This blog entry was posted on Conrad Business, Entrepreneurship and Technology Centre written by Chris Thorogood.

Read the original post here: https://uwaterloo.ca/conrad-business-entrepreneurship-technology/blog/post/science-standing-out-sienci-labs-enterprise-co-op

“What sets your company apart from the rest of the competition?” This is a question that I’ve heard almost daily as a founder of my new venture, Sienci Labs. On the surface, this seems like such a simple question, but it truly is one of the most important questions that any company should be able to answer about themselves.

You get to learn very quickly in the Enterprise Co-op program that your company’s value proposition is one of the most important sections of your business model canvas, and for good reason. If you’re claiming to have created a new technology or have improved upon an existing one, why should anyone believe that your system far surpasses existing technologies upon which whole industries are built? And even if what you’ve created is new, what’s stopping someone else from doing the same thing better?

Finding our Value Proposition

There are many ways that you can distinguish yourself from new or existing products or services, but the hard part is finding the few key aspects that indisputably legitimize your company’s existence.

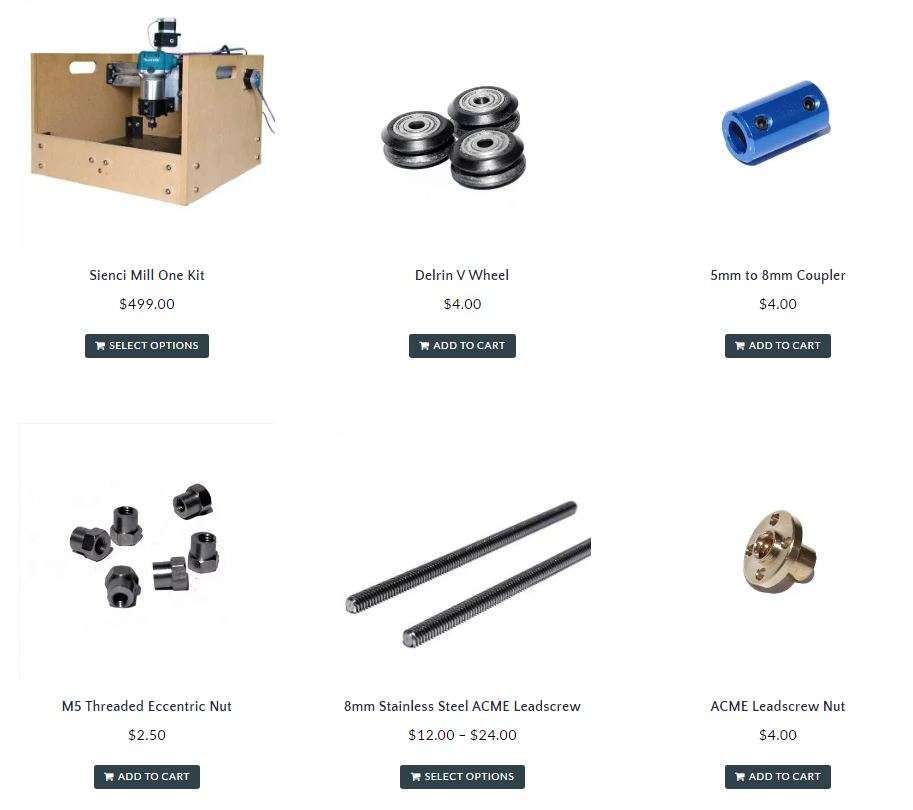

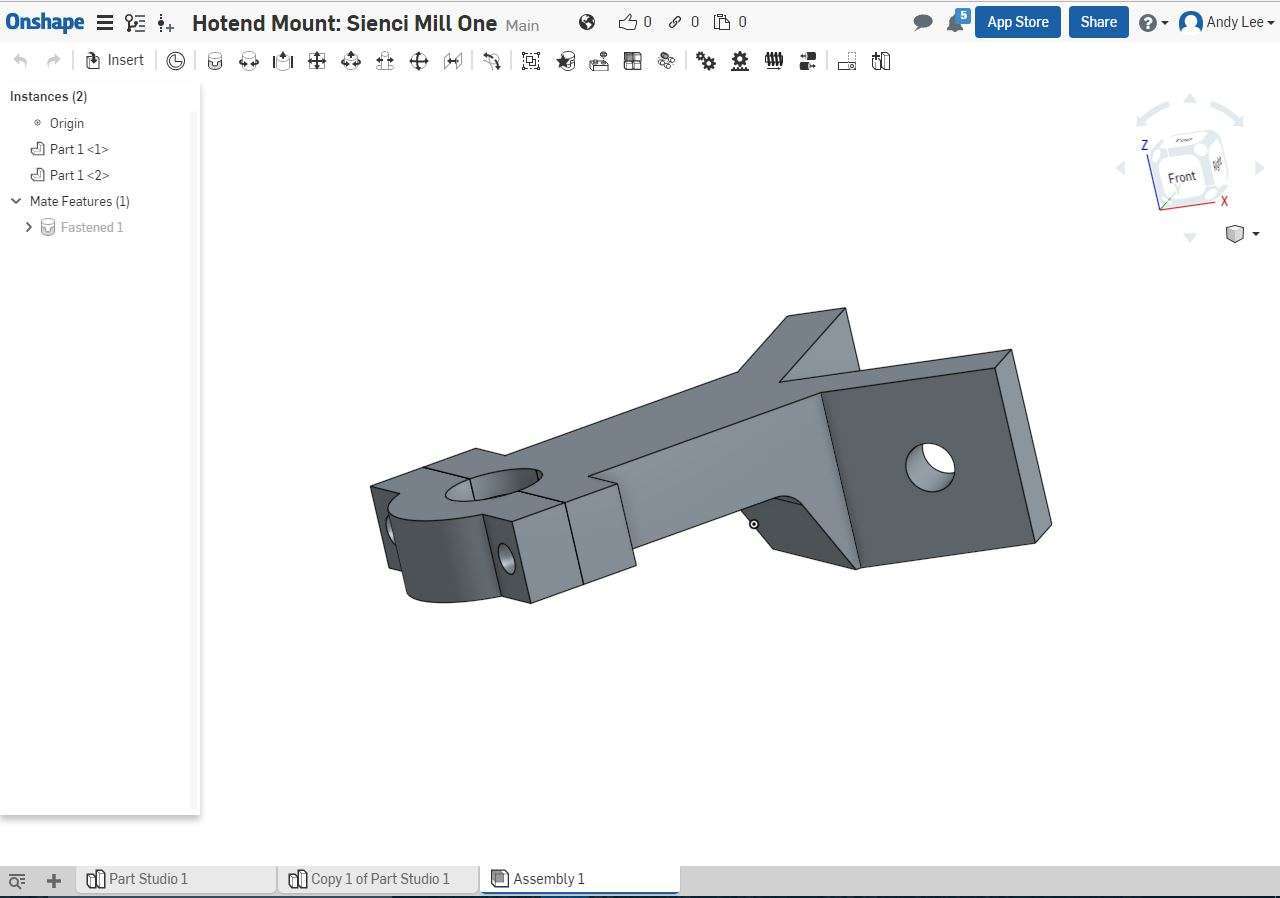

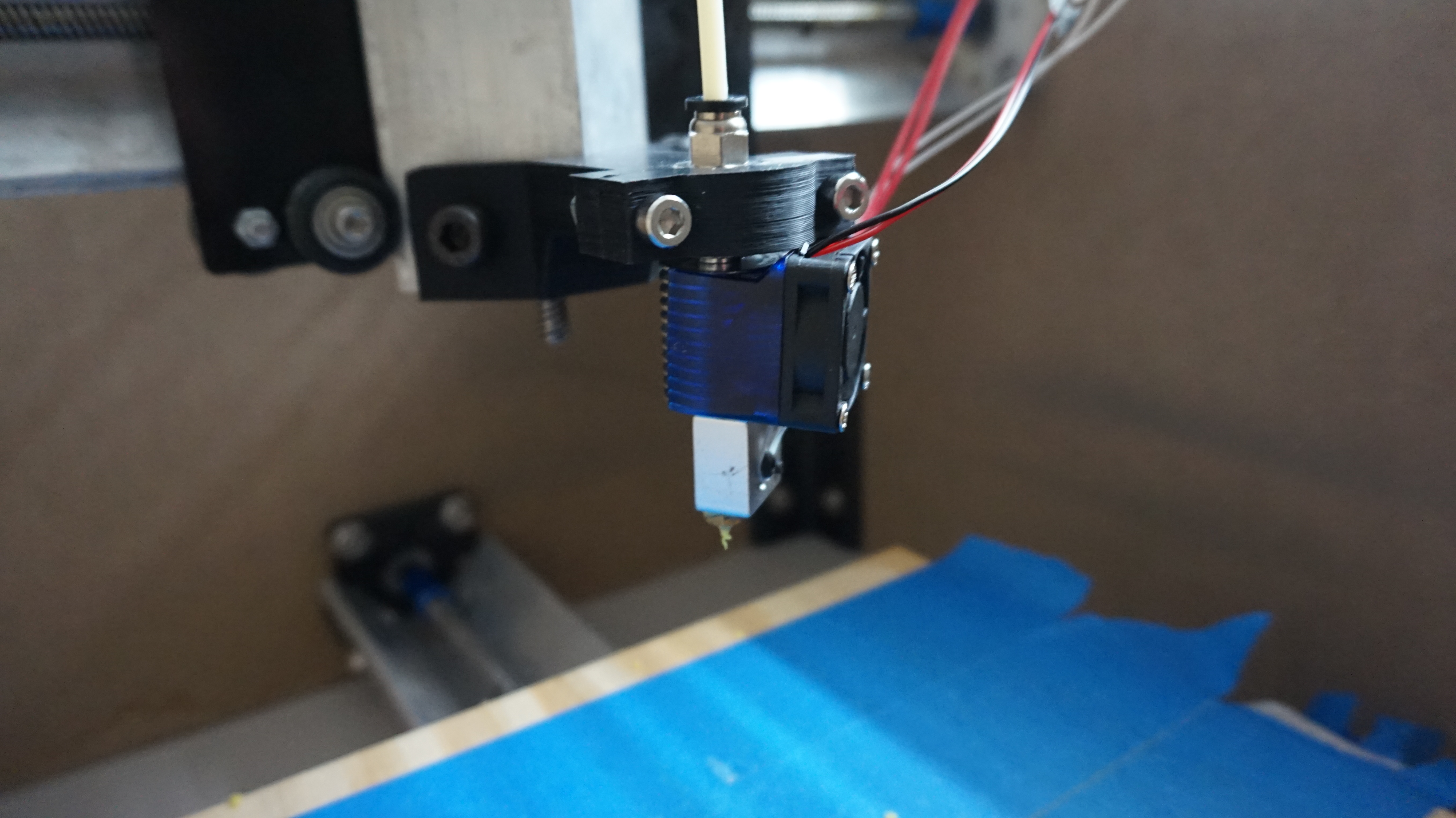

When it came to our first product, the Sienci Mill One, we thought that creating a cheap desktop CNC would be special enough to bring in customers. But what we failed to communicate was the simplicity of our product. Any machine could be made like ours to be cheap, but we learned that the true value that we delivered was not just in the precision of our affordable machine, but in its simplicity, ease of use, and our customer service.

Communicating our Company’s Identity

It’s very easy for consumers to evaluate your product solely based on price, so convincing them otherwise certainly isn’t an easy task. We make sure to stress our machine’s ease of assembly and ease of use at every contact point with our customers so they realize the value of their time. . If they’re buying a cheaper machine than ours then it’s certainly going to be lacking in one, if not all, of the areas we’ve got covered; that’s where our real value proposition is.

If the machine is less expensive, then it’s likely to be more complicated. This means that you’re more likely to spend the difference in cost in the additional time it would take you to assemble your machine and learn how to use the software.

