Hey everyone, here are the Oct 2023 production updates!

Ok so the marketing team asked me to do this in a video format, so enjoy.

Moving

A few months ago, we signed a lease on a new building a few minutes up the road on 120 Randall Drive. This space is not just double in square footage (around 8000sqft to 15,000sqft), we also get double high, 20ft ceilings, which will allow us to store a ton more materials as well as open up the possibility for new development space to help us build new products.

We now have full access to the building, and are starting some construction to outfit the space and get things moved over. Look out for an invite for housewarming in the next few months!

LongMill MK2 and Extension Kits

Production for LongMills and Extension Kits continues to move along smoothly. Shipments for these orders are generally shipping same day or within a few days.

We’ve recently made a small change to the laser-cutting process for the steel plates by switching to nitrogen from oxygen, which has shown to improve the quality of the cut edges on our parts. We expect the quality of the coatings and threading on tapped holes to improve because nitrogen reduces the impurities found on the edges of cut parts.

We don’t see a huge difference at this stage between the two different processes, but as we continue to work our way in processing all of the parts, we’ll be able to compare our QA reports to see if there is an improvement.

We’re also working on reducing our reliance on the 3D printing farm by experimenting with injection-molded feet. At the scale we are printing now, we believe that the cost of injection molding will save us money in just a few months.

We did run into a small issue where the manufacturer applied the finishing for inside the part rather than on the outside. As you can see in the photo, the outside of the foot is shiny, rather than a matt finish. The manufacturer is currently working on refinishing the molds so that they will look in our opinion, better for the next batch of samples.

In other news, we are also working on improving the quality of our lead screws. In the previous batch, we ran into a lot of issues of bent screws, so we started looking for some alternative suppliers.

This lead us down a pretty deep rabbit hole because we found that there are a lot of different types of threads and standards, some of which are country dependant. At this stage, we’re focusing on making the screws backwards compatible so that they are functionally the same as before.

Additionally, we believe that we can make the finish of the screws smoother, which may also lead to smoother motion and less wear and friction on the nut.

LaserBeam

LaserBeam orders are shipping out consistently and we have stock ready to ship. We are currently restocking some of our parts over the next few weeks.

Vortex Rotary Axis

We have now cleared the queue for the Vortex Rotary Axis for the pre-orders. We now have them in stock and can ship them within a few days. We only have around 70-80 units left, so make sure to grab one before we run out!

Production for the new batch is now underway, and we expect Batch 2 of the Vortex to be ready in about 3 months.

Sienci Router

Thank you for everyone for participating in our survey. If you haven’t participated and would like to, please check out the Sienci Router Survey which will help us learn more about what our users are looking for in a new router.

For the uninitiated, we’ve recently embarked on a new project exploring the possibility of building our own router or spindle system. Here are some reasons:

- The Makita RT0701 which is the most popular router used in hobby CNC machines have gone up in price, and may continue to increase in price.

- More people are reporting issues with the Makita RT0701, such as the bearings overheating, button breaking, and the speed dial losing its tension.

- There are no inputs to allow PWM speed control, unless you use a VFD and spindle combination

- Routers are loud

Our goal is to:

- Provide an alternative to the Makita RT0701 of a similar form factor so that it can be easily installed in place of it.

- Incorporate controls that allow on/off and speed control using gSender or in gcode directly, same as a spindle

- Improve the longevity and reduce noise

- Improve efficiency, power, and allow for a wide variety of bit sizes to be used

Additionally, we may incorporate features such as:

- Grounding through the bit, so that touch plates and bit setters can be used without needing to attach a probe to the bit or collet.

- Easier mechanism to change bits

There were a couple interesting things we found in the survey:

- While we assumed people would comment that they wanted more power from the Makita, we found that most people were satisfied with the power that it already provided

- We also assumed people would be more interested in using 1/2″ tooling, but it appeared it was not a feature a lot of people didn’t find useful

- Another very popular request that we didn’t include in the survey initially was an easier way to change tools, such as an auto tool changer.

- The majority of respondents told us that they would budget between $300 to $500 for a new router or spindle system, which is higher than we expected.

At this current time, we are in progress of researching some different motor options, as well as exploring different motor control options to validate that the basic functionality of the router can be produced. Once that is complete, we will be working on developing the mechanics and structure of the router. There is no set timeline yet, but I expect that we’ll likely have something ready to share by the end of the year.

