It’s been a short 10 months since we first launched the AltMill.

We’ve learned a lot with our first batches of the AltMill and we’ve combined all those things into improvements to our latest version. We’re now excited to share our second iteration of the MK2, which bring improvements to the quality, ease of construction, and quality of life, as well as preparing for new iterations and development for the Sm-AltMill and 4×8 machines in the future.

The MK2 refers to the platform change, which means that any machine with the new design changes are part of the MK2 family, which means that the AltMill 2×4 is also a MK2 machine.

If you’re looking for more information about the AltMill MK2 2×4, please check out this other blog post.

Production changes and challenges

AltMill lead times have continued to be long since the first launch of the machine. While our production rate has continued to increase over time, decreasing lead times have also coincided with increased demand, due to the growing public knowledge and interest of the AltMill. We are working on a number of things to decrease lead times and our goal is to eventually have units ready to ship in 1-2 weeks on average.

Batch sizes

To mitigate the risk of quality and technical issues in the shipping of our first batches, we’ve kept batch sizes relatively low, with Batch 1 being 50 units, Batch 2 being 200 units, and Batch 3 being 250 units. Batch 4, which we are currently in, is something of a split batch of 500 units. I am calling it a “split batch” because some components have been ordered and produced in a batch of 500 while some have been ordered in a batch of 250, based on cost, size, and our confidence in the part quality. Additionally, we’ve been working to diversify our supplier portfolio, so that we can split up parts from the same batch across two or more suppliers, allowing us to decrease lead times.

Supplier diversification

As our part complexity and quantity grow, we’ve worked to diversify our portfolio of producers and manufacturers. The first is to distribute work to decrease lead times. By using more than one manufacturer to produce the same component, we can ensure that if one manufacturer has issues or is delayed, we still have a second source for the products. Plus, if parts take a long time to make, having a smaller batch to produce can reduce the total production time.

Second, we’ve been working with different manufacturers to understand their strengths and distribute work based on their competencies. We found that some manufacturers may be proficient in extrusion production but not in machined components. Traditionally, it was easier to aggregate production to reduce the number of suppliers and logistical overhead, but at this point, we’re at the scale where it makes more sense to have manufacturers focus on their core competencies to have the best quality possible.

Production space changes

Since moving into our new space in north Waterloo in November 2023, our space has adapted significantly. We’ve implemented new racking and equipment to increase the storage capacity of our production area. However, as we increase our batch sizes, our demand for space will increase as well. At this moment, our team is working on expanding the production area with potentially taking over more of our current building, as well as looking into a second space for warehousing.

Design changes and challenges

When working on the first batch of AltMills, we encountered a number of problems, some we were expecting and some we weren’t. Much of MK2 development is to address and improve the overall manufacturability and ease of customer assembly.

Extrusion

As we found when we first developed extrusions for the LongMill MK2, we knew that ensuring the flatness and straightness of the new extrusions were going to be critical in ensuring the precision of the machine. With the AltMill, with larger rails and the addition of linear guides, tolerancing was going to be an even more important part of the process.

Having material furthest from the center of the axis of rotation or flex offers the most rigidity in a structure. This is why in the initial design, the inside of the rail did not have any cross bracing. This might be counter intuitive, but actually is the most optimal way to design the rail. However, what we learned was that having some sort of cross-bracing would improve the straightness of the rail in production. While there is a small tradeoff in weight and potential performance, these differences are negligible for the added benefit of having higher production yield.

The original design and the current design both use machined surfaces to ensure that even with some deviation in the straightness and flatness of the rail, the linear motion would still mount without binding, but we found that in extreme circumstances, the rail would be so bent that the center of the rail wouldn’t get machined at all. These rails would need to either be re-machined or scrapped.

Another unexpected small benefit was the fact that the cross-brace increased the resonant frequency of the system itself so that the machine “rings” less.

