We’re thrilled to announce that the AltMill CNC is now officially available for preorders! Don’t miss your chance to secure yours by visiting our website!

We’re thrilled to announce that the AltMill CNC is now officially available for preorders! Don’t miss your chance to secure yours by visiting our website!

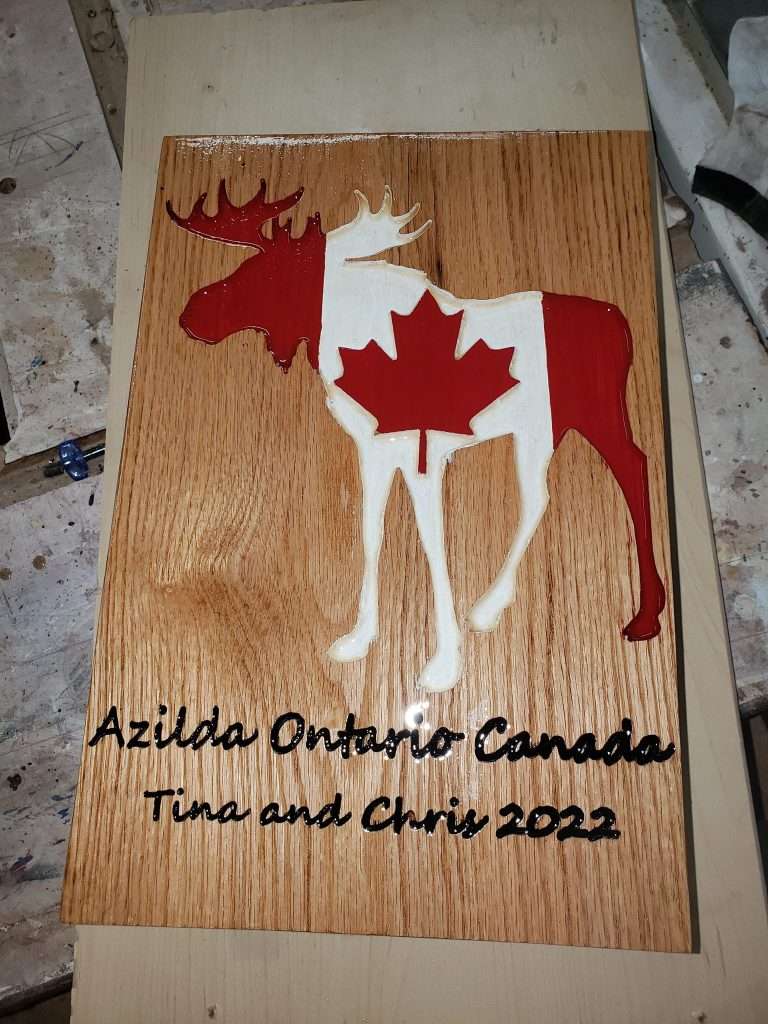

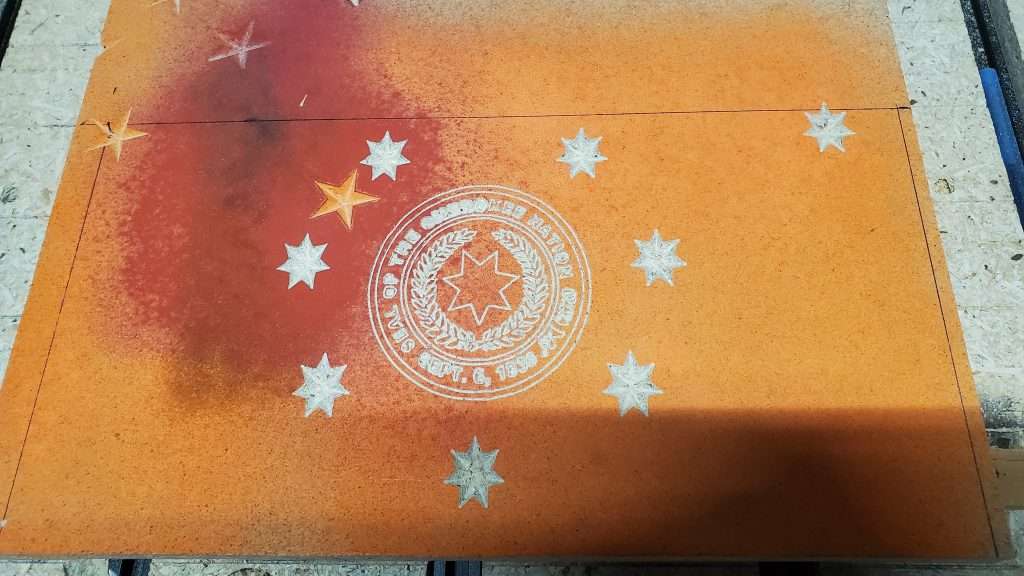

Happy Friday! Thanks for showcasing the amazing flags you’ve created with the LongMill.

We are happy to announce that Marcus Pedroza, Derek Carriere, Jim Ullett, Lester Brake, Lalo Munoz, and Shane Jiang are the flag projects contest winners. Watch out for a prize!

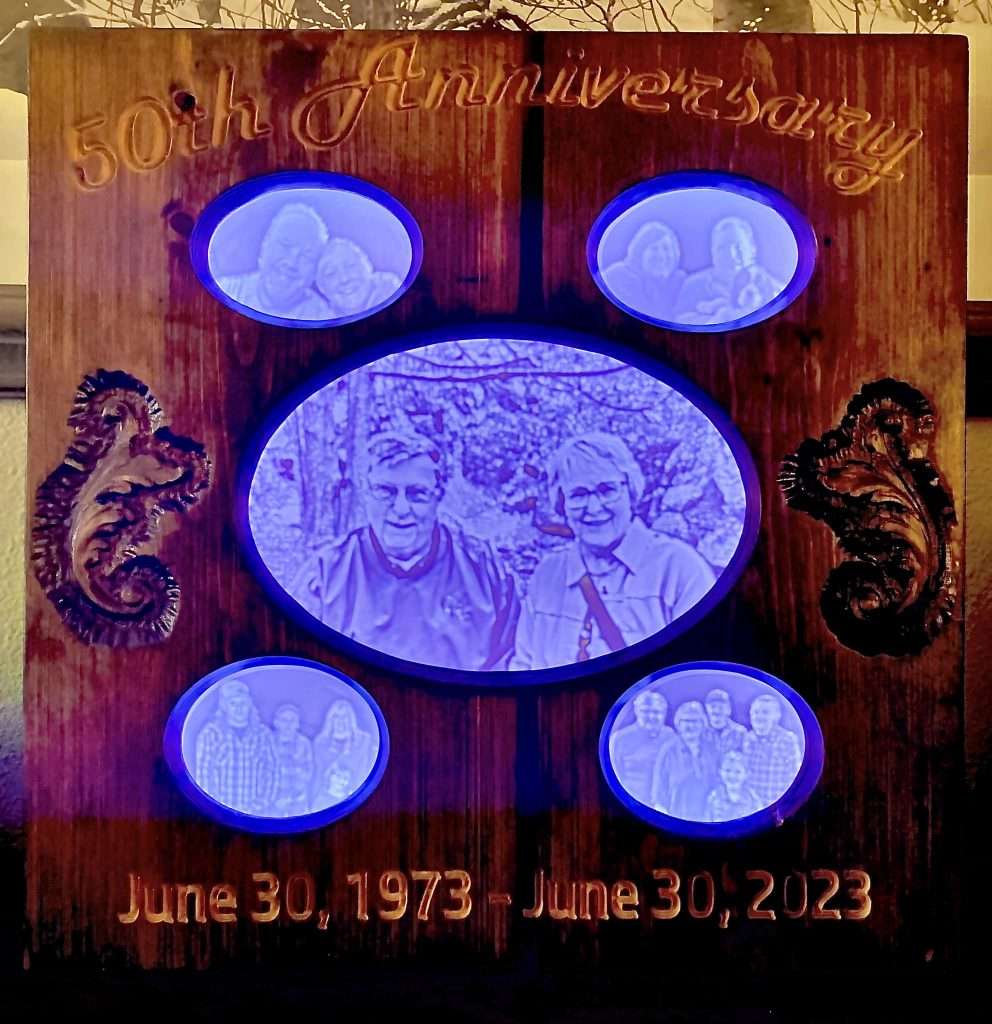

Theme of the week: ‘Decorative Projects’! Share your LongMill creations for decorating spaces: wall art, signs, frames, carvings, figurines, and more. Winners get prizes!

Have ideas for themes? Let us know by commenting below!

Happy crafting!

Hey guys, it’s Andy here. We’re excited to be launching a new CNC machine, the AltMill! This article is designed to tell you everything about the AltMill that we possibly can.

The AltMill name is derived from “alternative”, “alter”, and “mill”. We believe that “alternative” fits the namesake of the AltMill because this machine represents a different way of approaching things in engineering, technology, and the way we build our company as a whole. We believe “alter” fits the purpose of the machine, which is to take materials and alter them into new forms, uses, and purposes. And of course, since we use milling as our way of altering the material, we can put these ideas and words together to form the name “AltMill”.

The AltMill is a culmination of new technologies, hardware, experience in manufacturing, and customer feedback. Our goal was to take all of these things and build a machine we felt brought the most value to the CNC user by incorporating our ability to engineer high-performance, quality machines at scale.

The focus for the LongMill was to be a medium-format, hobby-focused CNC machine. Most users typically are looking to make things with a CNC in their spare time. Because of this, we made the LongMill the most affordable option possible in this size category, while being useful and effective enough to handle just about any CNC woodworking project you want to throw at it. We define LongMill’s success in its ability to make CNCing accessible to the average person.

