Another round of news on tariffs is here! Let’s get right into it.

Changes to the current tariff situation

We’ll start off by talking about what the situation looked like back in March, then move into how things have changed since.

- While initially it seemed like there would be a 25% tariff on imported goods into the US from Canada, after a few days, it was changed to allow USMCA goods to continue to cross the border tariff-free as it had been before the trade war. This meant that a significant number of products we produce, including the AltMill and LongMill, could travel tariff-free.

- Although talks to remove or reduce de minimis were held, which allowed goods under $800USD in value to cross the border without tariffs and duties, this ultimately did not come to pass

- Items not under USMCA were subject to a 25% tariff.

While at first glance it seems a lot has changed, in our case, things appear to remain largely the same.

- Items under USMCA continue to be tariff-exempt as before for our products. This means that most major products, including LongMill, AltMill, and accessories, can travel without tariff.

- The $800USD de minimis rule still continues to apply, although talks have still continued in changing or abolishing this.

- Other items remain at a 25% tariff for Canadian goods not certified by USMCA.

For a full list of USMCA-certified items, please see this list.

Due to these specific circumstances, while we have had some minor issues dealing with the new tariffs, we have been avoid them for the most part. At the current time, there is no indication from the White House on when it expects to revisit these tariffs.

How the tariffs apply to everything else

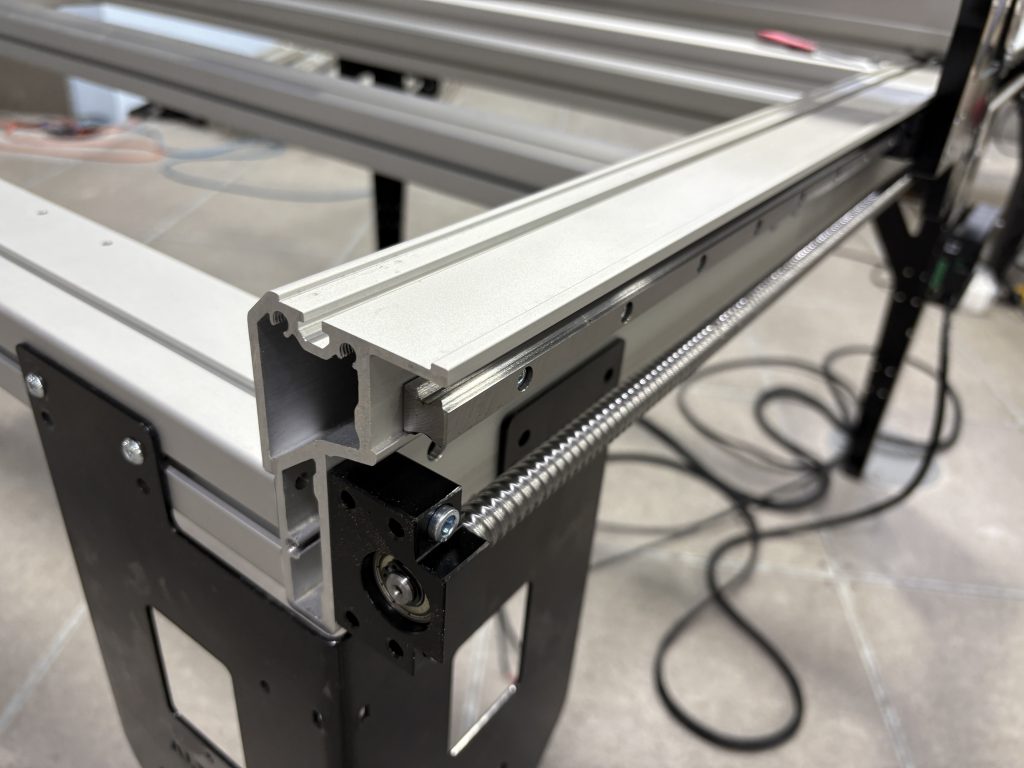

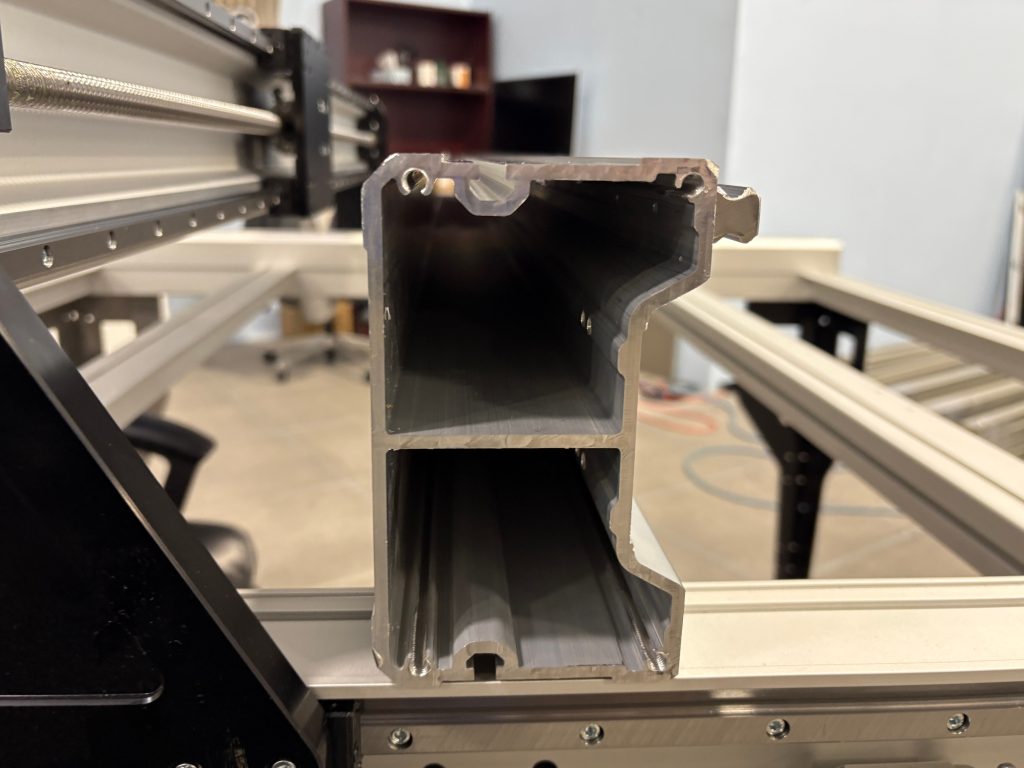

While it seems like we’re able to dodge much of the repercussions of the trade war due to our specific circumstances, as we discussed in the previous post, this will have a widespread impact on the CNC market, especially for US producers. Just like the auto industry, parts used to build CNCs come from all across the world.

Newly imposed retaliatory tariffs on countries such as China, Taiwan, Vietnam, Australia, Malaysia, and approximately 60 countries, plus a 10% baseline tariff on imports that span on 185 countries, means that the cost to produce CNCs in the US will increase.

