Description

***Included with your LongMill MK2.5***

- All rails, gantries, fasteners, lead screws, and other hardware parts to make a complete LongMill

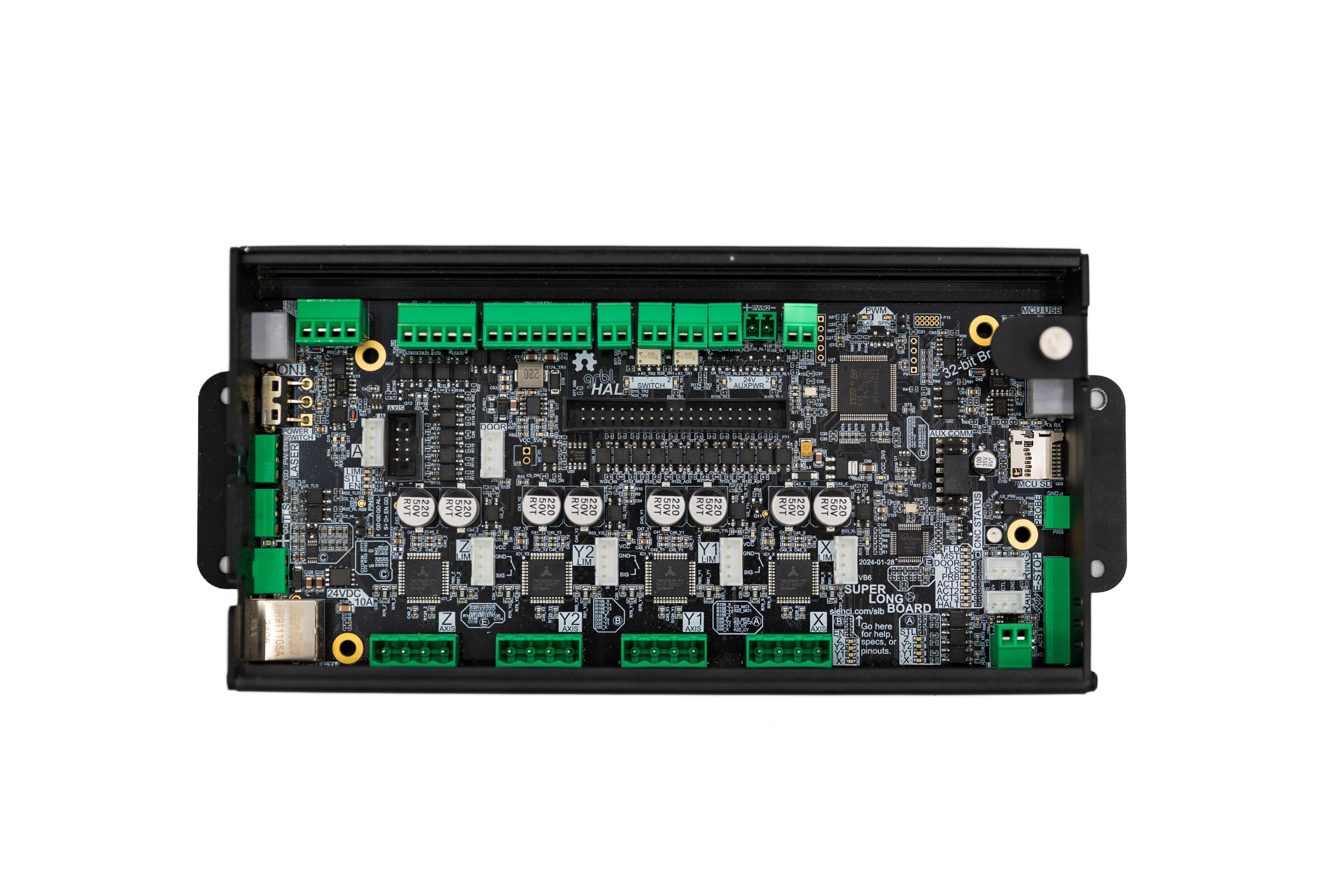

- All electronics, including power supply, controller, drivers, and motors; power to 110V/120V

- Welcome package

***Not included with your LongMill MK2.5***

Check out our recommended products tabs for an ideal set up, but note the following ARE NOT included with your order:

- Computer or laptop

- Router*

- End mills or bits

- Work surface (e.g. MDF sheet)

- Screw drivers, standard bits or drill for assembly

Please Note: Power supplies are 110V only, (North America). If you live in a country with 220V/240V power, our standard LongMill MK2 power adapter must use a transformer with a rating above 300 watts to convert your power to 110V/120V. Routers that we supply will be 110V only (North America). If you live in a country that uses a different voltage, please purchase a router in your region.

