Hey there, here’s another month of production updates from Andy Lee, and our latest production video with even more info and updates.

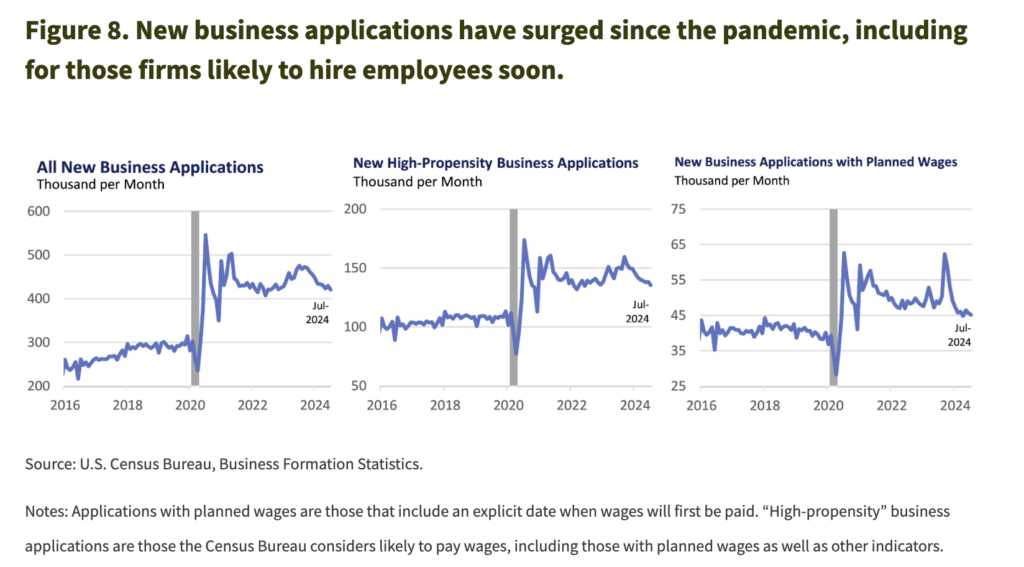

Tariffs

Tariffs continue to cause confusion. You can read more about the current situation here.

As referred in the article, we’re seeing an uptick in people who are running into issues with shipments to the US. We’ve been able to resolve issues without too many issues, but we are asking folks to be patient as we work through them. At the beginning, we had quite a few hiccups but we’ve been able to get through most of them and are finding issues are happening less frequently.

Unfortunately at this time we are finding a large number of shipments are getting returned to us without any obvious reason, which are slowing down our production rate. Although initially we suspected this to be due to incorrect customs documentation, even orders that have proper documentation and have historically been unproblematic are being returned.

What’s quite eye opening is DHLs suspension of shipments above $800USD to the US.

While this does not directly impact us at this time since we don’t use DHL, it’s a significant signal on the complicated customs situation. At this moment, all shipping couriers are under immense pressure to update compliance, and DHL is the first as far as I know which has folded under the new change.

It has been reported that Trump intends to change deminimis rules that originally allowed most goods under $800USD to enter into the US without duties and taxes on May 2nd. The implementation of this may have a crippling effect on all shipping couriers since all Chinese shipments will be charged the current tariffs or be charged with a $100 flat fee, whichever is higher. While deminimis rules will not change for non-Chinese goods, these changes will likely negatively impact the transit times of all goods.

48″ T-Tracks

To better support the AltMill line, longer 48″ T-tracks are now available! We’ve designed these more specifically (although you can use them in other machines or applications) for the AltMill, as it allows users to avoid having to join more than one track together when setting up their wasteboard.