For example, the popular Masso controller used with several notable CNC producers in the US is produced in Australia, which will soon have a 10% tariff imposed. With previous tariffs and duties imposed for Chinese aluminum extrusion exports, we’ve seen growth in aluminum extrusion exports from Vietnam and Malaysia as new sources, but with increased tariffs of 46% and 24% means that producers using materials from these countries are also facing added costs. Things like carbide material from Germany used in the CNC industry is expected to have a 20% tariff and Taiwanese bearings and linear motion components will have a 32% tariff. But most importantly, with an additional 34% tariff added to the existing 20% tariff on China, the largest source for CNC parts and materials, the cost of producing CNCs is expected to increase across the board for US producers.

The point here is that in our market, simply buying USA-made won’t be the solution for consumers to get around the tariff, especially when costs for US producers are expected to rise as well. While Trump is pushing the narrative that tariffs will protect American jobs and the economy, it isn’t without some compromises. Additionally, if other countries put in reciprocal tariffs, it is likely to affect CNC demand for US-built machines, adding to the pain to US manufacturers.

In some ways, this trade war puts Canadian CNC manufacturers in an even stronger position, such as us, where USMCA laws, plus the fact that duties on importing goods from across the world necessary for CNC manufacturing are cheaper due to the added costs that come from tariffs. With current events in mind, even considerations for Canada to strengthen its economic relationship with China have been part of the discussion on the Canadian political stage.

Impact on our current business

As it stands now, since the imposition of tariffs, sales of our products have declined, but not completely. With 75% of our sales revenue coming from the US, there is hesitancy to order at this very moment due to the uncertainty of how much customers may need to pay to bring their machines across the border. Given that we are still unsure about whether new tariffs will be imposed, and with our current choice not to accept the added cost of the tariffs for machines shipping after March 4th, we expect sales to be slow until this policy changes.