For routers, we recommend the Makita RT0700/RT0701. It’s reliable, powerful, speed-adjustable to a large range (10-30K RPM), and its uniform outer body allows for versatile z-axis mounting. We’ve been using the Makita on our CNC machines for years. The LongMill MK2 comes free as standard with a 65mm router mount, which is compatible with the Makita RT0700/RT0701 and most variations of this router design.

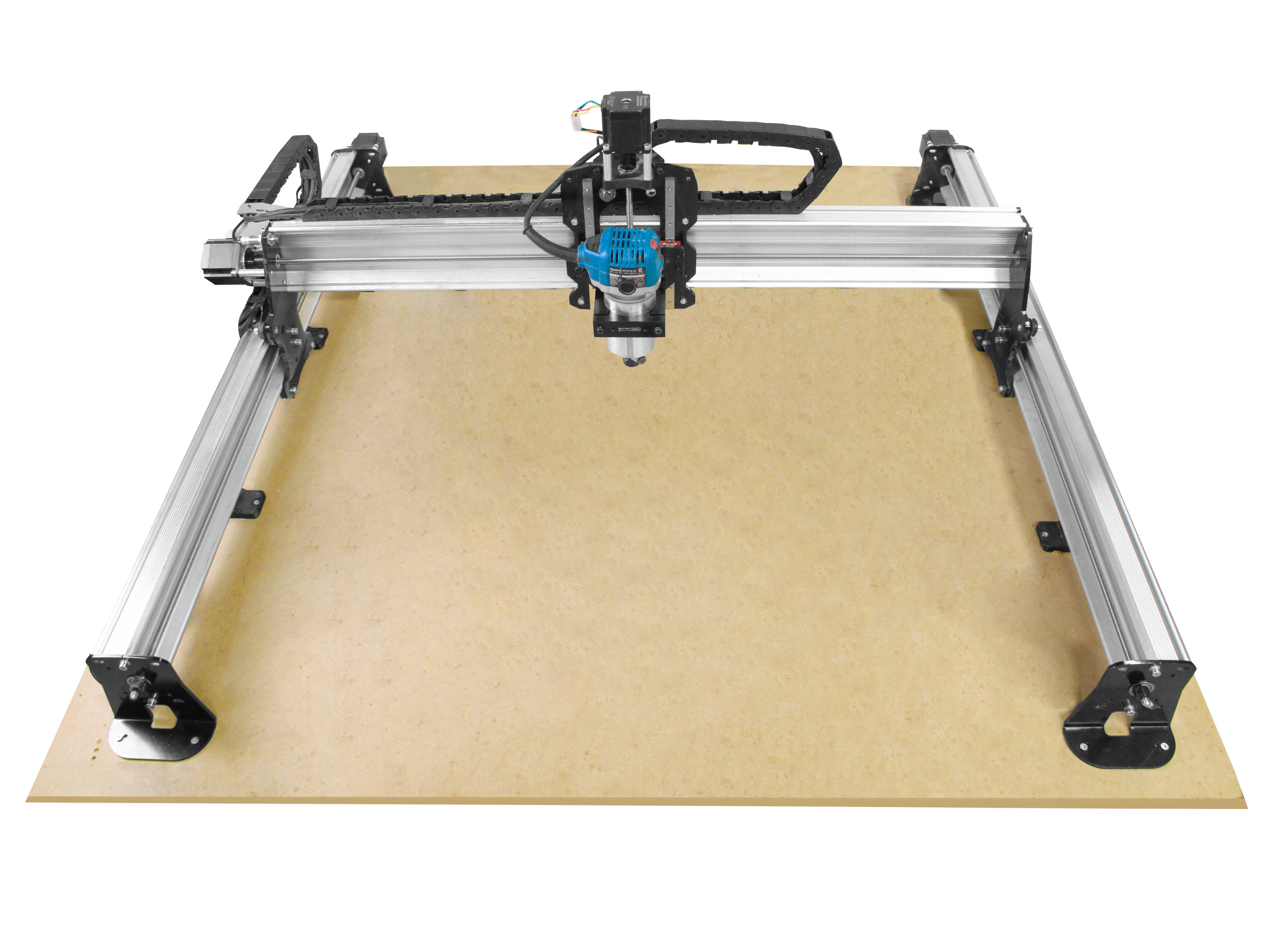

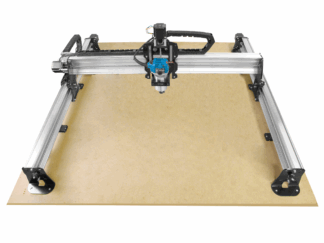

Some photos may contain items for illustrative purposes, such as routers, work surfaces, dust shoes or additional shelving. There may also be cosmetic differences between the machine in the photo and the production version of the LongMill.

We designed the LongMill to be the best hobby CNC router in its class, offering rigidity, and reliability. With large extruded aluminum rails, fully supported Y-axes, 1/4″ steel gantries on all axes, high power NEMA 23 motors, and high precision MG-12 type linear guides on the Z-axis, the LongMill MK2 is the most powerful CNC router in its class at its price point.