Additionally, to aid with assembly, the Y-rails come with a small extruded “ledge” that helps keep the crossbeams supported and straight. This also improves the speed of assembly as the crossbeams can be held in place by the ledge while being bolted together, and the table does not need to be flipped twice during assembly to mount the table legs.

Crossbeams also now mount using a custom tall-head screw, making it impossible to drop into the rail, and improving accessibility of the screw head for easier assembly.

To add one more change to the Y-axis extrusion design is the integrated dust cover for the ball screw, instead of the stainless steel covers used on the MK1, which serve the same purpose, but reduce the assembly time and total part count. The addition of the ledge for the drag chain also helps keep it aligned during use. This recessed area also exists on the X-axis rail to help align the drag chain as well.

A last subtle difference in the MK2 extrusions is the consistent use of a more fine bead blasted and anodized finish on all extrusions including the crossbeams. This is more costly than the unanodized crossbeams used in the MK1 AltMill, but greatly enhances overall polish of the machine – even if these parts get hidden by the wasteboard.

Machining

One aspect of the manufacturing that proved to be a larger headache than expected was with the threading of the extrusion, notably, the M4s used with the linear guides and end tapping with the crossbeams. With the manufacturing of the LongMill MK2, we ended up developing a system to tap the extrusions in-house, especially since we had also started cutting rails for each of the various sizes for the LongMill as well. However, given the larger number of tapped holes, we had to bring the tapping out of house.

We found that some of the tapped holes had weak threads, causing them to strip during the assembly of the linear guides or when installing the crossbeams.

We’ve improved the quality control and documentation so that our manufacturers are able to catch poor threading, however, we recognize that ensuring proper threading would always be a part of the manufacturing process, so we are working towards bringing the machining and tapping in-house as well. As a redundancy, threaded sections of all rails have been strategically thickened for reducing the likelihood of strip-out when over-torqued.