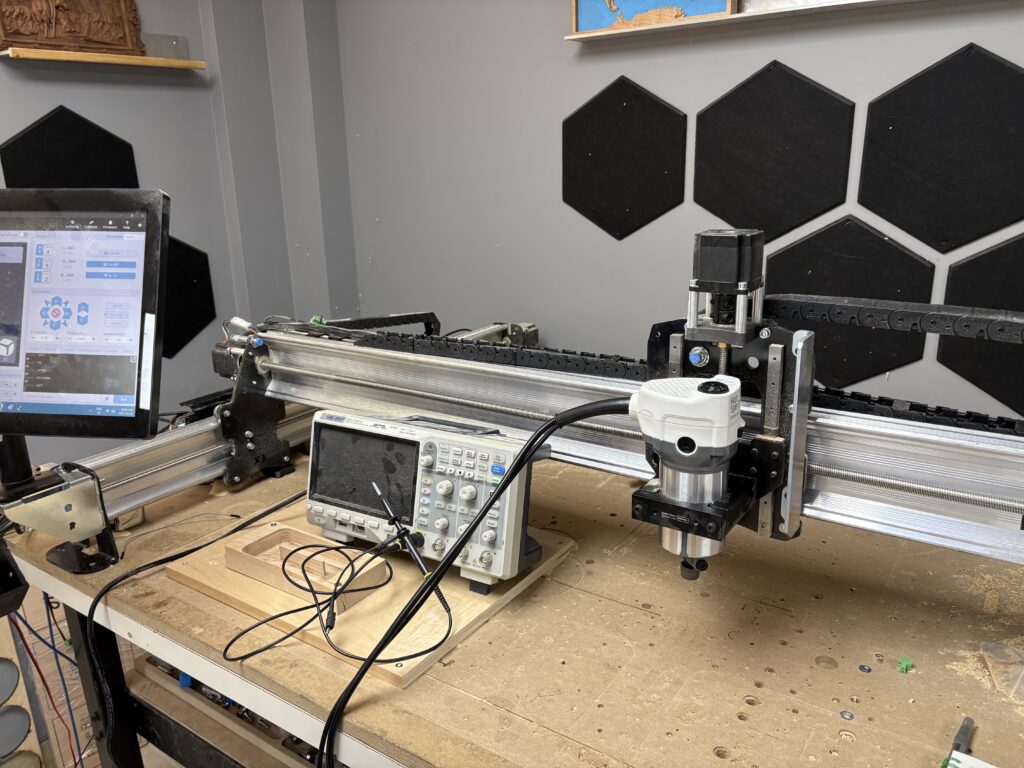

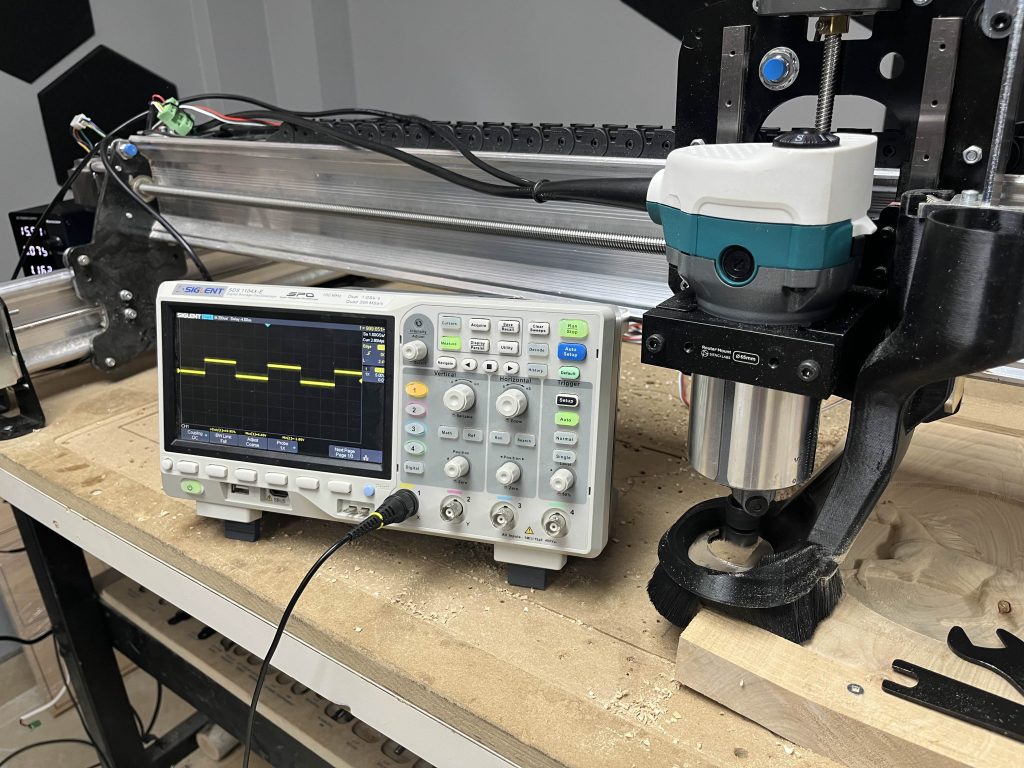

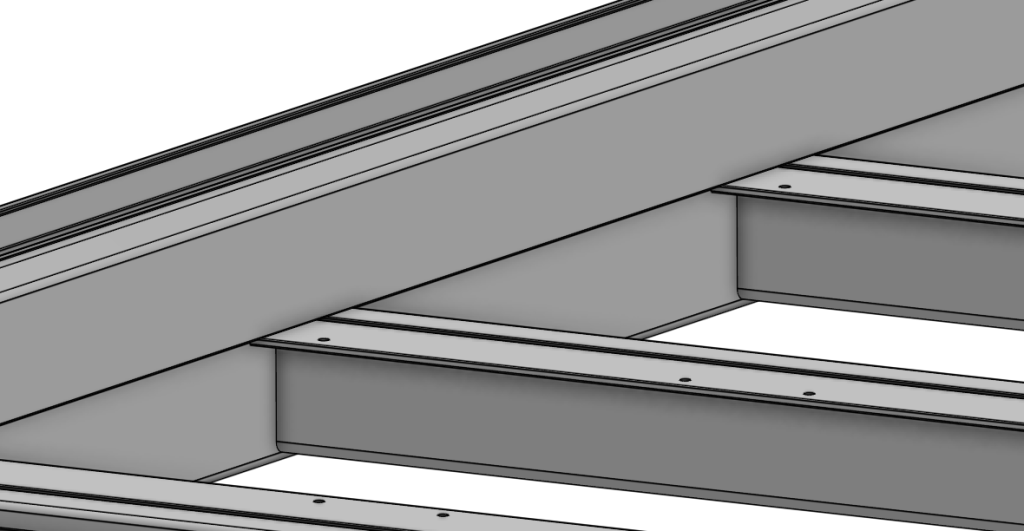

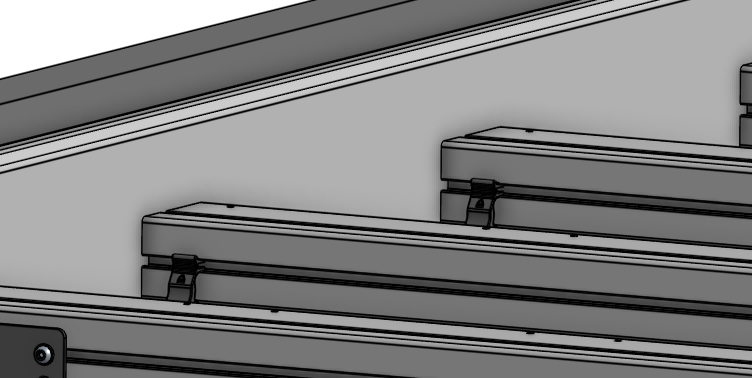

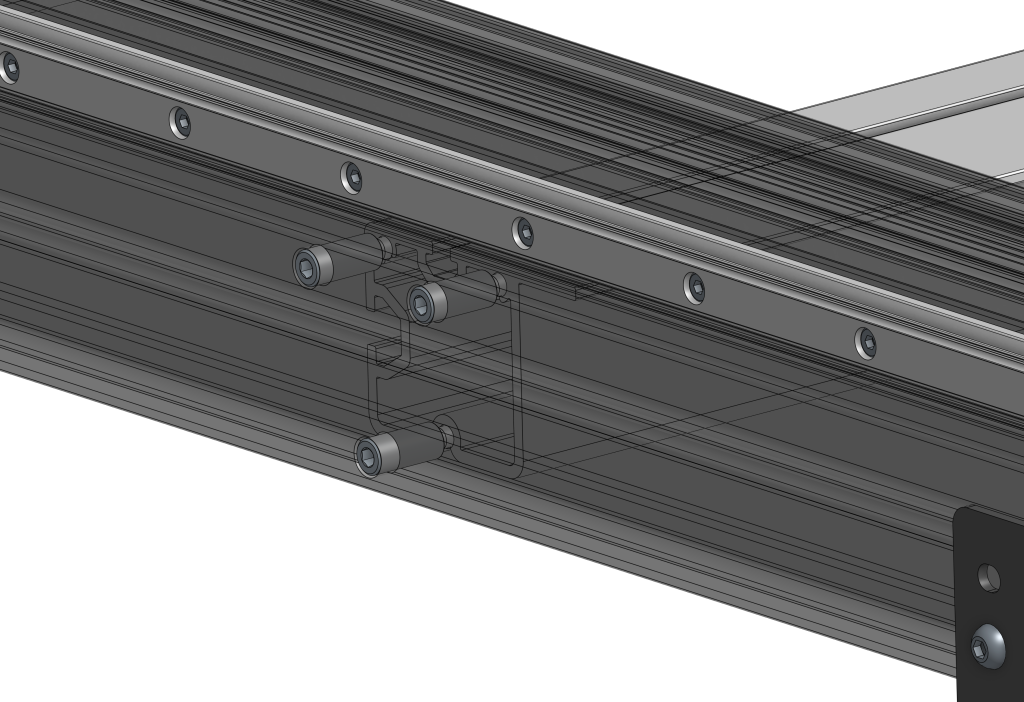

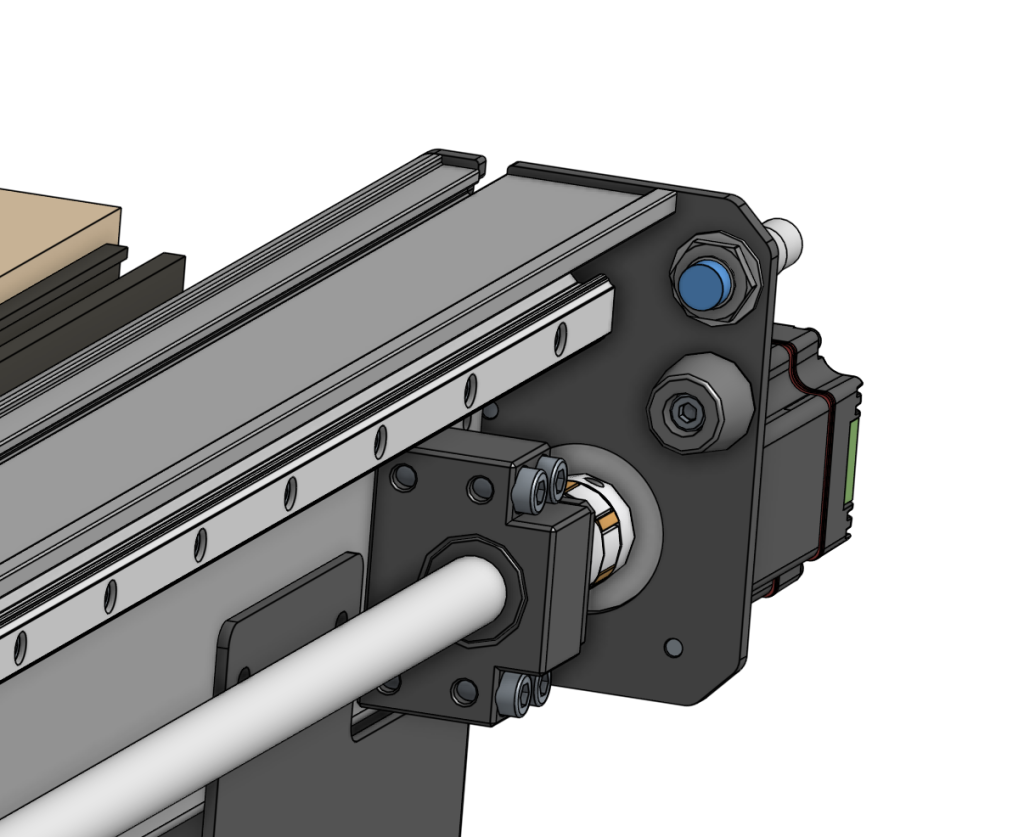

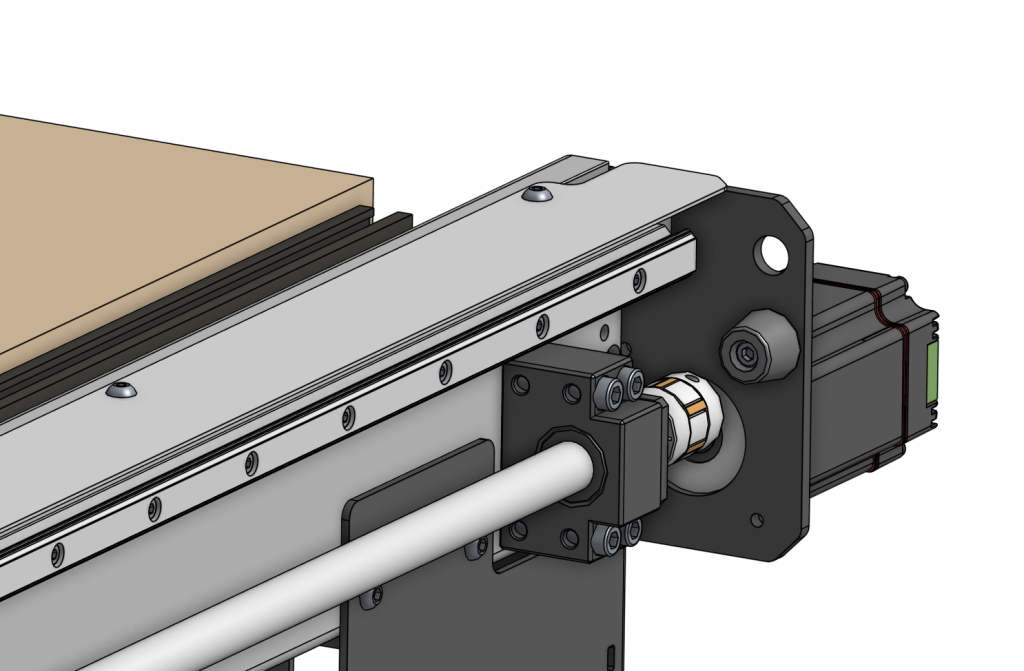

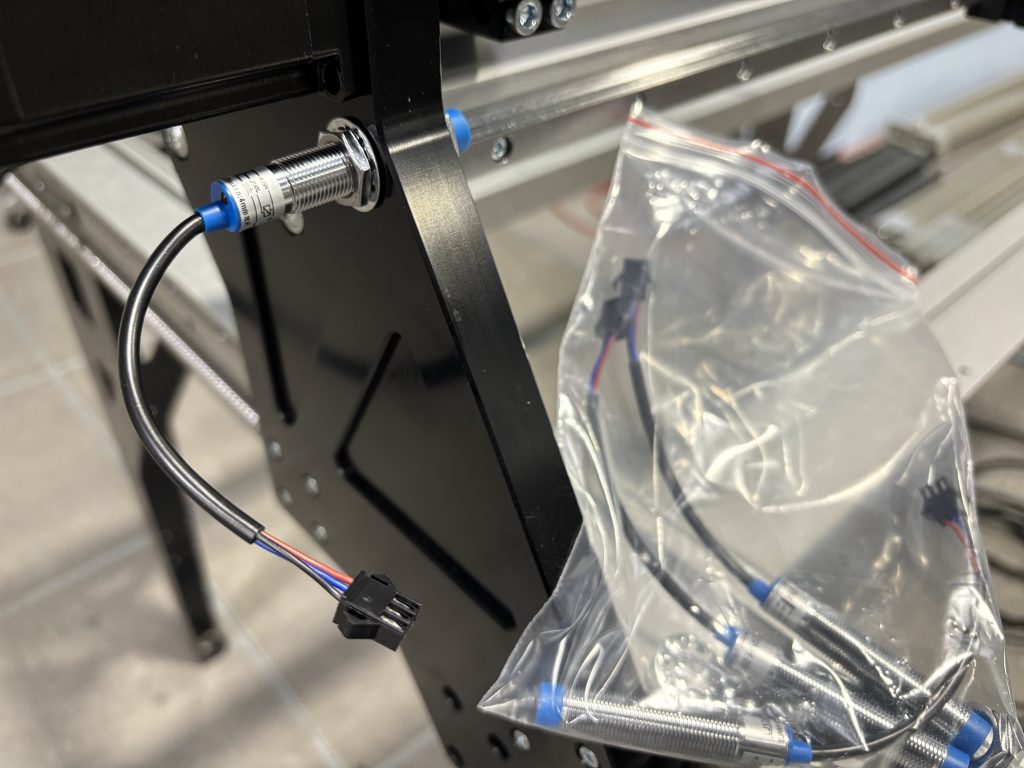

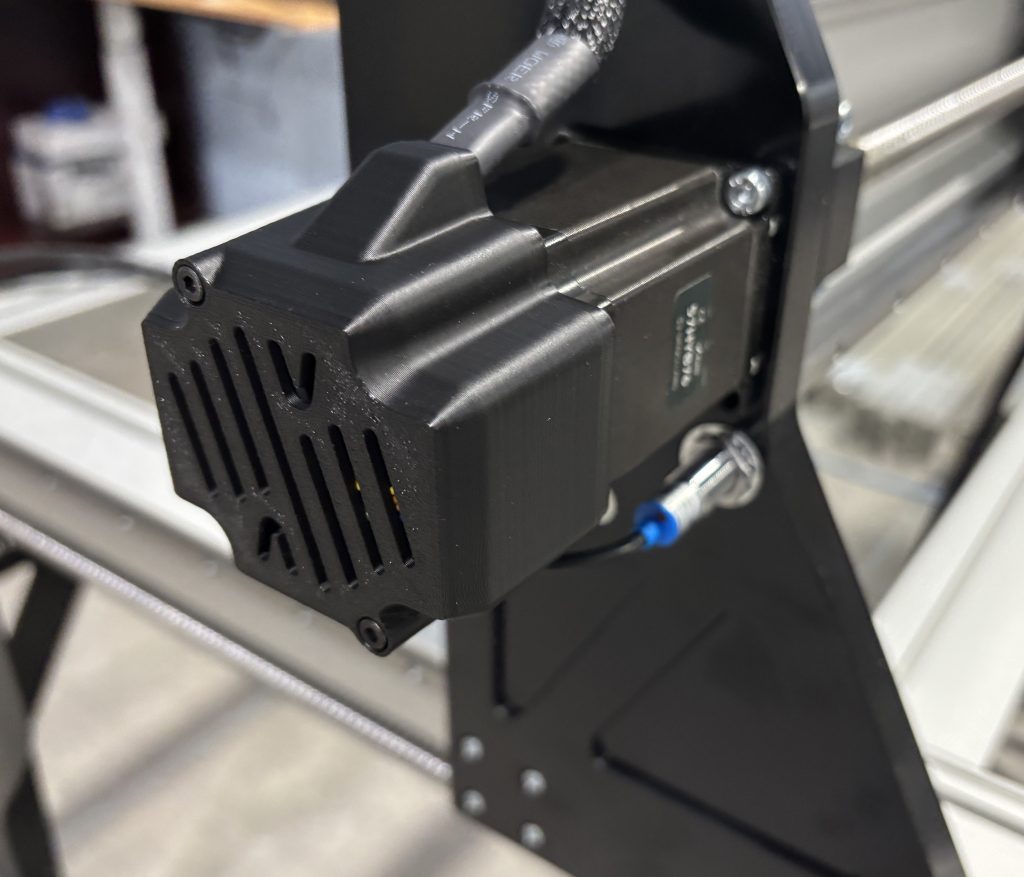

