Description

***Included with your LongMill MK2.5***

- All rails, gantries, fasteners, lead screws, and other hardware parts to make a complete LongMill

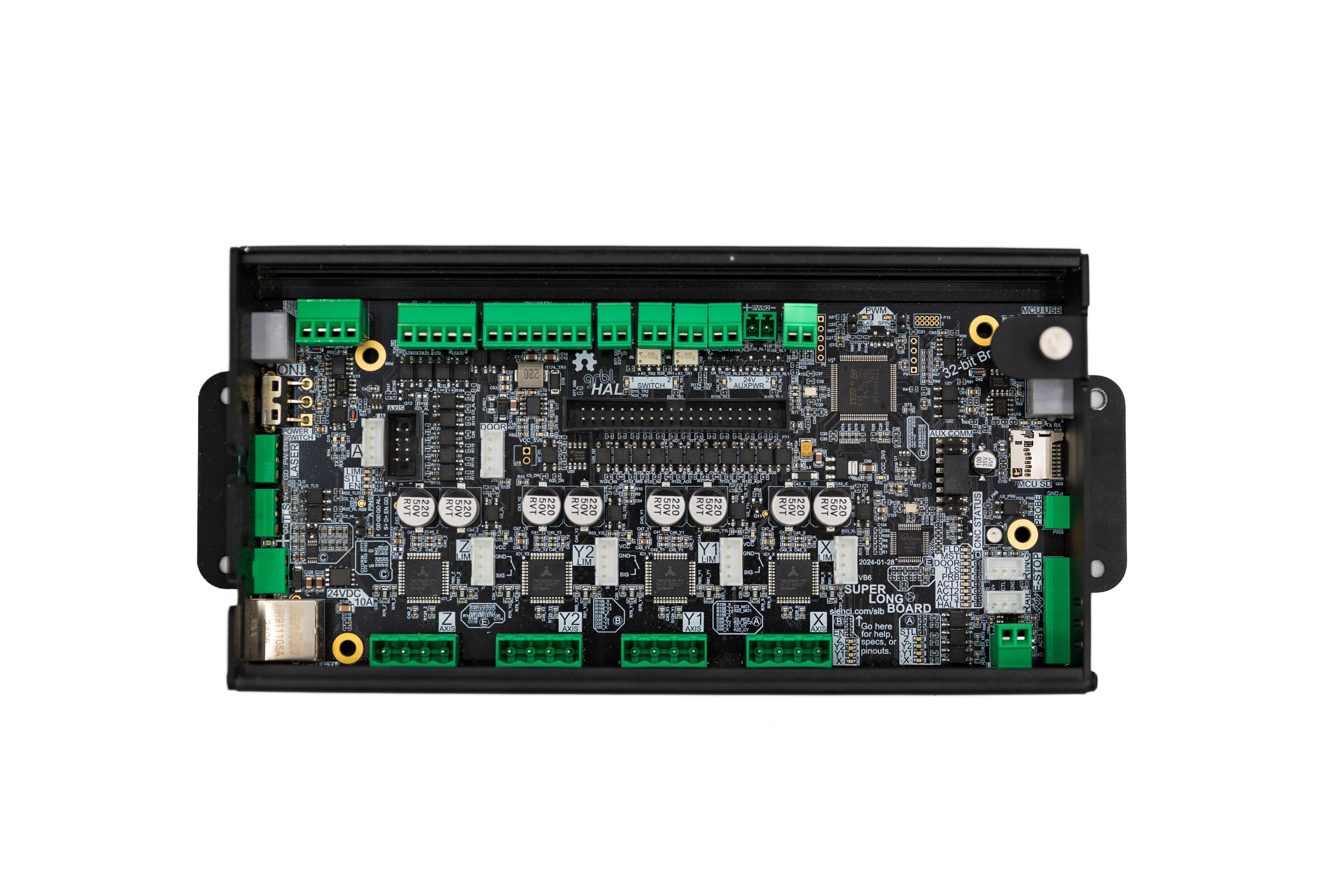

- All electronics, including power supply, controller, drivers, and motors; power to 110V/120V

- Welcome package

***Not included with your LongMill MK2.5***

Check out our recommended products tabs for an ideal set up, but note the following ARE NOT included with your order:

- Computer or laptop

- Router*

- End mills or bits

- Work surface (e.g. MDF sheet)

- Screw drivers, standard bits or drill for assembly

Please Note: Power supplies are 110V only, (North America). If you live in a country with 220V/240V power, our standard LongMill MK2 power adapter must use a transformer with a rating above 300 watts to convert your power to 110V/120V. Routers that we supply will be 110V only (North America). If you live in a country that uses a different voltage, please purchase a router in your region.