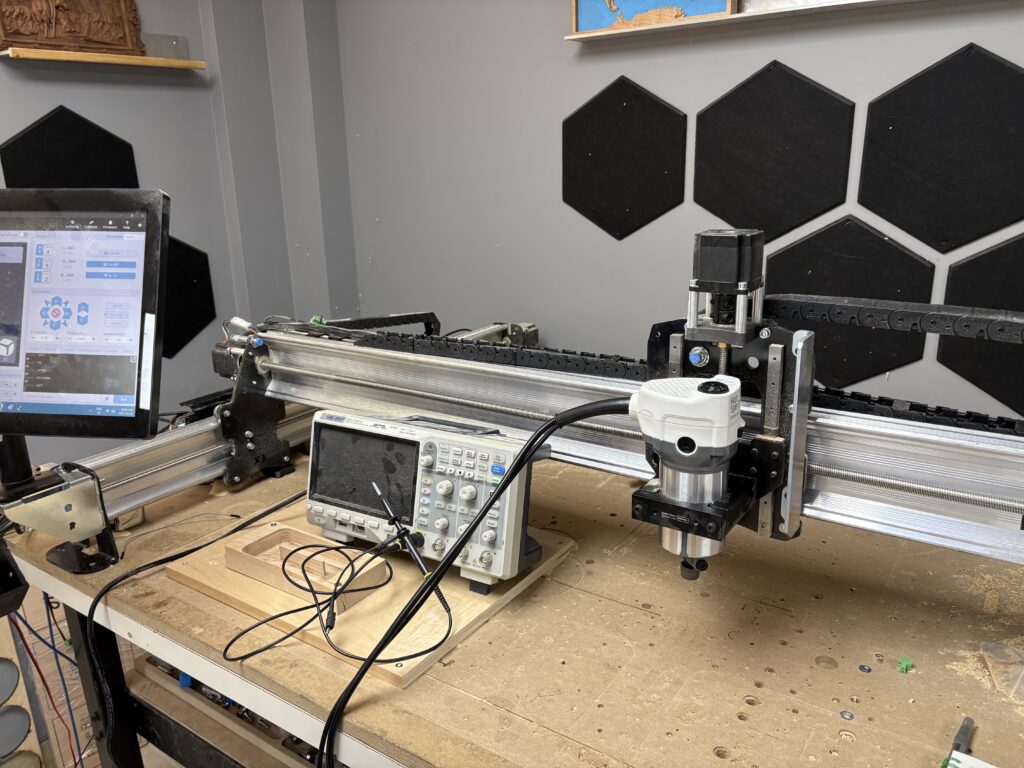

AltMill 2×4 and 4×4

AltMill 2×4 and 4×4 have started to ship this month and we are working our way through the queue! We’re expecting to ship another ~200 AltMills this month to wrap up Batch 4. However, we’re expecting to be waiting on more parts to arrive come June to continue production on Batch 5. Batch 5 will be larger, with 750 units being built for this new batch. New orders for AltMill are expected to start shipping in June or July and will be part of Batch 5.

