Description

***Included with your LongMill MK2.5***

- All rails, gantries, fasteners, lead screws, and other hardware parts to make a complete LongMill

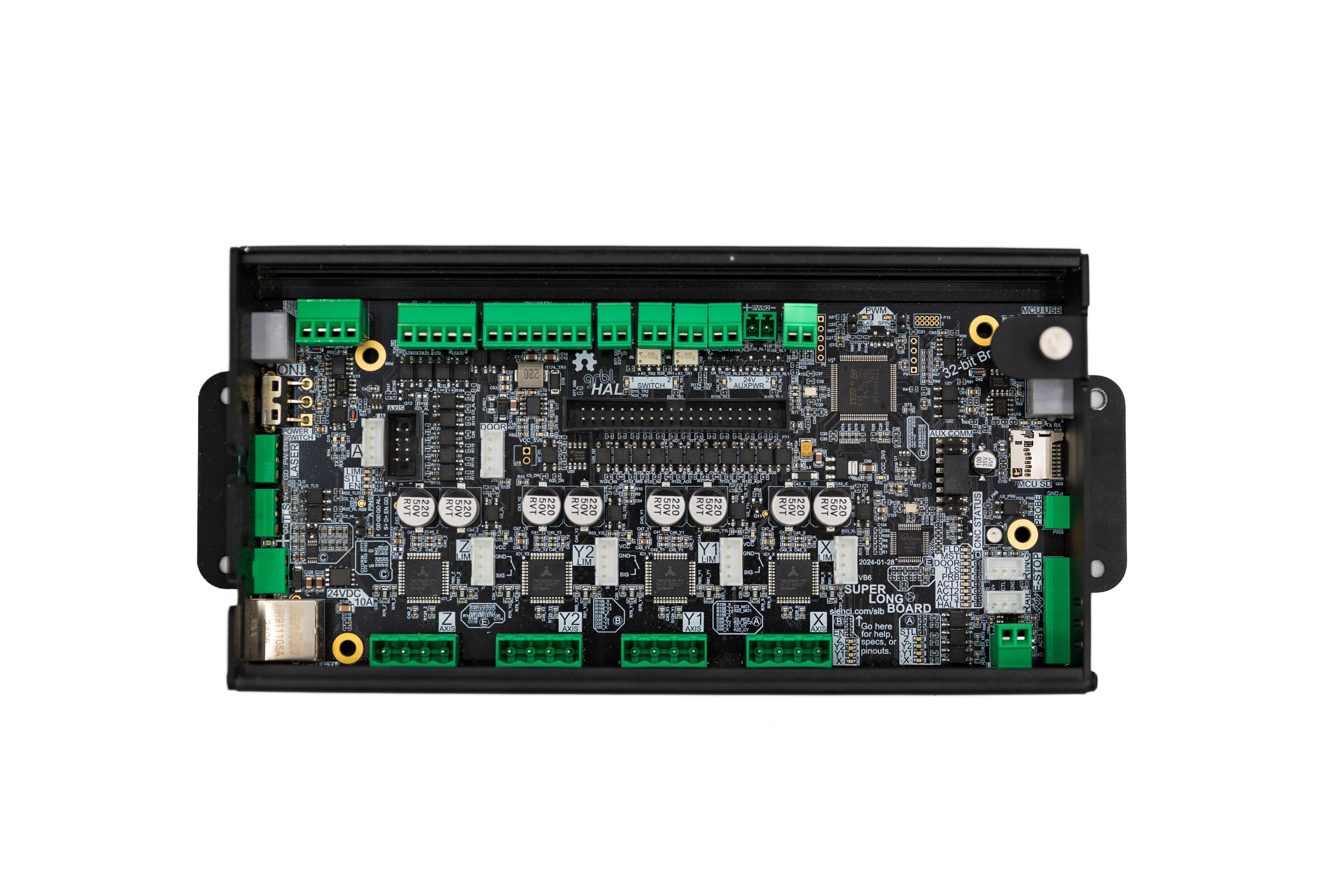

- All electronics, including power supply, controller, drivers, and motors; power to 110V/120V