For routers, we recommend the Makita RT0700/RT0701. It’s reliable, powerful, speed-adjustable to a large range (10-30K RPM), and its uniform outer body allows for versatile z-axis mounting. We’ve been using the Makita on our CNC machines for years. The LongMill MK2 comes free as standard with a 65mm router mount, which is compatible with the Makita RT0700/RT0701 and most variations of this router design.

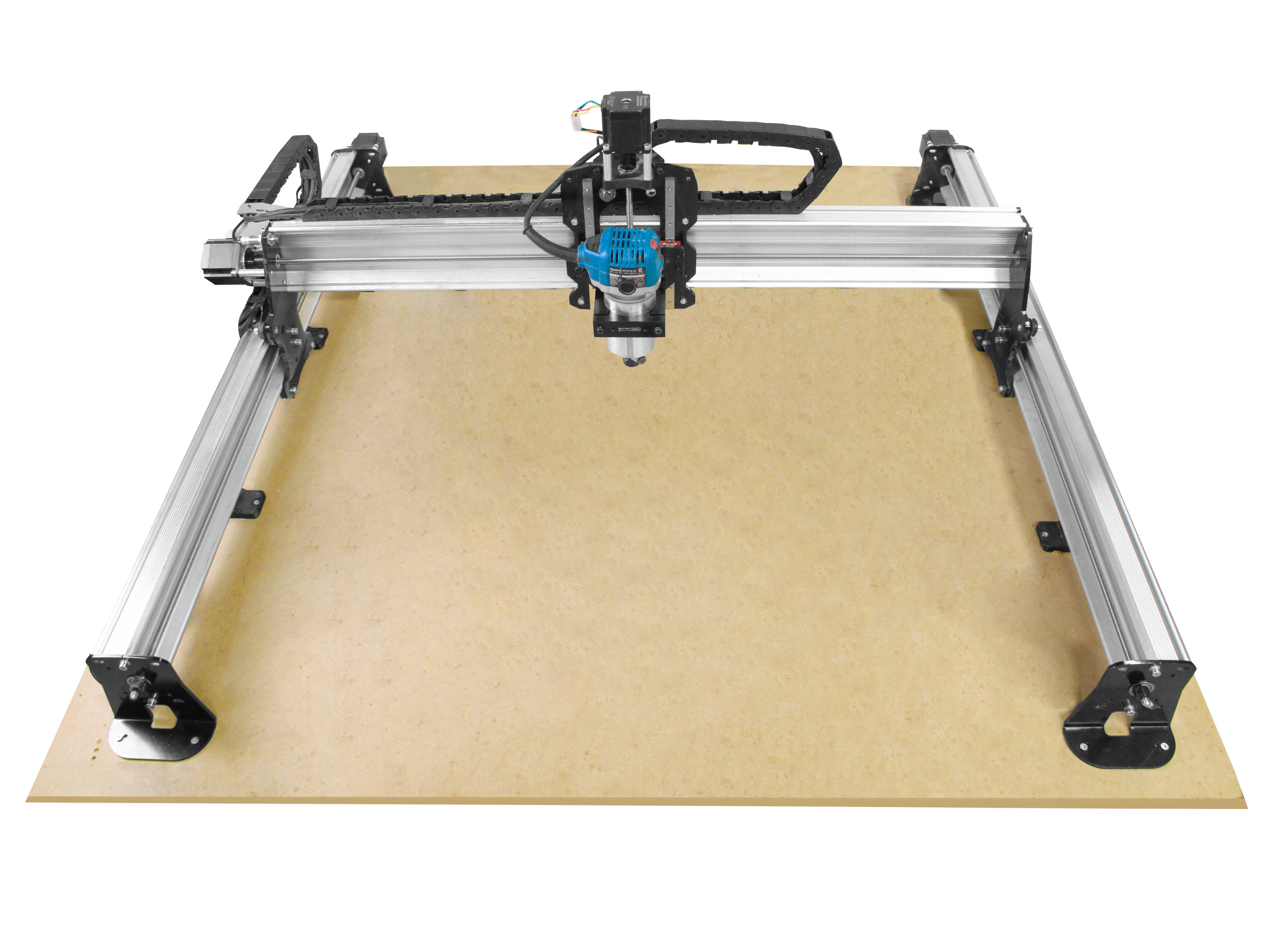

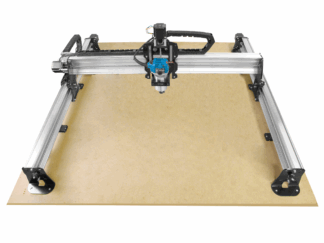

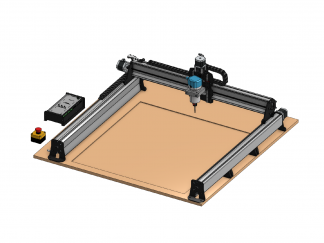

Some photos may contain items for illustrative purposes, such as routers, work surfaces, dust shoes or additional shelving. There may also be cosmetic differences between the machine in the photo and the production version of the LongMill.

We designed the LongMill to be the best hobby CNC router in its class, offering rigidity, and reliability. With large extruded aluminum rails, fully supported Y-axes, 1/4″ steel gantries on all axes, high power NEMA 23 motors, and high precision MG-12 type linear guides on the Z-axis, the LongMill MK2 is the most powerful CNC router in its class at its price point.

