Here’s your Sept 2025 production updates!

AltMill 2×4 and 4×4

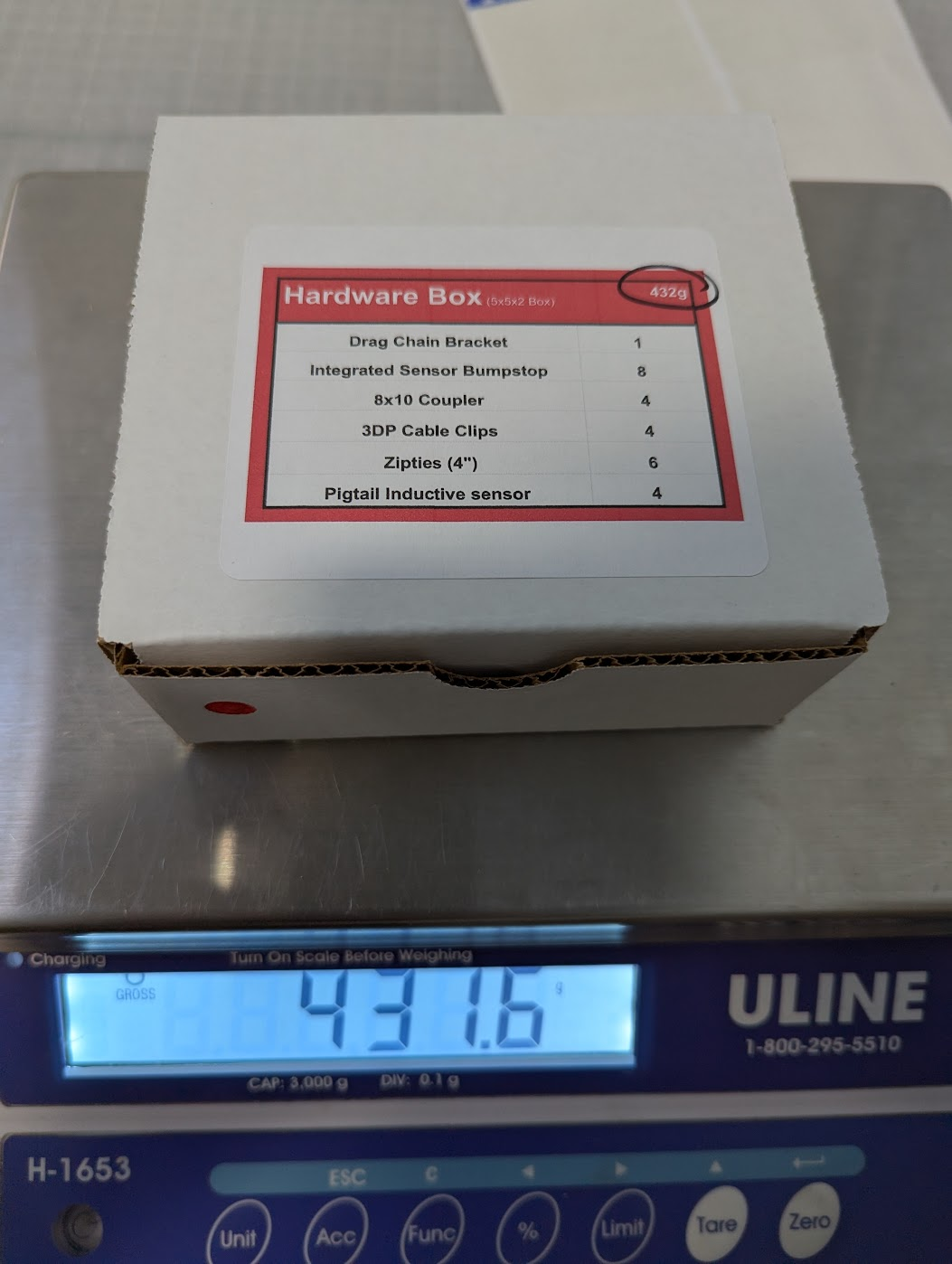

AltMill production has been moving forward at a breakneck speed, with us shipping out nearly 100 AltMills per week. We are now stocking up for Batch 6 units for Oct 2025.

