Hey everyone, welcome to our June 2025 Production Updates. Here we go!

A lot of development continues to happen, so some of these are updates from previous blog articles. If you want more context, make sure to check out our blog for our monthly production updates.

Order Status Page

I’ve been seeing a bit of chatter about the Order Status page. I just want to reassure everyone that no one is skipping the line, unless you are a big-time content creator (at the current time, Hamilton Dilbeck and Ryan Drapela are the only people who have received their machines early for marketing purposes).

We get bribed a lot by individuals to skip the line. We will never accept these.

There can be discrepancies that make it look like the order of which machines are being shipped don’t look like they are in order. Here’s how that can happen.

- The specific variant of the order has a different shipping schedule. For example, the 2×4 and 4×4 AltMill are built on different schedules, but they are both on the order page.

- The order isn’t fully complete. If the order is partially shipped based on part availability, the order will not show as shipped. This can create gaps between each order on the list.

- The customer asked us to put their order on hold.

We do our best to ship based on the order of which they are placed. There can be some variation sometimes, for example, if we can batch the products together, so we build all of the 2x4s in one go for example, we can reduce the overall average time to ship units because we don’t have to go back and forth with setting up production stations constantly. While it may throw out the order a bit, overall we expect for people to get machines quicker this way, which I think is a reasonable tradeoff.

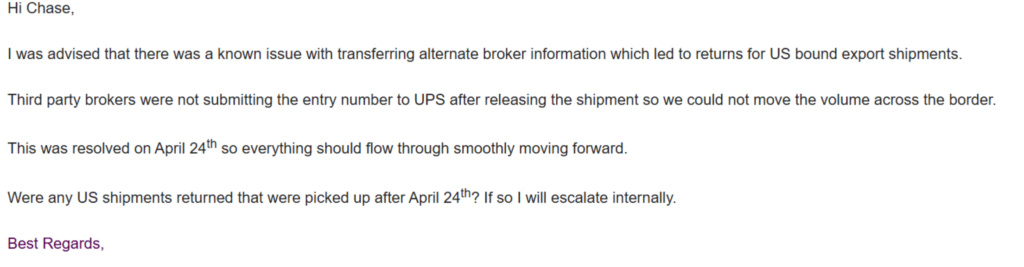

Tariffs

As referenced in the previous update, we had been experiencing a lot of shipments being turned away at the border. One of the changes in the process was that all shipments in a truck crossing the US must have customs pre-cleared before it can enter the country, and any truck that had even a single item without proper clearance would be turned away. The below email references issues causes by some 3rd party brokers which appears to be resolved recently.

Shipping seems to continue to be a bit of a mess, but generally speaking, the issues have reduced a lot since the tariff war. Fewer orders are getting shipped back, and more are clearing without issues.

Starting April 23, we’ve also re-updated our shipping system to note DDP for all US-bound shipments. I should also note that most US-bound shipments prior have also been changed to DDP as well. For those who don’t know, DDP (delivery, duty paid), designates the shipment to have any duties and fees charged to the shipper (us). We used to have DDP set up, but during the trade war, we changed it to DAP (delivered at place), which would have the receivers (you) pay duties and fees. Since we are able to clear pretty much all of the shipments without duties and tariffs, we’ve reverted to this. Some customers were being charged brokerage fees and tariffs, even though they shouldn’t be, and it seems to be happening to other folks, not just in our company. We are helping customers get refunds, but now that we have changed things to DDP, any refunds will be able to be processed just through us without customer intervention.