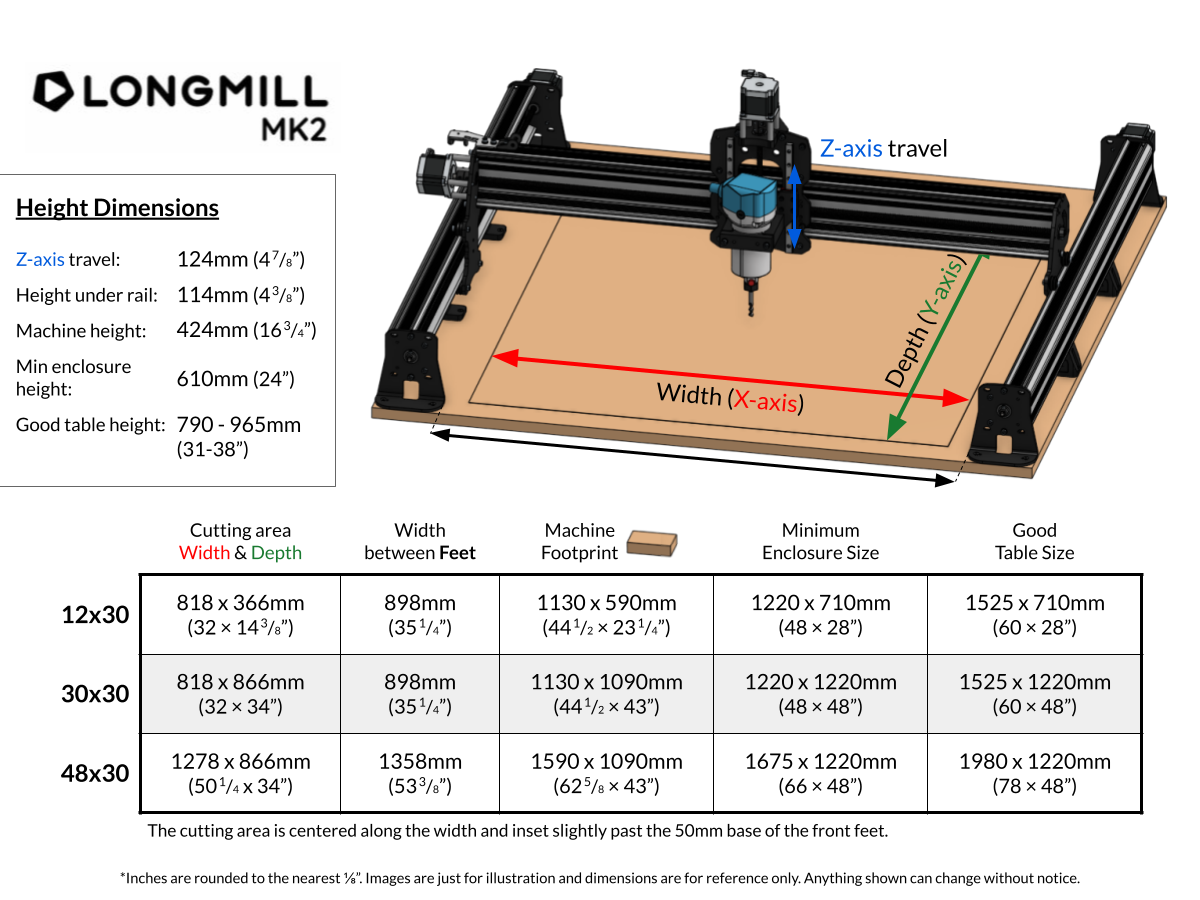

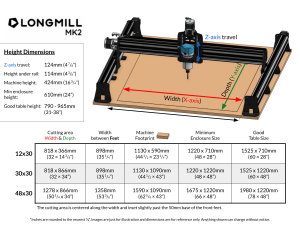

Measurements & Specifications

Specifications

If you’re looking to properly size a space to put your machine or are making a dedicated table, ensure that you leave enough room for the LongMills control box and any other peripherals that you might be using like a laptop, monitor, keyboard, etc. The control box is roughly 150mm x 280mm, has holes so that it can be easily screwed or mounted to any surface, and has a USB port on its left side which allows you to connect your computer to control the machine.

FAQs

Choosing an LongMIll vs an AltMill

https://youtu.be/7-sgkZQwWMk

What materials can it cut?

The LongMill is primarily designed for cutting wood but is capable of cutting foam, plastic, and soft metals such as aluminum and brass.

Where can I buy end mills and other tooling?

End mills and bits are available on sale on our website as well as online such as Amazon and Ebay, or at your local hardware store such as Home Depot or Lee Valley.

What software can you use with the LongMill?

The LongMill is compatible with dozens of free and paid CAM software. The LongMill is compatible with standard G-code. You can check out our resources page at www.sienci.com/resources and look under the software tab. We’ll be hosting webinars and creating additional resource videos to help you learn to design and program your CNC machine.

What system requirements are there?

You can run your machine off virtually any modern laptop made in the last 5 years running Windows, Mac OS, and Linux. We’ve tested our machine with Intel Celeron and AMD Phenom processors with less than 2GB of RAM with no issues (although it is a bit slow). For any other downloadable CAD or CAM programs that don’t run on the cloud, please check with the software creator for minimum system requirements.

What spindles or routers can I use?