- Welcome package

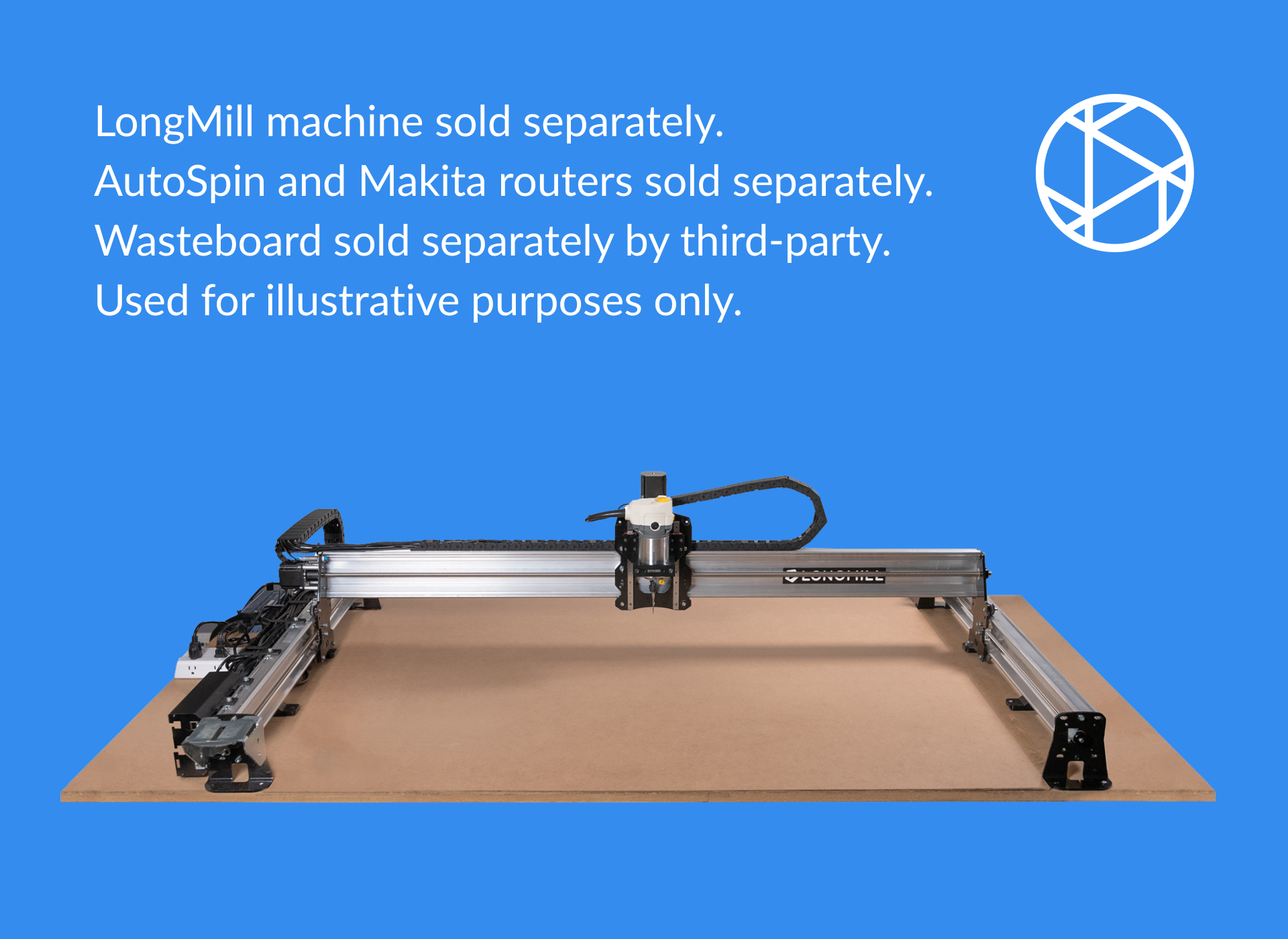

***Not included with your LongMill MK2.5***

Check out our recommended products tabs for an ideal set up, but note the following ARE NOT included with your order:

- Computer or laptop

- Router*

- End mills or bits

- Work surface (e.g. MDF sheet)

- Screw drivers, standard bits or drill for assembly

Please Note: Power supplies are 110V only, (North America). If you live in a country with 220V/240V power, our standard LongMill MK2 power adapter must use a transformer with a rating above 300 watts to convert your power to 110V/120V. Routers that we supply will be 110V only (North America). If you live in a country that uses a different voltage, please purchase a router in your region.