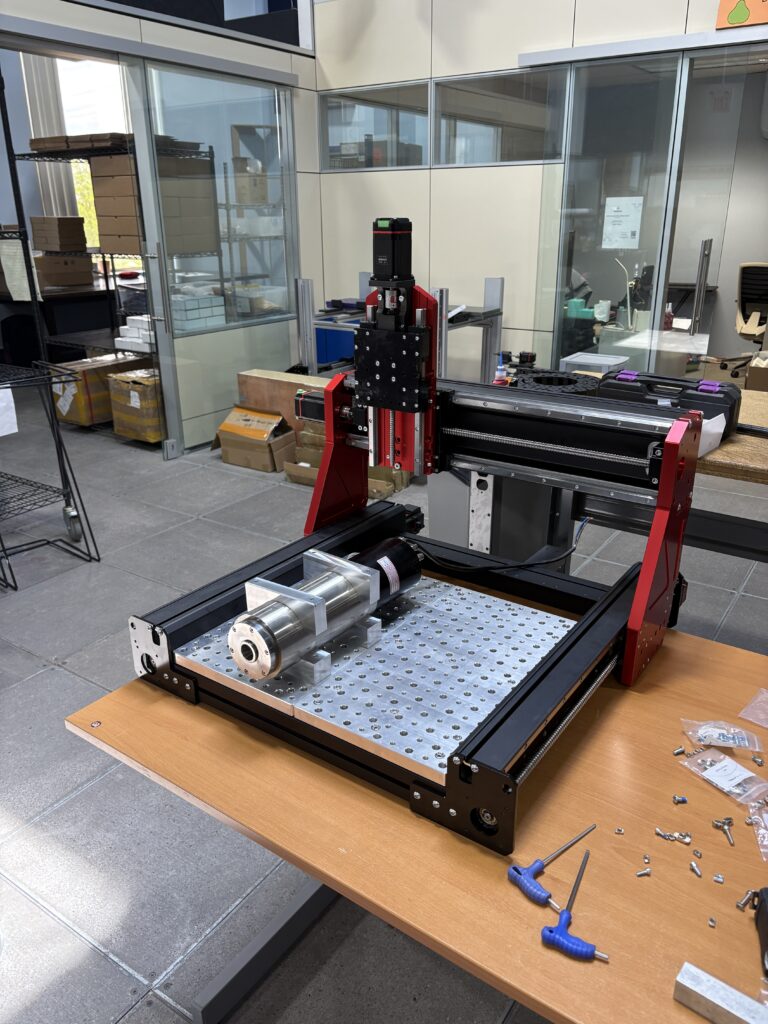

AltMill

First off, we’re excited to share that the AltMill MK2 assembly video is now available!

Some folks were also confused about what batch their order for the AltMill is in. For the customer, it should not matter because the machines between Batch 4 and 5 are the same, and we don’t have a specific delineation for orders between the batches. However, if you ordered your AltMill around mid-April, there is a good chance that your order is in Batch 5. We expect to complete shipping Batch 4 at the end of this month the start of June.

As mentioned in the last blog post, we expect Batch 5 to start shipping in July based on the arrival of additional components. Our team is working to update the order status page based on updated news on parts arrival as shipping dates approach. Please have patience as these days may vary a bit based on the continued news. We are continuing to pre-assemble parts to prepare for another large push of shipments in the next coming weeks when everything arrives.

We have started building some of the 2×4 AltMills as well. The shipping for these may be a bit sporadic since we need to switch back and forth with the 4x4s. This may contribute somewhat to the spottiness of shipping on the Order Tracking list as well.

