. NZ is 240V AC power supply so I needed to buy a transformer to run machine. If you made the machine and router unit dual 110/240V it would open up more markets for you. Not a big issue.

2. I had a bad vibration on Y-axis when jogging at GO speed. After hours of checking lead screws were tight and playing with wheel adjustments and anti-backlash blocks I still had same issue. I eventually dropped Y-axis max speed to 3000 and the problem was solved. Issue was vibration of lead screws at speed.

3.Hardest part of assembly would have to be V-wheel adjustments. Currently the Y axis v-wheels are fully open and wheels very hard to move by hand but travel ok.

4. Instructions on X/Y squaring are good and simple. However could do with ones on Tramming Z. I have Tramming on X axis good as there is some wriggle room in bolt holes of router mount block. However no simple way to Tram along Y axis but only out by a small amount so it is ok for what I am doing.

I was use to Mach3 but moving to G Sender I found it very easy and is good to use.

Overall I find the longmill a great machine and would recommend it anyone. Keen to add the laser unit but will have to wait till I save up for it.

Thanks

Kelvyn Savage

Dennis Causby (verified owner) –

Great machine took about 7 hours to assemble