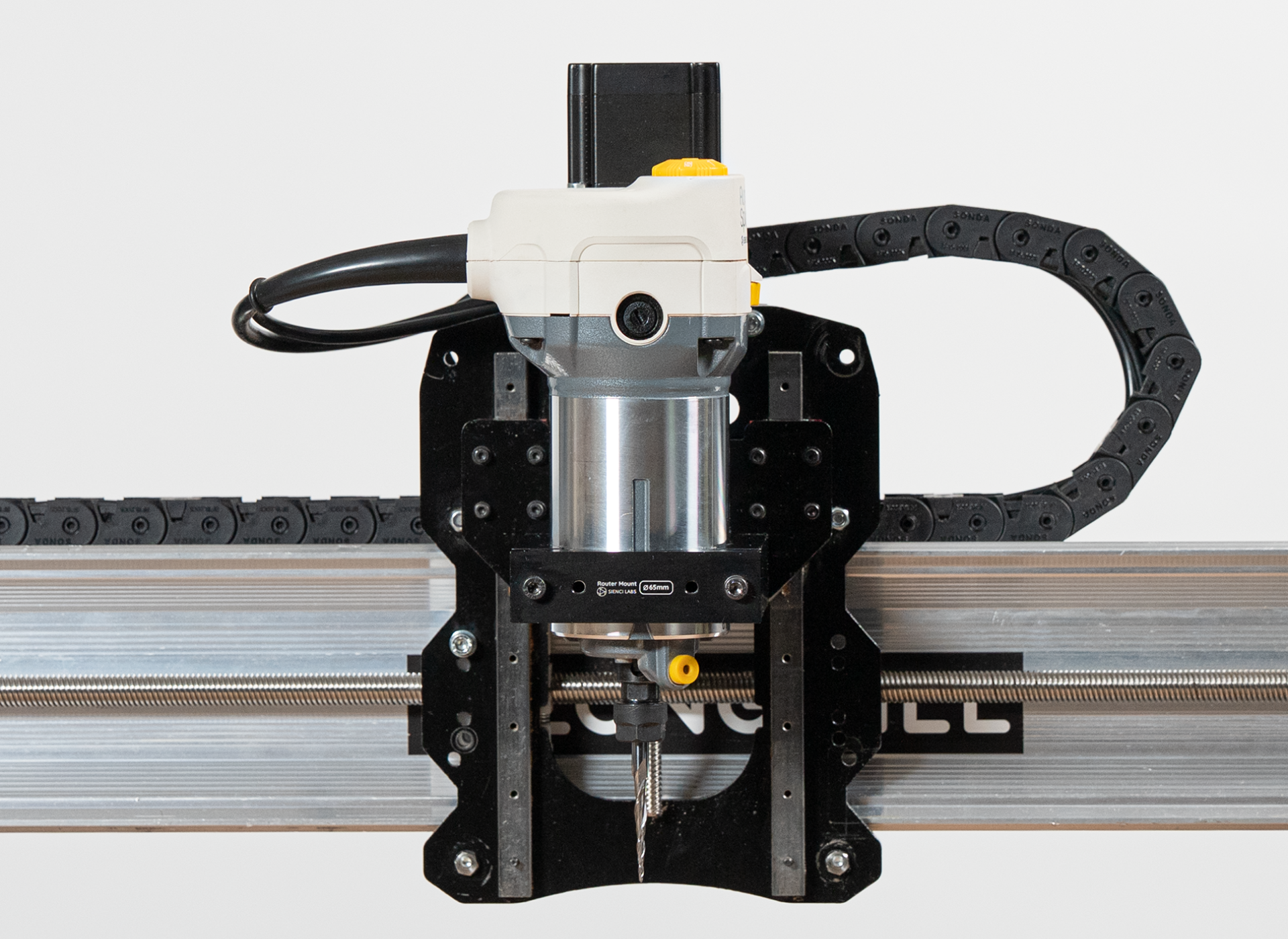

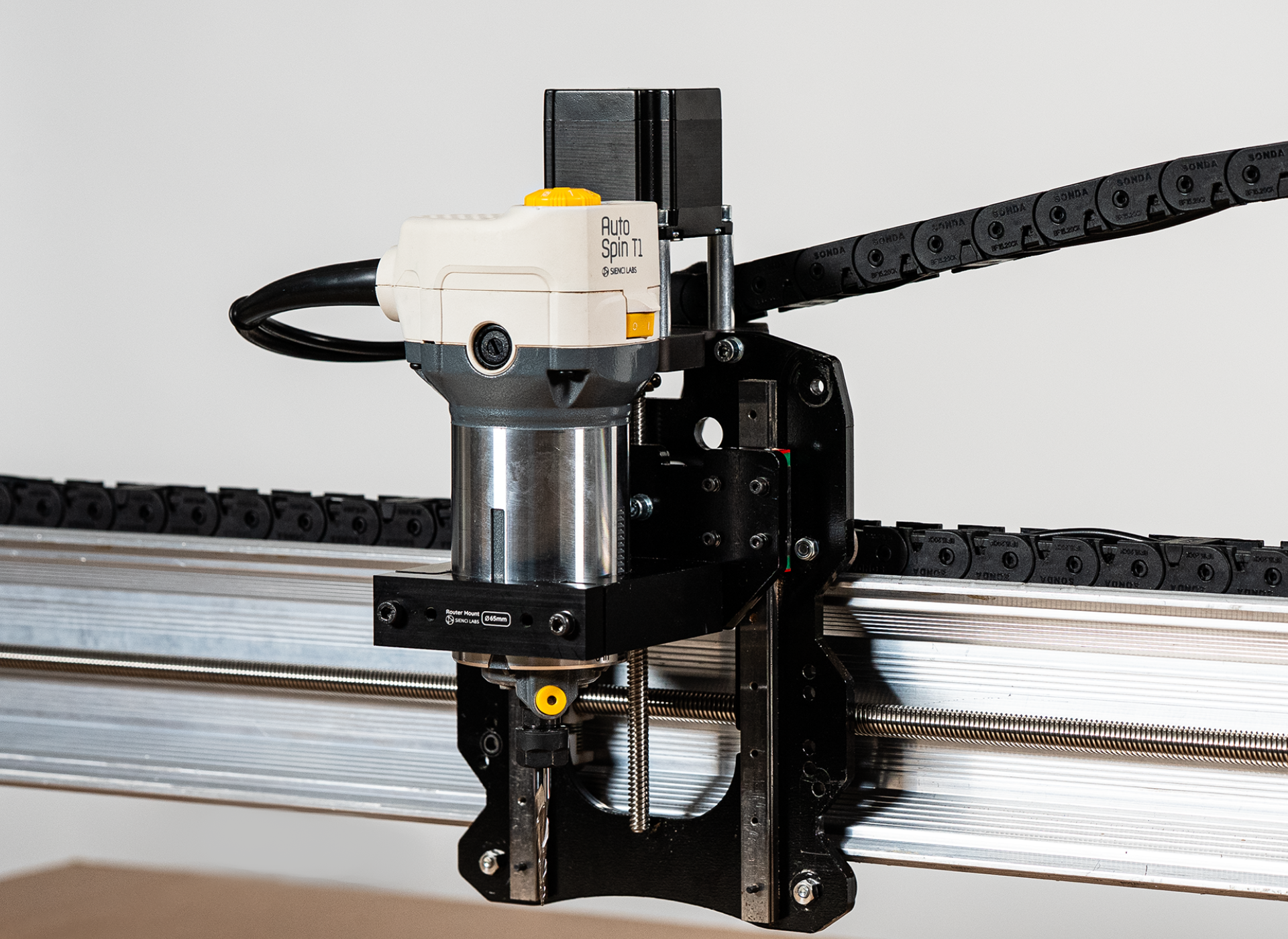

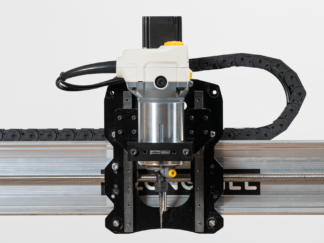

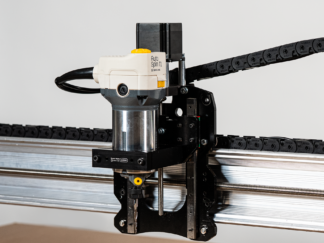

For routers, we recommend the AutoSpin T1 Router or the Makita RT0700/RT0701. Both are reliable, powerful, speed-adjustable to a large range (10-30K RPM), and their uniform outer bodies allows for versatile z-axis mounting. We’ve been using the Makita on our CNC machines for years, and the AutoSpin. The LongMill MK2.5 comes free as standard with a 65mm router mount, which is compatible with the AutoSpin T1, Makita RT0700/RT0701 and most variations of this router design.