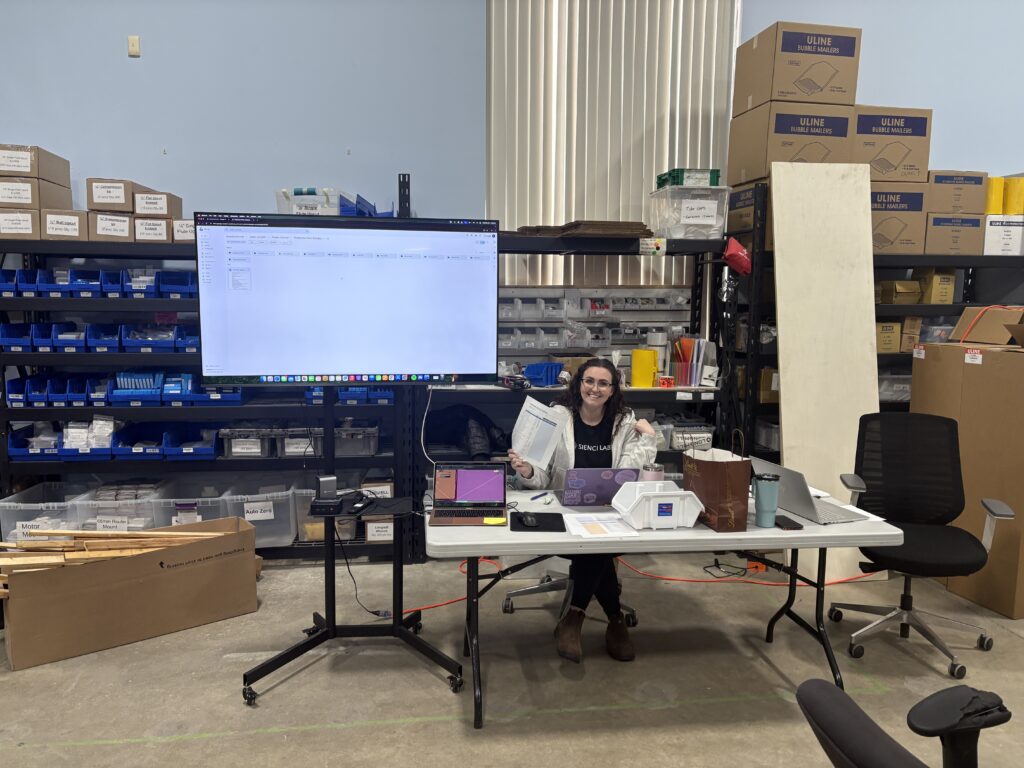

We’ve brought on a number of new packing staff and implemented additional production hours towards clearing our queue. Michael and the rest of the production team have continued to accelerate our production significantly, with this past month having shipped around 180 AltMills. While it feels like we’re making little to no progress (perhaps it even looks like we’re slowing down), we’ve doubled our production volume in the past 6 months, which is a significant achievement for the team. Unfortunately, or perhaps not unfortunately, as we’ve accelerated shipping, we’ve been met with an accelerating volume of sales for the AltMill as well, offsetting our gains in scaling up production and where we are with decreasing lead times.

As mentioned in the previous update, we’re waiting on shipment of components for another 750 units, and our supply chain team is also working to prepare components for an additional 750 units to arrive in the fall. This is an aggressive amount of purchasing as we are working to eliminate parts availability as one of our production bottlenecks and prepare ourselves for the peak season for sales in the fall and winter.