We have been addressing issues that some of our new customers have faced, some of which frankly are a little embarrassing, like sending two left side rails instead of one left and one right.

We appreciate everyone’s patience as we get some of these things ironed out. The team has been working to put in the proper checks to ensure that things like this don’t get missed, both as we understand it can be frustrating for the customer to have to wait a little longer to get their machines together, as well as our time and cost to do the replacements.

A lot of this is housekeeping to get production tidied up and streamlined, and we expect the overall experience for the user to be improving as we go along.

We did take a short pause on shipping to wait on restocking for power supplies, however we are expecting them any day now and expect lead times to stay within 5-7 weeks for customers that ordered in August. Once we get these parts in, we’ll be able to ship out the next few hundred machines and get prepped for the next batch!

AltMill 4×8

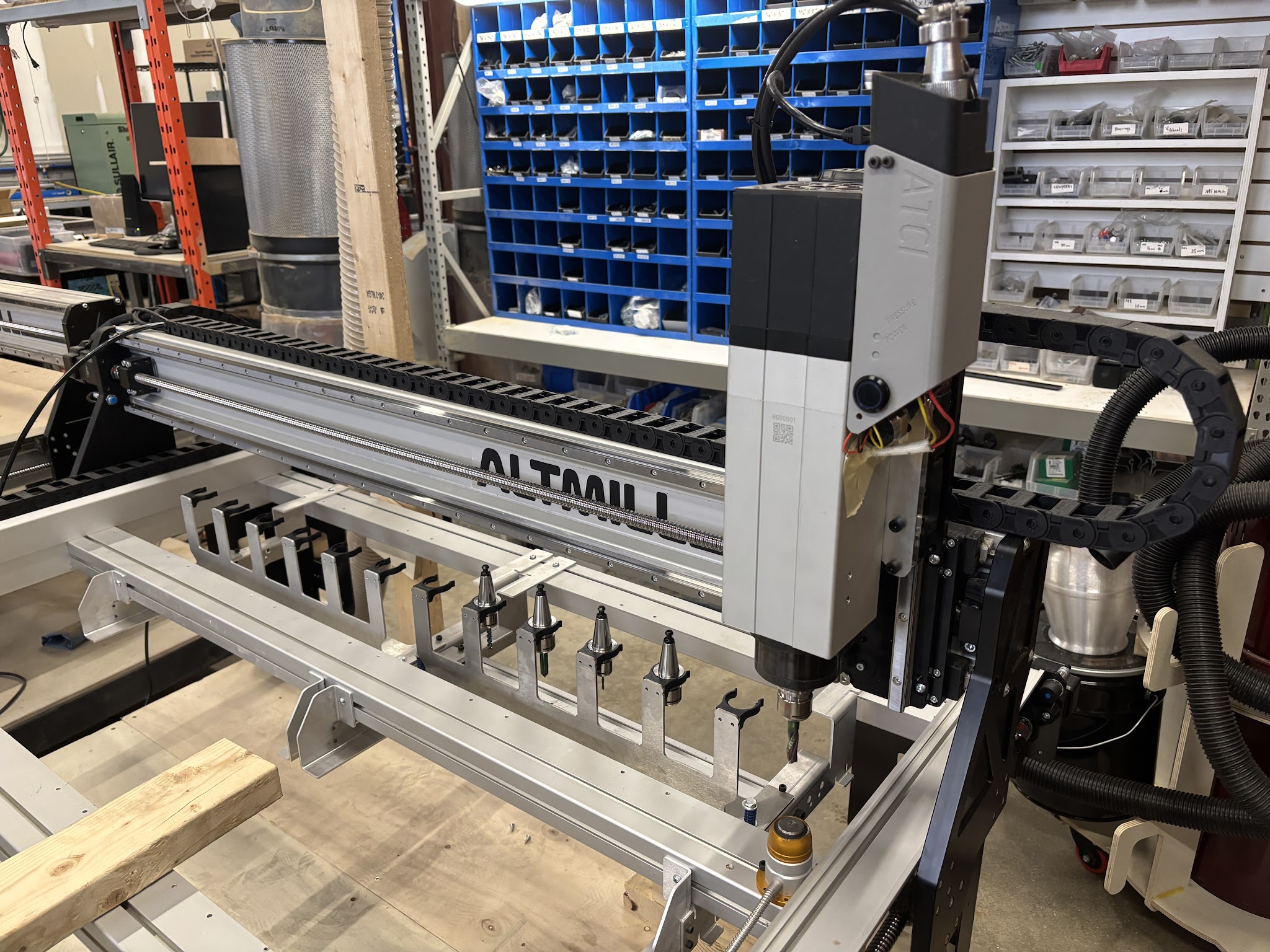

We’re excited to have done our first round of test cuts with the first prototype of the AltMill 4×8. Want to follow along on the development process? Check out Ben’s videos! These will be a series of videos coming out every few weeks, so make sure to subcribe to our Youtube channel if you want to keep up to speed!

We are now deep diving into longer term stress testing for the 4×8. One of the key areas we’re digging into is the long term wear impact of the rack and pinion system. Some of the areas of consideration to improve longevity include:

- Lubrication of the rack and pinon

- Hardness of the rack and pinion components, and the impact of wear based on the difference of hardness between the rack and pinion

- Teeth count, profile and shape of the pinon

- Hardening methods including nitriding and carbourizing

We have now ordered parts to build three beta machines that will have production parts and we should have of them to start by the end of the month.

Auto Tool Changer

A lot of progress on the ATC this month. Here’s a quick look at testing the software integration of the ATC.

A lot of new developments for the ATC system. We’ve now 95%-completed the mechanical design for the spindle and we’ve tested it to be powerful and reliable. A couple of features that come along with this include:

- Manual mode button, allowing for tools to be changed by button press rather than with a programmed sequence