Some interesting things we found:

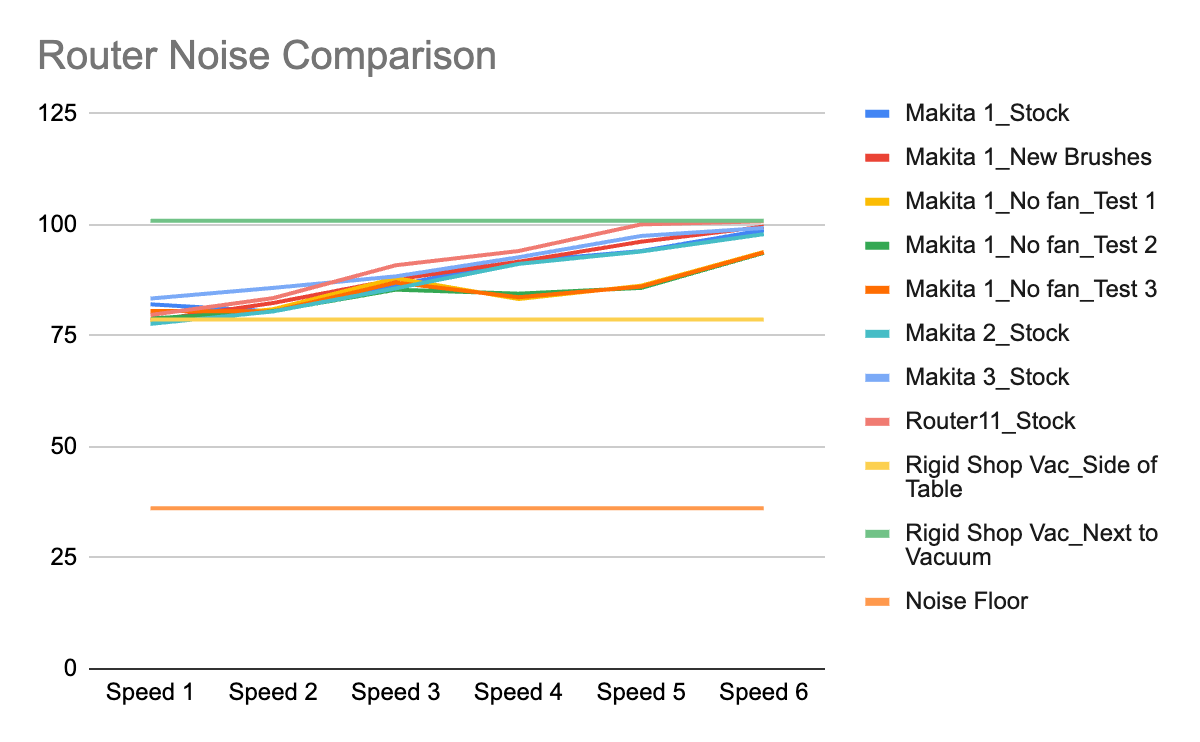

First is a comparison of running the Makita without a fan, which means basically ripping out the one in there already. We found that there is a decent change in volume at higher speeds. In practice, it sounds quieter as well because the frequencies coming from the fan is more perceptible (lower pitched) than the other parts of the motor.

Johann also mentioned that he found NSK bearings in some routers and CW in some of the new Makitas we were taking apart. The hypothesis is that during the pandemic, there may have been supply chain issues with getting NSK, so Makita used CW in production instead, which coincides with a larger number of bearing failures or overheating issues that we’ve seen happen in the past year.

SuperLongBoard

SuperLongBoard beta testing continues.

We recently received the newest version of the prototypes, which we expect to be put into production after validation. We now have 25 boards we are working with to complete phase 2 of beta testing.

Here’s a video of us testing the macro buttons, which allow the user to program a specific code or function into the buttons themselves, rather than just start, pause, and stop, which is hardwired into the current control board. In this case, it’s being used to move the machine to a specific position to assist with getting the machine out of the way for changing tools and materials.

We have received the version 2 of the SLB early last week and have been doing our internal testing before we prepare them for use. Here’s a bit of an update (this is the email I sent to the beta testers earlier).

– V2 has a couple of components that had issues and we are manually replacing parts and updating the design. This is minor surgery but a bit tedious working with small parts. We were hoping to start sending out the V2 version at the end of last week, but we are shooting for end of this week and the start of next to have the first 3 boards ready.

– The development team are working on testing and implementing features, listed in the attachment below. This is an excerpt from the main development notes we have. Thought I would share so you guys know what to look forward to them. Some have already been implemented but not tested.

– We also have a newly designed case that we are 3D printing and assembling, which allow you to install the case to the rail of the machine, or on the table or in another place. We are starting production of it now, which will be made from aluminum and acrylic. We should be getting them in Nov-Dec.

Chargeback/Fraud Instance

We recently ran into an issue with someone having placed a few orders for LongMills on our site using different aliases and charging the orders back after they had shipped. It appears to be done using stolen credit cards, but we are looking into this further.

Although this happens very rarely, it is a part of business that we can’t avoid. I just wanted to mention this to warn people to be cautious if they run across any LongMills for sale, still in the box, that seems suspicious, especially in the Montreal area…