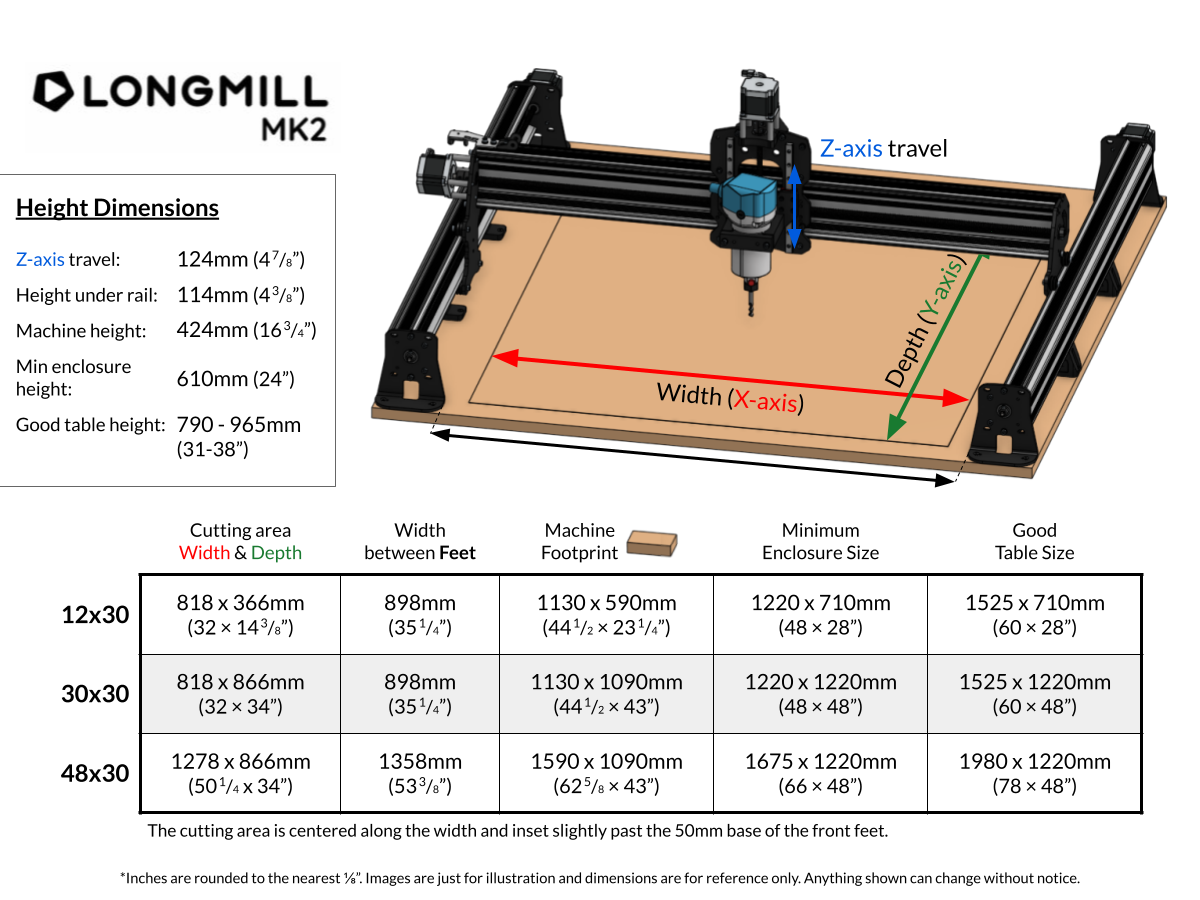

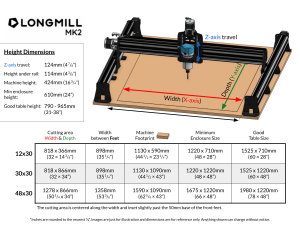

Measurements & Specifications

Specifications

If you’re looking to properly size a space to put your machine or are making a dedicated table, ensure that you leave enough room for the LongMills control box and any other peripherals that you might be using like a laptop, monitor, keyboard, etc. The control box is roughly 150mm x 280mm, has holes so that it can be easily screwed or mounted to any surface, and has a USB port on its left side which allows you to connect your computer to control the machine.

FAQs

Choosing an LongMIll vs an AltMill

https://youtu.be/7-sgkZQwWMk

What materials can it cut?

The LongMill is primarily designed for cutting wood but is capable of cutting foam, plastic, and soft metals such as aluminum and brass.

Where can I buy end mills and other tooling?

End mills and bits are available on sale on our website as well as online such as Amazon and Ebay, or at your local hardware store such as Home Depot or Lee Valley.

What software can you use with the LongMill?

The LongMill is compatible with dozens of free and paid CAM software. The LongMill is compatible with standard G-code. You can check out our resources page at www.sienci.com/resources and look under the software tab. We’ll be hosting webinars and creating additional resource videos to help you learn to design and program your CNC machine.

What system requirements are there?

You can run your machine off virtually any modern laptop made in the last 5 years running Windows, Mac OS, and Linux. We’ve tested our machine with Intel Celeron and AMD Phenom processors with less than 2GB of RAM with no issues (although it is a bit slow). For any other downloadable CAD or CAM programs that don’t run on the cloud, please check with the software creator for minimum system requirements.

What spindles or routers can I use?

While we recommend the Makita RT0701/RT0700, you can also use other trim/palm style routers. You will be able to let us know what tool you want to use and we will send you the appropriate mount.

