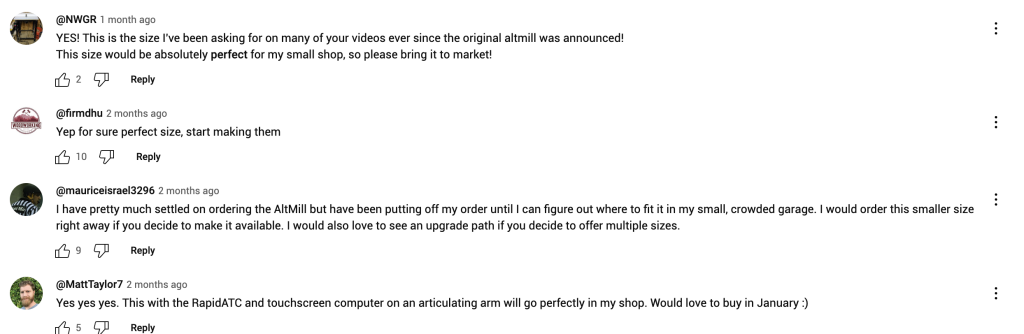

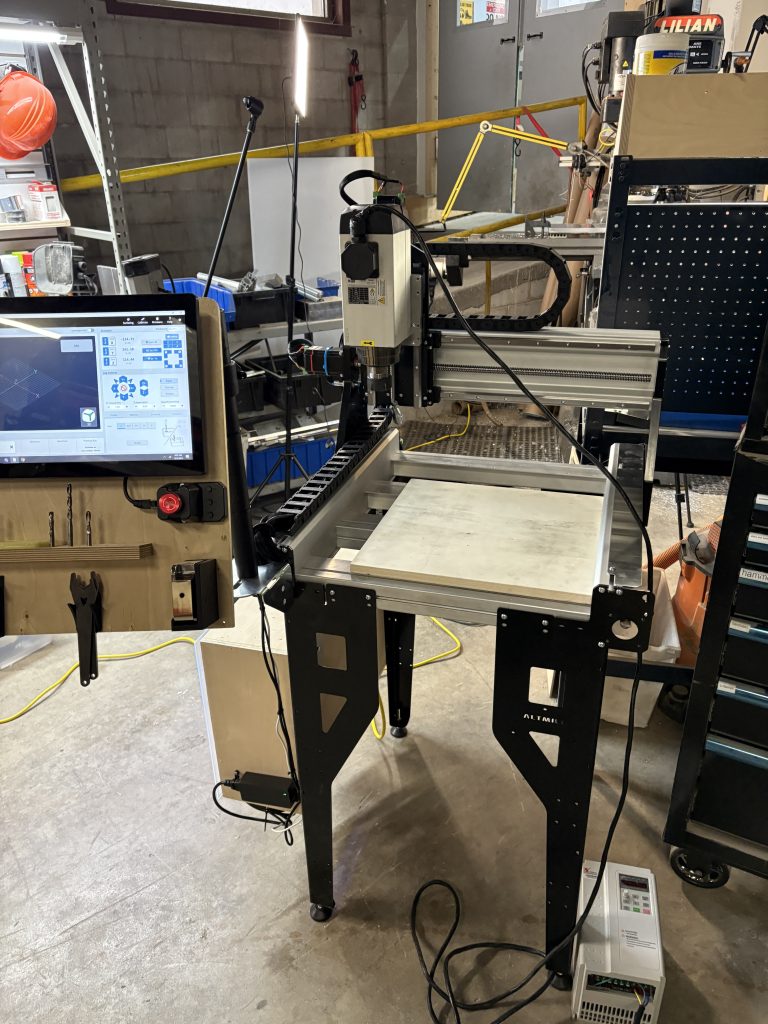

Hey everyone. I’m excited to share more details about the AltMill 2×4 (the AltMill with a 4×2 ft working area) and other sizes coming soon. We are expecting the launch of the AltMill 2×4 A few months ago, Ben took some time to put together a version of the AltMill with a 2×4 foot (approximate) working area using spare and scrap parts left over from production and posted a video about it. Since then we had a lot of interest in smaller versions of the AltMill.

Availability to order the AltMill 2×4 is tentatively scheduled for Jan 29, 2025 and expect to ship at the end of March. The AltMill MK2 2×4 will be available for order on Jan 29, 2025 at 11AM EST.