AltMill 4×8

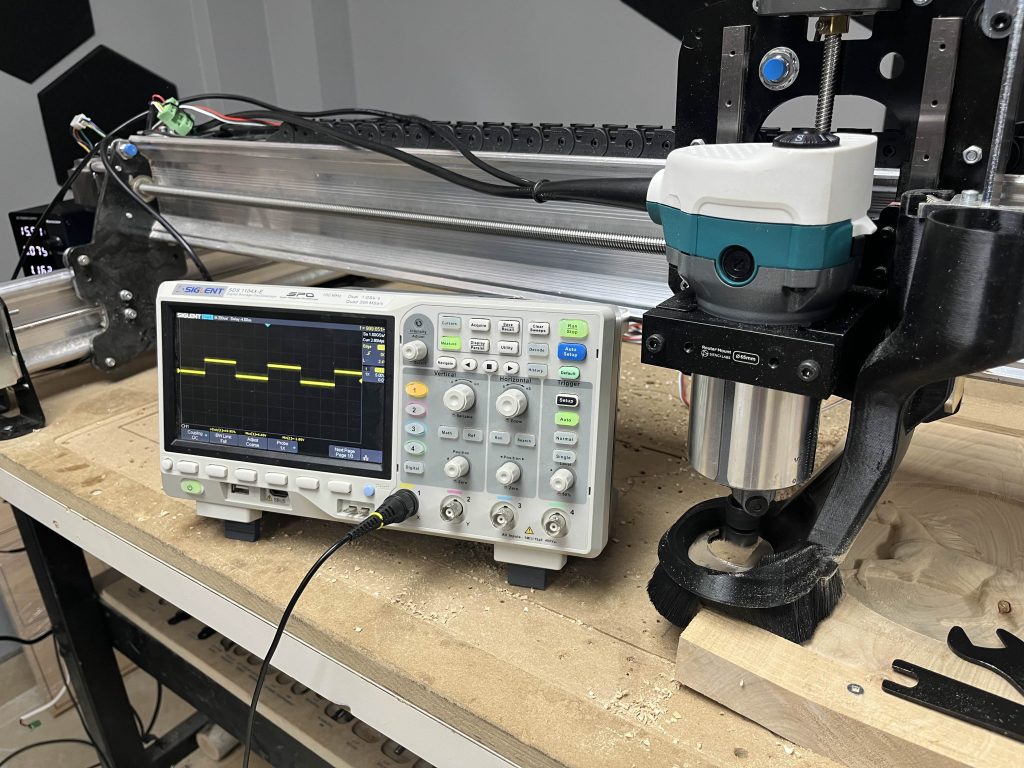

Although we’ve pulled back a bit with development on the 4×8 AltMill so that we can focus more on the production setup on the 2×4 and 4×4 AltMills, we’re continuing to make progress. We are currently working on a couple of things:

- Ordering and testing each type of rack and pinion system (different pitches, helical vs straight, etc) for precision and accuracy

- Considering shipping options for longer parts, such as the 9-10ft Y-axis

- Long term mechanical testing for reliability and wear

I don’t have too much news at the moment but expect to see some more things to come down the pipeline as development continues.

LongMill

LongMills continues to ship without delay. We expect existing stock to remain until this fall.

What is notable is a jump in aluminum extrusion costs, around 21%, from our previous batch in December. From what we understand, this jump comes a combination of a change in demand for North American manufactured aluminum parts, tariff pressures, and layoffs and lost jobs in the aluminum raw material production sector. We are not planning to adjust pricing to reflect this at the time. However, we’re keeping an eye out on aluminum prices

VFD Certification

In our last production update, we mentioned that we were looking into proper certification for the H100 VFD. Prior to this, we were purchasing the VFDs from the same supplier as the spindles. Since they are not the manufacturer of the VFDs, we were told that the VFDs could not be certified. During Johann and Daniel’s trip to China, they were able to track down the original manufacturer, and not just that, able to learn that the H100 line was certified in 2022, but the certificate expired and was not renewed. This give us a lot more confidence in being able to certify the VFDs, as we don’t believe there to be any significant changes between the 2022 and current version of the H100. This also brings us to two longer-term potential directions. We are in talks about renewing the certificate, but we expect this process to take a couple of months.

This means that we can start providing the stock H100 VFDs, pending certification approval with ETL or UL equivalent certification. This may help open up markets that require more regulation, such as in schools and institutions that may need specific certification.

