If you guys don’t know Joel, he’s known as the 3D Printing Nerd. He’s well known in the 3D printer community for his awesome Youtube channel, which covers news, reviews, and projects around 3D printing. He came by to interview us at Midwest Reprap Festival this year. Skip to 18:40 in the video to see the interview!

Category: General News

Pallet of parts arrives in Canada

Our shipment of motors, leadscrews, 3D printer filament, and other items arrived this Saturday and was released from customs last night. We went to a warehouse in Brampton to pick the items up. The weight of our shipment was 377kg (or 830lbs) so the car was riding pretty low as we drove back to Waterloo.

We’re going to be cleaning out the garage to make some room for the new items. We are considering potentially moving out of the garage soon because it is quite cramped with all the inventory we have in there.

Now that we have our 3D printer filament, we are going to start up the 3D printer farm soon. It’ll take a little while to get everything organized and checked, but now we finally have everything in place to start making our batch of 100 Mill Ones.

Two new 3D printers in the 3D printer farm

The two new Cetus printers are set up and ready to run. We now have a total of seven 3D printers as part of the 3D printer farm which produces parts for the Mill One. Our shipment for 120kg of 3D printer filament has just landed in Canada, and we will be picking it up sometime this week. Having these new printers means we can produce more parts every day, and based on our experience with the Cetus printer we use currently, will reduce the amount of downtime we’ve had with the other 3D printers.

The shipment from China had been shipped late by two weeks, but we’re glad to finally be getting the new items this week. According to the paperwork, the total weight of the shipment is over 330kg (720lbs), so we’ll have to make some new space in the garage!

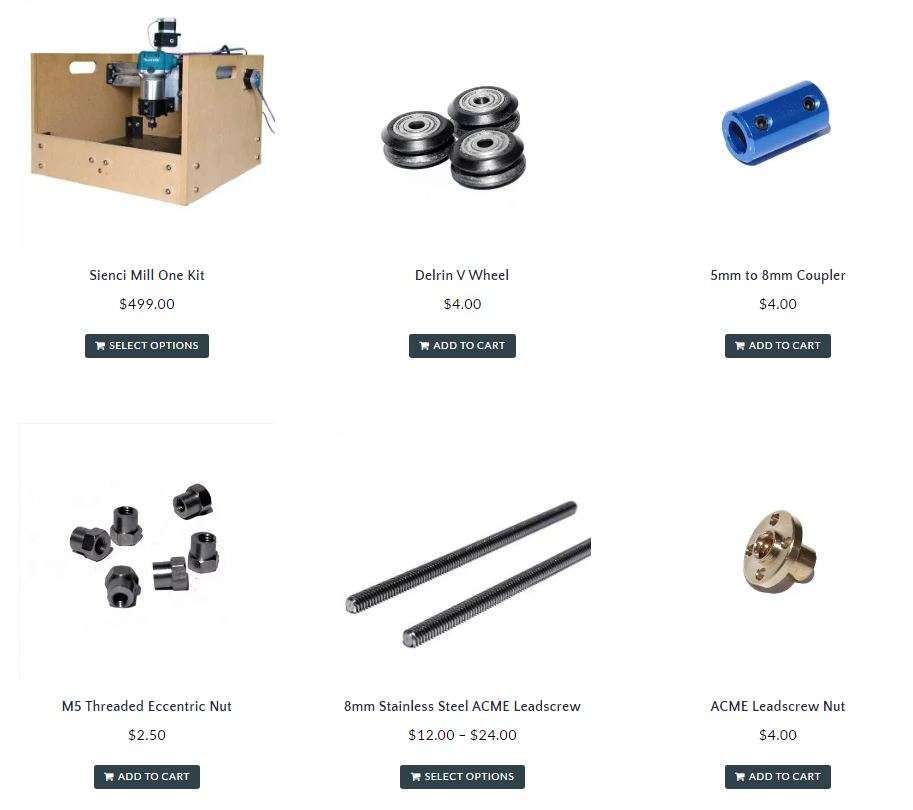

New items in the Store

Looking for parts for your Mill One or wanting to build your own? Parts are now available on our store for purchase.

More parts will be added to the store soon, based on demand and inventory.

We have also updated our available shipping methods to offer lower rates on parts, especially when ordering multiples of items.

Go to the store: https://sienci.com/shop/

3D Printer Chat Sienci Mill One Review – First Impressions and Love at First Sight

Last month we sent Nathan from 3D Printer Chat a Mill One to review and he loved it.