While we recommend the Makita RT0701/RT0700, you can also use other trim/palm style routers. You will be able to let us know what tool you want to use and we will send you the appropriate mount.

Will there be 4th or 5th axis support?

In the immediate future, there will not be 4th or 5th axis support for the LongMill. If you would like to implement an additional axis to your machine, we encourage users to try creating their own and sharing it with the community!

Warranty

The LongMill has a 90 day warranty once it arrives at your door.

We want you to have a great experience with your machine, so if any parts are found to be missing or damaged, please email us. We will ensure that you receive the support you need to restore your LongMill to operating condition or provide a full or partial refund.

You may cancel an order if it has not shipped yet, please contact us if you wish to do so. We do not offer returns for LongMills that have already shipped.

General Warranty and Limits of Service:

Effective March 4, 2019

Throughout this policy the words “we”, “us” and “our”, or “Sienci Labs” will be used to refer to Sienci Labs Inc. herein and “LongMill” or “machine” will refer to Sienci Labs’ Sienci LongMill 12×12, Sienci LongMill 12×30 and Sienci LongMill 30×30. Additionally, the words “you”, “your”, “user”, and “operator” will refer to the original purchaser/customer, user, or viewer of any of the products or media provided by or through Sienci Labs.

Sienci Labs Inc. (the “Company”) grants the LongMill (the “Product”) a standard warranty within Canada and the US to the original customer to be free from missing parts, defects in material, and defects in workmanship for a period of ninety (90) days from the date of receipt by the original purchaser. Sienci Labs Inc. will ensure that the appropriate support is provided to the original customer to restore the LongMill to operational condition or provide a full or partial refund under the sole discretion of the Company.