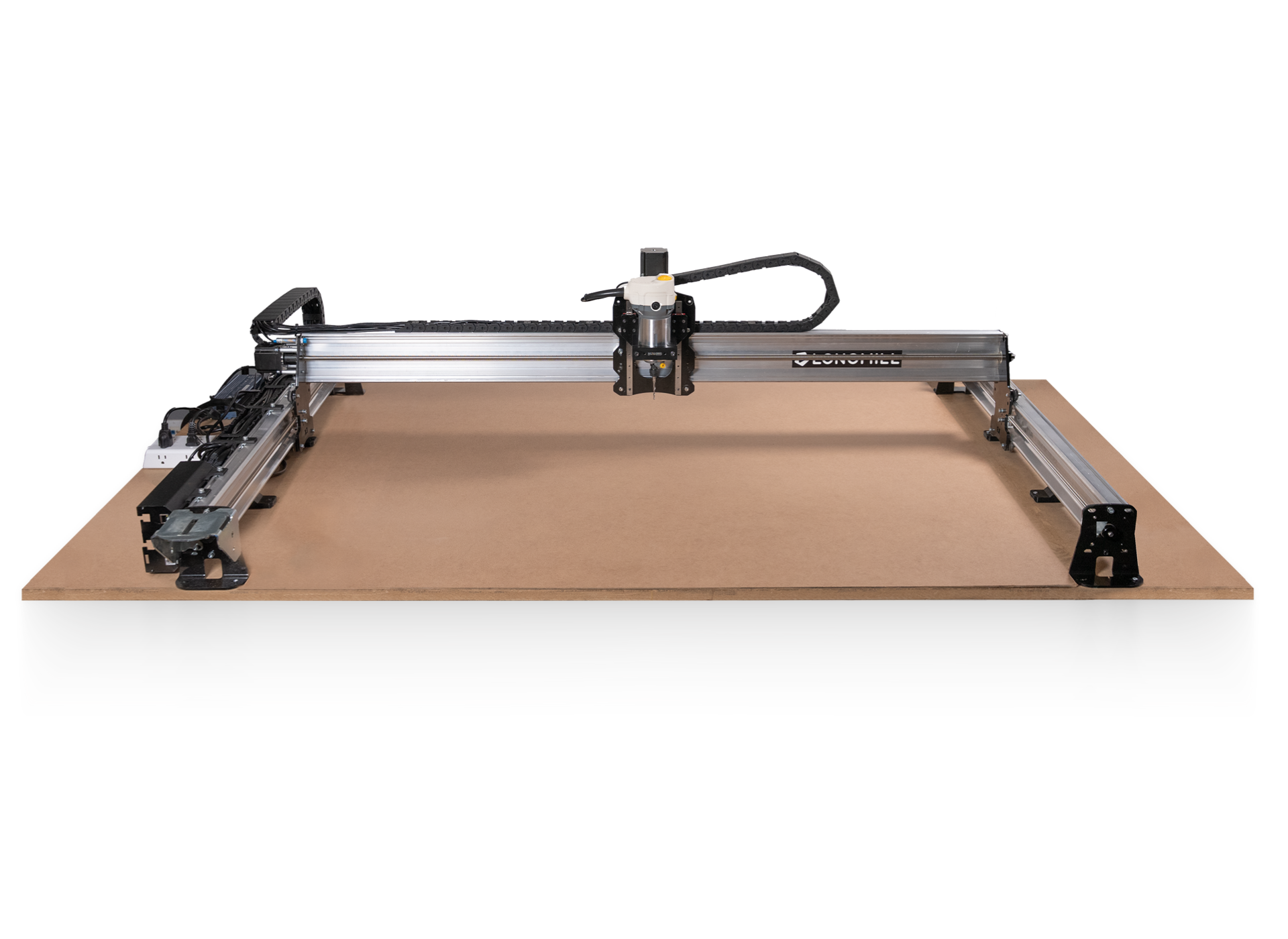

Some photos may contain items for illustrative purposes, such as routers, work surfaces, dust shoes or additional shelving. There may also be cosmetic differences between the machine in the photo and the production version of the LongMill.

We designed the LongMill to be the best hobby CNC router in its class, offering rigidity, and reliability. With large extruded aluminum rails, fully supported Y-axes, 1/4″ steel gantries on all axes, high power NEMA 23 motors, and high precision MG-12 type linear guides on the Z-axis, the LongMill MK2.5 is the most powerful CNC router in its class at its price point.

