Hey everyone, here’s our October 2024 Production Updates.

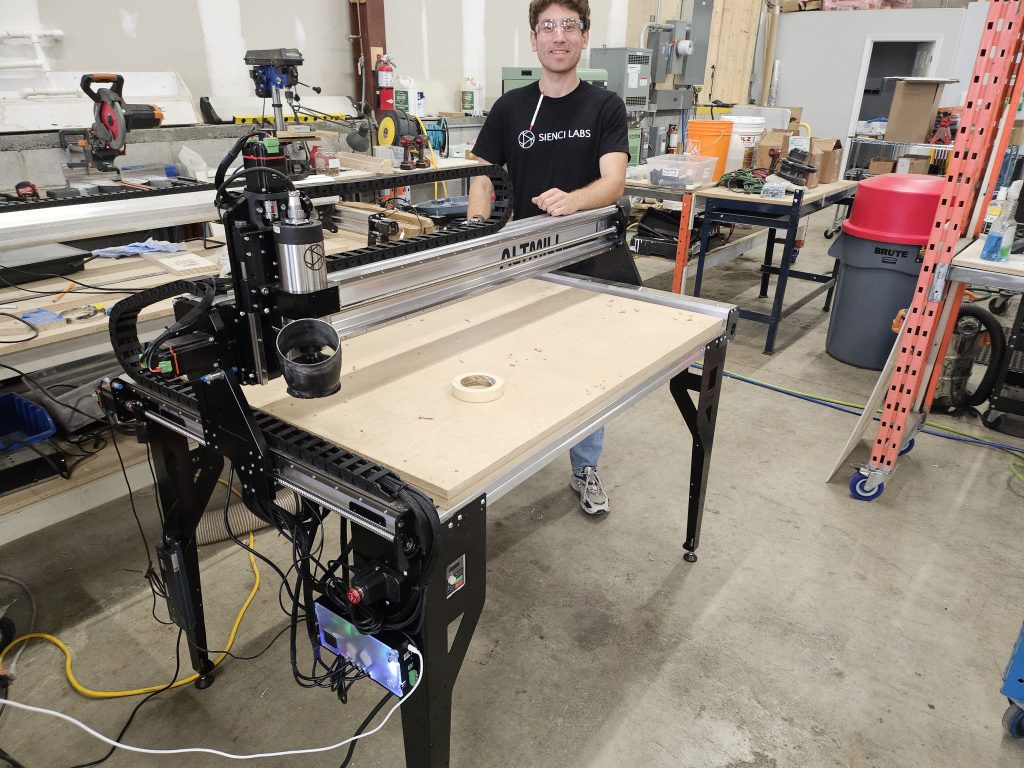

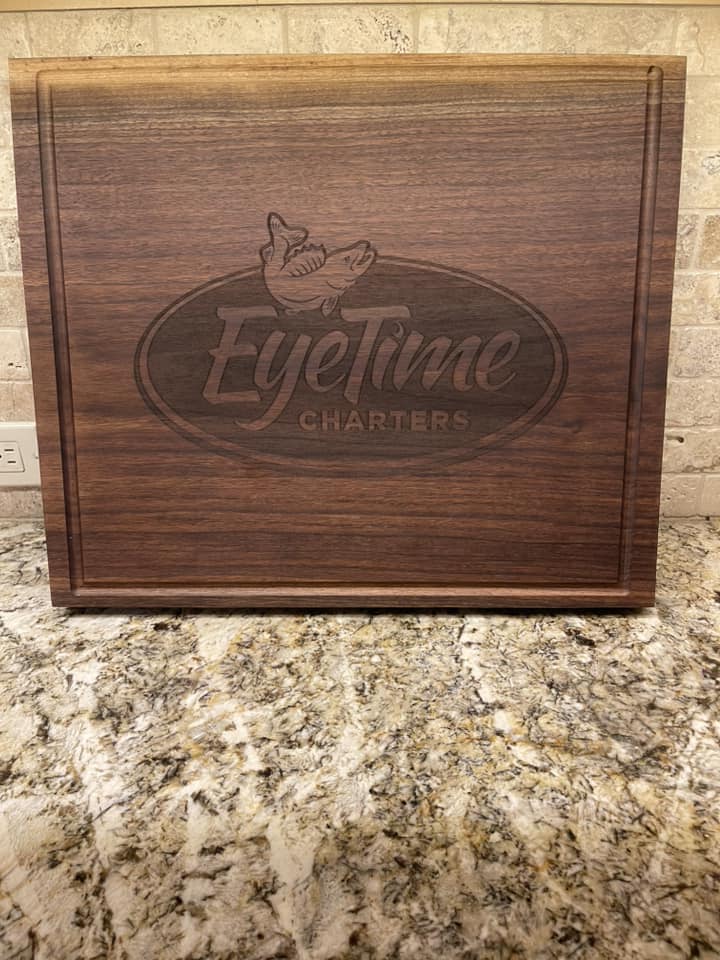

AltMill

We’re excited to have another batch of parts arrived in September.

We’re sort of hitting an interesting new wall in manufacturing, where the number of parts that we need to make with each manufacturer is more than they can handle in a reasonable time, so we’re working on diversifying our group of manufacturers so that we can move faster in scaling up production.