This warranty does not cover damage due to improper use or assembly, lack of maintenance, normal wear and tear, or modifications to the LongMill which are not produced or authorized by the Company. Consumables such as cutting tools and sample or stock materials which may have come with your LongMill are not included in this warranty.

This warranty will become void if the operator does not follow the Safety Warnings and Guidelines, uses the Product for illegal purposes, intentionally causes damage to the Product, or transfers the Product to another owner.

The original customer must contact Sienci Labs Inc. within ninety (90) days of receiving their order to make a warranty claim to be eligible for warranty service. Proof of purchase, tracking number, email address, or other material will be used to confirm the original purchasing date and the identity of the original customer. If damage was due to shipping, original packaging materials must be kept in the original received condition. Photos, videos, written descriptions, and other items may be requested to assess and validate a warranty claim. In the case Sienci Labs Inc. requires the original parts to be returned, the customer is solely responsible for packing all items securely. Damage incurred during return shipping will not be covered by the warranty. A method of payment such as a credit card may be requested by Sienci Labs Inc. to cover shipping costs or damaged items if Products are not eligible for warranty service.

Only logged in customers who have purchased this product may leave a review.

Robert DeHart (verified owner) –

Can not say anything but good, with the on line install information , made it full proof, straight forward install no problems, unit works great a little bit of a learning curve with the software but with Gsender made it easy to run programs on the Long mill. Highly satisfied

Stanley S. (verified owner) –

I bought a cnc laser about a year ago and fell in love! I knew I had to have a cnc router. After some convincing of the wife I got my order in. I did a lot of research and thought the Longmill would be the best bang for the buck. I was right for once!. This is an incredible machine! I have been a mechanic for 30yrs, So it took me 4hrs to get it up and running and it has rarely stopped since. To any one getting into cnc I would truly recommend the Longmill!. Get the software you plan on using first and get use to it, It helps a lot. Thank everyone at Longmill, Great product!!

Dale Shoemaker (verified owner) –

Haven’t set up yet due to back issues. Customer service was outstanding getting the product here. That’s a great start. I have no doubt any issues will be handled to my satisfaction.

Robert S. (verified owner) –

Have been very impressed with the machine. Really like the auto zero touch plate, makes set up so simple and easy. Would recommend this machine to anyone looking to buy one.

Warren H. (verified owner) –

Overall, I love the LongMill MK2. I previously had a smaller hobby CNC and this thing blows it out of the water with it’s stability. Combined with some good bits, the MK2 can perform with some very aggressive cuts/speeds.

Larry Sellers (verified owner) –

The machining of the parts is above standard! Everything fits perfect. The instructions are also excellent!!!! The only weak spot is the couplings. Still, I love my LONGMILL…I would also like to give a thumbs up to Garrett Frome.

John `Corbin (verified owner) –

Took me about 6 hours to assemble, I’m admittedly slow and I did make some mistakes, but it worked on first power up. I had a slight issue in the beginning with the X axis binding, which was resolved by loosening the backlash bolts and it then stopped binding. SInce, I have made a few test projects and gotten familiar with the machine, I really like it, and see many projects in my future using it

Michael McCurley (verified owner) –

Great machine and excellent company. Couldn’t be happier.

Calvin J. (verified owner) –

The LongMill is a great Machine, Works great with Laserbeam as well and with the top notch support it makes the perfect purchase!

George H. (verified owner) –

It is a great machine for the price $1000 less than comparable ones I’ve looked at. Very easy to put together simple instructions. I had 1 piece missing on my dust boot called and was shipped the same day. Great service great product. A friend that works for National Parks Service said it was comparable to their $9000 machine that wasn’t working at this time.

Jeffrey Reed (verified owner) –

The MK2 has been great. Easy to set up and easy to use. The machine is very precise. I have only had one problem and it is with the router. The casting around locking button broke, with very little pressure. That does not take away from the machine. Will buy again.

Lindey K. (verified owner) –

Purchasing my 30×30 Longmill was very easy once I made up my mind. I had to finish building my table for the CNC and now I’m finishing up the installation process. The instruction manual is probably the best I have ever seen! Easy to follow with great illustrations. I am looking forward to powering up the unit creating some projects.

