Midwest Reprap Festival coming up soon! Hosted in Goshen, Indiana, The MRRF brings thousands of makers around the world to share their reprap (replicating rapid-prototying) projects. We’ll be there to show off the Mill One all the other awesome projects we’re working on, because we love 3D printing too.

This is the first time we are attending MRRF and we are super excited to be there this year. Will we be the only desktop CNC company there? We’ll see!

Want to attend? Admission is free, sign up for a ticket here: https://www.eventbrite.com/e/2017-midwest-reprap-festival-mrrf2017-aka-mrrf-tickets-28382784673

Read more about previous years on Hackaday: http://hackaday.com/tag/midwest-reprap-festival/

Schedule:

FRIDAY March 24, 5pm – 10pm

Setup day and hangout day as in past events, with many people showing up and bringing in all their stuff to show off. The event hall will open at 5pm and stay open until 10pm for setup for anyone coming to attend. If you’re just coming to walk through you’re welcome to come friday as well! Plenty of hang out time and meetups on Friday. Feel free to wander out and grab food then come back and hang out.

SATURDAY March 25, 10am – 6pm

Doors open by 10am and let the show begin!

SATURDAY March 25, Noon – 6pm

We’ll have speakers and presenters throughout the day starting at noon giving talks on all things 3D printing and/or related.

INTERESTED IN GIVING A PRESENTATION? CLICK HERE TO SIGN UP

SATURDAY March 25 7pm-9pm

Dinner for all registered attendees. Chinese Buffet is where it’s at again, so come hungry!

SUNDAY March 26 10am – 5pm

Doors open by 10am. There will be FPV Drone racing outdoors weather permitting and a few more presentations this year on Sunday. Event ends 5pm and load out/cleanup afterwards.

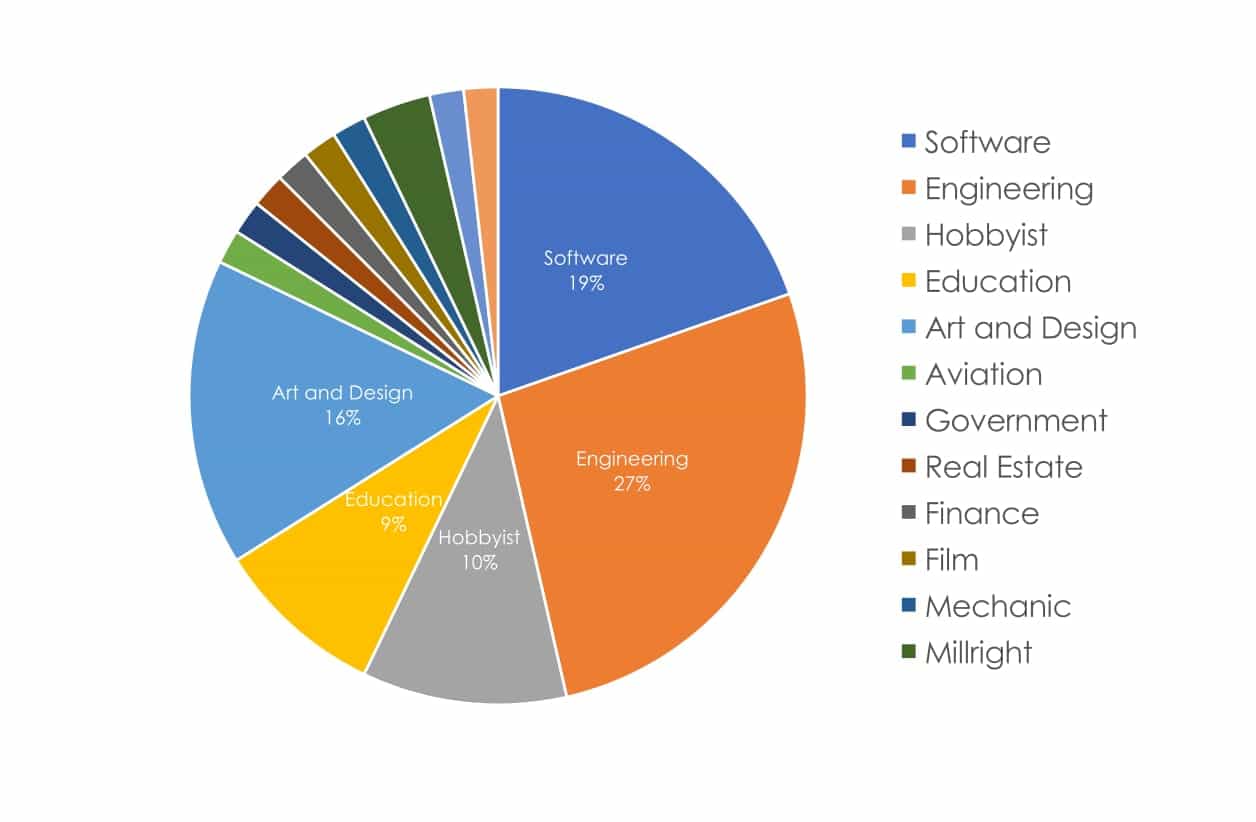

As you can see, most users are in engineering, followed by software and art and design. It’s pretty amazing to see the diversity in the people who purchased a Mill One.

As you can see, most users are in engineering, followed by software and art and design. It’s pretty amazing to see the diversity in the people who purchased a Mill One.