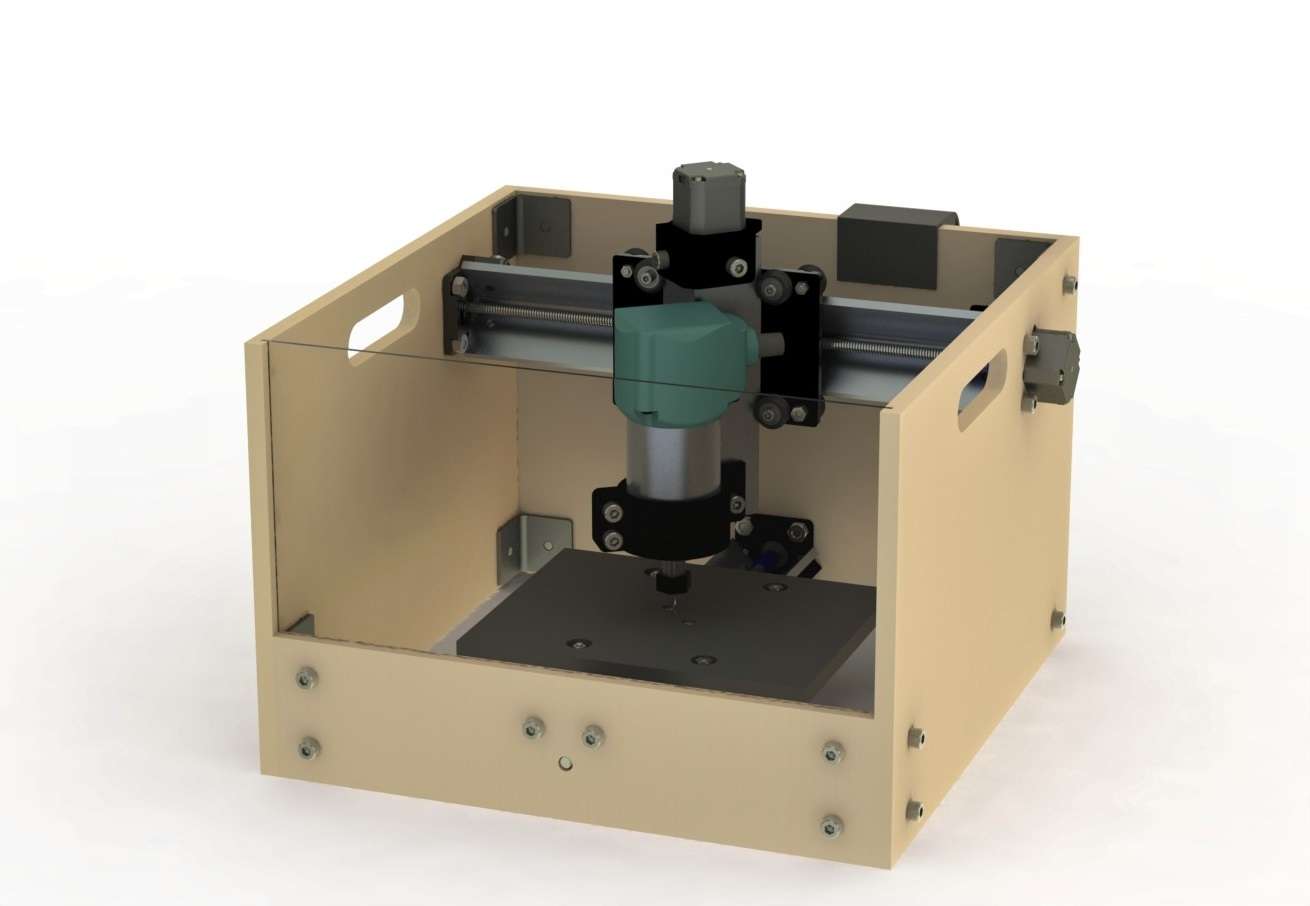

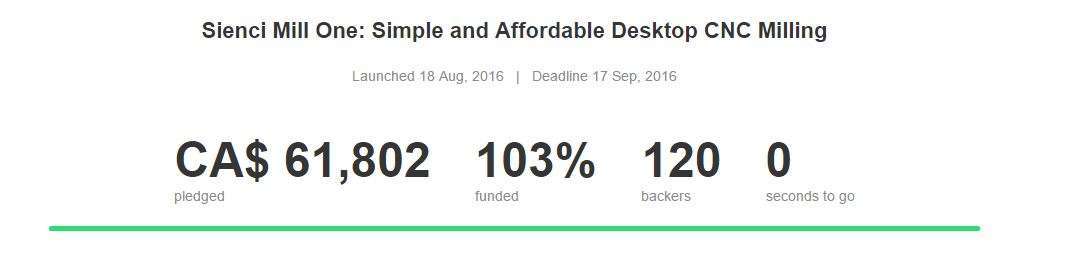

What Kickstarter lets you do is take an idea, a prototype, a brand new product built by people you’ve never heard about and turn it into either a burning failure or a fledgling of a company. We turned to Kickstarter to help mass produce our first batch of Sienci Mill Ones because we didn’t have the money or support to do it ourselves. Thanks to the amazing support of the friends, family, industry partners, institutions, and most importantly every single backer, we made this project into a reality.

We’re proud to have jumped over all the hurdles to build over eighty desktop CNC machines through our Kickstarter campaign and continue our company’s legacy in building a future of liberating automated manufacturing. This project helped us build a foundation to continue manufacturing the Mill One and give us the knowledge and skills to grow our company.

While we stuck as close to the schedule initially drawn out at the beginning of the campaign as we could, and actually fulfilled most of our orders early or on time, there were a lot of challenges, many late nights, and plenty of setbacks on the way. With everything we faced we used it as an opportunity to improve the Mill One and our company as a whole. The design and manufacturing processes we used for the first machine we shipped to the last machine has changed dramatically. Our backers were fundamental in making improvements, providing us with the support and feedback we needed to make changes, as well as the motivation to keep pushing forward.

We’d like to thank everyone for being with us every step of the way. We accomplished so much more than we could have ever dreamed of in the last eight months. A special shoutout and thank you to local businesses, Jeremy from Inksmith, Andrew from Netherton Solutions, the team at Structur3d, Adam from Boko, John from Nithside Weldfab, the team and engineers at JGW