The AltMill is designed to have the most “effective value” as possible. Its success is defined by how much value it can create versus the cost of the machine itself. In simple terms, we wanted the machine that would bring the highest ROI and productivity. The AltMill focuses on the intersection where we believe the performance versus cost ratio is the highest it can be for these users.

Here are some spec comparisons to highlight the differences between AltMill and LongMill:

That being said, there is an overlap between these two machines. The process of using the AltMill is basically the same as the LongMill, which means that our resources and education translate over between the two machines, and the ease of use and process of using of both is similar. Additionally, both machines are designed primarily for woodworking use, and the types of projects we expect users to create will be similar as well.

Should I get the AltMill or the LongMill?

This depends primarily on your budget and what you want to do with the machine.

Here’s why you would want a LongMill:

On the other hand, here’s why you would want an AltMill:

Of course, the higher performance of the AltMill comes at a cost. We discussed the breakdown of costs one should expect with the LongMill in our article here. Here are some rough estimates on what you should budget (in USD).

Based on my estimates, you should budget around $4500USD to fully set up an AltMill from scratch, about double the cost of the LongMill. You may have some of these items already which will lower your costs.

The machine itself ($2950USD)

This is the machine and all the doo-dads to have a working machine, minus the spindle, wasteboard, and computer.

Unlike the LongMill, the AltMill comes default with table legs, so you don’t need to build a bench for it. Additionally, the AltMill comes with inductive homing sensors by default.

Based on our rough estimates, shipping within US and Canada should cost between $150 to $200USD.

Spindle and dust shoe ($515USD)

We recommend users to use a spindle with their machine, because running the Makita router on the AltMill will make the life of the router very very short and unenjoyable. We expect the majority of users to order the Spindle and Dust Shoe Kit which we offer as an add-on kit.

For users wanting to add their own spindle, we expect after all of the parts, wiring, and extra things you’ll need with the machine, it’ll run around $500USD on the low end, but could cost up to a few thousand dollars for some really high end spindles.

We are offering a 1.5KW 110V spindle at this time because we believe it will accompany the most number of people at the launch of the AltMill. However, we will likely offer higher-powered spindles requiring 220V in the future. Users planning to implement higher power spindles should also budget the cost of hiring an electrician for any extra work.

Dust collection ($300 to $1000USD)

Assuming you get the Spindle and Dust Shoe Kit from us, the dust shoe comes with a 4″ hose mount. To get the full performance from the AltMill dust shoe and to keep up with the cutting rate of the machine, a dedicated dust collector should be used. A regular shop-vac can be used, but may not be able to keep up with the waste material generated by the AltMill when running quickly.

Computer ($250 to $800USD)

The AltMill and the LongMill share the same system requirements, which can be found on the System Requirements page in our Resources.

At minimum, you will need a computer to run gSender to control the machine.

Wasteboard ($50USD)

Like the LongMill, you will need to mount a wasteboard to the machine. A 4x4ft sheet of 3/4″ is recommended as the base. On the AltMill, the wasteboard is mounted to it’s frame using screws. You can additionally purchase t-tracks if you wish to add some workholding to the wasteboard directly.

Tooling ($100-200USD)

You’ll also probably want to order some endmills and bits for your machine. You can use the same tools between the LongMill and AltMill, although we will likely expand our range of endmills to accommodate the larger collet sizes we can use with the AltMill spindle. Tooling costs vary widely, but we sell affordable end mills on our store.

Software ($0USD to $699USD)

The AltMill works with our free gSender for all of your machine control needs, along with additional features such as machine calibration, firmware changes and updates, surfacing g-code generation, and more.

For CAM, all of the software that works with the LongMill also works with the AltMill. You can learn more from our Software Resources. There are both many free and paid software options for the AltMill.

The most popular software, and the one we recommend frequently is VCarve Pro, which offers advanced 2D and some 3D carving features, flip-milling set-ups, 4th axis support, and more. This software has a one-time cost of $699USD.

Please note that at the time of writing, we are starting the first production run of the AltMill. You may find relevant information about the Order Status page or in our Production Updates in the blog.

The AltMill comes in three large boxes. They have been specially designed to fit compactly to reduce shipping costs as much as possible. We estimate each box will weigh about 70lbs. With UPS or other courier shipping, you should expect transit times within the US and Canada to take around 1 week.

Based on some general shipping cost calculations, customers should expect to pay around $150-250USD for shipping within the US and Canada for an AltMill.

Large portions of the machine will come pre-assembled, but final assembly of joining the sub-assemblies will be necessary. Most of the machine is put together with M5 and M6 screws, and a set of metric bits or allen keys are required to finish the assembly. Additionally, you will need to provide and mount your own wasteboard. We recommend using 3/4″ MDF.

We will have resources to help users set up and assemble their AltMill on our Resources in a similar style to the LongMill and other products we’ve created. Users should allocate between 3-5 hours for the assembly and set up.

Users will also need to provide a computer that can run gSender. More information about downloading gSender and details about its setup can be found in the gSender Resources.

The AltMill works just like the LongMill and most other CNC machines. We’ll provide more guides on setting up the machine for different types of work. Beginner users may find content in the LongMill Resources relevant. We expect this group of users to be a bit more advanced, and some of the content and information will reflect this. Additionally, users should expect revised content such as updated feed and speeds and installation for the add-ons to come soon.

The AltMill maintenance is simple, but needs to be done regularly to prevent damage to some of its components and have optimal performance and longevity.

Here are some estimates for bearing maintenance:

We will provide thorough resources and guides to perform proper maintenance for the AltMill.

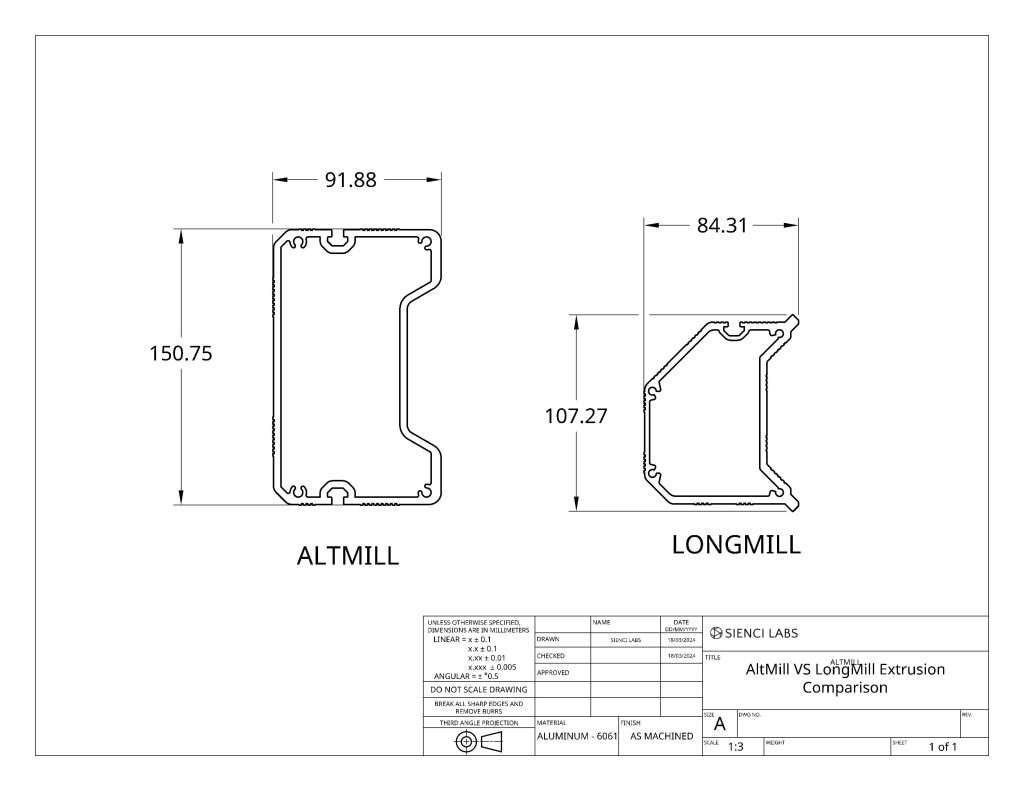

The process of designing the LongMill extrusions gave us a lot of experience in designing extrusions for high precision and rigidity critical applications. Since then, we’ve used this knowledge to manufacture parts such as the t-tracks and the enclosures for the SLB. This experience was able to help us understand the quirks and strengths of aluminum extrusion in the construction of the AltMill.

