Happy New Year all. It’s been quite a year in 2022. Here are a couple of milestones we’ve hit in the past year.

This post was originally shared in our internal company newsletter.

Launch of the LongMill MK2

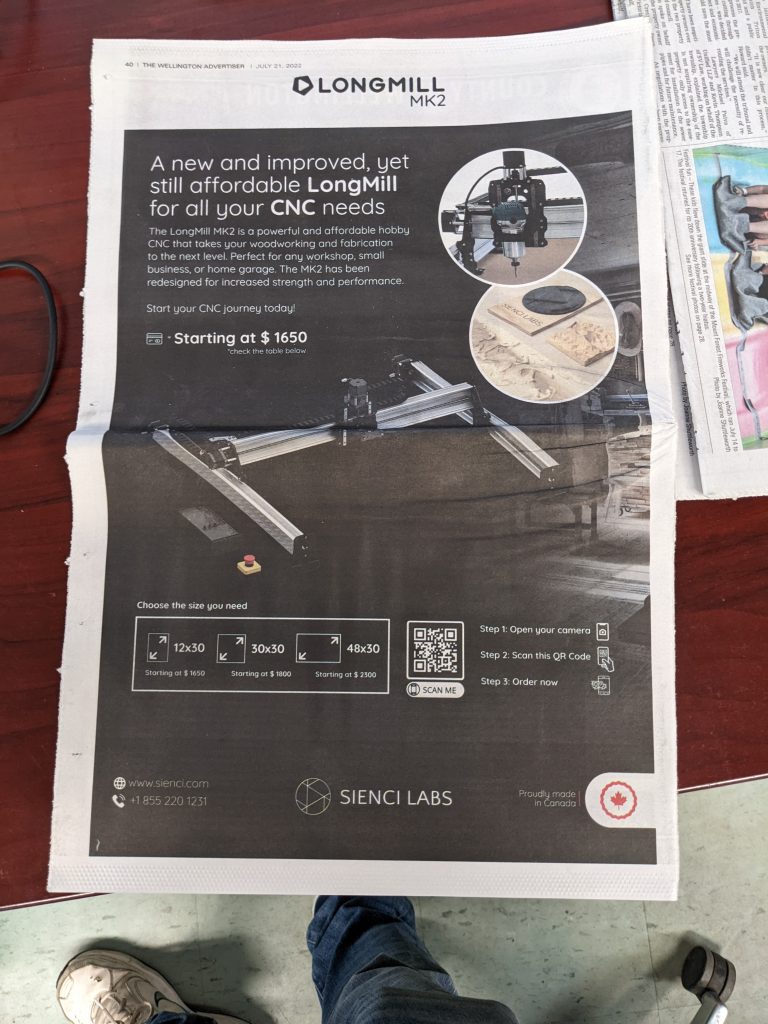

In early 2022, we launched the LongMill MK2, the successor to the LongMill MK1. This was a big milestone for us as the LongMill MK2 was a culmination of learning and experience in two years of shipping the LongMill MK1.

Also with the LongMill MK2, we introduced a new size, the 48×30. This new size allows for the use of full 4ft wide sheets. It is now the most popular variation of the LongMill.

Chris and I are happy to say that the launch of the MK2, albeit with some hurdles, went smoothly, with our resource development and customer service teams handling these areas amazingly well.

Launch of the AutoZero Touchplate

Our launch of the Autozero touchplate is a major milestone in the hobby CNC industry as the first to allow for zeroing straight and irregularly sized bits. This project took a lot of time to develop, especially in the manufacturing side. To date, we’ve sold close to 1000 units, and this continues to eclipse the original touch plate in sales.

gSender development

gSender, first launched in closed Alpha in early 2021, has now gone through 10 iterations through 2022. This is an insane pace of development, with a new version almost every month. Some new features implemented this past year include:

- Improvements to the surfacing tool, such as adding zig-zag pattern and overall stability

- Addition of machine profiles outside of the LongMill ecosystem

- Better visualizations to firmware settings

- Pendant mode

- AutoZero touchplate compatibility

- Updates to keybindings and joystick compatibility

Additionally, there have been many back-end improvements to stability and performance. gSender is becoming widely known as the best gcode sender for hobby CNC machines in our industry (https://www.reddit.com/r/hobbycnc/comments/zdw2tl/whats_the_best_gcode_sender_out_there/).