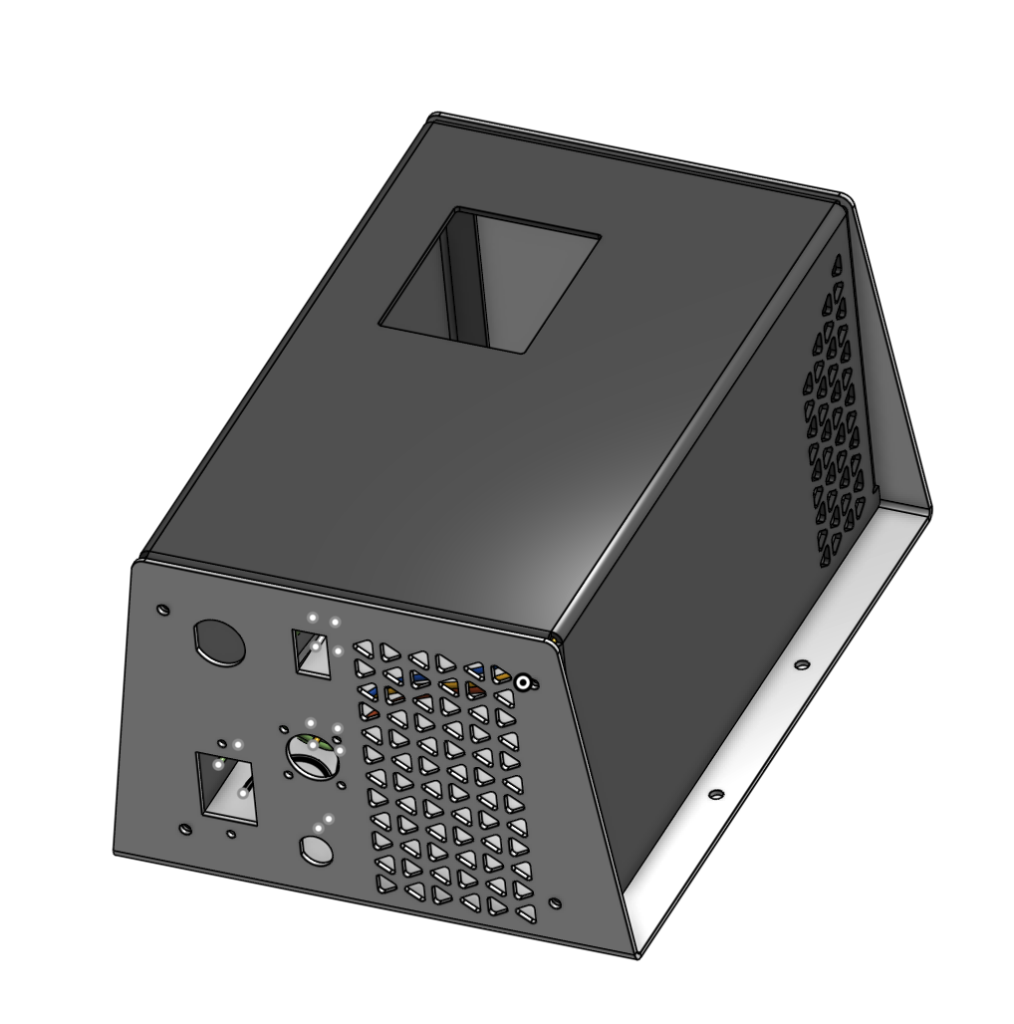

Additionally, with our new knowledge of VFD and spindle design, we have been working on VFD enclosures and systems that may improve the wiring and installation of spindle kits in general, which this manufacturer is willing to work with us on. We’re working on some VFDs in-house now that will have SPE1000 certification for compliance that should be similar to a new design that can be manufactured in China or here. We are expecting to have inspections done on these devices in the next few weeks.

2.2KW Spindle

Somewhat related to the VFD-related work we’re doing, we’ve been also working on figuring out what to do about offering the larger spindle options. Here’s the situation:

- For customers who only have access to 120V power, the 1.5KW is the most powerful option we can offer due to electrical limitations that come at that voltage. However, 1.5KW, while acceptable for the majority of cases, doesn’t unleash the full potential of the AltMill.

- To be able to provide more performance, we must use a higher voltage. 220V and 3-phase are generally considered the most common options, with the 220V being a lot more common for residential use. This allows for power over around 6KW.

- Once you get above a 2.2KW spindle on 220V, the size of the spindle also increases, which makes current dust shoes and spindle mount for AltMill not fit. This means these parts need to be redesigned.

This is our current plan – while we are still working on the higher power spindles, because 2.2KW 220V spindles are so readily available, it’s an option we can provide with little additional development. So we’ve went ahead and ordered a few hundred in the meantime as a stop gap for a potential larger option.