Check out the review here: https://3dprinterchat.com/2017/04/sienci-labs-mill-one/

Please note: No money was exchanged this review. We simply provided a review unit to 3D Printer Chat in exchange for an honest review for the Mill One.

Assembled units from Kickstarter shipping now

Assembled units for the Sienci Mill One ordered on Kickstarter are shipping now. Three left our garage today, and the remaining units will be shipped next week!

Finding the right sized boxes was kind of tricky, but we did find a couple that matched the dimensions we needed at Home Depot. That’s why if you ordered a assembled unit, you’re going to get a Home Depot branded cardboard box. Actually, for extra protection, we put another, smaller Home Depot box inside the large one plus some extra padding to make sure everything is packed as securely as possible.

We’re happy to say we’ve had no items damaged through transport yet, and we hope we can keep it that way!

Clearance sale ends tomorrow!

We are currently in the process of building another 100 Sienci Mill Ones and are clearing out space to make way for new inventory!

Exclusive coupon codes for Midwest Reprap Festival and our mailing list will be expiring tomorrow!

How can the Mill One be used in your makerspace?

3D printers, CNC machines, laser cutters, saws, tools galore. Makerspaces are the best place to go when you need access to tools and machines to create your next product. One of the challenges the people who operate makerspaces is that machines offered to their members need to be robust, reliable, easy to use, and affordable.

While easy to use and reliable 3D printers can be found in abundance, and there are a wide selection of laser cutters, there are no clear choice for a CNC router. With CNC routers coming in all shapes and sizes, some costing a few hundred, all the way to hundreds of thousands of dollars, it can be daunting when choosing the right tool.

So where does the Sienci Mill One come into play? Learning to use a CNC machine is a daunting, and with industrial size machines, can be dangerous as well. Users need to understand concepts like feedrate, depth of cut, and different types of passes to have success with a CNC milling machine. The Sienci Mill One offers a easy to learn platform to get users familiar with basic CNC milling concepts that can be used in all types of CNC milling machines. And at the price point it offers, makerspaces can purchase several units for the price of one expensive unit, giving more members access desktop CNC milling technologies.

The Sienci Mill One currently resides in several makerspaces in North America, and we’re looking forward to be putting our machines in more areas where people can mill amazing things!

