Description

***Included with your LongMill MK2.5***

- All rails, gantries, fasteners, lead screws, and other hardware parts to make a complete LongMill

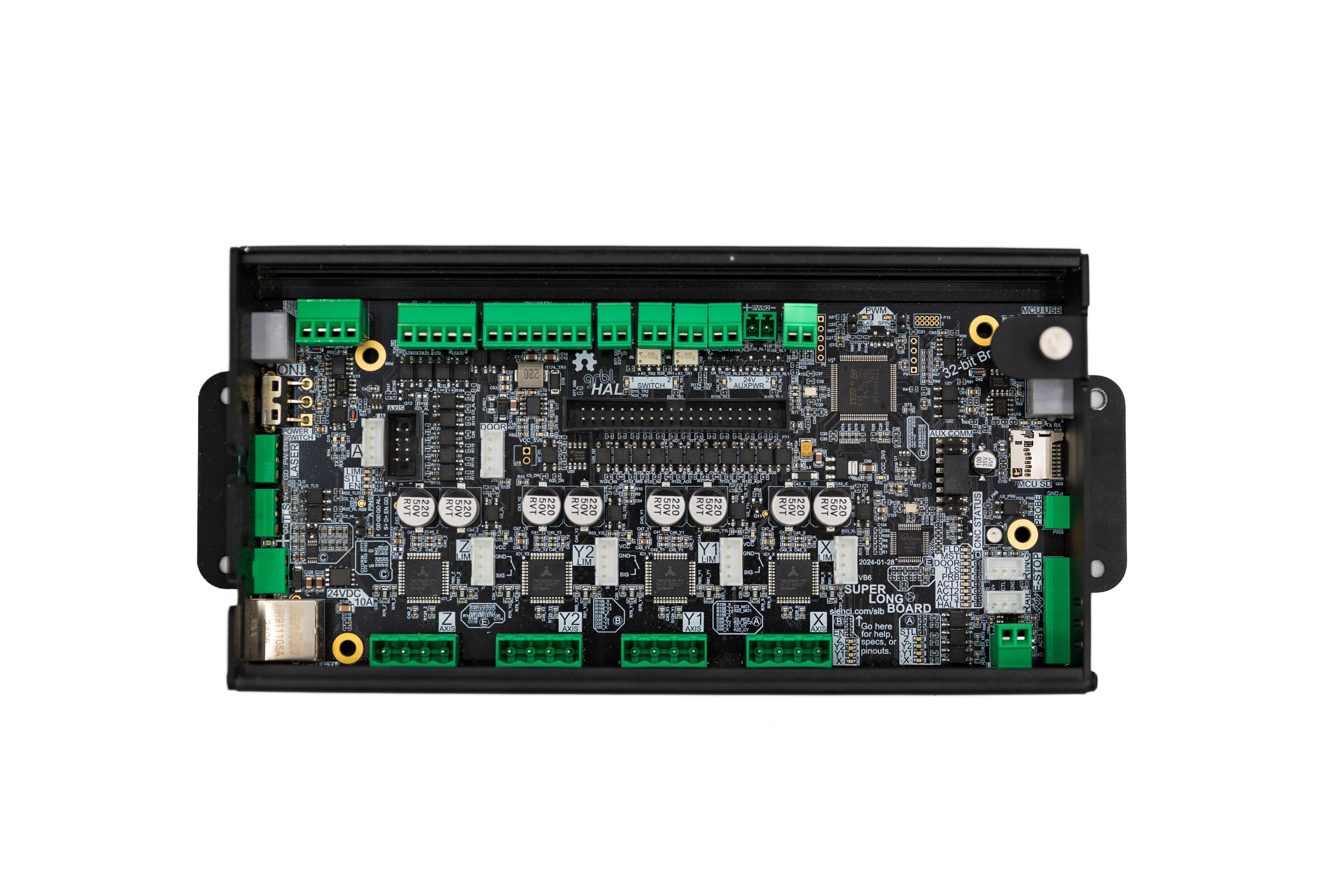

- All electronics, including power supply, controller, drivers, and motors; power to 110V/120V