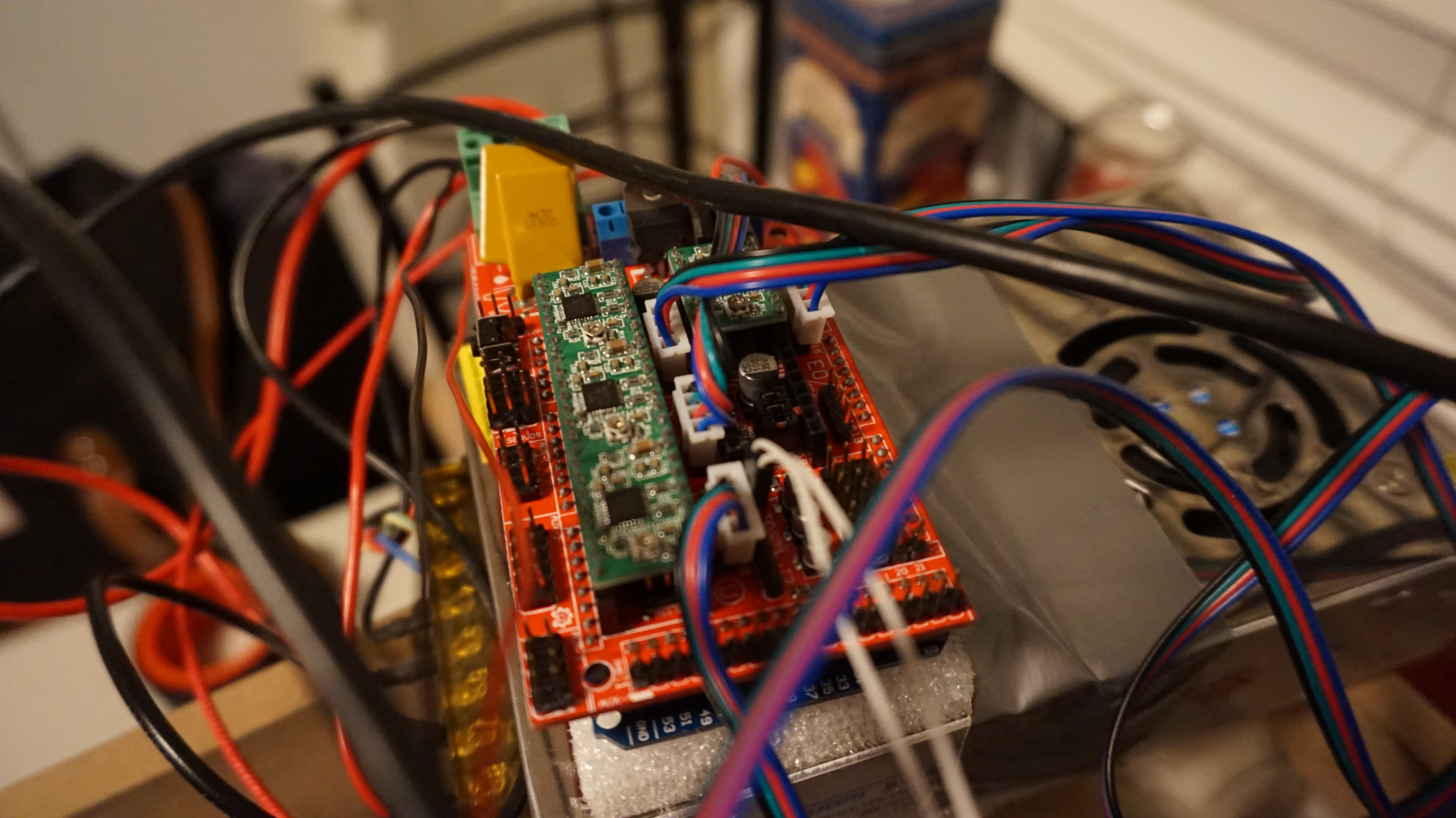

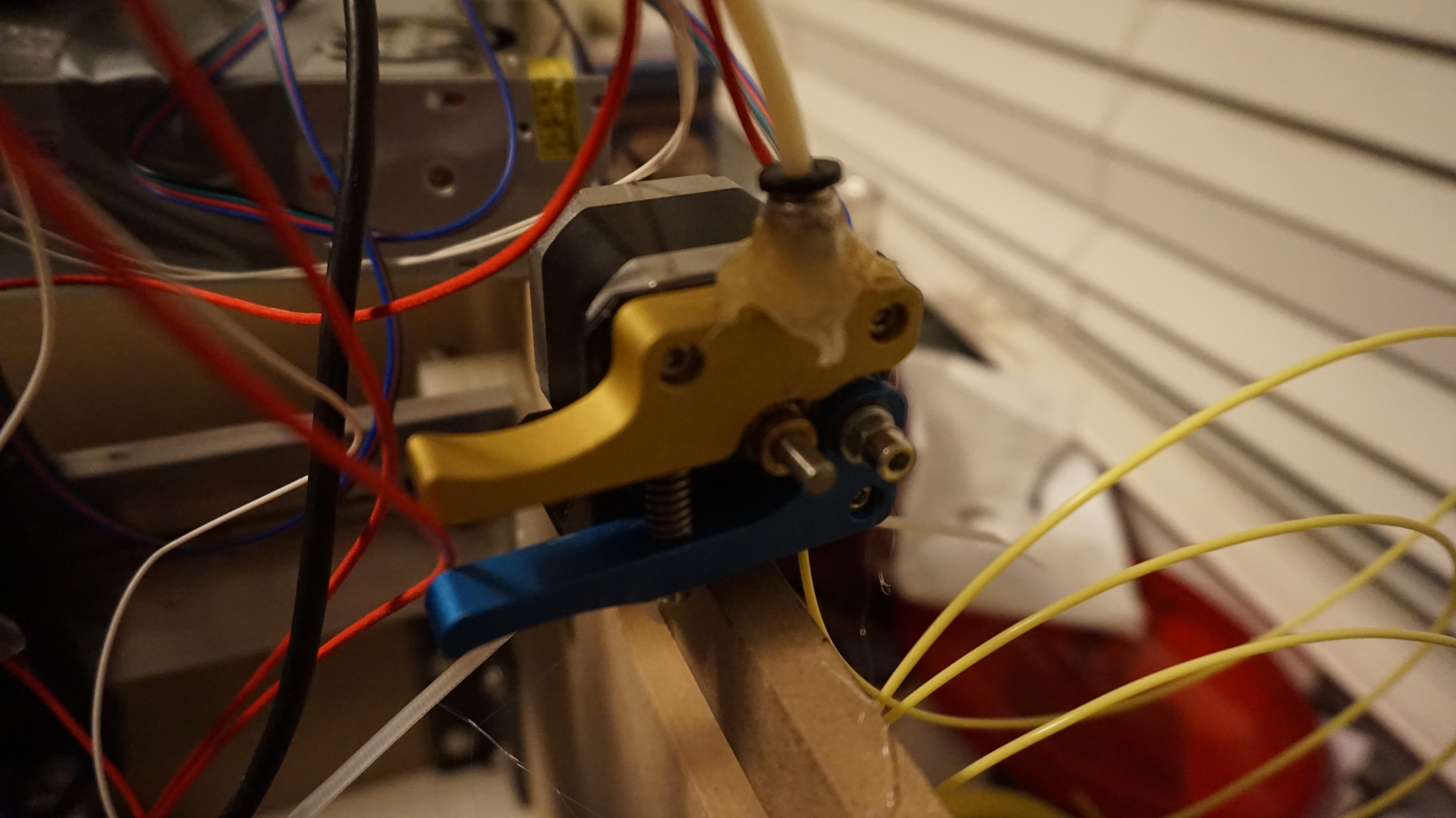

Our simple design allows for fewer points of failure so the machine is very solid, and in the event of breakage, buying replacement parts and getting the machine up and running again is a breeze. I’m very happy to say that we took no shortcuts when making our world-class machine assembly videos and assembly manual. We’ve also continued to develop a software package that is the easiest on the market to learn and use so that anyone who’s new to CNC routing will have no problem using the software’s intuitive interfaces.

The Long Road to Success

We’ve come very far since the successful completion of our Kickstarter campaign back in mid-September 2016. Our progress is steady, but we’re certainly nowhere near the end.

In these past four months in E Co-op, much of what we thought we knew has been challenged and proven wrong. There are many important concepts to keep in mind in a startup environment, and one of the prominent ones is remembering to fail fast. It’s hard to know if you’re doing something right unless you’ve already proven that all the other solutions are wrong. So, strive to fail, discover your customers, find your company’s value, and go out and make your own success!

Keep up with Sienci Labs through their mailing list!