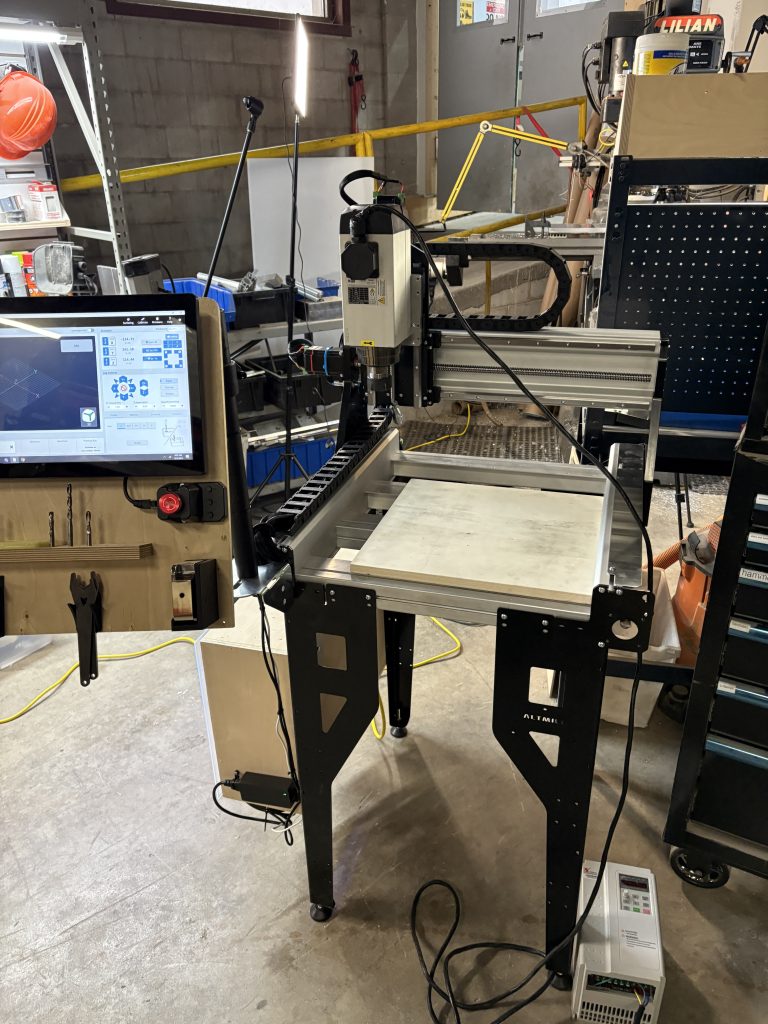

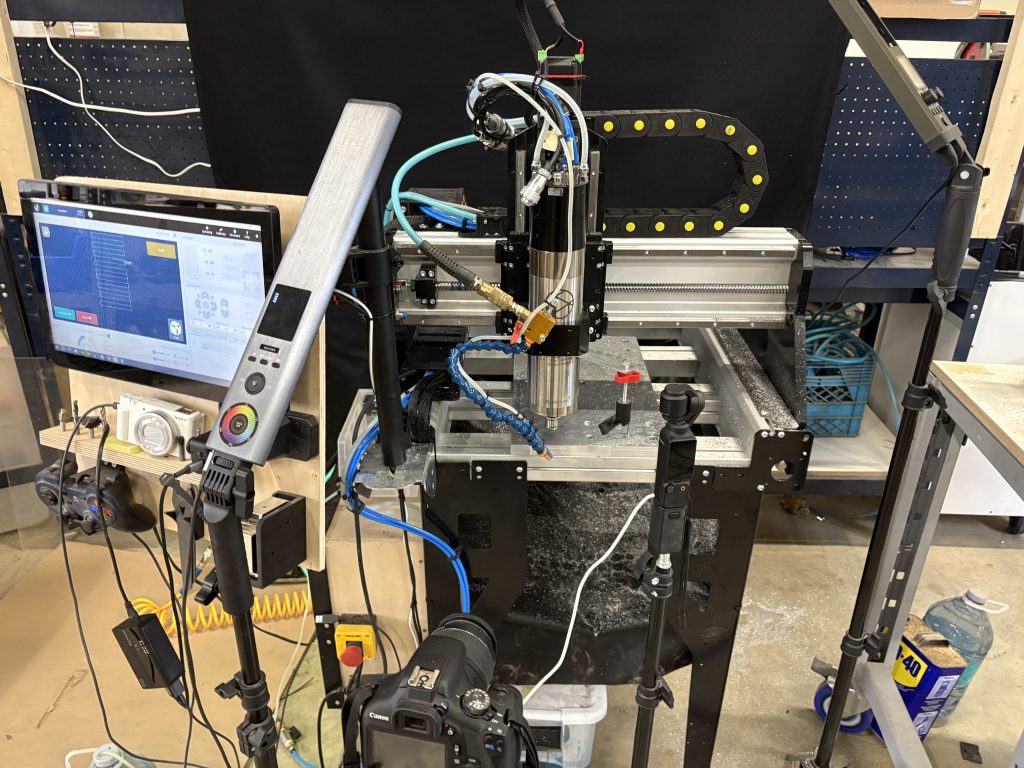

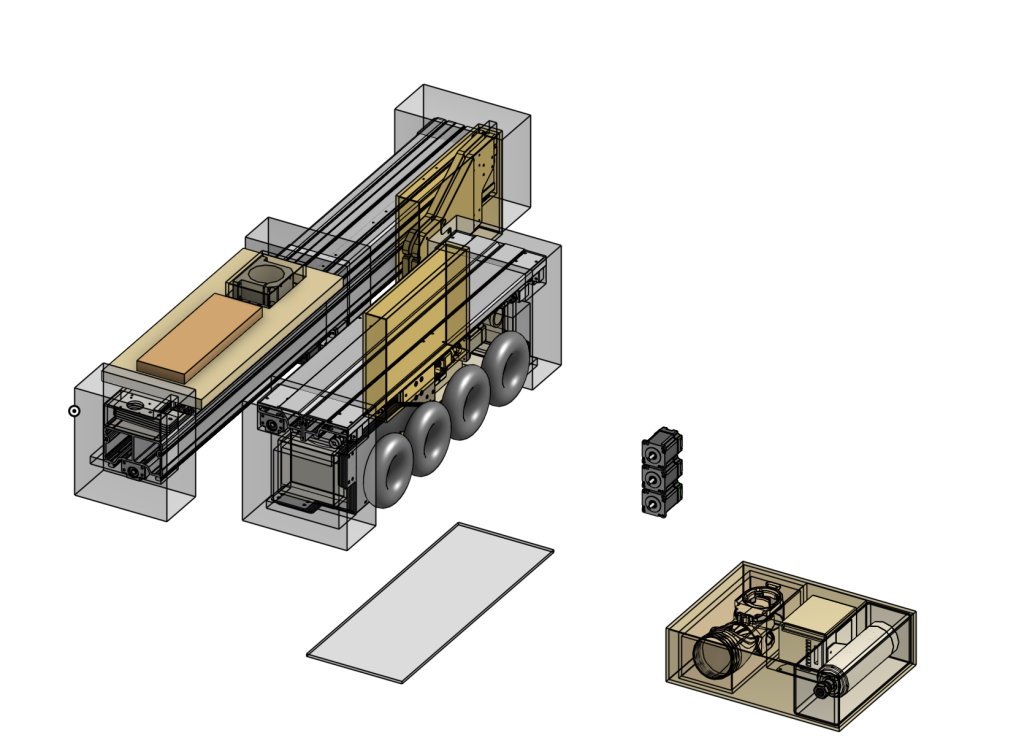

Thankfully, with over 400 AltMills currently in the queue, and with plans to complete shipping of all 400 units in the next 8 weeks, it is a relief that we won’t have to face significant costs for the customers who ordered prior to our changeover from paying duties and taxes on behalf of the customer to having customers pay for customs at import back in March 4th.

At the end of the day, we are still trying to catch up with demand, and we expect lead times for AltMills to be long for some time. While in the short term, sales may be slower than what they would be without the trade war, I see this as an opportunity to catch up on our queue and focus more on our production side without being overwhelmed by sales. The plan is to prepare ourselves for another wave of orders for CNCs once the trade war resolves or find ways to restrategize around it. Additionally, while sales may not be where they could be, I would note that we have still seen a 50% growth in revenue between 2024 and 2025 year to date, allowing us to save some money to adapt to changes in the market.

It’s also important to remember how dynamic the economy is, and we should also consider:

- If demand for parts and products needed for our manufacturing drops across the board due to tariffs, will we be able to get lower pricing on materials?