Health and safety

We now have further established our health and safety at Sienci Labs. Thanks to Kelsey, John, Mike, Steph, and the rest of the operations team, we now have stuff like training videos, first aid, WSIB certification, eye wash stations, and properly stocked first aid kits.

SR&ED

Thanks to Kelsey, we made our first filings for SR&ED in 2022. This means we are able to receive nearly $300,000 in tax credits to apply against the corporate taxes. While the engineers aren’t thrilled to do the paperwork needed to make the claims, it does cover a substantial amount of our R&D costs.

We expect to make a new filing for 2023 covering additional developments for items such as the laser, rotary axis, and control board development.

Team growth

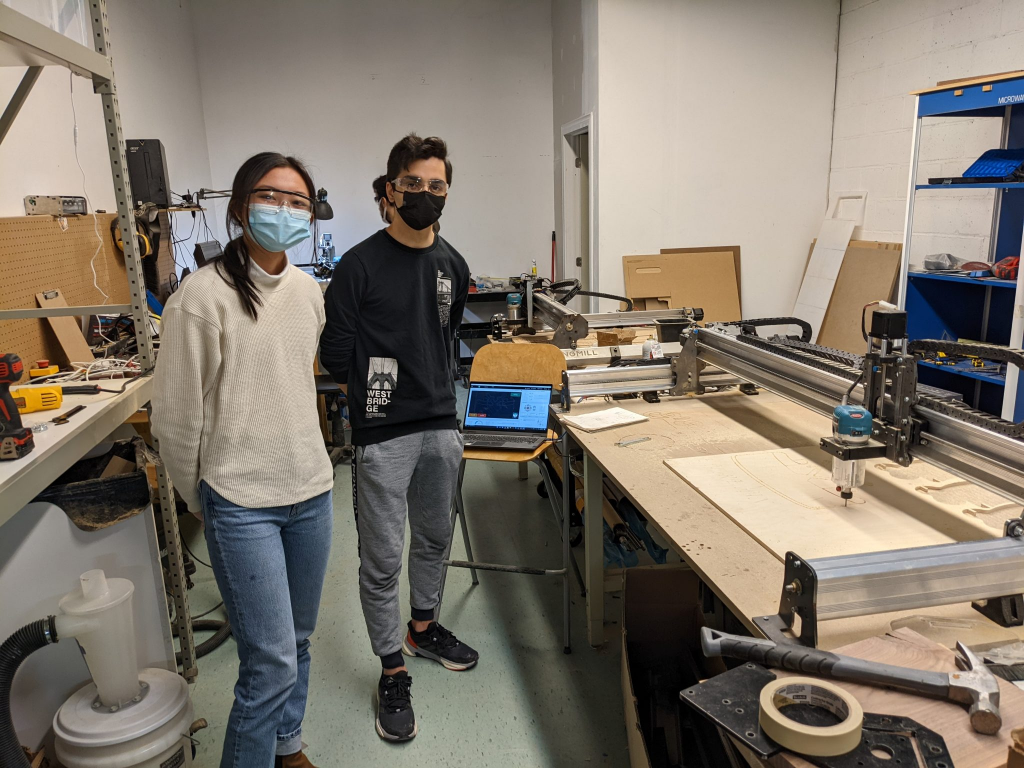

2022 is also highlighted by a big jump in the size of our team. In 2022, 10 new employees joined our team, with most new members being in engineering, software development, and marketing. Given we were about 19 people strong at the start of 2022, this means we had a 52% growth in our team.

2021 was an extreme growth year, with our revenues growing by 75.5%. This made put a lot of stress on our team as we received way more traffic than we expected. 2022 was a year of establishing our team. By bringing on new talent, we were able to streamline and improve many aspects of the company, such as inventory management, customer service, marketing, and resource development.

Revenue growth

While smaller than the spectacular 75.5% revenue growth in 2021, we still saw a respectable 34.7% in revenue growth. We saw a big jump in revenue in software and add-ons sales, as we grew our offerings in those areas.

The start of 2022 was quite slow, partially due to economic factors and issues with our supply chain causing lead times to extend and cause delays. Despite these issues, once we had them resolved, we’ve reached record sales at the end of the year, October to December being the highest in sales we’ve seen in company history and exceeding my initial projections.

Operational Improvements

There have been many improvements to operations. Some notable ones include:

USMCA certification: By creating USMCA certification, we’ve eliminated a large of taxes being paid when LongMills and other Canadian-made products cross the border. Those working in customer service would have been familiar with issues arising when folks needed to pay for duties and taxes, which this new certification eliminates.