Shipping was put on a hold as we wait on restocking for spindles. They were expected to arrive Sept 20, 2024, but due to shipping delays at the port due to a recent rail strike, they are expected to arrive Sept 30th. We’ve asked for a rush on these items. Other parts for orders are being assembled now and we will work to ship as much out as we can as soon as the spindles arrive.

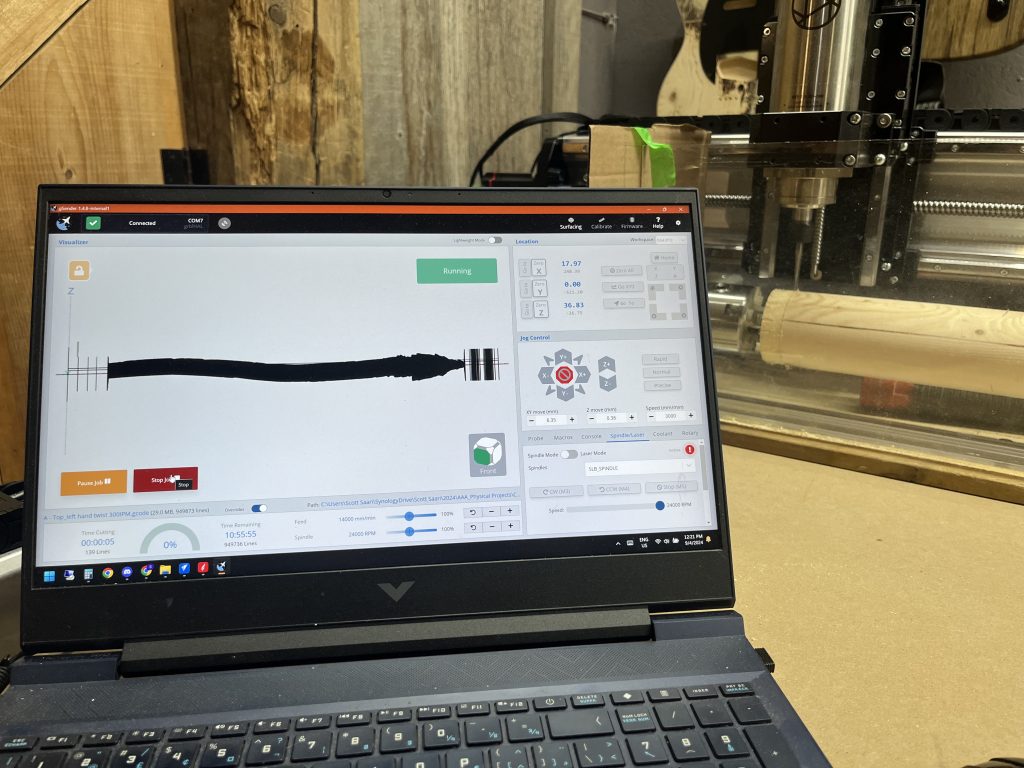

Assembly videos for AltMill are coming very soon to Youtube, as they are going through final edits now live on our Channel! These will supplement the written assembly instructions found on our Resources soon.