- Welcome package

***Not included with your LongMill MK2.5***

Check out our recommended products tabs for an ideal set up, but note the following ARE NOT included with your order:

- Computer or laptop

- Router*

- End mills or bits

- Work surface (e.g. MDF sheet)

- Screw drivers, standard bits or drill for assembly

Please Note: Power supplies are 110V only, (North America). If you live in a country with 220V/240V power, our standard LongMill MK2 power adapter must use a transformer with a rating above 300 watts to convert your power to 110V/120V. Routers that we supply will be 110V only (North America). If you live in a country that uses a different voltage, please purchase a router in your region.

For routers, we recommend the Makita RT0700/RT0701. It’s reliable, powerful, speed-adjustable to a large range (10-30K RPM), and its uniform outer body allows for versatile z-axis mounting. We’ve been using the Makita on our CNC machines for years. The LongMill MK2 comes free as standard with a 65mm router mount, which is compatible with the Makita RT0700/RT0701 and most variations of this router design.

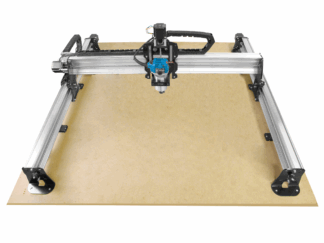

Some photos may contain items for illustrative purposes, such as routers, work surfaces, dust shoes or additional shelving. There may also be cosmetic differences between the machine in the photo and the production version of the LongMill.