- Status lights to indicate proper pressure before use

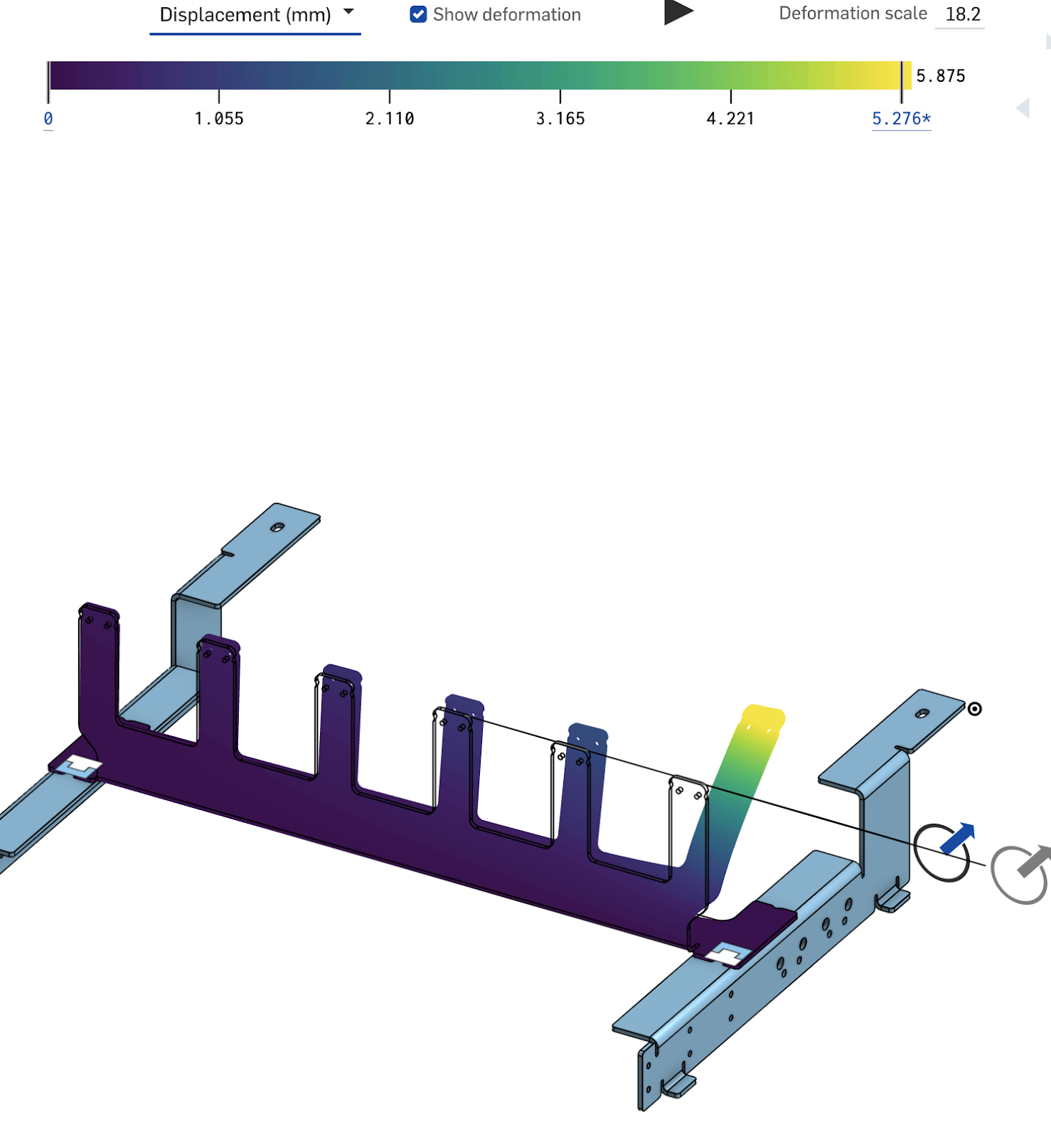

Some of the core focuses for this month have been with the tool rack, a couple of features developed or in development include:

- Pivoting mechanism to prevent damage during crashes

- De-dusting process to prevent dust and chips from getting caught in the spindle

- Positioning and mounting to preserve work area on the machine

- Tool length sensor

Also check out this video that shows off the early version of the ATC system!

AutoSpin T1

Last month we mentioned that we had put the router production on hold to resolve some issues around the certification. We are glad to say we’ve been able to work out the details and continue the production. We are in the process of recertification and expect it to be ready around the end of September. This is still in progress so we will have a more solid update by the next production update.

We’re tentatively expecting to complete production in early October. Our general plan right now is once we have our production units ready, we can open up units for pre-order after we’ve inspected the first batch of production units. If we stick to this timeline, we should see the new routers ready to ship in late November to early December.

Based on current estimates, here’s the general plan:

- Receive updated certification mid-September

- Receive first few units off production line end of September

- Test first few units. If units work successfully, we will launch pre-orders

- Production for approximately 2000 units completes early October; with shipping to our warehouse, we should expect to have units ready to ship by early December

We will continue to provide more info as we move forward, so stay tuned!

These are of course still tentative plans, and we will provide more news as time goes on.

110V 1.5KW ER20 Spindles and 220V 2.2KW ER20 Spindles

Both 110V and 220V spindles are now shipping! These are uncertified VFDs for the US market. These are shipping with AltMills (if ordered with machines) or have an approximately 3 week lead time currently.

We also have started shipping replacement certified VFDs to customers who have been waiting on them. More info in our blog post here: https://sienci.com/2025/08/12/everything-you-need-to-know-about-certified-vfds/. We are currently working on manufacturing for a new batch of certified VFDs to sell to the Canadian and international markets. We have now certified around 90 units and have started shipping them out to customers who are waiting on them. We are expecting to have these available to sale once we have completed shipping out the first batch.

Between the Racks Fireside Chat

For Waterloo Tech Week, we are hosting a small talk about hardware! Event will be Sept 11, from 6:30pm/

Learn more here: https://lu.ma/rxneke6j