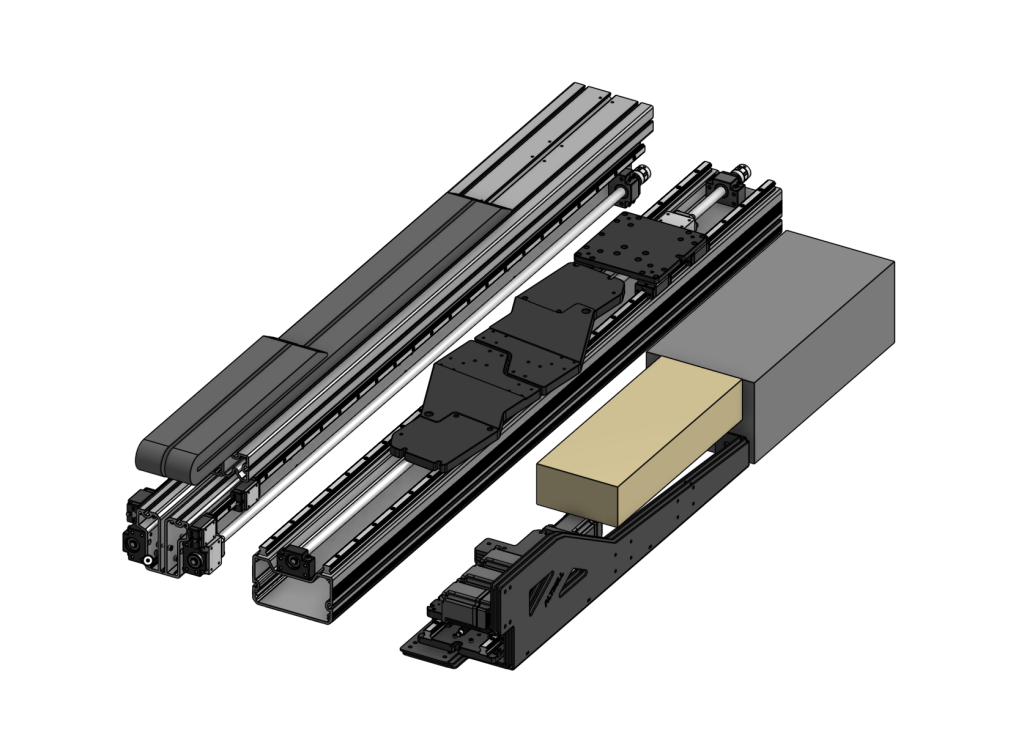

The AltMill extrusions are big, especially compared to the LongMill, which lends to its strength and rigidity. If you want to check out the video where we talk about this more, see it below:

To make sure that the frame and axis of the AltMill are straight, a few additional steps have been incorporated to make extract as much performance and accuracy from the extrusion as possible.

First is in our process of extruding and milling the critical surfaces flat. Once the extrusion is pressed, it gets annealed and straightened, which allows for fairly high tolerances. However, there can still be sub-tenths of a millimetre deviations in the tolerance and straightness of the extrusion. To eliminate this, mounting surfaces for the linear guides and the ends of the extrusions have been machined to ensure they are flat and parallel.

Second, additional extrusions that make up the base of the machine are designed to help keep the Y-axis rails straight and parallel. Each of the bottom rail ends have been machined to make sure they are of an exact length, so the distance between the two Y rails is extremely accurate. This also provides additional support and rigidity to the machine, plus having mounting points to make it easy to add a wasteboard to the machine.

Users will find that the extrusions also come with many different design aspects, such as t-tracks and mounting points for motor components, legs, drag chains, and more, allowing the machine to be easier to assemble and maintain while saving costs by reducing the number of parts needed to build the machine.

One of the challenges that come from getting a CNC machine, especially a large one, is getting it from the factory to the door. Most machines in this range do need to be shipped in multiple boxes and the AltMill is no exception.

To make it as inexpensive as possible to ship, we have made a lot of considerations such as:

The AltMill is designed to come in 3 large boxes weighing around 60 to 70lbs each.

Because of the more complicated procedure for assembly of the AltMill, a lot of consideration was made to make the machine as easy to assemble as possible internally. Here are some considerations for the design for assembly:

One of the biggest differentiators between the LongMill and the AltMill comes from the use of linear guides and ball screws. While the LongMill’s v-wheels and lead screws offer an affordable, simple, and forgiving linear motion experience, ball screws and linear guides offer another step above in precision and rigidity.

Our ability to integrate linear guides and ball screws comes from a few different areas of expertise we’ve developed over the years and additional research and testing we’ve done in this project.

Linear guides and ball screws are much more expensive than v-wheels and lead screws. However, we have been able to source them at a lower cost because we are able to order them in larger quantities. For context, ordering them at wholesale can cost 1/3 or less than retail prices, and we can pass those savings onto the customer. Second is our ability to understand the differences and context of the cost and in-practice differences between different linear motion components. The AltMill doesn’t use the highest-end, most expensive components because we know that for our users, they won’t experience or notice the benefits of it. By being able to balance cost and performance, we’re able to choose the right components for our application.

We’ve also had the chance to work with different linear motion components in the production of the LongMill Z-axis, as well as through other internal projects. Through this experience, we’ve been able to better understand the process of assembling and working with different linear motion components at scale, see firsthand the results of long term use and lack of maintence through LongMill users, and test linear motion parts from different designs and manufacturers.

We do expect some new challenges with working with linear guides and ball screws, mainly in educating users on proper maintenance of these components. While these components can last a very long time, proper cleaning and lubrication is critical to make sure they perform properly. From our experience, the biggest factor in the longevity of these components is in the proper lubrication. It should be noted that one of the main downsides of using bearing-based linear motion components is that lack of lubrication can dramatically accelerate wear and cause catastrophic damage. To mitigate this, we plan to provide proper instruction and lubrication supplies to make it easy for users to perform proper maintenance for their machines.

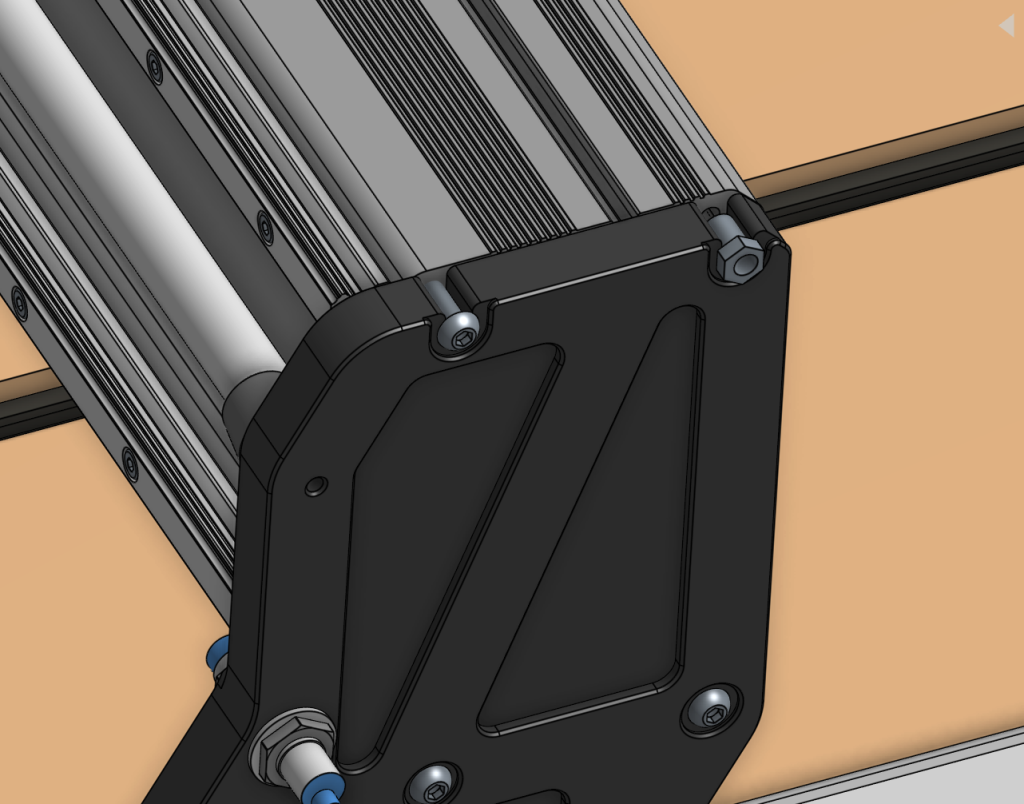

For those who aren’t familiar, tramming is the process of adjusting the position of the router or spindle, typically by tiling it forwards and backwards, and/or left to right. This ensures that the cutting tool stays aligned with the Z-axis. Having a machine out-of-tram can result in things such as ridges or artifacts, especially on surfacing operations with wider bits.

The AltMill, as far as we’ve been able to find, is the first hobby CNC machine to have nod adjustment, allowing for the X-axis rail to tilt slightly forwards and backwards, eliminating the need to shim the spindle mount. Additionally, the AltMill offers tramming on the spindle mount, which allows the user to move the mount left and right slightly as well.

I should note that the eccentric bushings are only used for tramming. In the regular set-up, they have a bolt securing through them, or a shoulder bolt which aligns them to the gantry by default. Also, I should note that currently the tramming for the Z-axis is only built into the default 80mm mount. We do have mounting options for the LongMill 65mm mount, but this does not have tramming.

It should be noted that having the machine assembled in the default position will be within spec enough for virtually all users. Most of the relevant parts are machined to very high tolerances, and there are also many reference mounting points and hardware to help have the machine aligned and straight out of the factory in the assembly process. It is unlikely users will be able to easily make meaningful adjustments without tools like a tramming tool or gauge and a surface plate, and we recommend keeping the machine at its default position.

Why did we add this as a feature? To be completely honest, I hadn’t even thought about it, but one day when I asked Daniel if he’d thought about it, he just shrugged and said he designed the whole thing just for the heck of it.