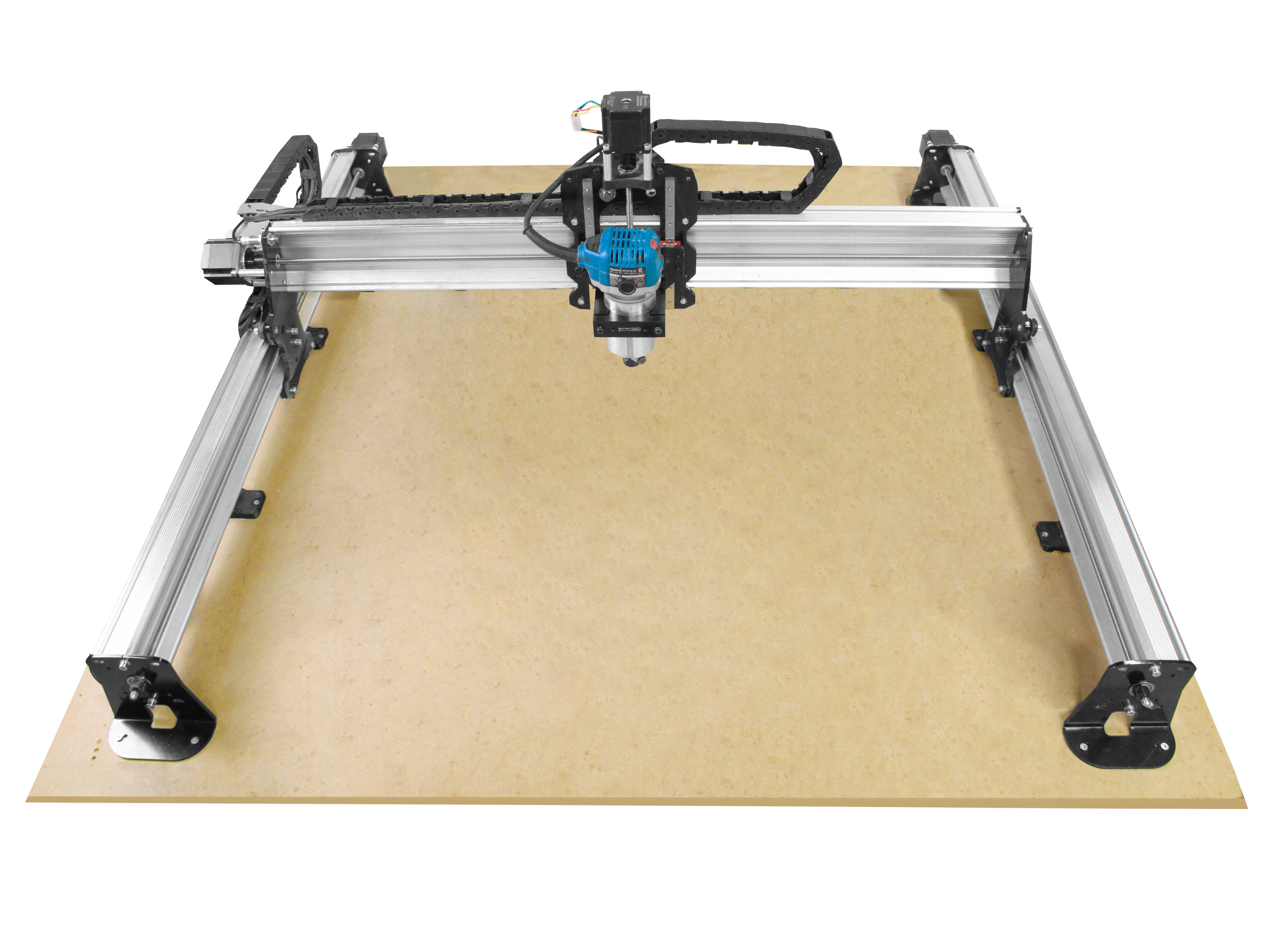

We designed the LongMill to be the best hobby CNC router in its class, offering rigidity, and reliability. With large extruded aluminum rails, fully supported Y-axes, 1/4″ steel gantries on all axes, high power NEMA 23 motors, and high precision MG-12 type linear guides on the Z-axis, the LongMill MK2 is the most powerful CNC router in its class at its price point.