Wire management

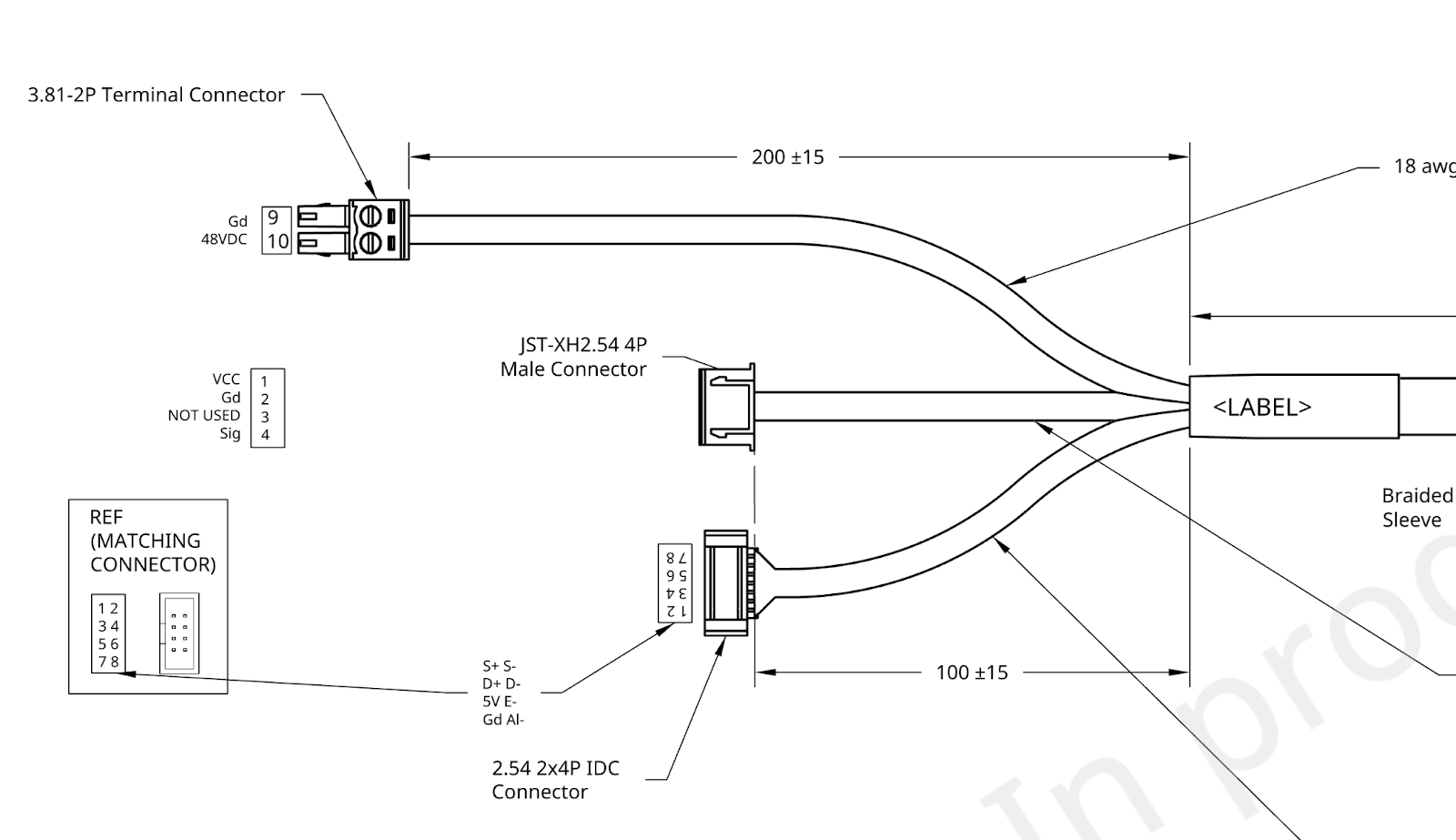

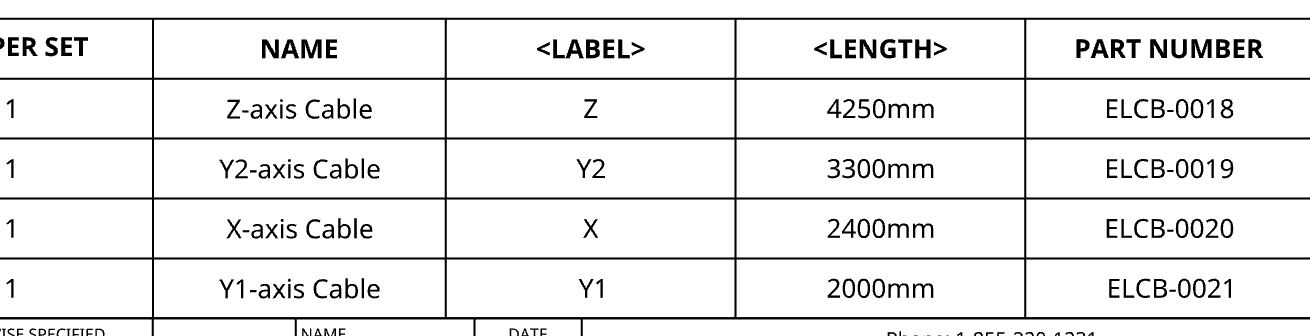

One of the common criticisms of the AltMill was its lack of well-thought-out wire management. This means that users would end up with a pile of wires at the SLB. Since all of the motor cables are the same length, depending on how far the motor is from the controller, the user would end up with varying amounts of excess cable. Additionally having bundles of long cables going to each corner of the machine can be unwieldy and prone to assembly error.