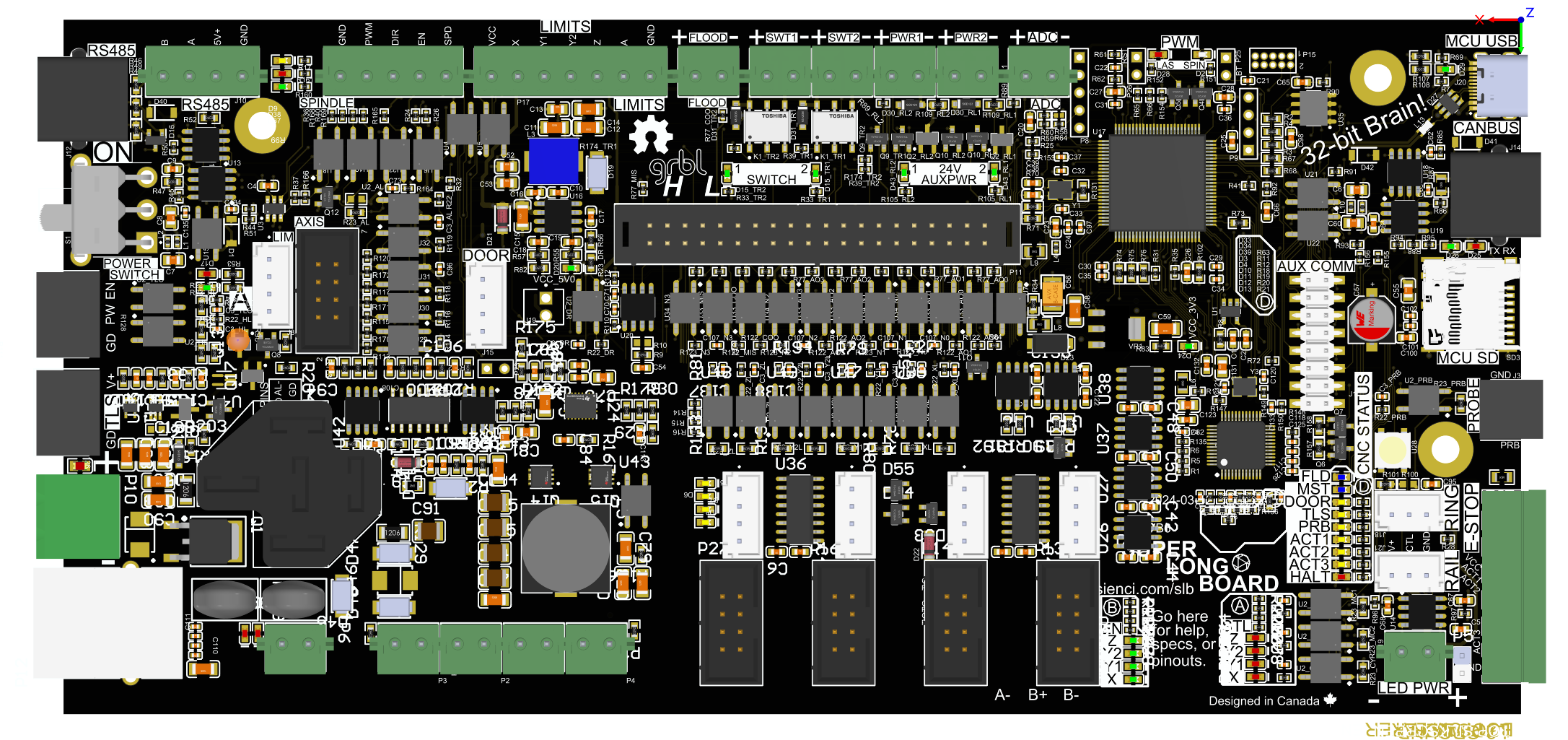

While the SLB initially started off as a project for the LongMill, many of the technologies and improvements will be present in the AltMill as well. We are currently in the development of a new version of the SLB (code named ALT-SLB or SLT-EXT) that will allow the use of external drivers that the AltMill uses for its motion system.

The main focus of the SLB was to improve stability and reliability of the LongMill’s motion control. We believe the development in this area will translate to rock-solid connection between gSender and the controller. Additionally, on-going development to have a dedicated, on-board computer will be able to be used for both the AltMill and LongMill.

There are some other important aspects and features that we believe are very relevant for the AltMill, including*:

*Please note that some of these features are in-progress and are not ready for release yet.

Along with the “brains” of the board, we are also working on an external power-switching system to distribute power to the motors and interface with the e-stop to ensure the power is cut completely in the case of an emergency.

It should be noted that the SLB and the SLB-EXT are not interchangeable. The SLB is primarily focused on being a controller designed to be plug-and-play with the existing motors on the LongMill, and does not support external drivers for the X,Y, and Z axis. The SLB-EXT does not have integrated stepper drivers on board and must use external drivers.

During the pandemic, due to the chip shortage, the original power supply that we were using for the LongMill became extremely expensive due to a specific chip needed for manufacturing. Because of this, we spend a lot of time looking into alternative power supply designs. By switching to a design more commonly used in lighting applications, not only were we able to decrease the cost of the stepper motors, we were able to improve the reliability of the power supply because we were able to internally encapsulate the components to protect it against moisture and vibration. Additionally, we were able to more easily make larger power supplies because of the improved heat dissipation properties of the new power supply.

With this change, we’ve seen a dramatic decrease in power supply-related issues for the LongMill while being able to provide more than 20% more power than the previous design. The AltMill power supply offers nearly double the power of the LongMill power supply at 48V, which allows for additional benefits.

The main benefit of a 48V system is the ability to run the motors faster. Stepper motors lose torque the faster they turn, which means that the faster the machine moves, the more likely it is to lose steps. Increasing the voltage allows stepper motors to “flatten” the torque curve, allowing more torque at higher speeds. With our initial testing with open-loop steppers, we were able to see some small gains in motor speed by about 20%.

When we first started prototyping and testing the AltMill, we quickly found out that one of our bottlenecks was the speed of the open-loop steppers we were using. Over the last few years, the technologies behind motor control has greatly improved, and the cost of these components has come down as well. Additionally, because of our ability to purchase the components at a higher volume, we’re able to also make the machine as a whole more affordable as well.

Closed-loop steppers are motors with an encoder that provide the driver with feedback on the position of the motor. With this information, the driver can correct the position of the motor in real-time, compensating for lost steps and adjusting power consumption based on speed and load.

With the LongMill open loop steppers at 48V, we were able to hit speeds of around 4000-5000mm/min. With the new closed-loop motors, we were able move the machine at around 25,000mm/min before the ball screws start vibrating and jam up the machine. We were also able to push the AltMill all they way to 5000mm/min^2 acceleration rates, 6-7 times higher than the LongMill’s defaults.

There are a number of additional features that make the closed-loop steppers an exciting part of the AltMill because:

Given how powerful the AltMill is, having a spindle is a must. Looking into different spindle options has continued to allow us to look into many different considerations when it comes to picking the right one.

As I talked about in the past in this article, the quality of different spindles varies widely. Because of this, we’ve been hesitant in offering a spindle option since we knew there would need to be a lot of work involved in finding the right manufacturer for it. However, now that we need to get one for the AltMill, we’ve learned a lot about them. Here are some of the considerations about the spindle sourcing including:

We have a pile of VFDs and spindles in the testing phase. We haven’t settled on a specific combination yet, but we are planning on choosing one soon.

At launch, we plan to offer a 1.5KW 110V spindle that can run off a regular North American outlet. We are currently in the process of testing a 4KW spindle option that will require more power.

One of the main reasons why we didn’t end up making a 4×4′ LongMill is because we would need to move away from the “mount the machine to a big piece of MDF” design. Basically, since the machine needs to be larger than it’s working area. If we wanted to go for a 4×4′ working area, the material the LongMill sits on would need to be a bit larger (probably around 6×6′).

I should also add here that the main reason we chose a 4×4′ working area for the AltMill is because most standard sheet goods like plywood and MDF come in 4×8′ sizes, so the AltMill can process half the sheet at a time. I should also note that because of the back end of the machine is open, you can pass materials through the back, so you can put the full sheet on, cut into it, and move it out the other end without cutting it in half.

If we were to have the AltMill come without legs, users would need to have a larger bench, also about 6ft wide and long, to accommodate. If you took two 6ft wide workbenches from your hardware store and put two of them together, you’d probably be paying around $800 for the pair. The extra legs on the otherhand, cost about $150USD and are made from bent and welded sheet metal in a local shop near us.

Additionally, the AltMill carries a lot more inertia when it moves, which means that the structure it sits on needs to be as solid as possible. This is why a lot of industrial machines use cast steel and welded steel frames, since the mass of its structure dampens the movement and reduces vibration. Of course, we’re not getting into that realm, but we knew that if we built our own table legs, we could make sure it was to the specifications and level of stability we would want to see users have by default. Additionally, we wanted to take the chance to build in a few extra features including:

We’ve found that at some really high accelerations and fast movements, the machine can “walk”, and so we’ve been considering sandbagging the machine to see if we can up the speeds even further. It’s probably not practical, but something of consideration.

One of the things I sort of realized is that for most hobbyists and beginner-level users, it’s hard to get context on how much “performance” a CNC machine has. So We figured that the best way to show it was to film videos on the machine doing stuff. So here are some videos below.

Here’s also another non-scientific test.