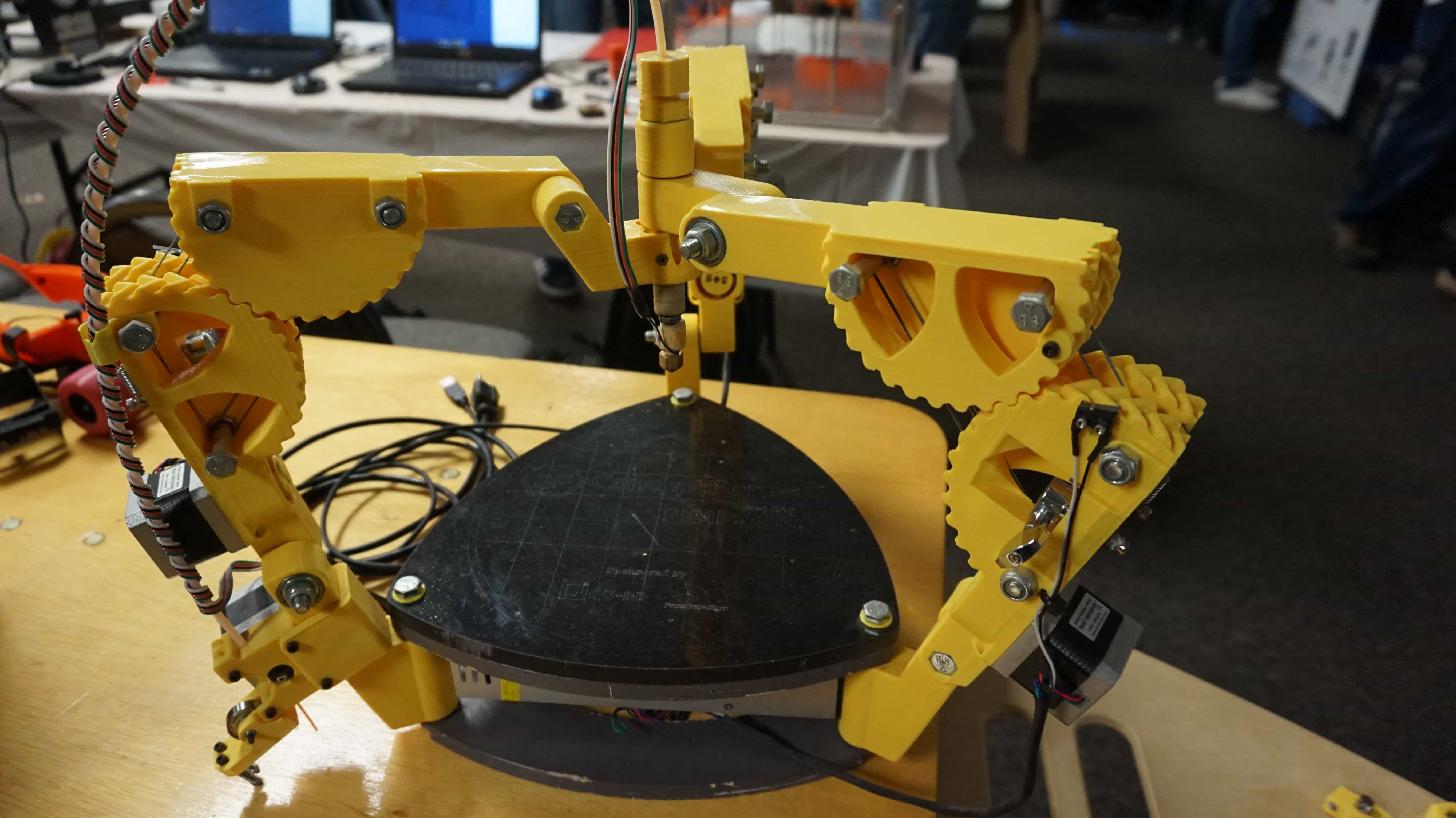

Back from MRRF 2017

The Midwest Rep Rap Festival was amazing! Last weekend, over 1200 makers gathered together to share their projects and ideas. Our trip started off with a 600km journey to the middle of nowhere.

It was about a three hour trip through southern Canada, then through Michigan, Ohio, and finally to Indiana. We stopped a few times for gas and the washroom, but what really kept us going was the shepherds pie I had made at 2am last night.

And finally, we made it! We made it to Goshen, IN, home of MRRF.

Over the next few days, we’d be talking to hundreds of really interesting people, checking out really cool projects, and having a great time.

Well until next year, MRRF!

PS. A special thanks to everyone who came out and especially Kelly, who was our photographer for the trip.

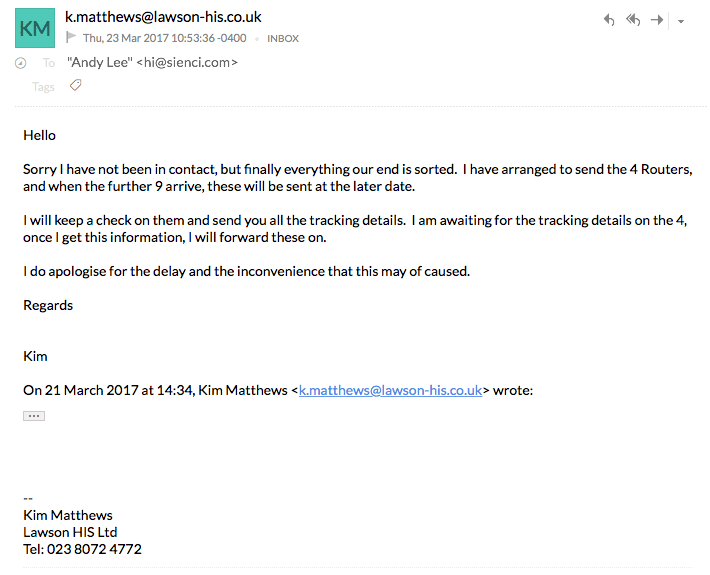

220V Router Delays

If you’re one of the 13 backers who are waiting on kits with 220V routers, we are still waiting on our UK supplier to receive new stock from Makita. In the meantime, they have offered to send us 4 routers which are in stock first.

Thank you to the 13 backers for their amazing patience as we figure this out. Your kits are currently ready to go and are just waiting on the routers to arrive. Once they are here we we’ll ship them out immediately!