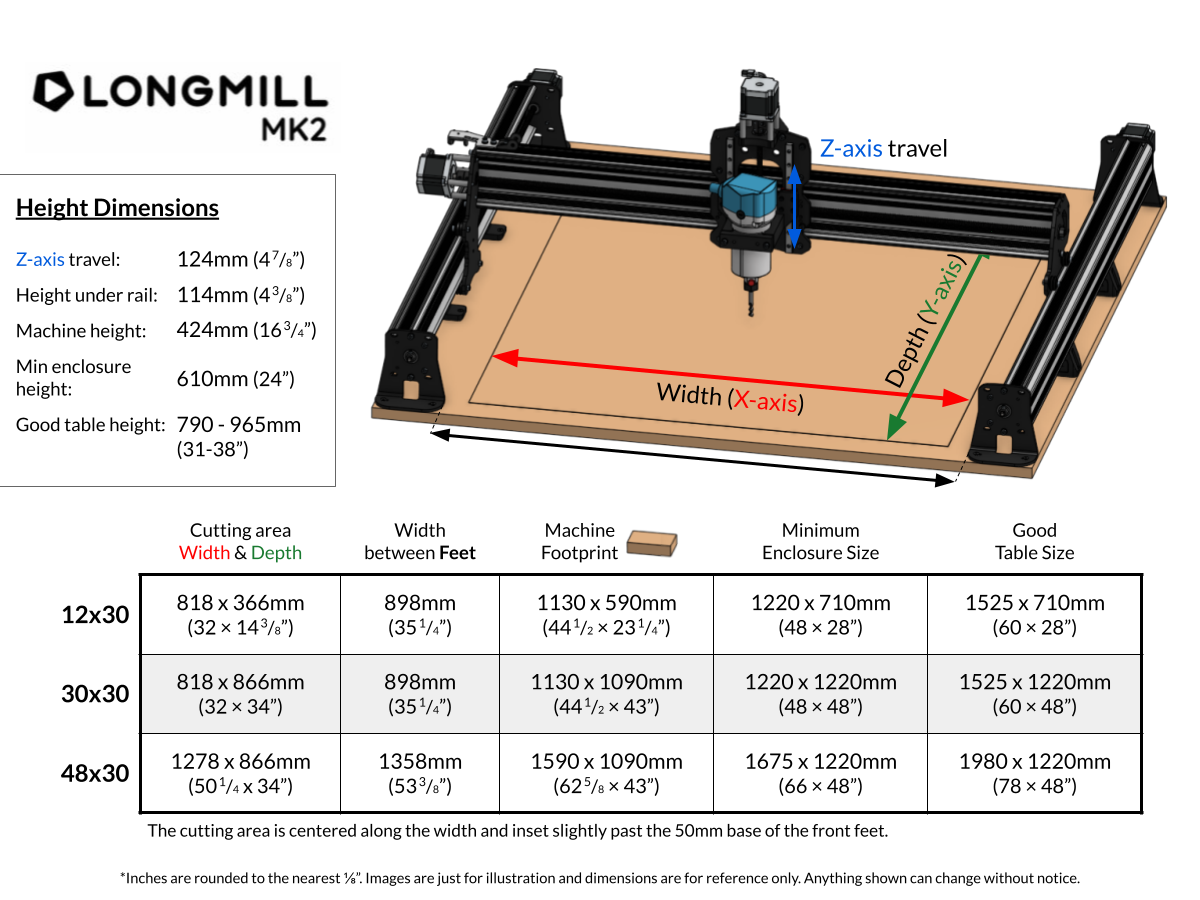

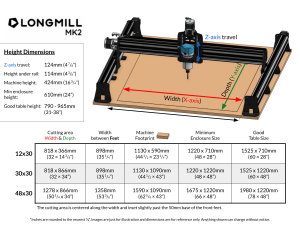

Measurements & Specifications

Specifications

If you’re looking to properly size a space to put your machine or are making a dedicated table, ensure that you leave enough room for the LongMills control box and any other peripherals that you might be using like a laptop, monitor, keyboard, etc. The control box is roughly 150mm x 280mm, has holes so that it can be easily screwed or mounted to any surface, and has a USB port on its left side which allows you to connect your computer to control the machine.

FAQs

Choosing an LongMIll vs an AltMill

https://youtu.be/7-sgkZQwWMk

What materials can it cut?

The LongMill is primarily designed for cutting wood but is capable of cutting foam, plastic, and soft metals such as aluminum and brass.

Where can I buy end mills and other tooling?