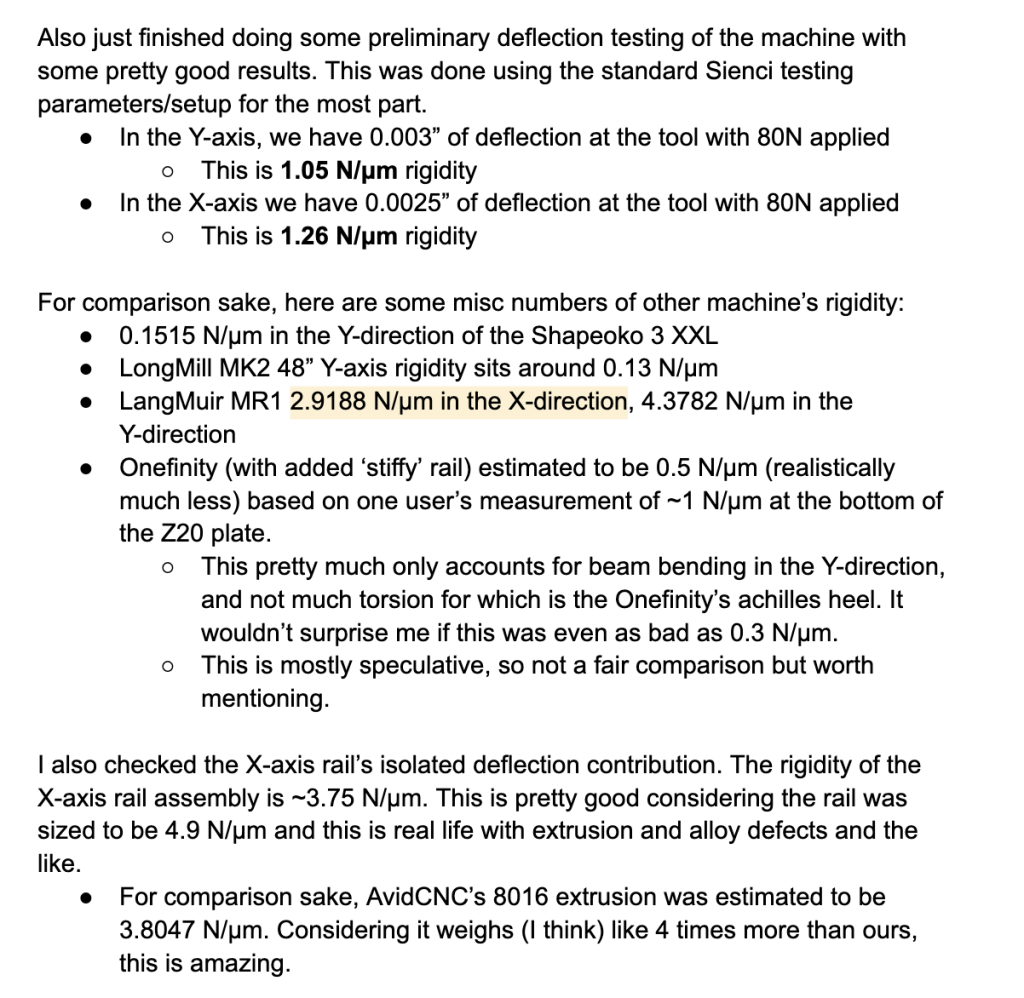

Here are also some of Daniel’s notes about the rigidity, which should provide some context on where the AltMill stands based on his estimates. I should note that these are just rough estimates based on calculations from tests done by other users, so they may be incorrect.

I see a lot of similarities between the launch of the original LongMill and the original AltMill in a number of ways. When the LongMill was first launched, it competed directly against machines such as the Shapeoko 3 and the XCarve. At that time, there were a lot fewer hobby CNC companies, and those were the most popular machines at the time. At this stage, cost was a really important barrier for people to get into the hobby, and we knew we needed to design something robust enough for people to use the machine to make valuable products while being affordable enough to get that ROI back as soon as possible.

First, we made the LongMill design as simple as possible. This allowed us to have fewer parts, which not only reduced the cost overall, but made it easier to pack, assemble, and ship the machines. Second, we tackled the most common complaint and limiting factor that users (including Keith) complained about, which was the use of belts. By using leadscrews on the LongMill, we made this machine an even more compelling option. Even though our company was not very well known at this point, I believe that a combination of our approach to designing a better machine at nearly half the cost of the competition got a lot of new users on board into the hobby.

The idea of a 4×4′ CNC router table isn’t unique. In this market, the AltMill competes directly with machines like the Onefinity Elite Series, Shapeoko 5 Pro, Shapeoko HDM, and XCarve Pro Series as a mid to high-end CNC hobby router. However, by reading and studying the feedback from users of all of these machines, we’re able to focus on addressing these things in the AltMill design itself. I won’t go into them here in this article specifically, but some examples include:

Additionally, although the price difference between the AltMill and it’s direct competitors is not as dramatic as it was for the LongMill, it is still priced extremely competitively and minimum $1000USD less expensive than it’s closest priced counterparts.

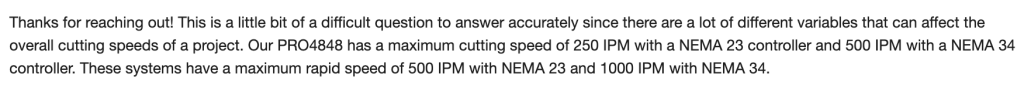

Moving beyond that, we believe that the AltMill may have some customers looking for high-end hobby to semi-industrial machines who are also considering the Avid PRO4848, Phantom SC44 and StepCraft Q.404CNC. These are machines in the $8000-13,000USD price range.

Just to be clear, the AltMill is not a direct competitor or replacement for a semi-industrial or industrial machine. A lot of these higher-end machines may have things like welded steel frames, which is technically better for high-speed cutting. In practice though, there is still a lot of overlap because both machines can do the same projects and run at pretty high speeds.

I sent an email to Avid to ask about the specs for the PRO4848 and this was the response:

In any case, Daniel and I had a long discussion about where the AltMill falls. It feels like the AltMill with its speed, power, and price, blows all of the hobbyist-level machines out of the water. When comparing the AltMill to some of the upper-level machines, the distinction between them also starts to shrink.

Here are some of my final thoughts:

There are a few areas I do feel like we need to work on to make the AltMill even more compelling and competitive which include:

There is a lot of engineering that can be transferred between the lower end of our product line (the LongMill) from the AltMill to make improvements, as well a lot of things we learned from the LongMill in the manufacturing of the AltMill.

Some AltMill development that may trickle into LongMill include:

Some LongMill developments that may trickle into, or have already impacted the AltMill feature set include:

Additionally, as we make more volume of each new product and technology, we can bring the price point and improve accessiblity because we can leverage economies of scale and the fact that the work of each project impacts more people overall.

So a bit of backstory. Sometime last year, we started rediscussing the potential of designing and developing a new machine. From this discussion, we had three contenders, the AltMill, the CO2 laser, and some sort of mill dedicated to milling metals. The decision was made that we should try to make all of them, one way or another. Both the AltMill and the CO2 laser are in development now, which leaves the metal milling machine project still up in the air.

Just for a bit of context, the engineering team had a general idea of making something similar to the Langmuir MR1, or basically an affordable, hobby-level gantry mill.

The plan was to make the AltMill first, and shrink the AltMill down to make our a gantry mill using the same core parts and electronics. Based on Daniel’s testing on material removal rates, it looks pretty promising we can build a competitive machine in this realm.

In my travels in the past year to Brazil and China, one of the gaps that I’ve seen has been in the way CNC machines such as VMCs are used for production. While large industrial machines have their place in making high-precision parts, their running costs are high, even if the parts are small, of lower value, or don’t require small tolerances. The idea is, rather than using expensive big machines all the time, smaller, less expensive machines could be used for milling batches of smaller, lower tolerance parts. Additionally, factories install and use several machines for the space and cost of one large machine to scale up their throughput.

The team and I have a lot of interest in exploring this avenue next, I expect the things we learn from AltMill design and production will help us tackle this new vertical.

That’s not to say we have some other things on the docket of considerations, such as:

We’ll probably worry more about this after the launch and first production of the AltMill. But if you want to share your thoughts about what you want to see come from us in the future, make sure to share it through our form.

Here are a list of questions people have been asking us. Please note that there are more FAQs on the main AltMill landing page.

Will the Spindle Kit be available for sale on its own?

A lot of people, especially LongMill owners, have been asking about if the spindle kit for the AltMill will be available as a separate option. The short answer is, yes, because we won’t stop people from buying stuff from us if they really want to. However there are a few things to consider.

First is that the 80mm spindle is pretty big and heavy. There is some testing and validation we’d want to do before making it an “official” LongMill spindle option because of this.

Second is that we’re also working on a “Sienci Router”, which we plan to launch in the next couple months, which will be a drop in replacement for the Makita router, with speed control, and a brushless motor that allows for around 800 to 1000 watts of usable power, or around double the power output of the standard Makita router, which will be cheaper, lighter, and more suitable for the LongMill.

I do recognize that at around $500USD, this spindle kit still offers a lot of value, and is priced competitively compared to other, plug-and-play kits. I think there will be a number of people outside of the LongMill and AltMill ecosystem that we can serve with this kit as well, so we will explore that option in the future.

Why offer a 1.5KW spindle when the AltMill can handle a 2.2KW or larger spindle?

Based on our testing between a number of 1.5KW and 2.2KW spindles, we felt like the power difference between these two options were not large enough to justify the extra complexity of having the extra 220VAC wiring. We are continuing to do both real-life testing and establishing a bench test to measure the true output of the spindle.

Based on our estimates, to get the full potential from the AltMill, a 3-5KW spindle would be best suited for the machine. However, most households would need to invest in having an electrician set up the appropriate power outlets installed to allow this use.

This comes to another question, which is “how powerful do we really need to make the AltMill”? The other bottleneck that we need to address is the strength of the end mills. Based on our real-life testing, another reoccurring issue is that if we run the job too fast, the end mills break. For us to cut even faster, we’d need to use larger-diameter end mills. In some cases, this may be useful, such as in projects like surfacing and boring lots of material, but this is a small subset, and may not make sense to offer a spindle designed to do that all-day, every-day, if the alternative is to slow down the machine during these types of jobs.

Will you be making a larger/smaller AltMill?