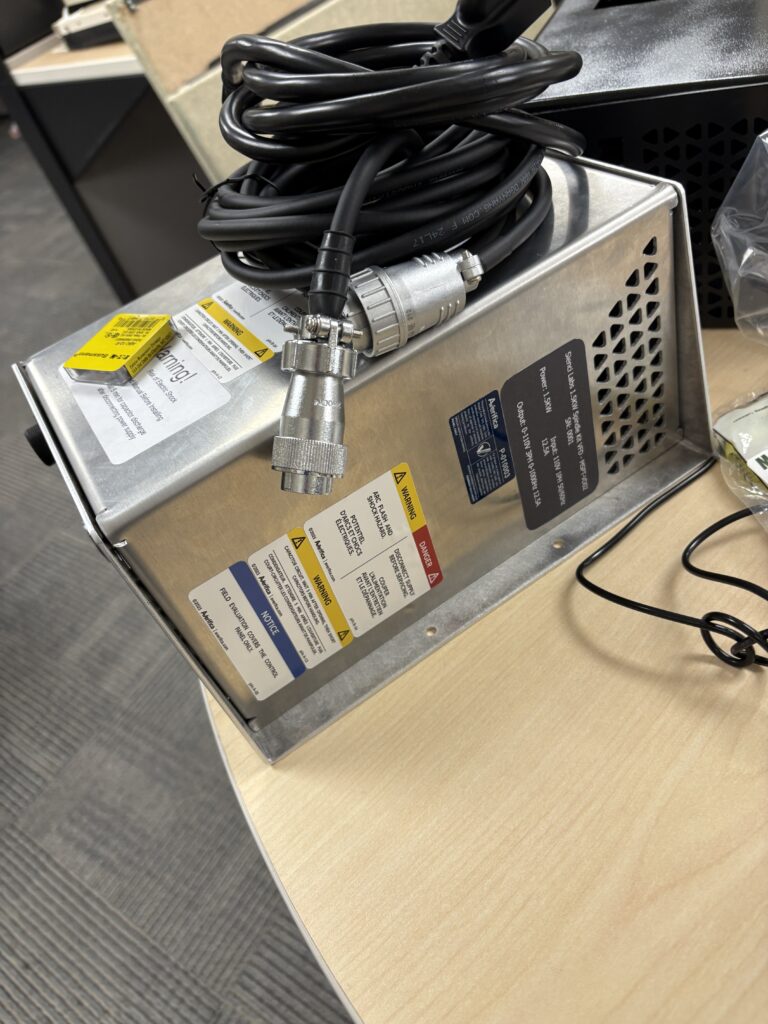

VFD certification

Adding to last month’s news, we’re excited to announce that our first VFD was certified on May 5th and we are now going through the process for building a new batch.

If you ordered a spindle in Ontario and are still waiting on it to ship or are waiting on a replacement, then we will switch to this option automatically for no extra charge. For customers who are wanting to order a spindle for the Canadian market, these will be available as well, albeit at a slightly higher price than the non-certified option.

In somewhat good news, as we continue to work on the development of higher power spindles, we’re finding that we are able to build different variations while keeping the same casing and form factor, which we expect will make upgrades and replacements much easier in the long run. Additionally, since we know that our base design is compliant, we expect future safety approvals to be much faster and straightforward.

As of time of writing, we’ve started getting our first batch of sample components for our testing and finalizing some design and wiring processes as we prepare for our larger batch of manufacturing.