Murray Pritchard (verified owner) –

I think the price is very reasonable for the unit. I had no experience going into this and was always wanting to do something like this a s a hobby. Machine assembly was good. I found the the instructions were well laid out and easy to understand. I did not vary on any assembly and followed the instructions to the letter. The only trouble I had and seem to continue to have is the backlash nuts on the x axis seem to loosen. I am trying to set them now with a drop of blue titebond. the access to these screws is a little difficult. The other problem is the setting of the eccentric nuts on the v-wheels. Very inconsistent and hard to set properly. When I do get them set, they tighten after use. I contacted customer service and response was good. I am still having a little problem with this set up. I am making signs, tried some 3D carving, stacked text. Huge learning curve but well worth it.

Jimmy Webb (verified owner) –

I love the longmill just have to learn how to use the software to make the things I want to make

Gerald (verified owner) –

So far no problems with the machine

Curtis (verified owner) –

Well built machine, great quality for the money

Brian V. (verified owner) –

I am a Machinist by trade. I took over two months researching as many cnc machines as I could. I looked at a few factors that helped me make an educated decision. First was the quality of the machine. Second was how easy the machine was to operate. Setup of the Longmill 30×30 was a breeze. One of the biggest factors in getting into the CNC game for most people is the cost. I believe for the money the Longmill is a great buy. If your looking for a cnc router you can’t go wrong with a Long -mill.

Dan U. (verified owner) –

Super fun and easy to use

Ben Panter (verified owner) –

Easy build. I have not been able to get this machine to talk to my computer. So to this point not impressed

Mike D Blanchette (verified owner) –

What a awesome machine. Watched video on setup. Started setting up machine followed instructions step by step .was so easy. Great way to learn about the machine. Being greener than green about cnc machine thought would be hard learning the software. Watched a lot on YouTube with Garrett & Bucky . Their is so much good information out there that I don’t feel overwhelmed when using the mk2. Every time I use it I am learning something new , even on the epic failures. I never thought I would ever get into CNCing but you have shown me a vision of all the possibilities I can achieve. Thank you so much for making it so easy to get started. Can’t wait to see all the things I’ll make.

Steve (verified owner) –

Brand new into this cnc routering, over age of 60 and not real computer savy. (Disaster in the making!) However bought the longmill 2 (30×30) and the Vetric Pro software and I haven’t looked back. Putting it together I had a few issues mostly caused by failing to read everything, but did get it together and it works GREAT! I have had a couple issues where the rod came out of couplers ( at the start) but did get them back on and they still work. Adjusting the Vee wheels was challenging. I think I would like to see the allen head screws changed to Torx heads (my preference) less likely to round out. I think the hardest thing to master is the software. You need to spend time learning the software and watching all those good Ytube videos. There is a long learning curve for this type of machining but if you stick with it you can learn. I would highly recommend the longmill 2 for someone starting out. Customer service is A1 ( have used them twice so far) As far as projects go a few small clamps, a 3D model in vetric ( I struggled) a Ipad holder, dog dish using the box maker gaget and other small items. Remember Small Steps will get you there also

Michael Finnegan (verified owner) –

As a first time CNCr, I have been enjoying the challenge of learning this new skill. Having never worked a CNC machine, let alone put one together, I was able to assemble my machine intermittently over the course of a few weeks or so. Since then, I have learned the basics of Gsender and a few CAD/CAM programs and have created several carvings that I have given away as gifts. I am really loving the process. Thank you.

Catherine R. (verified owner) –

Very satisfied with my 30×30 longmill

Bruce Murphy (verified owner) –

The assembly videos on YouTube made the process go very smoothly. No issues with the machine thus far and I am running it about 3-4 hours a day. Thank you

Anonymous (verified owner) –

Putting the machine together took me 4 days, but let’s not forget to say that this is my first experience with CNC machines ever. Over all it was a breeze. I just took extra time to get familiar with all of the pieces, what they do and how they work before I assembled it. After getting the control board replaced, due to a faulty touch probe connection, I found that some other minor issues resolved themselves also. I’m stoked! I can’t wait to get my spoil board flattened so I can make something.