Will there be 4th or 5th axis support?

In the immediate future, there will not be 4th or 5th axis support for the LongMill. If you would like to implement an additional axis to your machine, we encourage users to try creating their own and sharing it with the community!

Warranty

The LongMill has a 90 day warranty once it arrives at your door.

We want you to have a great experience with your machine, so if any parts are found to be missing or damaged, please email us. We will ensure that you receive the support you need to restore your LongMill to operating condition or provide a full or partial refund.

You may cancel an order if it has not shipped yet, please contact us if you wish to do so. We do not offer returns for LongMills that have already shipped.

General Warranty and Limits of Service:

Effective March 4, 2019

Throughout this policy the words “we”, “us” and “our”, or “Sienci Labs” will be used to refer to Sienci Labs Inc. herein and “LongMill” or “machine” will refer to Sienci Labs’ Sienci LongMill 12×12, Sienci LongMill 12×30 and Sienci LongMill 30×30. Additionally, the words “you”, “your”, “user”, and “operator” will refer to the original purchaser/customer, user, or viewer of any of the products or media provided by or through Sienci Labs.

Sienci Labs Inc. (the “Company”) grants the LongMill (the “Product”) a standard warranty within Canada and the US to the original customer to be free from missing parts, defects in material, and defects in workmanship for a period of ninety (90) days from the date of receipt by the original purchaser. Sienci Labs Inc. will ensure that the appropriate support is provided to the original customer to restore the LongMill to operational condition or provide a full or partial refund under the sole discretion of the Company.

This warranty does not cover damage due to improper use or assembly, lack of maintenance, normal wear and tear, or modifications to the LongMill which are not produced or authorized by the Company. Consumables such as cutting tools and sample or stock materials which may have come with your LongMill are not included in this warranty.