Wrapping into the VFD discussion, we ordered the 2.2KW spindle motors themselves but we are still working on a few decisions around the 2.2KW VFD as well. This means that although we will get the spindle motors first, we won’t be able to ship full systems until we get the VFD as well.

AutoSpin T1 Router

We’re excited to share that the beta testing phase of AutoSpin T1 Router has been successful. Johann and Daniel also went to visit the factory which will be manufacturing this product and start the production soon. We are going through the first phase of safety inspections which is expected to take around 20 days, then we’ll start a production cycle for around 2000-3000 units which is expected to take about 50 days.

This should put us somewhere in the summer for having the product ready to ship.

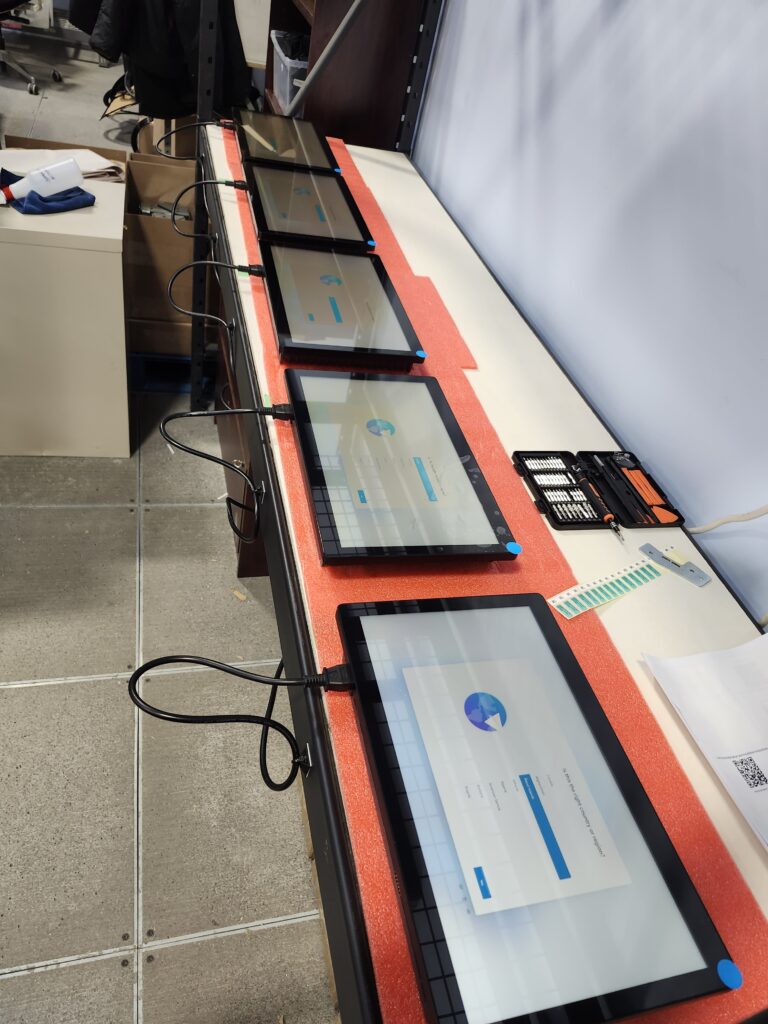

gControl Panel Computer

We have continued to ship gControls this month without a wait time. However sales have continued to increase and we expect stock to run out around the start of June. A new batch of computers are currently on order and is expected to arrive mid-June, so we are not expecting major changes in ship times moving forward.

LaserBeam

I forgot to mention this in the video for the production update but I’ll mention it here. We have completed selling the stock we have for the LaserBeam and have currently put the product sales for this on pause. We still have replacement parts available for service to support current customers, which are available on the store.

For those who still want to add a laser to their machine, we full support the majority of laser diode modules from other manufacturers. Resources for this can be found here: https://resources.sienci.com/view/slb-manual/#laser

I felt that after a few years of LaserBeam sales this product is due for an update to make it competitive in price and power to new developments in the laser space. We have it on the roadmap to work on in the coming months so keep an eye out for news soon.