Very likely yes, since the AltMill offers a platform that can be made larger or smaller by changing the size of the rails and linear motion parts, as well as mixing and matching some of the components. Making a smaller machine is probably the easiest, since it doesn’t have the same problems as making a larger machine, as we will discuss next, and we have some ideas for making a machine more dedicated to milling smaller projects or metals, similar to the Langmuir MR1.

There are two main challenges to making a larger machine, which in this case is probably going to be a machine that is for cutting 4×8′ sheets. The first is in the power transmission system for the Y axis. The longer the ball screws get, the more prone to “whipping” there is, especially at higher speeds. To avoid whipping, we would need to consider other options such as a rack and pinion system, which isn’t something we have a design for. The second challenge is in shipping. The AltMill comes in three large boxes which can be shipped with a courier like UPS. A 4×8′ machine would need to have parts that are around 10′ long to make up the Y-axis, which would be heavier and harder to transport. This adds extra complexity in shipping and packing these parts safely.

That being said, we definitely see a strong interest for a 4×8′ machine. If you’re interested in one, please share your feedback in our Product or Feature Request Form.

Will there be a toolchanger available for the AltMill?

We do have a lot of people asking about this feature. With the SLB’s input and output suite and stronger Z-axis capabilities, the AltMill will be able to support a toolchanger in the future.

As in typical Sienci Labs fashion, we want to do a lot of testing and see if we can build something high-quality, reliable, and affordable, or work with another company to add this feature.

At this time, users will need to invest in retrofitting their own aftermarket toolchanger to the AltMill.

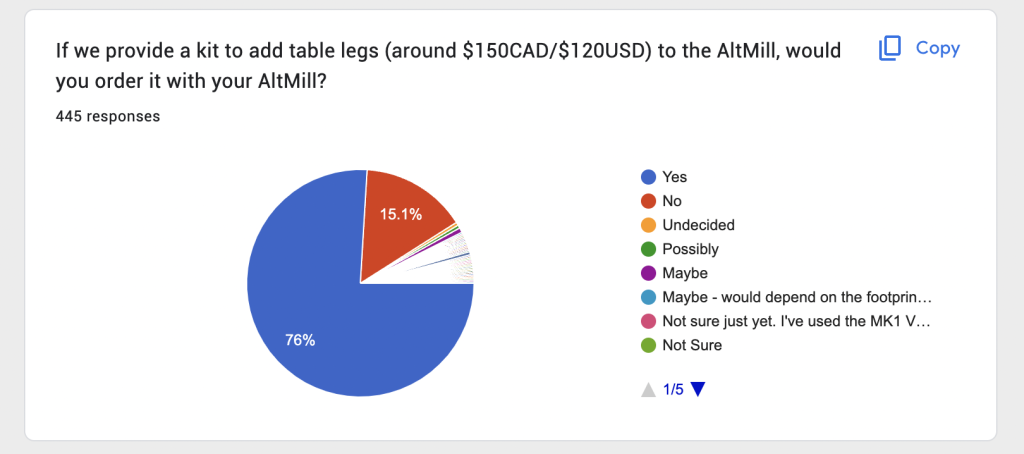

Can I buy the AltMill without the table legs?

Initially we were planning to have this a separate option, we’ve made the final decision to have the table legs a default part of the AltMill kit. There are two reasons for this.

First is that based on survey data from over 400 respondents, the majority said yes to wanting to order them. To save money overall, we decided that it would be most effective to design the packaging with the legs included.

This in theory leaves a small but not insignificant group of people who don’t want the table legs (24%), which is still a lot of people.

Back when we didn’t have a default router mount size (65mm) for the LongMill, a lot of people ordered the 80mm mount thinking that they were going to toss on a spindle instead. What happened in reality was that most of these people decided to not go down that route and just get the Makita router we’ve been recommending. Because these customers would need to order the 65mm after getting their machine with the 80mm mount, we found that it was just more cost-effective as a whole to make the 65mm the only option, and have the other mount sizes at an additional cost, especially if you took into account the extra customer service, shipping, packaging complexity, returns processing, and time wasted.

I feel like the table legs may follow a similar story because designing and making an AltMill bench will probably cost a lot more time and money than slapping on the ones we’ve made. I believe if we make the legs optional, there will be a lot of people who don’t order the legs at the beginning, realize this fact, and then have to spend the extra shipping cost to get a set of legs sent to them.

For someone who truly doesn’t need the legs, yes they may go to waste. However, in the grand scheme of things, making the legs defacto makes the overall cost to the customer lower.

Hey everyone, we’re excited to share our launch date for the AltMill.

The AltMill will launch on Wednesday, March 27, 2024 at noon, EST. You can access the order page at https://sienci.com/product/altmill/ when the page goes live.

Our livestream will be happening on the same day at 1PM EST. Please join us at https://www.youtube.com/watch?v=QufxkgPRxCU

If you’d like to learn about the AltMill itself and the engineering behind it, please read our Everything You Need to Know about the AltMill article.

For more information about the AltMill project, please see https://sienci.com/altmill/. If you have any questions about the AltMill, please see the FAQ.

The AltMill will come at a base price of $2950USD/$3990CAD, which includes the table legs.

Users can also purchase the Spindle and Dust Shoe Kit for an additional $515USD/$690CAD.

As noted in past updates, we’ve jumpstarted the process by starting production on the first 50 AltMills in December 2023. This allowed us to tackle some of the major unknowns/questions, such as:

As of the time of writing, the plan is to offer the first 50 machines directly to select users and for internal use before our “main batch”. The first batch of AltMills represents our trial-run for production and comes with a couple of you-should-knows, especially if you’re planning to be one of the users in this batch.

We also plan to collect comments and feedback from our first batch of AltMill users to improve the user experience and tackle any initial quirks and issues in the first part of the product launch.

Some parts are still in shipping and manufacturing, and we expect the first 50 machines to start shipping in May 2024.

This is what we expect most users will be part of. We will begin taking pre-orders at the end of March. Please check www.sienci.com/altmill for more information and a link to the order page.

The goal for our first main batch is to build enough units to leverage economies of scale to make our relatively low price for the AltMill viable. This not only involves the unit cost of the machine, but the work and labour needed to build each batch of machines, which might include work done to set up tooling, packing stations, and the ordering of parts.

Please note that to place your order for the AltMill, the total amount must be paid to hold your place in our queue.* You may cancel your order at any time before your order ships for a full refund. Once your order is in the possession by the courier or arrives at your door, our standard store policies apply.

The number of machines we’ll make in the first batch is still undetermined and will be based on the number of orders we get at the beginning of the launch.

We expect the “main” batch to start shipping in July 2024. However, we will ship orders based on when they were placed, which means that if your machine is in the later part of the batch, you will receive your order accordingly after July 2024.

If you feel that pre-ordering the AltMill now isn’t right for you, you will eventually be able to order and have an AltMill ship to you in a shorter amount of time, just like the LongMill. However, when this will happen is dependent on when our production capacity can meet the demand for the product, which is unknown at this point.

The goals for the future production of the AltMill is as follows:

The size of future batches will be adjusted based on demand once our main batch has completed.

We will continue to share and provide updates in our Production Updates which are released at the start of each month at www.sienci.com/blog

Additionally, we will write order updates as we currently do with our other products at www.sienci.com/order-status

For the most reliable way to get news and updates, please sign up for our email mailing list.

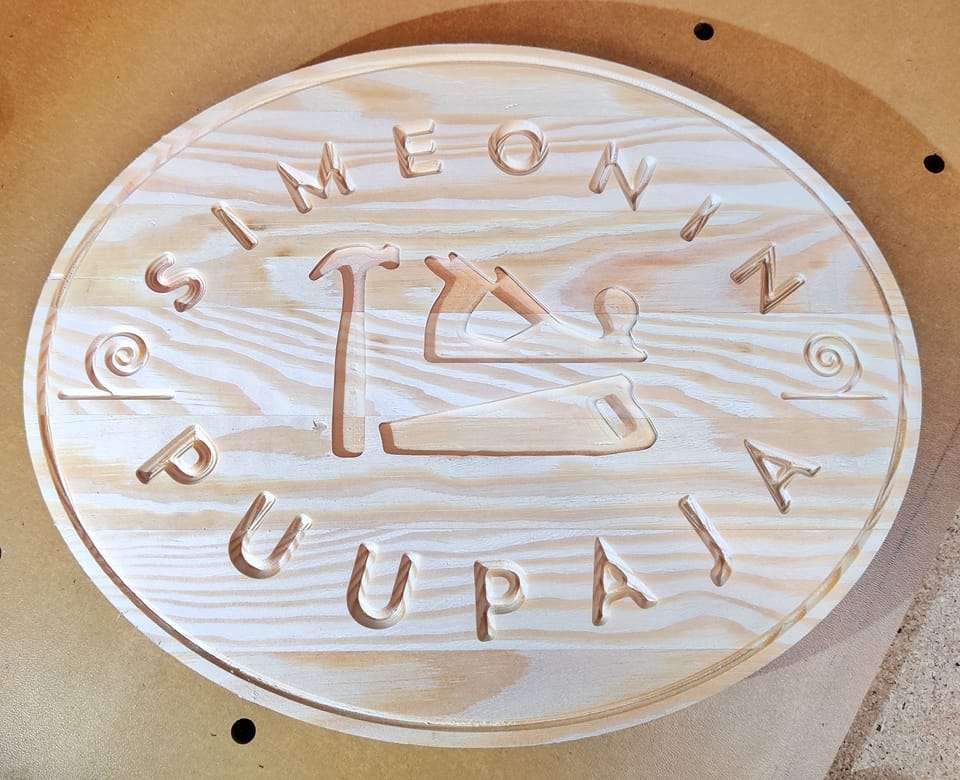

Good afternoon, everyone! Thanks for sharing the fantastic signs you’ve crafted using the LongMill.