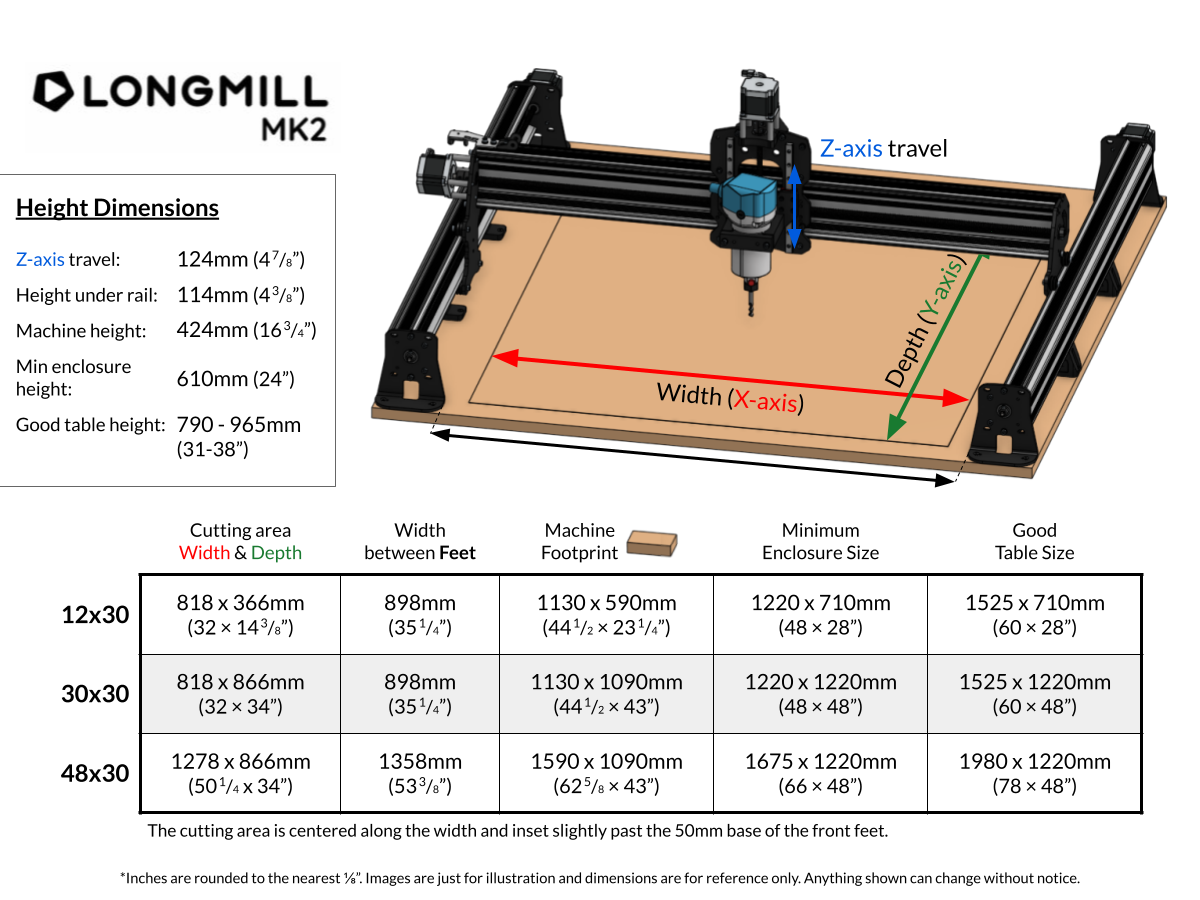

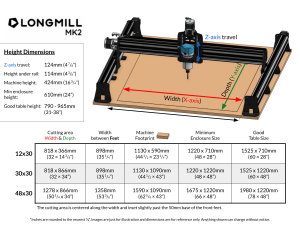

Measurements & Specifications

Specifications

If you’re looking to properly size a space to put your machine or are making a dedicated table, ensure that you leave enough room for the LongMills control box and any other peripherals that you might be using like a laptop, monitor, keyboard, etc. The control box is roughly 150mm x 280mm, has holes so that it can be easily screwed or mounted to any surface, and has a USB port on its left side which allows you to connect your computer to control the machine.

FAQs

Choosing an LongMIll vs an AltMill

https://youtu.be/7-sgkZQwWMk

What materials can it cut?

The LongMill is primarily designed for cutting wood but is capable of cutting foam, plastic, and soft metals such as aluminum and brass.

Where can I buy end mills and other tooling?

End mills and bits are available on sale on our website as well as online such as Amazon and Ebay, or at your local hardware store such as Home Depot or Lee Valley.

What software can you use with the LongMill?

The LongMill is compatible with dozens of free and paid CAM software. The LongMill is compatible with standard G-code. You can check out our resources page at www.sienci.com/resources and look under the software tab. We’ll be hosting webinars and creating additional resource videos to help you learn to design and program your CNC machine.

What system requirements are there?

You can run your machine off virtually any modern laptop made in the last 5 years running Windows, Mac OS, and Linux. We’ve tested our machine with Intel Celeron and AMD Phenom processors with less than 2GB of RAM with no issues (although it is a bit slow). For any other downloadable CAD or CAM programs that don’t run on the cloud, please check with the software creator for minimum system requirements.

What spindles or routers can I use?

While we recommend the Makita RT0701/RT0700, you can also use other trim/palm style routers. You will be able to let us know what tool you want to use and we will send you the appropriate mount.

Will there be 4th or 5th axis support?

In the immediate future, there will not be 4th or 5th axis support for the LongMill. If you would like to implement an additional axis to your machine, we encourage users to try creating their own and sharing it with the community!

Warranty

The LongMill has a 90 day warranty once it arrives at your door.

We want you to have a great experience with your machine, so if any parts are found to be missing or damaged, please email us. We will ensure that you receive the support you need to restore your LongMill to operating condition or provide a full or partial refund.

