Hey everyone, I’m excited to announce the introduction of 1/8″ compression bits to our arsenal of affordable and high-quality end mills to our store! Compression bits work great for cutting products that are prone to splitting from both sides of the material, most namely with plywood and other softwoods.

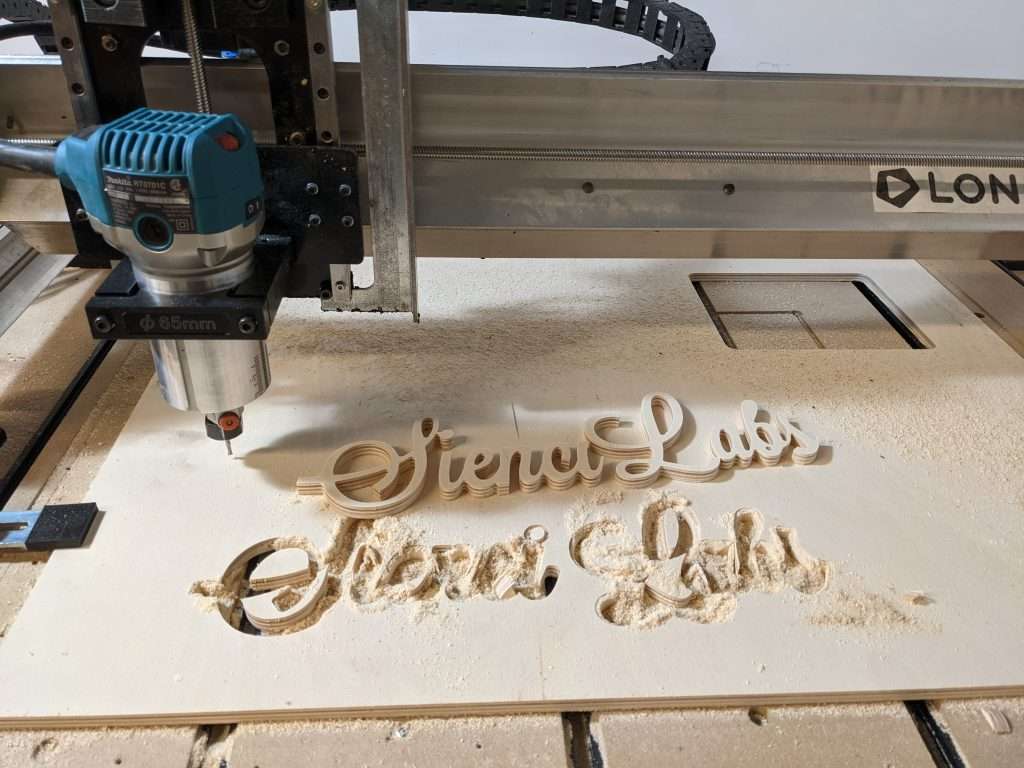

This is a game-changer for folks that make signs and other plywood-based projects that require cuts that go all the way through the material. Our testing with this new compression bit results in clean edges on both sides of the material with little to no sanding needed.

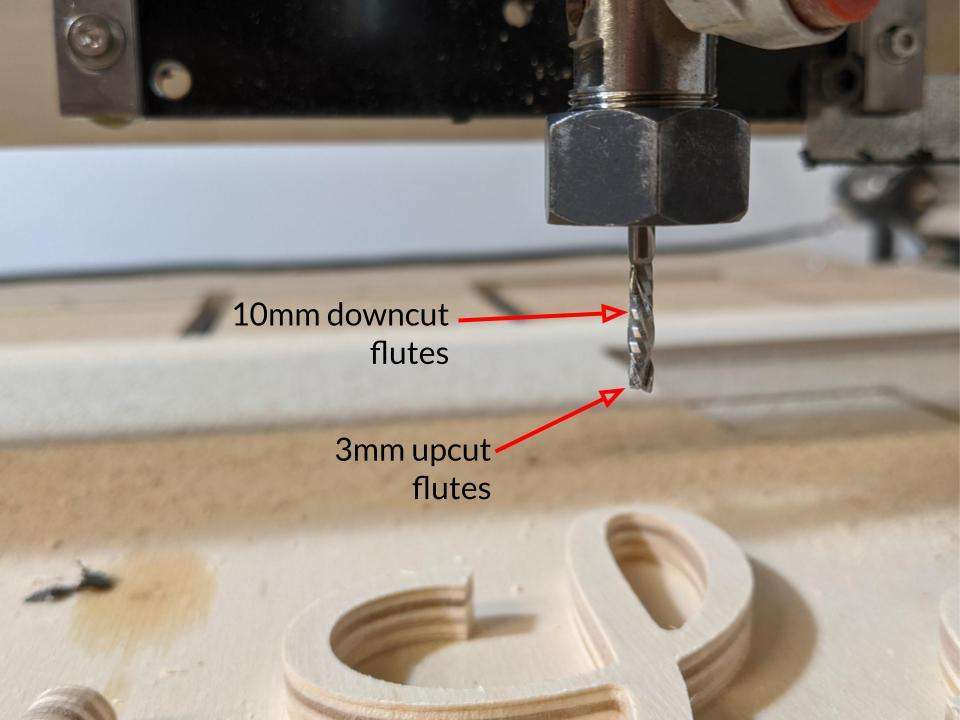

So what is a compression bit? A compression bit combines both upcut and downcut flutes into the same bit.

With some materials, cutting with a regular upcut bit causes splintering and fuzziness on the top edge of your cut as shown in the project below.

Using a downcut bit pushes the chips downwards leaving a clean edge, but cuts along the bottom edge of the part are pushed down, causing a rougher edge on the bottom of the cut.

A compression bit on the other hand offers the best of both worlds. The tip of the bit works as a upcut bit, while the top of the bit works as a downcut bit. Used properly, the upcut part of the bit cuts the bottom edge of your workpiece, while the top of the workpiece is cut with the downcut part of the end mill. This helps provide a clean edge on both the top and bottom of your part.

Want to get your hands on your own compression end mills? Make sure to check out our store here: https://sienci.com/product/1-8end-mill-compression-bit/

How to use a compression bit

With any compression bit, you want your first pass to be deeper than the length of the upcut side of your flute. In the case of our 1/8″ compression bit, the upcut part of the bit is 3mm long so we want our depth of cut to be larger than 3mm.

In the case of the demo video shown above, the settings this cut was 3.8mm depth per pass at 1300mm/min. You can use any depth of cut as long as your first pass is larger than the length of the upcut portion of your bit.

Then the rest of the cut should finish with the bottom of the part being cut using the upcut portion of the end mill cutting the last layer of material.

P.S. We are expecting to get 1/4″ compression bits around the end of March/start of April so make sure to look out for that!