End mills and bits are available on sale on our website as well as online such as Amazon and Ebay, or at your local hardware store such as Home Depot or Lee Valley.

What software can you use with the LongMill?

The LongMill is compatible with dozens of free and paid CAM software. The LongMill is compatible with standard G-code.

What system requirements are there?

You can run your machine off virtually any modern laptop made in the last 5 years running Windows, Mac OS, and Linux. We’ve tested our machine with Intel Celeron and AMD Phenom processors with less than 2GB of RAM with no issues (although it is a bit slow.) For any other downloadable CAD or CAM programs that don’t run on the cloud, please check with the software creator for minimum system requirements.

What spindles or routers can I use?

While we recommend our AutoSpin T1 Rotuer and the popular Makita RT0701/RT0700 routers, you can also use other 65mm trim/palm style routers

Warranty

The LongMill has a 90 day warranty once it arrives at your door.

We want you to have a great experience with your machine, so if any parts are found to be missing or damaged, please email us. We will ensure that you receive the support you need to restore your LongMill to operating condition or provide a full or partial refund.

You may cancel an order if it has not shipped yet, please contact us if you wish to do so. We do not offer returns for LongMills that have already shipped.

General Warranty and Limits of Service:

Effective March 4, 2019

Throughout this policy the words “we”, “us” and “our”, or “Sienci Labs” will be used to refer to Sienci Labs Inc. herein and “LongMill” or “machine” will refer to Sienci Labs’ Sienci LongMill 12×12, Sienci LongMill 12×30 and Sienci LongMill 30×30. Additionally, the words “you”, “your”, “user”, and “operator” will refer to the original purchaser/customer, user, or viewer of any of the products or media provided by or through Sienci Labs.

Sienci Labs Inc. (the “Company”) grants the LongMill (the “Product”) a standard warranty within Canada and the US to the original customer to be free from missing parts, defects in material, and defects in workmanship for a period of ninety (90) days from the date of receipt by the original purchaser. Sienci Labs Inc. will ensure that the appropriate support is provided to the original customer to restore the LongMill to operational condition or provide a full or partial refund under the sole discretion of the Company.

This warranty does not cover damage due to improper use or assembly, lack of maintenance, normal wear and tear, or modifications to the LongMill which are not produced or authorized by the Company. Consumables such as cutting tools and sample or stock materials which may have come with your LongMill are not included in this warranty.

This warranty will become void if the operator does not follow the Safety Warnings and Guidelines, uses the Product for illegal purposes, intentionally causes damage to the Product, or transfers the Product to another owner.

The original customer must contact Sienci Labs Inc. within ninety (90) days of receiving their order to make a warranty claim to be eligible for warranty service. Proof of purchase, tracking number, email address, or other material will be used to confirm the original purchasing date and the identity of the original customer. If damage was due to shipping, original packaging materials must be kept in the original received condition. Photos, videos, written descriptions, and other items may be requested to assess and validate a warranty claim. In the case Sienci Labs Inc. requires the original parts to be returned, the customer is solely responsible for packing all items securely. Damage incurred during return shipping will not be covered by the warranty. A method of payment such as a credit card may be requested by Sienci Labs Inc. to cover shipping costs or damaged items if Products are not eligible for warranty service.

Only logged in customers who have purchased this product may leave a review.

Courtney Logue (verified owner) –

Great Value. Easier more accurate Tram method would be good.

Rene Poel (verified owner) –

Wat een prachtige machine!

Snelle levering, makkelijk in elkaar te zetten en mijn eerste werkstukken zijn werkelijk geweldig geworden.

Kortom, ik ben superblij en verwacht er nog heel lang plezier van te hebben.

DAVID (verified owner) –

I have enjoyed the using the machine with >50 projects made I continue to teach and improve my techniques.

Don Rutan (verified owner) –

Machine works great though have alarm issues with auto stops some times and have to reset

Jeff Small (verified owner) –

Rock solid. I enjoyed taking the time to assemble and fine tune once installed on my newly built CNC table. The CNC has been very reliable and I have had to do very little in terms of maintenance. I couldn’t be happier.

William Bartlow (verified owner) –

This machine is awesome easy to setup and get going, It has changed the way I work greatly increasing my productivity and allowing me to do things I couldn’t easily do before.

Greg Adkins (verified owner) –

Excellent value. I really like this CNC!

Sean Alexander (verified owner) –

Absolutely thrilled to own this.