AltMill MK2 2×4 (machine only) to be $3890CAD or $2790USD. Spindle and Dust Shoe Kit pricing at $690CAD/$515USD

Since showing off this version of the AltMill, the response from the community has been overwhelming, encouraging us to develop and work on exploring different sizes of the AltMill.

Why different sizes?

After building and testing the AltMill, it became clear to us that the design and platform had a lot of potential to be used in a lot of different applications. The main innovations of the AltMill come from optimizing the design for rigidity while making it as easy and efficient to assemble at scale, which translates to different sizes as well.

As it stands, we believe we haven’t fully unlocked the power of the AltMill. We still have a lot of development and progress to make with:

- Higher power spindle options

- Automatic tool changers

- Coolant options

- Advanced clamping, vices, and other hold-down methods

The main goal for building all the different sizes, ultimately, is to serve a larger audience who want to use their machines for different applications beyond just the typical woodworking projects that our machines and industry have been focusing on such as:

- Aluminum milling

- Steel milling

- Plasma cutting

- Fiber laser cutting

- Automating tasks such as drilling and tapping

Fundamentally, the AltMill serves as a platform for CNCs designed for many different uses and leverages development across all of the different platforms to trickle through the whole ecosystem.

Who is it for (AltMill 2×4 and smaller)?

We’re not a 100% sure yet but here’s some of our thoughts.

People who want to do small-scale production for a specific part:

Although a larger machine is more versatile, for users who want to have a machine suitable for machining specific products and parts, a machine just large enough for that specific part may be the best option, especially in space-constrained locations. For example, the AltMill could be jigged up to make guitars in a production setting, as the workspace is large enough for a full neck and body.

Another advantage of the AltMill is that businesses that need to do production can in theory order and have a machine shipped to them directly on short notice (or at least once we finish optimizing our production), allowing them to scale production quickly when they need additional machines.

Education or use in an institution:

We’ve also gotten interest from people who want to use CNC for teaching or institutional use, where the focus is less on producing parts and more on learning and testing. This could be in CNC software companies testing their CAM software or colleges that need lower-cost CNC machines that are robust enough for students to use while fitting in smaller classrooms.

The AltMill works on the same core technology as any industrial CNC machine, which means that it can provide an entry into CNCing without the risks and costs which come with industrial machines. The open-source nature of our designs and company also allows for institutions to adapt their machines to their needs as well.

For fun:

While AltMills are not cheap, they do come in at a price point that makes it accessible to most dedicated hobbyists. We expect pricing for all versions of AltMills to be around the current price of our 4×4, with variations based on size and configuration. This means that users may choose to buy a CNC machine just for the heck of it.