The MK2 implements new wiring that comes with pre-determined lengths and is pre-bundled for each axis. We’ve decided that although the packaging and supply chain may be a little more complicated on our end, ultimately, the improved tidiness and ease and speed of assembly would be worth it. This means that each cable is labelled and comes to an exact length to reach the controller. This also makes it easier to catch errors in assembly as wiring plugged into the wrong location would also be more apparent due to different wire lengths.

Additionally, each cable harness now includes an integrated limit switch cable, meaning less individual cables to route during assembly, as well as an easier time to identify where each limit switch plugs in.

Limit switches now connect to the integrated wire harness using a small locking connector. This makes installation of the switches and wiring a bit easier, as well as allows for easy replacement of limit switches if needed.

This work is also done in conjunction with adjustments to the front and back motor plates used on the Y-axis to utilize the inside of the extrusion to hide and protect the wiring. Additionally, we’ve made some changes to the SLB-EXT controller case to make wire management easier and cleaner.*

Please note that changes to the SLB-EXT are expected to come near the middle of the AltMill MK2 batch. Both controllers are the same and are cross-compatible with each other.

Motor covers

On the AltMill MK1, motor cables exit from the rear of the motor and curve backwards towards where the cables are routed from. In some instances, this could cause connectors to fall out, or individual cables to break in extreme cases. Early on, right after launching, the individual cable crimps were changed to prevent these individual cables from breaking or coming out, but it was still possible to have connectors become come loose from their socket.

On the AltMill MK2, molded plastic motor covers are used at all four motors to:

-Mechanically secure motor connectors from coming loose

-Provide strain relief for each cable harness and redirect this towards its cable routing path

-Provide protection of the motor and connectors without impeding any heat dissipation of the motor.

Backwards compatibility to AltMill MK1

It’s important to state here that the updates and changes made to the AltMill are primarily for ease of manufacturing and assembly. If you already have a AltMill MK1, it’s unlikely you’ll need or want to change or upgrade your machine to a MK2. Many if not most components are still cross compatible, which means that some replacement parts that will be available for the MK2 will also work with the MK1.

If I have an AltMill MK1, can I update it to the MK2?

If you already have an AltMill MK1, most of the parts are backwards compatible with the MK2. However, most of the updates made are to improve the assembly and manufacturability of the machine, so if your machine has already been assembled, there is little to no practical advantage to updating your machine from a AltMill MK1 to a MK2.

We will not have parts immediately available for purchase, but we are working stocking and uploading parts that can be used between the two machines.

Additionally, if you already have a MK1 on order and would like to change your order to a MK2, please contact us. Please note that changing your order from a MK1 to a MK2 may delay the shipping of your order, plus have a price difference, as we will complete shipping of AltMill MK1 before AltMill MK2.

Electronics and software remain the same and will continue to be updated in line with the MK2. Resources and instructions, and tutorials will still continue to be relevant to both versions of the machine.

If I have an AltMill 2×4, can I update it to a 4×4?

Theoretically yes. To update it to a 4×4 size, you’ll need to replace the Y-axis rails, ball screws, motor harnesses and add an additional 2 crossbeams. It is our plan to have, as we currently do for the LongMill, parts available for purchase in our store for modifications and changes. However, the cost of the conversion on an individual basis may be high, and we don’t have a specific timeline or roadmap for a dedicated kit or instructions, so we strongly recommend ordering and committing to the size that you plan to use for the long term.

Pricing

Base price for AltMill 4×4 goes from $3990CAD to $4290CAD or $2950USD to $3160USD, ($300CAD difference or $210USD difference).

Base price for AltMill 2×4 to be $3890CAD or $2790USD.

Pricing for spindles and other accessories remains the same.

We are adjusting pricing for the AltMill to reflect some of the changes and improvements we’re making to the MK2 and better reflect our current costs for production.

The AltMill 4×4 MK2 and AltMill 2×4 will be available to order with updated pricing on Jan 29th, 2025 11AM EST. On Jan 29th, only the AltMill MK2 versions will be available for order.

Please note that this is expected pricing but pricing may change.