You may cancel an order if it has not shipped yet, please contact us if you wish to do so. We do not offer returns for LongMills that have already shipped.

General Warranty and Limits of Service:

Effective March 4, 2019

Throughout this policy the words “we”, “us” and “our”, or “Sienci Labs” will be used to refer to Sienci Labs Inc. herein and “LongMill” or “machine” will refer to Sienci Labs’ Sienci LongMill 12×12, Sienci LongMill 12×30 and Sienci LongMill 30×30. Additionally, the words “you”, “your”, “user”, and “operator” will refer to the original purchaser/customer, user, or viewer of any of the products or media provided by or through Sienci Labs.

Sienci Labs Inc. (the “Company”) grants the LongMill (the “Product”) a standard warranty within Canada and the US to the original customer to be free from missing parts, defects in material, and defects in workmanship for a period of ninety (90) days from the date of receipt by the original purchaser. Sienci Labs Inc. will ensure that the appropriate support is provided to the original customer to restore the LongMill to operational condition or provide a full or partial refund under the sole discretion of the Company.

This warranty does not cover damage due to improper use or assembly, lack of maintenance, normal wear and tear, or modifications to the LongMill which are not produced or authorized by the Company. Consumables such as cutting tools and sample or stock materials which may have come with your LongMill are not included in this warranty.

This warranty will become void if the operator does not follow the Safety Warnings and Guidelines, uses the Product for illegal purposes, intentionally causes damage to the Product, or transfers the Product to another owner.

The original customer must contact Sienci Labs Inc. within ninety (90) days of receiving their order to make a warranty claim to be eligible for warranty service. Proof of purchase, tracking number, email address, or other material will be used to confirm the original purchasing date and the identity of the original customer. If damage was due to shipping, original packaging materials must be kept in the original received condition. Photos, videos, written descriptions, and other items may be requested to assess and validate a warranty claim. In the case Sienci Labs Inc. requires the original parts to be returned, the customer is solely responsible for packing all items securely. Damage incurred during return shipping will not be covered by the warranty. A method of payment such as a credit card may be requested by Sienci Labs Inc. to cover shipping costs or damaged items if Products are not eligible for warranty service.

Only logged in customers who have purchased this product may leave a review.

Derick (verified owner) –

My first experience with a CNC machine and I feel I made the right choice. Sienci Labs is a helpful company that was very quick to respond to my inquiry. I have made several items from various 2d to 3d designs and after a short learning curve, the machine is reliable and fun to use. From routing to using the laser, I am sure it will keep me busy for years to come.

Darryl Gilmore (verified owner) –

I really like the machine. I had some difficulty in getting the y axis to move in tandem with each other. It took me three assembly/disassembly tries before I got it to work. A little frustrating but necessary. It currently is working fine. Your online resources helped in working through the problems. I have the laser on and trying to learn it. I have completed a sign as a gift using the router and a Christmas ornament using the laser. Overall I am extremely happy with your products. What would be on my wish list? A more powerful laser to cut down on time. I have a full time job and can only work at night and weekends so a 10-12 hour job is tough to run. All things being taken into account, you have a great product and I am/will be recommending it to my friends and associates. I would purchase your product again.

William T. (verified owner) –

Ordered my mk2 30×48 machine after doing a lot of research online. The ordering process is easy and when the boxes arrived everything there(no missing pieces). The packaging was next to none(awesome).These guys know what their doing! Assembly was a breeze, between the detailed instructions and the videos it was a piece of cake. I’ve started making signs but this machine has opened my creative side and the sky’s the limit with what I can do. Exciting times ahead :o)

The Longmill Facebook group is a wealth of knowledge and everybody is helpful.

All around a great experience and I would (and have) recommend Longmill to friends.

Keep up the good work!

Serge L. (verified owner) –

Great CNC for a great price built by inspired minds.