We are happy to announce that Norm Emery, Christine Tanasiuk, Bruce MacDonald, Scot Lovdahl, James Stevens, and Tyler Dacosta are the charcuterie board projects contest winners. A prize is on its way!

This week’s theme is “flag projects”. Share your favorite LongMill-made flag projects for a chance to win prizes in our contest!

Have ideas for themes? Let us know by commenting below!

Happy making!

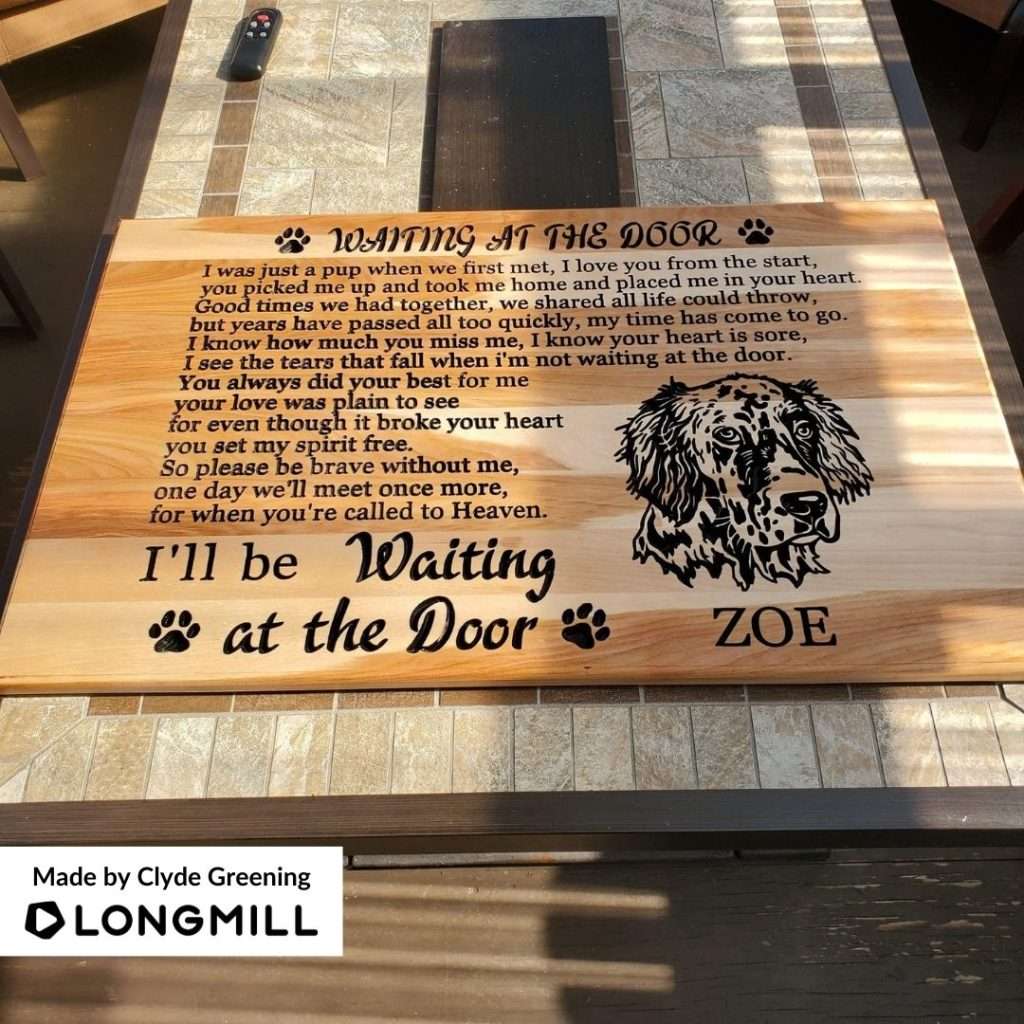

Happy Friday! Thanks for sharing the fantastic signs you’ve created using the LongMill.

We are happy to announce that Patti McKinlay, Ryan Webster, Glen Dwelder, Clyde Greening, Joel Lauterbach, and Roland Portman are the sign projects contest winners. Watch out for a prize!

This week, showcase your top LongMill-made charcuterie board projects for a chance to win free prizes in our themed contest!

Have ideas for themes? Let us know by commenting below!

Happy building!

Hey guys, it’s Andy again with March 2024 production updates. I am currently writing this in China, where I am taking a bit of a “work-acation” but also to visit some suppliers and manufacturers that we work with.

This also means we’ll film the typical production update video a bit later, probably on the week of March 11th when I get back.

March is expected to be a busy month, especially as we continue to make progress in our projects like the CO2 laser and Sienci Router, as well as prepare for shipping and launch of the SLB and AltMill.

Last month we paused shipping for LongMills as we waited for more controllers to arrive. We expect around 100 controllers to arrive in the next week or so (shipped on Monday). Once these parts arrive we will continue to ship machines and clear the backlog. More controllers are expected to finish the first week of March.

Additional production is underway for the LongMill, with motors, power supplies, and fasteners in production now.

LaserBeam and Vortex are shipping as usual. Ikenna and Abeku have developed a riser mount for the LaserBeam which allows for easier use in combining LaserBeam and Vortex to do engravings with the Vortex.

They are also working on some different magnetic mounting designs for the LaserBeam to make removing and attaching the LaserBeam faster and easier, and should have more stuff to share in the coming weeks.

This month we have finally put the machine together and started running it through the paces. Check out Daniel’s video on some more updates. I would have been there for the video, but I am currently away.

For more info and FAQ, please check the AltMill landing page.

Testing is showing some promising results. Here’s an excerpt from Daniel’s notes about the rigidity of the machine.

Also just finished doing some preliminary deflection testing of the machine with some pretty good results. This was done using the standard Sienci testing parameters/setup for the most part.

For comparison sake, here are some misc numbers of other machine’s rigidity:

I also checked the X-axis rail’s isolated deflection contribution. The rigidity of the X-axis rail assembly is ~3.75 N/μm. This is pretty good considering the rail was sized to be 4.9 N/μm and this is real life with extrusion and alloy defects and the like.

In other news, we are continuing to put together the online ordering infrastructure to prepare the AltMill for launch at the end of March.

At the start of the month, we received the sample motor we’ve been waiting on to do another round of development and testing. If you’re not up to date on the development here, make sure to check out the last post.

The new motor is much more powerful, and showing promising results. However, we are waiting on some improved motor tuning to happen as we have found some issues with the speed control to achieve a full 1KW of mechanical output. We are waiting on an updated control board expected to arrive in the next week or so.

Additional to this is that we’ve started exploring more spindle options for applications needing higher power past the 1KW the Sienci spindle can put out. If you saw Daniel’s update on the AltMill, the new machine is so powerful, that even the 2.2KW spindle ends up being the bottleneck in our ability to remove more material.

Eventually, we hope to provide several options, the standard Makita as a simple, powerful, and inexpensive option for routing, the Sienci Router as a step above with more features and power to run the LongMill at its full potential, and spindle options to maximize the AltMill’s performance.

I’m excited to say that the first set of the injection molded nuts has arrived. To learn more about this project, please see the long post about them here (put link here). While the T8s overall look good and function properly, unfortunately, we are still experiencing some warping and inconsistent threading on the T12 nuts. Since not all the nuts are affected, we’ve put on the store all of the nuts that are currently ok. We will work with our manufacturers to iron out the issues with the T12 nuts.

Demand for the new nuts has been super high, with all of the T8s already sold out, and with T12s expected to be close to selling out by the time this post goes out. Not to worry, however, we are working on making another batch of a few hundred sets and make sure we don’t run out.

It should be noted that existing LongMill kits will continue to ship out with the original style of nut. Once we catch up on orders sold for replacement, we will start moving to making them a default option for new machines. We currently don’t have a specific timeline for it, but likely in about 2 to 3 months, since production and assembly of the nuts can take a long time.

We’re excited to share that the new SLBs have started production and should be ready to ship in the next few weeks. We are also waiting on parts for the controller and estops to arrive in the next few weeks.

Work currently being done with SLB primarily revolve around checking for reliability and making bug fixes. We’ve also sent the SLB for testing to key grblHAL community members for feedback.

gSender has now been updated to natively support SLB and it’s features. You may have seen a toggle when connecting your machine to allow for GRBL and grblHAL available.

Additionally work on building controllers for the AltMill to provide external driver support, higher voltage, while sharing the same features is also underway, with first versions of the design expected to be ready in the coming weeks. However for the full development cycle, we expect it to take till end of April to have production-ready designs and firmware ready.

In addition to this, we have continued to work on the computer side of the SLB at a bit of a slow pace. However, we have put together this proof of concept where we have attached a VESA mount arm to the threaded holes at the front of the machine to allow for use with a touchscreen, as well as a mount for the computer. This design was created by one of our engineering students working at the company this term.

Hi everyone! Thank you for showcasing your incredible guitar/guitar-related projects made on the LongMill.

We are happy to announce that Ritchie Bedard, Ed Lagace, Mark Hunt, Kenneth Key, Darcy Boyer, and Jim Hambone are the guitar/guitar-related projects contest winners. A prize is on its way!

This week’s theme: “Sign Projects.” Share your most creative LongMill-made sign projects for a chance to win free prizes in our contest!

Have ideas for themes? Let us know by commenting below!

Happy creating!

Greetings all, Chris here again to emerge from my SuperLongBoard development cave and provide you with my news!