We now also have AltMill documents open-sourced! hey so I have the public version of the AltMill doc ready for release: https://resources.sienci.com/view/open-source/

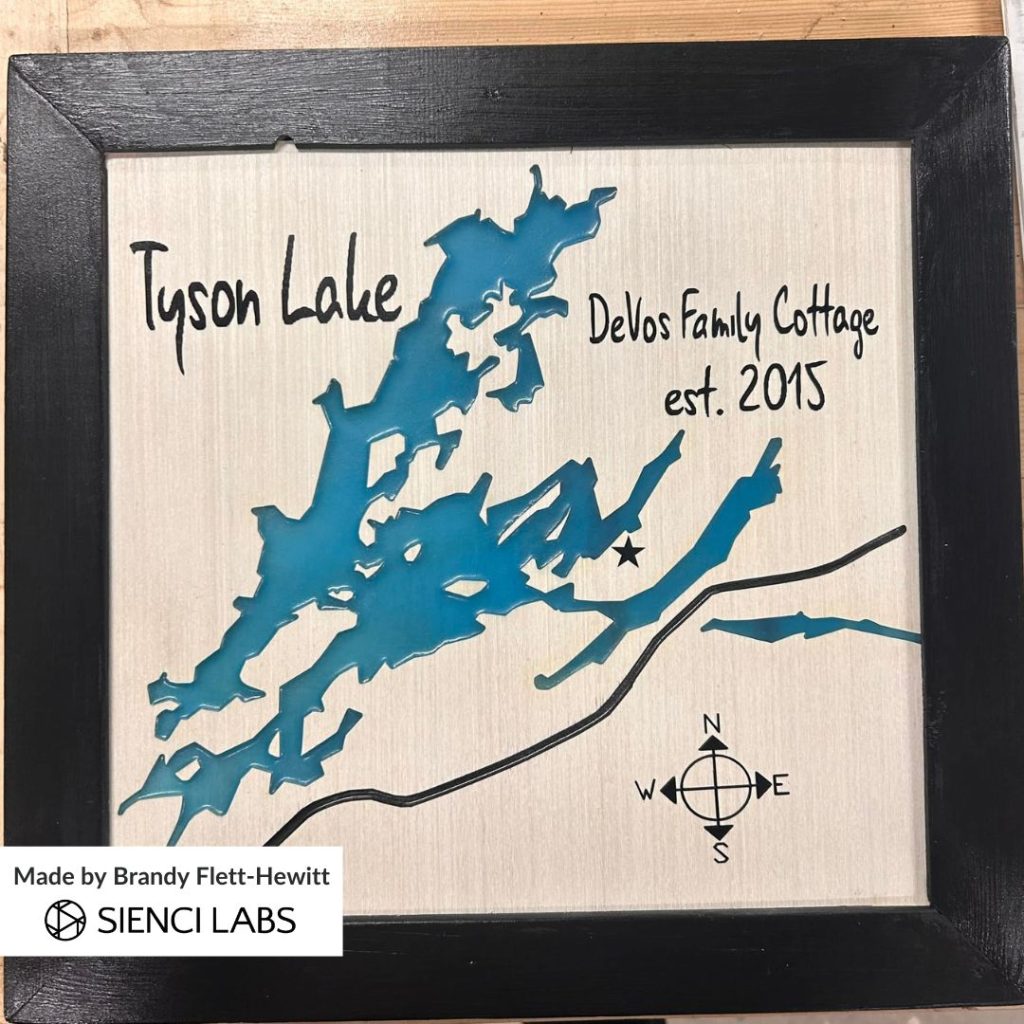

LongMill

LongMill orders continue to ship out without incident.