Improved QA processes: Thanks to Mike and Jon, as well as the other engineers, nearly all components now have QA processes and documentation. This has greatly eliminated having to ship out missing parts and overall improved the quality and performance of the LongMill. Employees can now use tablets, calipers, gauges, and other tools to collect more data and improve the quality of our parts.

Katana to Batching system: Kye and the rest of the operations team spent a lot of time in 2022 establishing a new inventory system. Initially, we were using ATUM, which worked for the most part but introduced instability in the website. Katana took inventory management a step further, but the work order system met resistance with the packing staff. We learned that with the high level of experience our packing staff had, work order systems aren’t as critical. We have now since doubled down on the batching system that was originally implemented in the inception of the company.

Improvements to the 3D printing farm: 2022 brought a number of improvements to the print farm. While the Ender 3s were good in the way that they were cheap and easy to come by, at scale, the overall improvement to the print consistency and features like auto bed leveling and filament run-out sensors of the Prusa printers turned out to be worth the extra cost. Also, with the implementation of the Kanban system turned out to streamline the inventory tracking process as well.

Ron has also been implementing improvements using his CAD skills, making brackets to hold power supplies and USB cables, further optimizing the farm.

Extrusion saw and tapping arm: Given that the cost to have extrusions cut and tapped out of house would have been around $30,000 per batch of around 500 units, it made a lot of sense to bring it in-house. I’m very proud of the purchase of our sub $2000 extrusion saw as well as the tapping arm system that Mike, Jon, Dylan, and Nini has put together to make this process cheaper, faster, and easier.

Workshop improvements: We’ve brought in a lot of new tools and equipment in 2022, especially with Adam’s organizational skills and Mike’s retail therapy. Our workshop started off as a mess but has now been better tamed, with easier access to working CNC machines and tools.

Forklift: We held out on getting a forklift by using liftgates and other lifting contraptions, but the propane forklift was ultimately a great investment. With the new sea cans, growing amount of inventory being transported, and the cost of using a liftgate, we now use the forklift all of the time. It’s also important to share that we now have several staff now certified to drive the forklift.