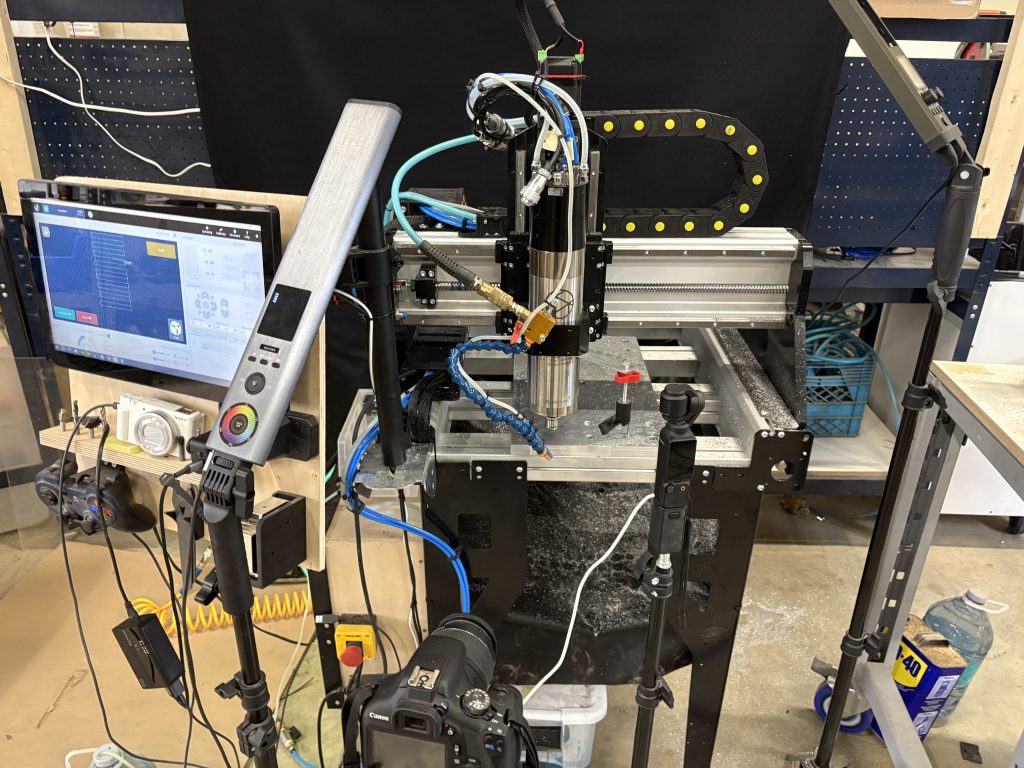

Sm-AltMill (Small AltMill)

Concepts of a smaller, metal milling-focused CNC internally called the “YesHappy” or “Sm-AltMill” have been tossed around in the shop for some time. From our perspective, we feel there’s a gap in the industry for a small, benchtop-sized CNC machine for milling aluminum and steel. While there are some options in the $2000-5000 range, we feel they are either underpowered and only good for small parts, and consumers need to spend around $10,000-$30,000 to purchase a smaller milling CNC or VMC.

Here’s a list of machines that we found that are sort of in this space.

| Machine | Price (CAD) | Cutting Area(in) | Spindle Power(kW) | Motion System | 4 Axis Compatible From Factory |

| Makera Carvera | 7800 | 0.2 | Slide Bearing | Yes | |

| Shariff DMC | 4550 | 2.2 | No | ||

| Sainsmart Gemnmtsu | 1945 | 0.4 | Delrin Wheels | No | |

| Yorahome Crossriver 6060 | 4107 | 24x24x5.8 | 0.5 | Linear Guide | No |

| Carbide 3D Nomad | 3640 | 8x8x3 | 0.12 | Slide Bearing | No |

| Source Rabbit Quantum | 12800 | 13x13x4 | 1.4 | Linear Guide | Yes |

| Langmuir MR-1 | 6500 | 23x22x6 | 2.5 | Linear Guide | No |

| Kitmill AST | 11000 | 8x5x4 | 0.1 | Linear Guide | No |

| Stepcraft-3 D420 | 3000 | 12x16x5 | 1 | No | |

| Coast Runner | No | ||||

| Onefinity Machinist | 2400 | 16x16x5 | Makita | 35mm Rail | Yes |

| Bantam Tools | 11000 | 7x9x3 | Linear Guide | Yes |

So where do we land for this? Here are some considerations:

- With our software and hardware stack, we can support advanced functionality such as 4th axis support, coolant control, closed-loop steppers, and more without additional development, since functionality has already been worked on and developed for AltMill and LongMill already.

- Since we are already assembling and building AltMill at volume, we can take advantage of economies of scale for many of the parts used in the other-size machines.

- The rigidity and accuracy of the AltMill generally exceed the majority of the machines on this list and can be optimized further. Based on our testing, we’re able to reach material removal rates on the regular AltMill 48×48 compared to the highest-powered machines in this list, and we expect that a smaller version of the machine would increase the overall rigidity to continue to meet or exceed performance across the board.

There are a couple of things that we’re working on now including:

- Reaching out to people in the machining community to get their thoughts on this sort of product

- Figuring out the balance between cost, features, and performance

- Playing around with different add-ons such as ATC and coolant

- Building a small batch of beta units

- Testing metal-specific tooling

Larger machines (AltMill 4×8)

On the other hand, we’ve also been getting a ton of interest in a 4x8ft version of the AltMill. Our team has been considering this as well, and identified two main short-term challenges and one main long-term challenge in bringing this to market.

First is the packaging. One of the main advantages we have is being able to pack and ship everything through a courier like UPS. This avoids the need to deal with complicated freighting and equipment needed to load and move large CNC machines. However, using a courier for very large shipments can be expensive and sometimes not possible depending on the size and weight of the order. Additionally, shipping items through couriers run a higher risk for damage, as shipments go through many hands and get stacked and piled on top of other shipments.