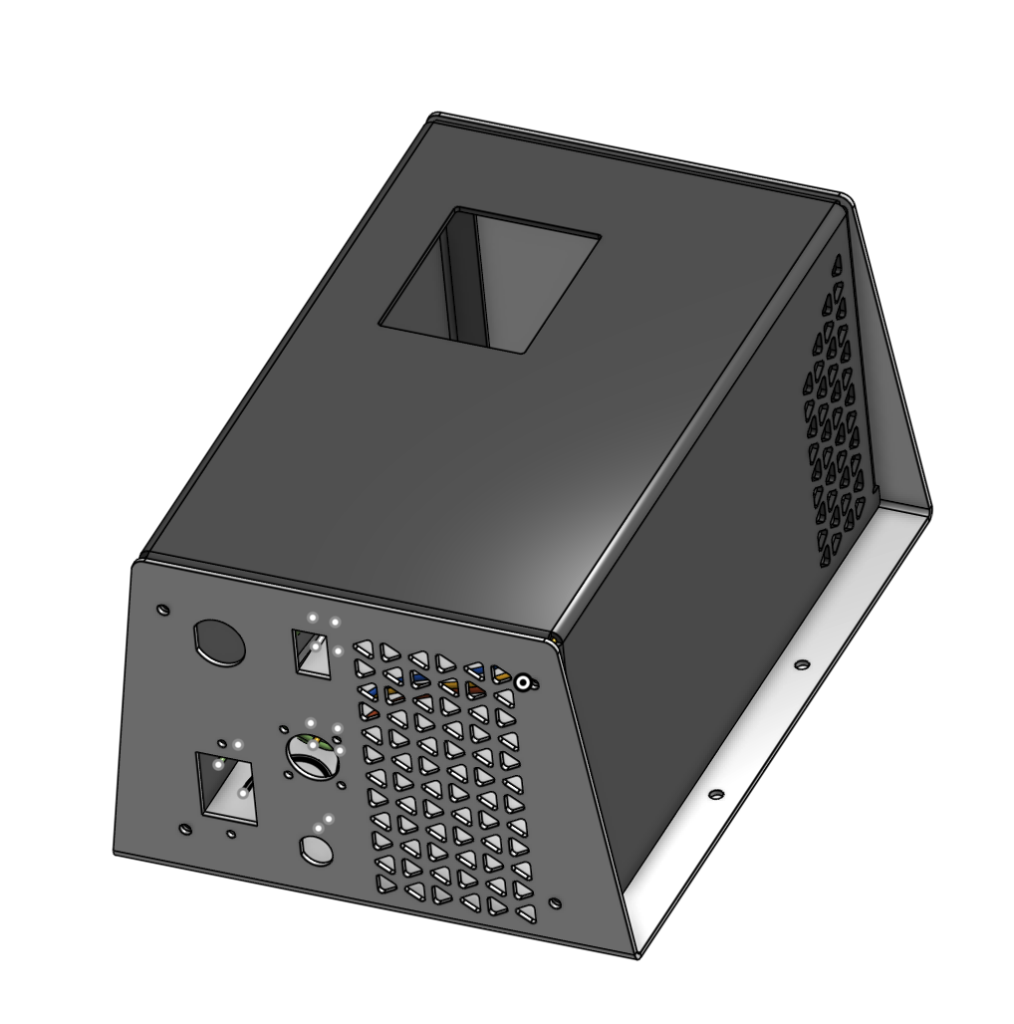

Auto Tool Changer

As we’ve alluded to previously, we’ve been working on a tool changer solution for the AltMill. While ATC is community supported, we currently don’t have official support and resources for this yet and likely a bit complicated for the average user.

We’ve now received several ATC spindles which we’ve been testing with different tool holder sizes and body types.

Of course there is a ton of consideration being put into place as we continue developing an ATC solution, including:

- What power spindle do users need

- Placement of tools and toolholder

- Toolholder fork design

- Pneumatics requirements

- Dust shoe compatibility

- Software interface and user experience

At the end of the day, we want to make sure that we have a product easy to use and accessible to both beginner and advanced users, and while we could be putting out a product for the sake of it, we’re focusing a lot of effort in making a product traditionally quite complicated into something simple.

AltMill 4×8

We continue to work on AltMill 4×8 development. Want to help us make some design decisions? Check out our survey below:

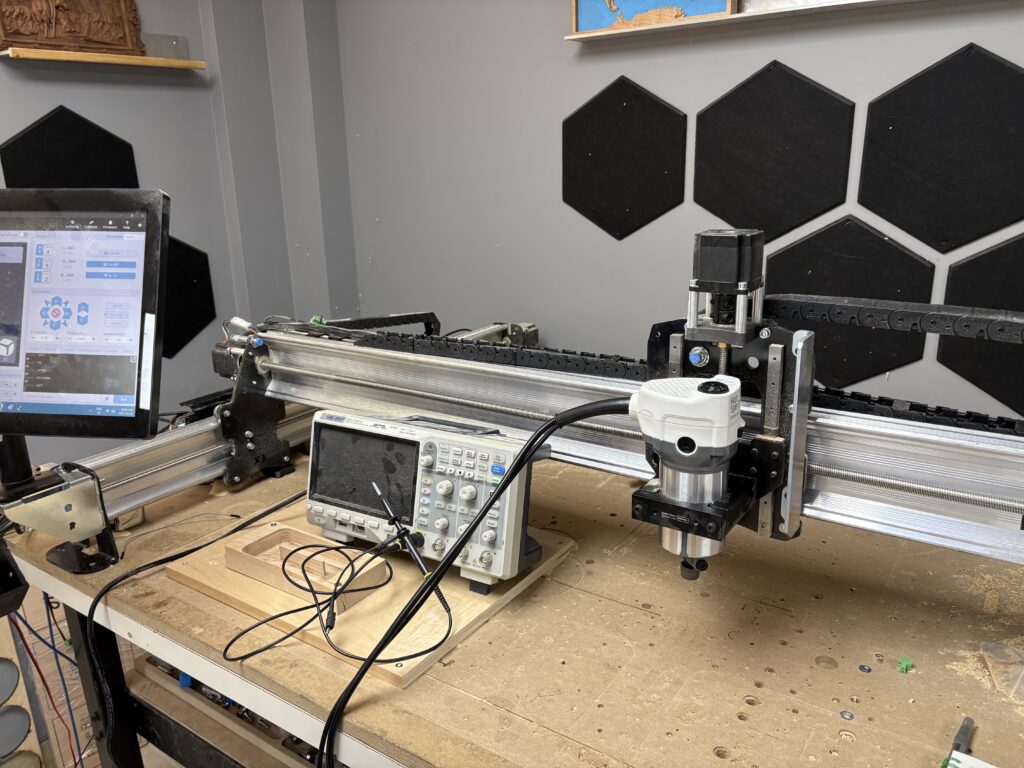

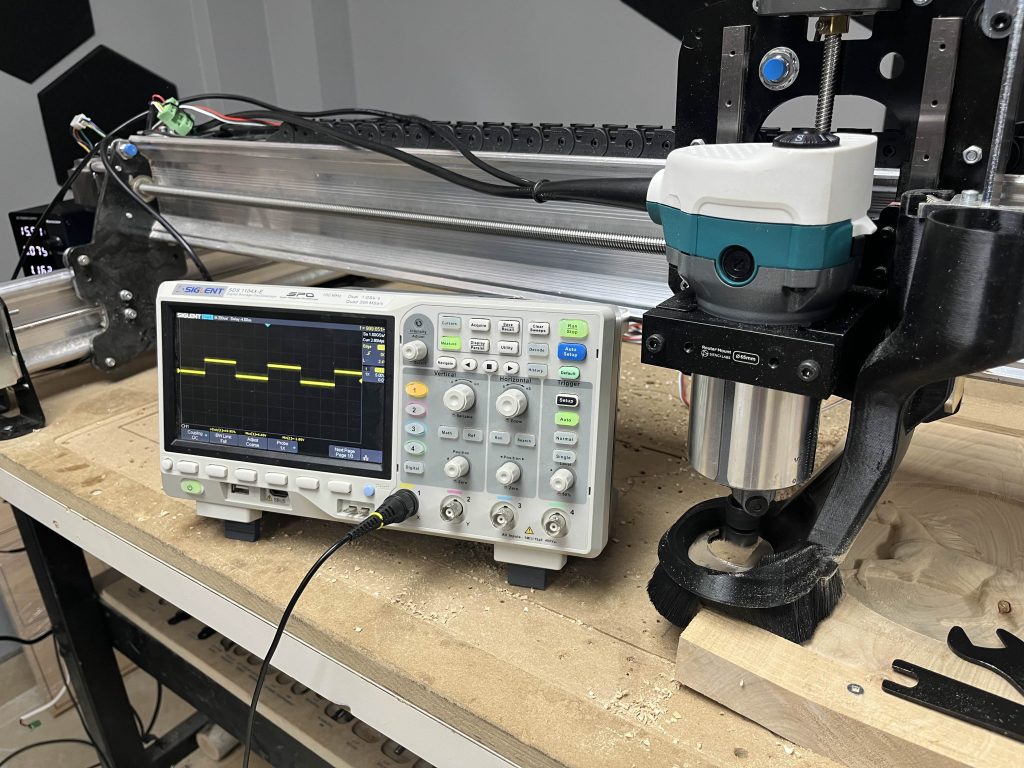

Much of the work so far has been around improving the rack and pinion design. While we’ve made great progress already in the design, we’re trying to reduce backlash in the system as much as possible. This has been in the way of testing different systems such as direct drive, using a pulley system, and gears. Reducing backlash is important as it will affect the dimensional accuracy in parts, especially in the Y direction. We’re also researching and playing around with motor tuning design to optimize between performance and accuracy.

We’re also working on designing the machine to reduce the overall footprint, especially focusing on the stickout from the motors. Additionally, we’re also looking at optimizing the form factor and design of the machine to make sure that the ATC placement is optimal.

We’re expecting some of the prototype parts to arrive in June or July, which should allow us to build and test early stage prototypes, and we’ll continue to work on and test smaller scale versions over the coming weeks.

We’ve gotten a lot of questions on why we’re not using a rotating ball screw design. Simply put, a rotating ball screw design is more complicated and expensive, and since the ball screw needs to be one continual length, this makes shipping extremely difficult compared to rack and pinion. The fact of the matter is that most industrial CNC machines of this size use a rack and pinion. Although a rack and pinion design is not as accurate inherently, we don’t expect users to need as high levels of accuracy in a way that a ball screw is the only way to go. Just for context, we’re talking about a difference of dimensional accuracy of between the thickness of one or two sheets of paper. It isn’t a design we’ve completely eliminated, but in general, we believe that it’s drawbacks outweigh the advantages.

LongMill

We continue to ship LongMills consistently. To improve production efficiency, we are slightly increasing lead times to 7 to 10 days. We currently have parts in stock, however, to reduce the need to switch back and forth between production of the AltMill and LongMill, some days will be dedicated to LongMill production only so that we can stockpile completed machines and ship them as needed. This means that many if not most customers will get machines shipped sooner than the estimated lead time, but depending on the production schedule, it may take up to 10 days to ship.