For anyone who still has yet to hear about our new and most ambitious Sienci Labs electronics projects to-date, our arguably aptly named SUPERLongBoard, is the graduated version of our current LongBoard and has been designed to be even more SUPER at all things hobby CNC.

This is a serious upgrade for a serious board, even if we had some fun with the name: culminating in what we hope to be an all-in-one solution and in many cases an upgrade to anything currently in its pricepoint on the market. The result is a 32-bit processing, on-board motor driving, Auxiliary output supporting, 4th axis controlling, laser, TLS, macro button -having board.

With that summary out of the way, you can catch up on past progress by looking at my update last month which also has links to past videos and past updates before it: https://sienci.com/2024/01/25/slb-january-updates/

Now let’s roll along to what new stuff I have to update you on this month 🙂

We’ve now pre-sold nearly 450 boards now…. and wow I’m so excited to see that everyone else is just as excited about this board as I am. To put into context: the current batch of boards we’ll be manufacturing was intended to be 500 but had to be reduced to 470 (I’ll mention the reason shortly) which means that we’ve nearly already sold out the whole batch before starting shipping! Needless to say, Andy and I already began discussions about a month ago on what our next steps are going to be if the reception to the SLB ends up being as good as we hope it will be to ensure we can have more on-hand in the coming months if possible.

Now the reason why we had to reduce to 470 is basically a math error, but in short:

Speaking of ordering parts, let’s take a look at what our full part table looks like right now as we start preparing to intake SLB parts and set up packing stations to check and ship them out:

| Subsection | Name | Amount | Shipping Status |

|---|---|---|---|

| Board Parts | SLB important PCB components | 1 | Pre-ordered and now being used for SLB board production |

| SLB PCB assembly | 1 | Underway, scheduled to arrive by air on March 18th | |

| USB-C Cable | 1 | To be ordered shortly after some more testing/validation | |

| E-stop | E-stop Button | 1 | Ordered, currently on boat and scheduled to arrive March 5th |

| E-stop PCB | 1 | Underway, scheduled to arrive by air mid-March | |

| E-stop Cable | 1 | Completed, will be shipped alongside E-stop PCBs | |

| Injection Moulded Case | 1 | Completed, currently on boat and scheduled to arrive March 15th | |

| #4 screws | 3 | In stock | |

| Enclosure Parts | Aluminum Extrusion exterior | 1 | Completed, currently on boat and scheduled to arrive March 15th |

| Front Panel | 1 | ||

| Rear Panel | 1 | ||

| Acrylic Cover | 1 | Arrived, to begin in-house production mid-March | |

| Steel Mounting Bracket | 1 | Underway, should be made and plated in a couple weeks by our local steel manufacturer | |

| M5-10mm SEMS | 3 | In stock | |

| M5 T-nut | 3 | In stock | |

| M4 Thumbscrew | 1 | Arrived | |

| #4 screw | 6 | In stock | |

| Packaging | Cardboard Box and inserts | 1 | Still being designed, should have a 1 week turnaround time by our local manufacturer |

We’ve tried to time things out using a combination of boat and air freight for international parts and the shorter timelines of our local producers. Hopefully the information isn’t too much to look at, but the long and short of it is that everything looks like it’ll all show up around the same time!

In the meantime, we’ve begun working on making space for packing and testing stations, working on designing our quality assurance procedures to test boards before they go out the door, all the while internal testing and Beta testing still continues forward as small tweaks to gSender support and to the Firmware are still being made to get everything working how we like it.

Please still bear in mind though, due to there being things that could still be outside our control, I would still conservatively estimate that SLBs begin shipping out the door last week of March or the first or second week of April. This would cover instances where delivery by boat or air has a slowdown, or we find something with the final batch of boards that need our attention. For example:

Yes of course! To be honest, after the inrush of pre-orders after the SuperLongBoard launch I’ve had more of a sense of duty to test-test-test the board as much as I possibly can as a higher priority than filming the boards capabilities. This is because, though I know there’s lots that the board can do, clearly everyone who’s already pre-ordered is already on ‘board’ with the SLB so I don’t think it would be fair for me to spend my time building more excitement for the board when I can instead focus my time on making it more bulletproof 🙂

And I think the nose-to-the-grindstone work has been paying off! There’s been tons of bug squashing and pushing machines to their limits by us and our trusty team of Beta testers:

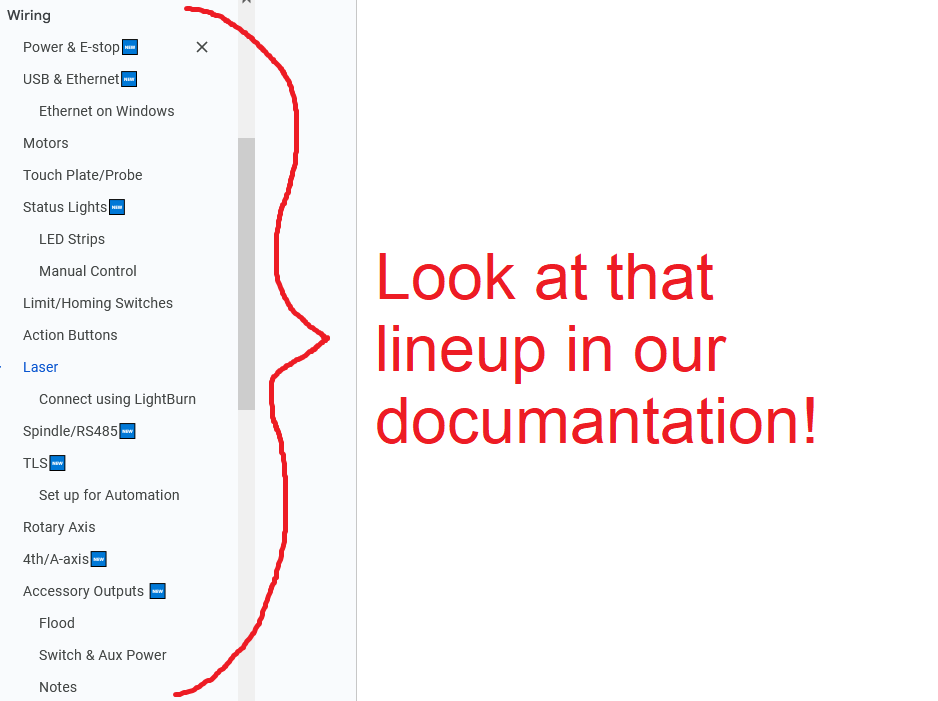

When it comes to roadblocks we’ve hit, the last month has actually been very good. Beta tester feedback has been a split of 40% gSender compatibility problems, 30% improvements to board documentation, then about 15% tweaks to firmware and the last 15% changes we had to make to the board design before we began production. This is good news because software and firmware are things that we can -and have- continued to work on while things are being manufactured and shipped over. This means that the gSender and Firmware teams still have most of March to finish polishing things up which seems very doable. The last remaining hurdles are to get things like 4th axis cutting and switching between spindle and laser working as smoothly as we can in gSender, and then completing the remaining documentation tweaks based on Beta testers continued feedback, then writing up a guide on how to do a full board swap for existing MK1 and MK2 owners. I’ll also be setting aside some time mid-March to establish final movement speeds and motor noise that can be expected.

With all that said, videos will definitely still be making more of an appearance as we begin to near the delivery date since I want you guys to see what you’re going to be getting before shipment begins 👍 Alongside this will of course be: continued updates to FAQs, starting to release parts of the SLB manual, starting to release a list of recommended hardware to use alongside your SLB for 4th axis, lights, and more. I might even do some Livestreams so you guys can see more of the board in action and have any of your other questions answered! Some of my current video/livestream ideas are:

If you’ve made it this far, here’s your award 🏅. This is to recognize that you once again lasted through another one of my treacherous, Engineering-writing posts, complete with its poor sentence structure and also a lack of pictures on this post especially.

In all seriousness, thanks for everyone’s continued support for this project and the other projects we’ve continuously strived to do with Sienci Labs over the years. It’s never been easy for us but the kind words and reassurance that the work we’re doing matters really helps to keep us going. Thanks for anyone who’s been helping give me and the gSender team the needed feedback to keep making more cool features and fix iterations that sometimes break things and thanks for posting all the cool stuff you do and helping each other out too.

If you have any other ideas for SLB content you’d like to see, please leave them in the comments of wherever you were when you saw the link to this post whether it was on Facebook, our User Forum, or elsewhere and I’ll try to find them and write them down.

Until next time!

-Chris

The LaserBeam Vortex Riser mount is now available for purchase! It is a new add-on made for pairing with the Vortex. The Riser mount increases the z-axis height of your laser, providing significantly more room for LaserBeam focusing. Additionally, the product allows for more variation in LaserBeam mounting positions and is compatible with all versions of the Longmill router mounts. Made of premium zinc-coated steel, this rigid and durable mount is the perfect addition to take your rotary laser engraving to the next level.

This mount raises the Z height of your LaserBeam so you have more room to focus the lens. Each LaserBeam Vortex Mount order includes: 1 Zinc coated steel mount 5 M3-10 screws This product uses both the Laserbeam and Vortex systems. For more information on this product, you can view our resources here https://resources.sienci.com/view/lb-manual-vortex-riser-mount/ and…

22 in stock

We’ve prepared a detailed resource page and a video on assembling and attaching the Vortex Riser Mount to your LongMill. Also, feel free to check out the additional update to the LaserBeam resources that details how to use offsets in g-sender with the Vortex Riser Mount and a variety of different Sienci mounts.

If you’re interested in learning more about the LaserBeam and Vortex Riser mount, visit our product page below.