John E. (verified owner) –

So far I love the CNC. the best part of the experience is your customer service! I had a small issue with the CNC and was given instructions on how to fix it. Also, and more importantly, my laser wasn’t working correctly (user error). Ikenna FaceTimed with me to help me understand. Best customer service, period. I have recommended you to friends.

shawn patterson (verified owner) –

I was hoping to get it sooner as I have two knee surgeries back to back. So I haven’t had a chance to get it built before that started. It was held up at customs. As soon as I can, I plan on getting busy with it. I’ve been a cnc machinist and programmer for 34 years and I’m looking forward to using the machine. I teach delmia software and camworks. I have made a post for use with Delmia makers software and I’ve been working to make a full simulation with kinematics in Delmia. I also bought the Vcarve pro software and learning that too. I plan on trying to purchase your 4th axis and maybe another machine….pretty excited to use it. Otherwise everything has been fine so far.

Daniel Brown (verified owner) –

This machine is all that it claims to be. I was impressed by how solid and how precise the manufacturing is. It was easy to assemble due to the very complete instructions provided. I have not needed any customer service regarding this machine so I have no opinion about it from experience. So far I have made a small name plaque, a box jointed drawer for holding my cnc accessories, dog bowl stands and a logo medallion. I also have the laser attachment. I have etched tiles and coasters with it and also put a grid on the cnc spoilboard. I still have a lot to learn and plan to make a great variety of things.

To be fair there are a few minor issues I came across. The laser module physically interferes with the dust collection attachment at some positions. It took quite a bit of adjustment to get the x-axis to not bind at the far left side. It may take several attempts to get the wiring positioned so it does not bind or interfere with operation. All these have satisfactory solutions so would not “break the deal”.

Thomas W. (verified owner) –

Have to say it was as easy as advertised. This was my very first CNC and it took may over a year to decide. I’m a bit land locked for space so some of the larger tables didn’t work, also my budget to consider. So my requirements were smaller footprint, but also larger than the desktop models – the 30×30 is perfect for me. I initially wanted to spend around $1000, but then review/options/size pushed it to $6000. That’s when a friend said “Maybe don’t spend $6k on your first CNC”, I’m glad i took his advice. I found the Longmill and what really sold me was the lead screws over belts, ease of installation(videos are great), the support is fantastic, and the price. My biggest hurdle

so far is my education of CAM processing. I’ve used Fusion 360 for a while in the CAD space for 3d prints, but the CAM is new to me. Selecting the correct tool paths, bits, speed/feed rates. I use gSender, had add-ons like auto zero touch plate and dust boot. As for as the Longmill’s performance I’ve done some minor engravings, but nothing as a finish product yet. If I had any wishes for modifications it might be a wingnut or something for the limit switch bracket on the Front Y axis – that was a pain with my lack of dexterity, and not a biggie but the usb controller connection on the opposite side of the connections restricted an under mount of my controller. Having one side with no connections would allow it to seat against a wall/side of my table.

Joseph Hamilton (verified owner) –

Hi Chris, I bought this machine for my neighbour, stretch, who has put most of it together and built a solid bench for it, but unfortunately when we put the first screw into the front foot, the back foot lifted up off the bench by about 10mm.

This highlighted a slight bow in the bench top, that was preventing the machine from being able to be fixed down without bending the rail.

So he had another crack at building a flatter surface, but he wasn’t happy with his 2nd attempt either. Now I’ve inherited the task, and I’m in the process of cutting out a sturdy flat base on my 2.5m x 1.5m

Australian made multicam cnc router.

If you check back in with me in a couple of weeks I’m sure he will have tried it out by then,

Cheers Joe

Mitchell Cheek (verified owner) –

The machine and the customer support have all been excellent. I have been running it hard with little issues. Assembly was simple enough with the instructions you provided. Thank you.

William Barnum (verified owner) –

So totally impressed with Sienci Labs and the machine I purchase, I recommend this company if one is in the market for a bench top CNC!

Harold Kemp (verified owner) –

Once I got it all set waste the fort I was doing my waste bored my router burnt up, but so far everything else is going good

David Lee (verified owner) –

Very Nice Machine! Followed the instructions and everything went together smoothly. Works very well.