AutoSpin T1 Router

The AutoSpin continues to make progress as we prepare for initial production. One thing we’re working on is further testing and resource development as we prep it’s use for common hobby CNC routers. We’ve found some small quirks for setup that we’ll make sure to address in the setup process for each machine. For example, users with a Onefinity machine will need to plug their router directly into an outlet rather than the relay controlled plug on some controllers.

We’re also working on the packaging and incorporating a couple important features, including containing basic information about the product, links, safety notes, while protecting the package. Additionally, to keep shipping costs as low as possible, we’re aiming to make packaging as compact as possible.

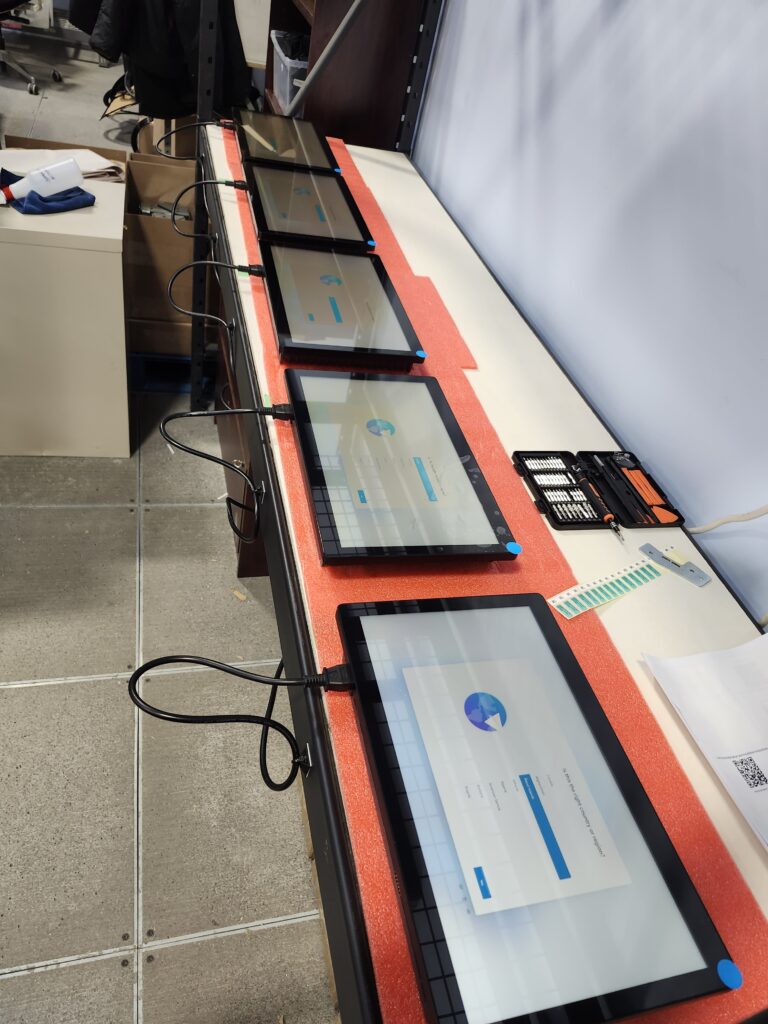

gControl Panel Computer

Production of another batch of 500 gControls have now completed and are awaiting shipment. We currently have around 70 more units, which means that it’s likely we’ll sell out of them before the new batch arrives. However, we don’t expect the delay to be more than a few weeks as the new batch should arrive shortly after the old one runs out.

Perhaps an exciting note to make is that gSender Edge (our early access version of gSender which eventually gets pushed out for the main version) now supports portrait mode. This means that users will be able to use their gControl computers in the portrait direction, just like the Masso controller. There are a few improvements that development is still working on, but features like “pinch to zoom” in the visualizer, have now been incorporated. If you’re interested in checking out gSender Edge, make sure to check out our Github.

In other news, Gilberto and the rest of the marketing team are working to release some new instructional videos to help users update, customize, and optimize their gControl experience, so keep an eye out for that soon!