We’re happy to share that the LongMill Spindle and Dust Shoe Kits are shipping and resources for installation are now available!

Due to the shipping delay as mentioned above for the spindles, we are expecting spindles to arrive Sept 30th and will start shipping kits soon after they arrive.

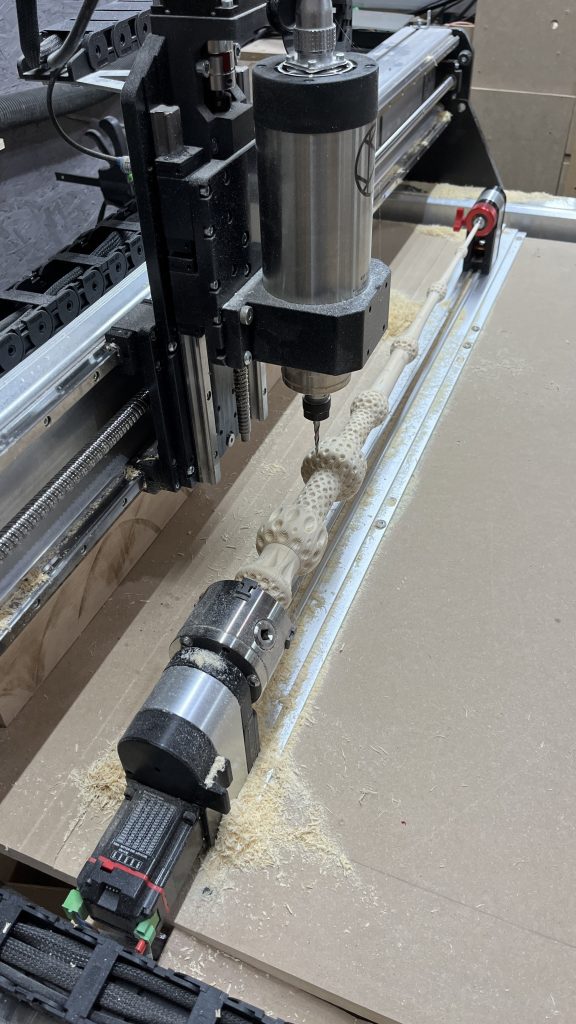

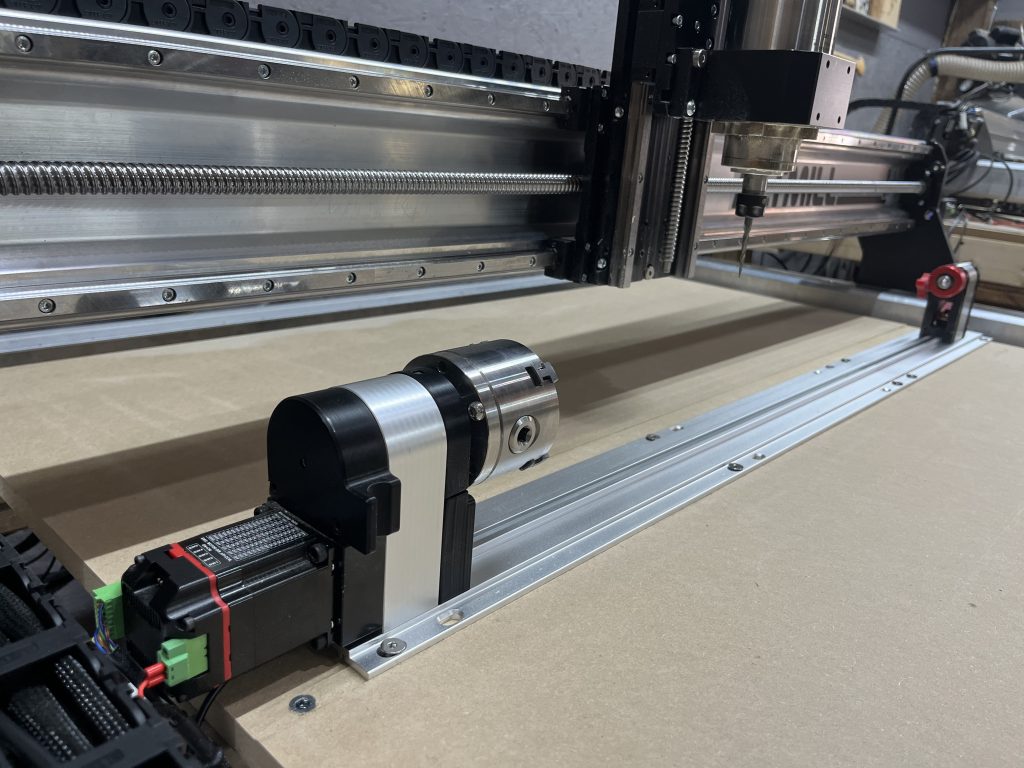

Vortex

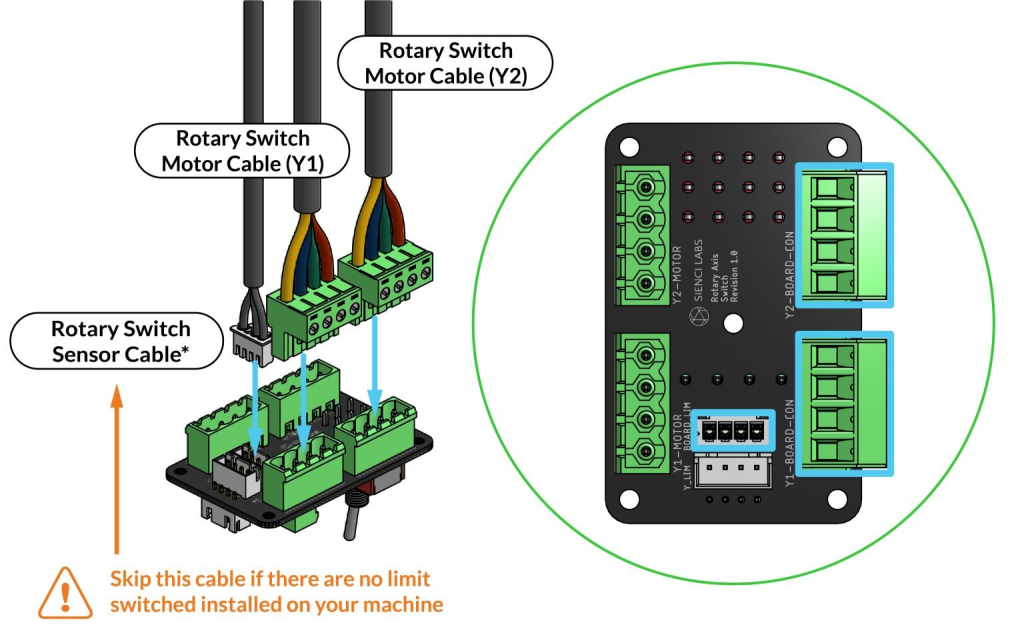

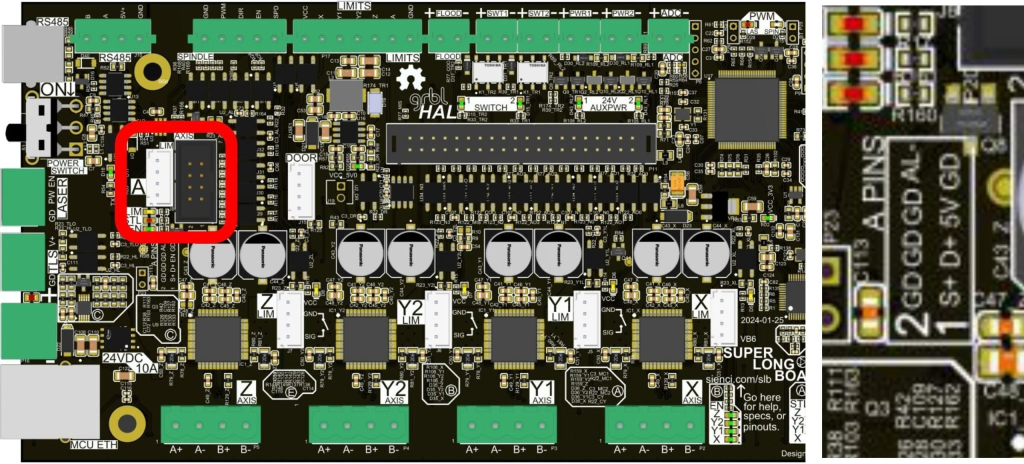

The big news for the past month is that closed-loop stepper support and full 4th-axis support is coming out now for Vortex. Learn more about it in our article here: https://sienci.com/2024/09/05/vortex-rotary-axis-close-loop-stepper-motor-update/.

Motors and cables for closed-loop steppers for Vortex have already arrived. We are currently working on testing, packing, and a few other details before they start shipping.

LaserBeam

Focus rings and sets are back in stock! New LaserBeam Safety glasses have been ordered and will arrive well before we run out of stock.

We are continuing to work on updating and adding new resources to the website for the LaserBeam.

We have started building a new, enclosed laser testing area to improve safety measures and also the level of technical support we can provide to you, our customers.

Keep an eye out for the new Magnetic LaserBeam mount, coming soon!