This warranty will become void if the operator does not follow the Safety Warnings and Guidelines, uses the Product for illegal purposes, intentionally causes damage to the Product, or transfers the Product to another owner.

The original customer must contact Sienci Labs Inc. within ninety (90) days of receiving their order to make a warranty claim to be eligible for warranty service. Proof of purchase, tracking number, email address, or other material will be used to confirm the original purchasing date and the identity of the original customer. If damage was due to shipping, original packaging materials must be kept in the original received condition. Photos, videos, written descriptions, and other items may be requested to assess and validate a warranty claim. In the case Sienci Labs Inc. requires the original parts to be returned, the customer is solely responsible for packing all items securely. Damage incurred during return shipping will not be covered by the warranty. A method of payment such as a credit card may be requested by Sienci Labs Inc. to cover shipping costs or damaged items if Products are not eligible for warranty service.

Only logged in customers who have purchased this product may leave a review.

David Braden (verified owner) –

My longmill looks like it’s going to be great. Don’t have my spindel yet to try it.

Anonymous (verified owner) –

Easy to assemble and use!

Bill V. (verified owner) –

great to assembled

Scott Noble (verified owner) –

Let me first clarify, my rating could be a 5, it’s only my 2nd entry level CNC machine and although I am very experienced with small scale wood working equipment I’m still naive when it comes to entry level CNC router machines IMO. But…

solid materials, easily assembled. It’s apparent these guys had some engineering education and drive. Don’t have to be a jet mechanic to assemble, though I am one. It’s talked about even at Sienci Labs as a hobby machine but I have run it steady from day one for at least 2-3 hours per day often more on products I sell.

I use gSender and create my gcode from Carbide Create with no problems. I tried an Xbox controller but it’s not as smooth as the screen controls on my laptop, don’t know how I could explain that better.

So I’m honestly shy about what I could say about my the Longmill or gSender for that matter. My “other” CNC is a Shapeoko 3xl. As you might already know you mostly need to use Carbide Motion to run gcode files (from Create). I say mostly because I tried to use gSender to run files from Create and it was really wonky and I didn’t want to troubleshoot why. And still don’t want to know why.

And so back to my initial review of the Longmill as requested from Sienci Labs. I purchased the Auto Zero gizmo and it is very accurate. I zeroed sooooo many times on my Shapeoko with the paper method and really thought I knew how to be accurate and not purchase a touch plate. I thought I knew better. Yesterday I used the AutoZero with a surfacing bit and it really bared down on the plate. Probably operator error. The rest of the day I used paper but only on that bit. On many zero’ing fuctions it hasn’t failed on any of my end mills. I’ve tried it on several V-bits nervous that it would bear down and hurt the bit but no, it was fine. Soon I’ll be getting back to more V-carves but I’ll make sure there are solid connections with plate and magnet.

Sorry, I don’t perform 3d carving so I can’t comment on that. No doubt the Longmill would move along nicely with those cut files.

I did purchase the dust pick up gizmo and installed the bracket, haven’t used the full attachment because I use my 3d printed dust boot I created for my Shapeko and it’s what I need right now for my projects. No doubt it will work when I get back to some sign engraving. It’s very well designed. And no, my 3d printed dust boot for 65mm routers is not available. It’s mine, all mine, my precious!

If you are window shopping for an entry level machine and ready to “take the leap” then I can say with confidence this young/energetic Canadian shop will meet your needs. I would purchase this machine all over again should my small productions needs increase. Good luck, happy machining.

Raymond Halicki (verified owner) –

Heat machine. Easy to assemble and big enough for most projects.

Matthew Bennett (verified owner) –

I had no previous experience with a CNC. After learning about the machine on Instagram I felt very attracted to the company, and the price point sealed the deal. Had a relaxed experience building it and learning about the machine with Chris’s online instructions. Along the way, through his videos, I got to know the company even better with his insights and anecdotes. The only stressful part of assembly was final squaring of the machine (even though I’d built a very careful torsion box to support it). But I got through it and achieved a pretty high level of squareness. Using it has been great, I’ve been able to implement many of the dream cuts Ive had in my head for years. One thing that was new to me was learning really how much the machine knew what it was doing. Eventually I learned that it’s effectively a perfect motion control system, and it sort of stops there. You have to babysit it a little and provide a watchful eye to make sure it’s cutting, not hitting anything it shouldn’t, the router and bit are working well, etc. Already I’m playing the game of revising g-code to see how fast I can cut things safely. I’m really just a baby in the CNC knowledge world but I’m looking forward to many more experiences with it. Overall its been wonderful, and it feels fantastic working with a Canadian made machine in a Canadian wood working shop.