Marketing and content creation

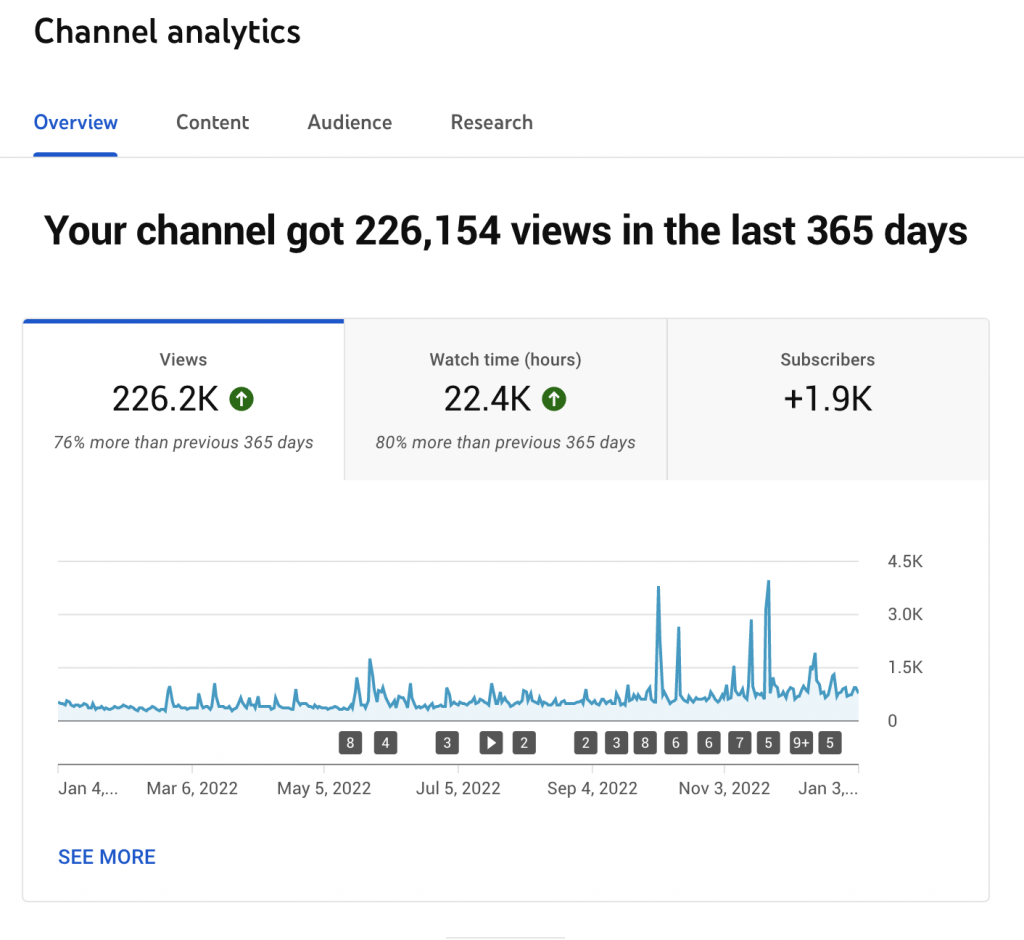

One of the largest areas of growth in our team is with our marketing and content creation team. With over half of our customers coming from Youtube, one big focus was in content creation. And with all the hard work, you can see we’ve greatly increased the number of engagements in our Youtube channel. Other marketing and content creation achievements include:

- Establishment of our weekly contests

- Improvements and optimizations to our Google and Facebook Ads

- Improvements to our file management systems and use of NAS

- A Sienci Tik Tok

- Regular LaserBeam podcasts

- Way better lighting in our videos

- and more…

Looking forward in 2023

2023 will be a year of innovation. I say this as our engineering and software development team continues to push out new products and developments which will play a significant impact in the establishment of the hobby CNC industry. Some developments include:

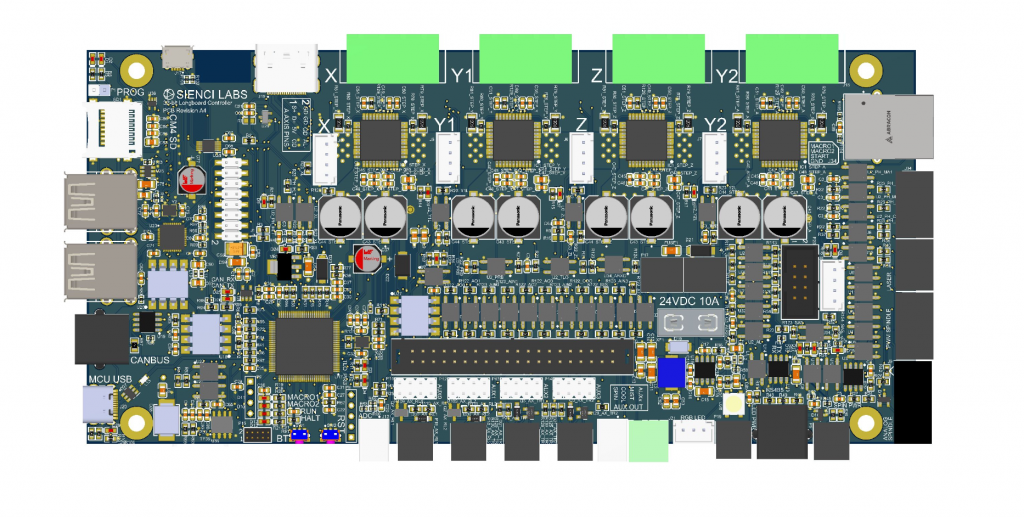

- A new, smarter CNC control board

- Continued developments and features in gSender

- Rotary Axis

- Continued development in the LaserBeam

- Improvements to the mechanical components, such as the couplers and locking nuts on the LongMill MK2

Additional potential developments on the horizon include:

- A new router/spindle system

- New, unique end mills and bits

- Heavy duty Z axis and other mechanical improvements to the LongMill

- AltMill and YesHappy development

- Plasma CNC development

Additionally, we expect to continue putting out more educational content and tutorials for our products. These include project videos, livestreams, and resource videos. This is expected to increase sales, as more than half of our customers find out about us through Youtube, but also bring more value to our community as we create useful content for the public to help them learn how to use our products.

As our company continues to grow and scale, it’s important to acknowledge the changes to Chris and my role in the company as well. I am grateful to have talented and hard-working people surrounding us to continue to push our company forward and take on many of the responsibilities that we previously handled. This has given us more freedom and satisfaction in our personal lives because of the talents of our staff.

Thank you to everyone who was part of our 2022, and we look forward to continuing our journey in 2023.

What do you want to see in 2023? Did I miss anything for 2022? Let me know!