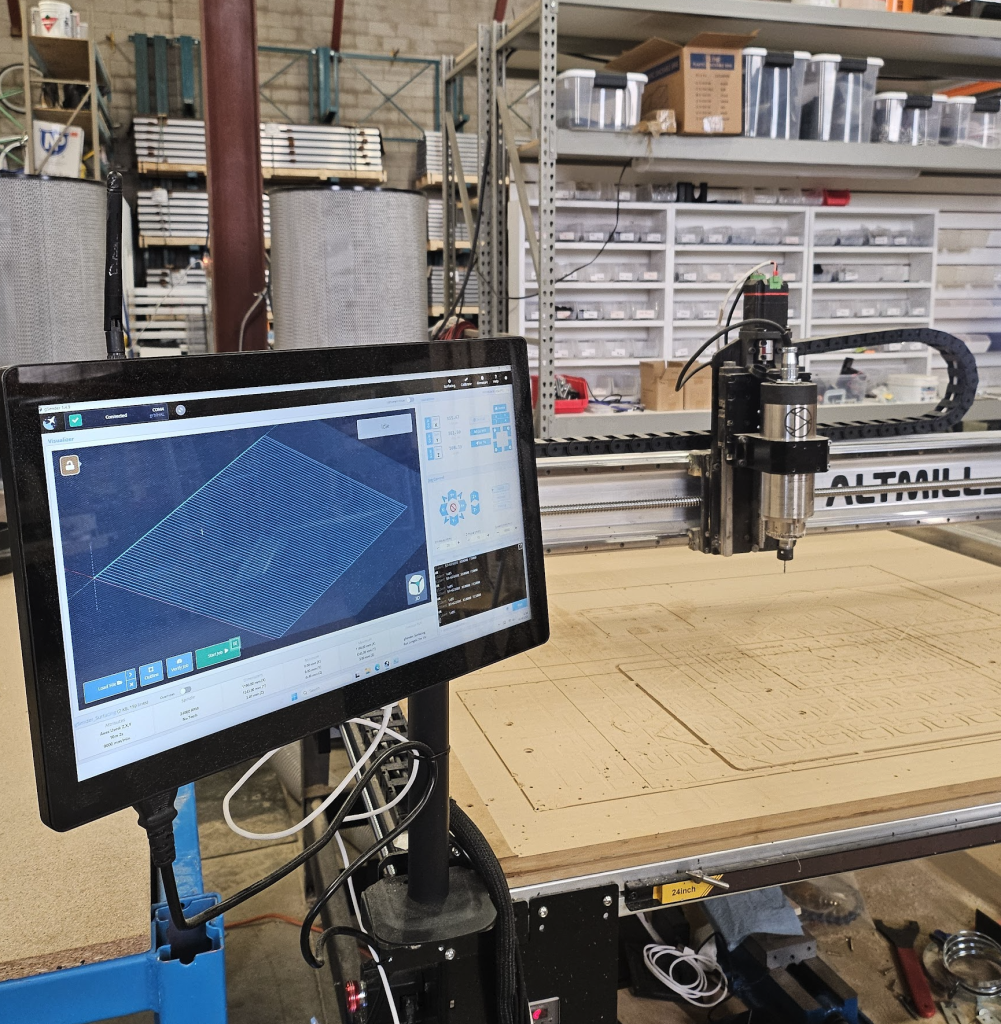

gControl Panel Computer

50-panel computers are now on the way! We are currently working on a few things to get these ready for ordering, such as the branding, the computer configurations, and other little things. Look out for a blog post coming out that’ll cover all of the details.

We now have 50 Microsoft licenses ordered and waiting on them to arrive. We are also working on doing the final configuration on the OS side. Brackets for mounting are also in manufacturing now and expected to arrive anytime.

Once we sell and ship the first 50, we’re going to be planning out how many we’re going to order for the second batch.

If you’re interested in this product and want to fill out a survey, please visit the survey here: https://forms.gle/E1vaWAaGsfuQB8yg9

Sprouter

So it turns out that someone else is using the name Sprouter for another project. So we’ll probably have to lay off on using that name going forward. If you have any suggestions for names, feel free to let us know!

Also, if you have a non-Sienci Labs machine, such as with a Masso or Shapeoko controller, we’d like to test if the PWM control integration works properly with your machine so that this router can work on all sorts of different hobby CNC machines. If you’re in the KW area and would like to let us test, please feel free to reach out.

Our first prototypes for the Makita clone have arrived and are going through testing. You can see from the photo, they are just like the regular router but with an extra cable sticking out the back for the PWM control.