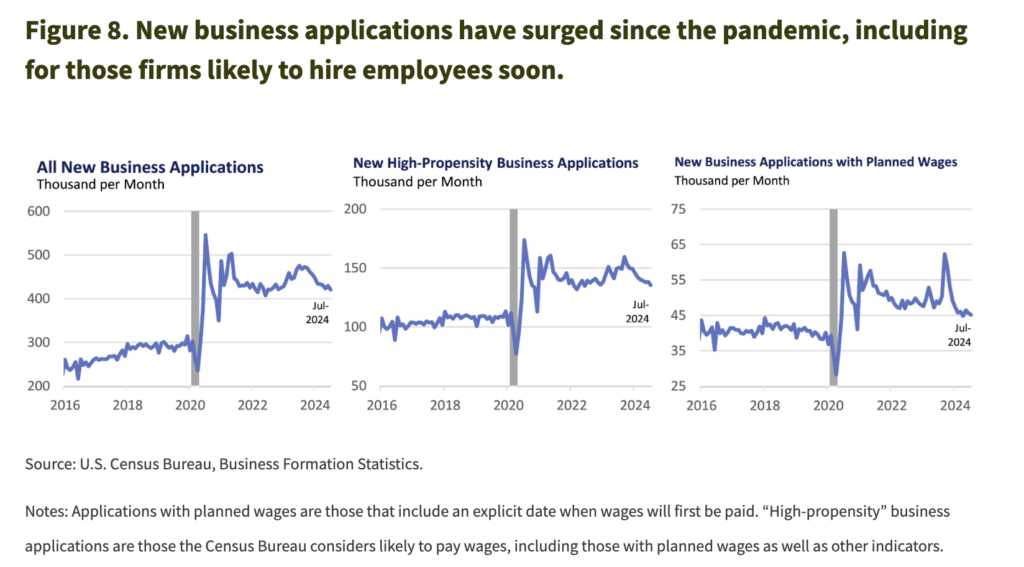

- Will we see people lose jobs and move to start businesses instead of choosing to find new traditional work?

- Will labour costs in manufacturing go down or stay stagnant to allow for products to be made more affordably?

- Will some of our competition falter, growing our market share and dominance?

Even though in one area costs go up, the overall impact might be offset by other factors in the market.

In the long run, as long as our company stays diligent in development, production, and scaling, we’ll be able to weather the ups and downs of the economy. Canada continues to fight back in the trade war with reciprocal tariffs, and has continued to hold them in place until the US drops their tariffs as well. I expect this to be the case until the end of the trade war.

Confusion at the border

With such dramatic and fast changes, we’ve seen an uptick in customs and border issues. While we’re able to clear most shipments without a tariff, a number of customers have been charged incorrectly. Thankfully, with our direct contact at UPS, we’ve been able to resolve issues and have UPS issue refunds for shipments that were not cleared properly.

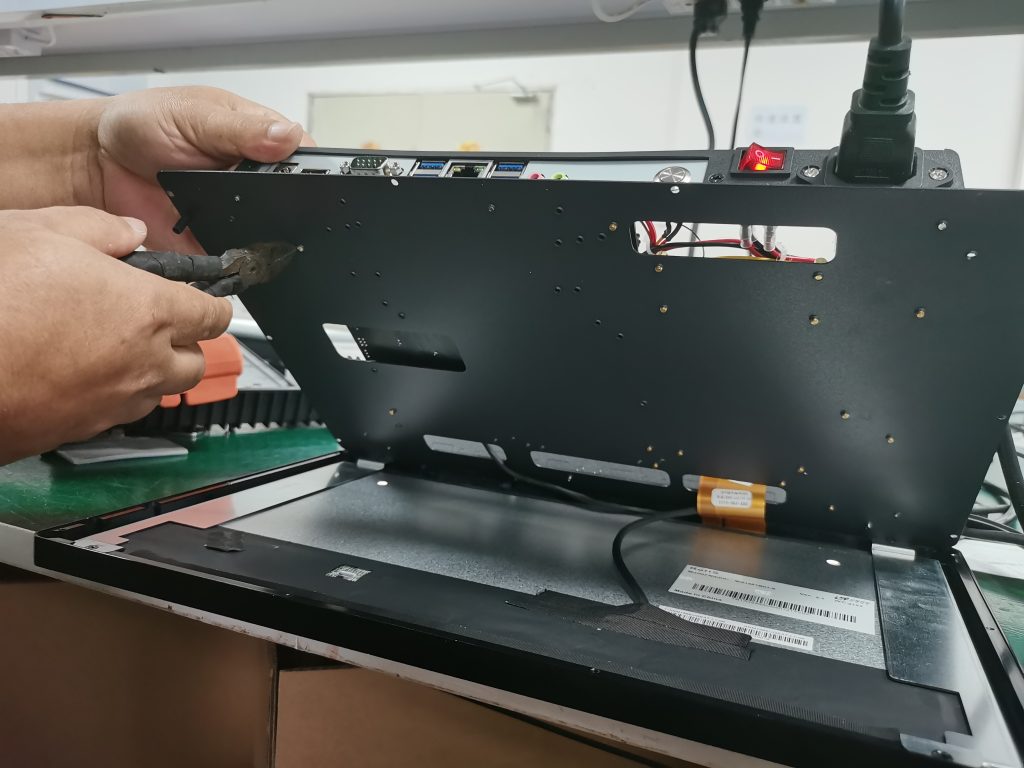

The fact of the situation is that much of the customs brokerage system is manually done and prone to error. While we do use EDI (electronic data interchange), which significantly streamlines the process, and as far as we understand, specific people in the UPS brokerage department are assigned to handle our shipments, human error can still happen.

If you run into issues with customs, please feel free to contact us, and we can help you resolve them.

Moving forward

We have been working with customers directly to help them navigate the tariff situation. It should be noted that at this moment, as long as products fall under our USCMA certification, they can cross into the US without tariffs. You may want to make a buying decision based on this.

We have now received parts to make a big push to clear the existing waitlist of customers. However, even as we ramp up production to 200 units per month, customers who place orders today will likely need to wait till June or longer to receive their orders. The situation may be different or change. For customers who are unwilling to pay tariffs, if the USMCA exemption is removed, we are advising customers to either place orders now and cancel their orders if a tariff is put into place, or wait until the trade war is over.