We believe that using the courier method does make things more accessible since we can deliver CNC machines to residential locations. However, the larger and heavier the machines become, the more difficult it is to work around the limitations. That being said, we’ve seen lots of examples of this, and we believe, we can sort out something that works.

The second challenge is with power transmission. Since the Y-axis needs to get longer, it also means that the Y-axis ball screws will become more prone to whip if we keep the same design. This can be mitigated with a number of options, such as using rack and pinion, larger ball screws, or something else, but this means that we’ll have to engineer another way to move compared to the existing solution. Of course, designs and solutions already exist, and we believe that we’ll be able to figure something out in this area too.

Lastly, the other, perhaps long-term challenge comes down to our company scale. Larger machines take up more space, and although we just moved into a larger office about a year ago, we’d be looking at moving into an even larger space as soon as we start production for 4×8 ft CNCs. Additionally, and perhaps the even bigger challenge, is hiring and onboarding more team members to support the new product.

With that in mind, we do believe that there is a space in the market for an AltMill 4×8, and we have been chipping away at the design and logistics to eventually bring it to market. Make sure to stay tuned for new updates.

Pricing

There are some fixed costs associated with all versions of the AltMill, such as:

- SLB-EXT controller

- Spindle (although the specific version may vary depending on the use of the machine)

- Closed-loop stepper motors

- Gantries (although there may be variations for machines designed for milling metals to accommodate vices and additional workholding)

- Couplers, bearing blocks, and other assorted hardware

On the other hand, costs for items that are size-dependent include:

- Linear guides

- Rails

- Packaging and shipping

We predict that material costs for smaller machines will be relatively close to the 48×48 AltMill. Some additional costs include:

- Resource and support costs for each variation of the machine

- Unique packaging and assembly costs

- Development costs

- Additional machine-specific accessories such as coolant support and vices

All in all, we don’t expect pricing to be dramatically different compared to the current AltMill, which we believe is well-priced on its own. Customers should expect pricing for the AltMill 2×4 to be similar to the current price for an AltMill 4×4. Finalized pricing will be available near or at launch.

Next steps

Production for more AltMill rails is now in production, which includes approximately additional rails needed to build around 100 AltMill 2×4 We’re expecting them to arrive around the end of February, which means we’ll have the first parts needed to start building around 100 units.

Our team is currently working on media and marketing materials to prepare for the launch of AltMill 2×4 on the store, which is tentatively scheduled for Jan 29th.

We expect AltMill 2×4 to start shipping in March.

Additionally, we are in production for an additional 25 sets of rails and parts for a 16×16 inch working area machine (Sm-AltMill), which will be focused on metal milling. We do not have a specific launch plan for this yet, but we are collecting feedback and doing market research to understand how we want to configure the design for this. We will be reaching out directly to potential users for sales of the first batch, so if you’re interested, make sure to fill out the survey.

We are expecting the Sm-AltMill to be sold and built on an individual basis and customized and tested for different uses, which means that they will not be publicly available for sale at this time.

FAQ

Is there going to be a way to upgrade from a 2×4 to a 4×4?

It is likely we will have a kit available, but we likely will need a few months after the launch to sort out the product and resources for size changes, so we recommend picking the size you’ll be committing to up front for now.

What is the footprint of the AltMill 2×4?

The footprint is approximately 52in wide and 39in deep. From the bottom of the foot to the top of the motor, the height is approximately 56in.

Do the legs come with the AltMill 2×4?

Just like the AltMill 4×4, the AltMill 2×4 comes with steel legs.

What accessories work with the AltMill 2×4?

Any accessory that works with the 4×4 will work on the 2×4. This includes any spindles, gControl panel computer, Vortex Rotary axis, and more. We expect that future add-ons and features designed and developed for 4×4 will work on 2×4 as well.

What is the price for an AltMill 2×4?

Official pricing has not been established, but users should expect pricing to be similar but slightly less than a 4×4.

When are AltMill 2×4 expected to ship?

2×4 machines are expected to start shipping in March 2025.

Where can I buy an AltMill 2×4?

Pre-orders will be available on our website at the end of January.

Will there be any other sizes of the AltMill?

Besides the Sm-AltMill with a working area of approximately 16×16 inches, we don’t have any immediate plans for other sizes at the moment.