Machine, just to name just a few. Thank you to local makerspaces Kwartzlab, MyShop Makerspace, WATiMake Lab and KW Woodworking & Craft Centre, as well as the University of Waterloo, the Conrad Centre for Business, Entrepreneurship, and Technology, Accelerator Centre, and the Waterloo Region Small Business Centre. There’s so many people to thank, so if we missed you in this list, we want to thank you as well.

The Future of Sienci Labs

We’ve officially sold over 100 Mill Ones and will continue to offer kits on our website at https://sienci.com/product/sienci-mill-one-kit/. You can also find parts on our online store at https://sienci.com/shop/ and we will continue to expand our store with more parts and other items. Our resources page at https://sienci.com/resources/ continues to grow as we add additional resources, and our Facebook user group at https://www.facebook.com/groups/166433110494695/ also continues to grow with more users.

We also have another 100 units ready to be packed, and we are working on updating packaging and assembly instructions for the new updated version. Design files and other open source documentation has been publicly available for a while now, but we recently put together an Instructable (http://www.instructables.com/id/How-to-Build-the-Sienci-Mill-One-Desktop-CNC/) if you want to build one from scratch.

We’re so excited to see what new opportunities may come in time. Some goals we want to accomplish over the next year is to bring new people on the team, mature the Mill One ecosystem, complete a bigger desktop CNC machine, expand our resources, and get the Mill One into as many hands as possible!

Kickstarter Experience Survey

We want to hear how we did and how we can improve! If you’re received your Mill One and have put it together, please take this survey.

Link to survey: https://docs.google.com/forms/d/e/1FAIpQLSeetGNWRb9My9DiBpP6-h7jMBjhsgh5bKKfp7QVeSR0GphEFA/viewform

Keep creating!

-The Sienci Labs Team