Glen White (verified owner) –

Been working great but since I updated g sender there are some bugs it will randomly shut off the router

Charles (verified owner) –

Quite pleased with this CNC! I have since upgraded to PWN spindle. The spindle kit was pretty straight forward to install. It is soooo much more quiet!

Matthew D. (verified owner) –

Love using this cnc

Anonymous (verified owner) –

I like my Longmill Mk2 a lot, but I found the final aspects of set-up (leveling and ensuring the two Y-axis rails are correctly oriented) has been the biggest challenge and I feel like I still don’t have it 100%. I also think there should be a mk2 dust shoe that can handle proper dust collector connect 4″ with an equivalent cross-sectional area through the shoe, for proper dust control as dust control is a health issue/concern. Also I find my travel in the X-axis can be a little choppy at medium to higher speeds. All and all for the price and compared to what is out there I love it!!

Paul N. (verified owner) –

I am still learning and a long way to go. Have not had the time commit as I am very busy with my full time job. Took some advise from other owners and really took my time to set it up. Worrked perfect first time.

Mark F. (verified owner) –

Had my machine for almost 2 years and due to a bad surgery I’ve only been able to use it now for the last six weeks. Absolutely loving it. I thought it was gonna be difficult to learn at first, but it really is not.

Bob (verified owner) –

I love my CNC. I am retired and really enjoy the challenge my unit presents as I figure out the programming and finally make it happen in wood. The unit is well built and I am very happy with it.

Gary Parks (verified owner) –

Took my time during assembly, had no problems. Routed electrical cables away from each other and hung my dust collector hose so no static induced issues. My original download of gsender worked from day one so I haven’t updated it. Works flawlessly for me.

STEPHEN COOLBAUGH (verified owner) –

I use V-Carve and g-Sender. On almost every project, the CNC stops running at some point, often it stops multiple times during a project. It disconnects from the port (with error message) or stops with no error message. I have a grounding wire from the vacuum, and the machine is on a surge protector, but neither seem to eliminate the problem. This is extremely frustrating, very time consuming, and very costly.

Ricky P. (verified owner) –

It took longer than I expected to install, but overall the product is good and the machine performs very well.

Russell Kalis (verified owner) –

Unit works as expected.

But let me tell you about my most recent purchase – the Control Panel. I got this unit a little more than a week ago. I have been working with Gilberto if you have any specific questions. The unit would not power on out of the box. How does this happen? Are these units not tested before they are shipped? I expected better.

But another issue I have is that everyone in your organization seems to hide behind email and your electronic correspondence form. It is VERY frustrating when you can’t talk to someone. I encourage you to try it. Do the undercover customer and just try to talk to someone in your organization. It is almost impossible. Maybe you will get a call back from a customer service person that cannot answer your questions. But you will not be able to get a phone number or a call transfer to anyone else. It’s as if the customer service person is trying to shield all of your tech people from calls. I don’t understand it. I am very frustrated. If you want to discuss further, call me at 269-998-8536. I don’t hide behind email.

Michael (verified owner) –

A lot of features for a low price. Works great and love the continuous innovations.

JAMES HAMANN (verified owner) –

Rock solid machine. I haven’t found anything it can’t do so far. Great company to work with and they really foster a good community

John Douben (verified owner) –

The cnc machine longmill 30 X 30 is fantastic after the setup, the dimensions with milling are just right. It was the right choice to buy the longmill. And fast that the machine is, unbelievable. Also the service is top, the machine came in with a dip in the x rail exactly where the wheel runs over, that was a bit of a shock but after contact with cienci labs the x rail was replaced without any problem free of charge. TOP guys !!. I would buy the machine again,

José Sánchez Díez (verified owner) –

Soy carpintero profesional con mucha experiencia y quisiera aprender a trabajar con máquinas cnc para mejorar profesionalmente, esta máquina cumple con todas mis expectativas. Está muy bien hecha, es fuerte y tiene un buen tamaño.

Cameron S. (verified owner) –

Amazing machine. I still have a lot to learn, but the mill itself is just great.

Max (verified owner) –

My experience was mostly rough carpentry, a bit of hobby woodworking, and a lot of 3d printing. Assembly took time but was pretty easy, did it solo only the occasional awkward lift and position.

Customer service is good from what I hear, haven’t had to reach out on anything.

Mostly making gifts for family members. Looking into doing a bit of cornhole customization, seasonal decorations, and I have an idea for workshop organizing that might be of interest to others.