Jurgen S. (verified owner) –

The cnc came faster then expected,

Assembly was easy

Have not done any projects with the router itself,

Have done a few engraving’s with the laser

George M. (verified owner) –

Very well made and easy to setup. The instructions are very clear for assembly. I was up and cutting quite fast. I have a bit of an advantage that I’ve been in the IT world going on 25 years, so using gsender was a breeze.

For someone that does not want a big learning curve, I suggest trying out Easel. It has a simple web browser interface. The driver for the controller works flawlessly. It does not have the depth of features like VCarve, but if you are looking to do mostly simple carving – it will do the trick.

I would also recommend getting the induction sensors. I know it’s not “required” but for the simplicity of being able to click home to send the spindle back to point zero is a time saver.

All in all – great machine (and Canadian made!).

Colby B. (verified owner) –

This is my second longmill and I continue to be impressed by not only the machine but the high quality customer service as well, if you are looking for a great quality machine don’t look any further the longmill is for you.

Doug Davidson (verified owner) –

None of the four corner feet were tapped in all four holes, I had to tap them myself like I saw on your video. The Ttracks never got shipped, I called and the nice lady I talked to fixed it very fast. All and all no big deal and I am happy with the machine. Not a new CNC guy, this was an up grade

Terence Chester (verified owner) –

I took a week to slowly built the machine, taking care with every step, and it paid off. The machine seems to work perfectly; I used the levelling program, and have made the samples you provided. I can see no problems so far. I am experimenting with the various software programs, and have decided on Carveco. I’m glad I chose the smaller machine, it fills my small hobby workshop just fine. I am very pleased with the product.

Brendon S. (verified owner) –

Very good quality machine with multiple applications great for the cost!

Mike (verified owner) –

As a new CNC owner, I took a lot of time researching the different brands available within the “Desktop” category and finally chose to invest in the LongMill. With being new to this, I relied heavily on existing reviews and was a bit skeptical, but am glad I made the decision I did.

Unit did take the 5 weeks to deliver and their customer service was very polite when calling to obtain status on the unit. Albeit, 5 weeks is a long time to wait when looking at a new toy and if you are impatient like me, it feels like forever. The one upside to this, it that it provides a very good opportunity to decide on software, download and install it, and start making designs to understand tool paths, cut depths, etc prior to the machine arriving.

When the machine arrived, assembly started and I was super impressed with the packaging and all of the resource materials available to move you from step to step. Machine was assembled within about 5 hours and I was able to test one of my design that day.

Highly recommend that if you are considering a CNC to move forward with the LongMill. The only regret I have is not getting the 48×30.

Kendall Caputo (verified owner) –

My Longmill was easy to assemble and works great. The Gsender software works great.

jeff Watson (verified owner) –

Learning something new everyday. Made a few things and working on more stuff

Eric H. (verified owner) –

This is the second machine I have purchased. I really like the design and setup of the MK2. Instructions were easy to follow and set up was easy. Awesome machine.

Dale Manley (verified owner) –

Other than Z Axis lead screw coming loose and falling through twice and ruining 2 projects everything has been working fine . I keep that lead screw fitting tight to the point of stripping it out and it still fell off twice. Not from motor side but lead screw side

Lynette Hoaglund (verified owner) –

Overall I love this machine. I don’t believe you can find a machine that is comparable at this price point. It done some unexplainable things when I first started running it but now seems to be operating as it should. However, I am still having trouble with getting the Vwheels adjusted and keeping them adjusted? I get them adjusted to where I believe they should be so that I can turn them by hand with a little effort but, after a short run they tighten up to where turning them by hand is impossible and they begin to make a squeaking noise while in operation or they loosen up and you can free wheel them? I’m sure it is something I am doing wrong but I can’t seem to find that sweet spot to where they stay in adjustment. Any advice on resolving this issue would be greatly appreciated.