Matt (verified owner) –

Great machine so far! Gsender is easy too. Easy to set up, I just followed the assembly videos. Now I just need to spend more time in design software to start trying projects!

Jeffery Davis (verified owner) –

This is my second LongMill CNC. My little business has grown to the point that I could not keep up with my demand. I considered other CNC Machines but chose to stay with the LongMill. I was up and running in a day. I would highly recommend the LongMill to anyone wanting to up their CNC game.

Mauricio J. (verified owner) –

Great machine. A great way to get into CNC with an affordable yet very capable machine. I’ve learned a ton! Since my longmill arrived. Although im getting a lot better at using it I’m still get a bit nervous when I hit start.

robert black (verified owner) –

I really am enjoying my longmill. I have made a few v carves & everyone thinks I’m smart. Of course, we know that its the machine doing the hard stuff. thank you to all the folks at longmill, bob black

Greg burns (verified owner) –

I love it

Richard Jaffe (verified owner) –

I am having a blast. My previous machine was a smaller belt driven machine that gave me a lot of problems. I built this machine with the controller and such on the right hand side as opposed to the left hand side as suggested because I am right handed and it makes it more convenient for me. In short, I love it!!

Bradley Soileau (verified owner) –

Love it

Mark Freund (verified owner) –

Hello Chris. I have been stuck with the programming. I can move the router with the laptop, zero it out with touch plate. but can’t seem to get the designs loaded into the program. I did get one but it’s backwards . I have also broken 2 bits already. I like the machine but I’m stuck.

Michael Schillizzi (verified owner) –

Price is very good for what you get. It adds up quicker when you start ordering other accessories and items that you need, but I would do it all over again.

The extra items are very needed to complete the tasks that you need and want to do.

All the items are very helpful to better yourself in your new venture.

RANDY C. (verified owner) –

Big improvement over my smaller 3018

Dave Vaughan (verified owner) –

Everything is good. My control box started on fire yesterday afternoon. I was going to come to your shop today. Roads are a skating rink right now. Might be tomorrow instead.

Michel Matton (verified owner) –

Excellent build docs! Machine runs like a charm after grounding the y rails and x gantry. Dust boot does a great job keeping things tidy. This is my first time building and using a machine like this.

Thomas (verified owner) –

The machine itself is great, great hardware, very sturdy.

Squaring can be difficult, including a jig for the proper distance between legs would be extremely helpful and achieved with a piece of either wood or metal.

Ralph Tate (verified owner) –

First let me explain that for years I was a machinist. I then worked as an inspector in the field of military products. After building the MK2 I was surprised how well the design was. The extruded beams are very strong. The configuration of the beams lend support and strength. No burrs were found on any parts. All threads were properly made and I had no problem with any application of the bolts. Your instructions and videos were very helpful with the build. All electronics were well made and easy to attach. Once the machine was squared and tramed, I ran a break in program for 50 passes without any complications. Once that was completed I attached my spoil board and used the gsender program to face the surface. The cut was clean and without any ridges. My only suggestion would be to extend the rail clip on the x axis. The wires ran along the y axis rail chain and could possibly cause a pinch point. I extended mine with a small piece of wood that had two holes drilled into it for tie wraps. Now the wires clear the chain without problem.

Brian (verified owner) –

The online reviews are what convinced me to order this unit and I am not disappointed. The setup process is straightforward and the instructional videos are very detailed. I would recommend the MK2 to anyone who wants to build things successfully with confidence.

David Lemons (verified owner) –

this thing is junk had it more than six months and haven\’t made one cut that is right.

Bill A. (verified owner) –

It’S an awsome machine. gsender is is probably the best software I’ve used. looking forward to using it more when winter is over.

Phillip Price (verified owner) –

Other than adjusting the router by shimming the mount it is very good. No problems

Antonio Gonzalez (verified owner) –

I’m very happy with the purchase but life got delayed the set up and construction and it is still in the box waiting to be assembled

Will advise once is put together

Thanks