In the mean time, the team is working on conceptual designs for the top motor housing to work with the extra cable for the PWM signal and for wire management and cooling.

In other news, we are currently waiting on a new version of a VESC driver to be made that can handle up to 200V. We recently tested VESC up to around 100V, with fairly good results, but to get to the RPM range of around 24,000RPM, we need to have a controller that can handle the 200V. One of the main questions we have now is if we’re able to get reliable and fast speed control response at the higher voltage and speeds. We expect the new drivers to arrive in the next month or two.

In our last tests for the BLDC version, we found that the bearings were operating at a higher temperature that we’d like. We suspect that this may be caused by a number of factors, suchas due to improperly machined bearing seats. New bearing seats have arrived and we are going through assembly and testing now.l

Vectric 2024 User Group Meeting

We’re thrilled to announce that we’ll be part of Vectric’s 2024 User Group Meeting! Join us at the Embassy Suites Round Rock in Austin, Texas, on Friday and Saturday, October 11-12, 2024, for a weekend packed with learning and fun. We’ll showcase the AltMill and Vortex, and Scott will be a guest speaker. If you’re attending, be sure to stop by and say hello!

For those new to Vectric, they’re the creators of VCarve, a top-notch design tool for CNC projects. You can purchase it from our website and enjoy full ownership without any subscription fees.

To learn more about the 2024 User Group Meeting, visit Vectric’s event page.