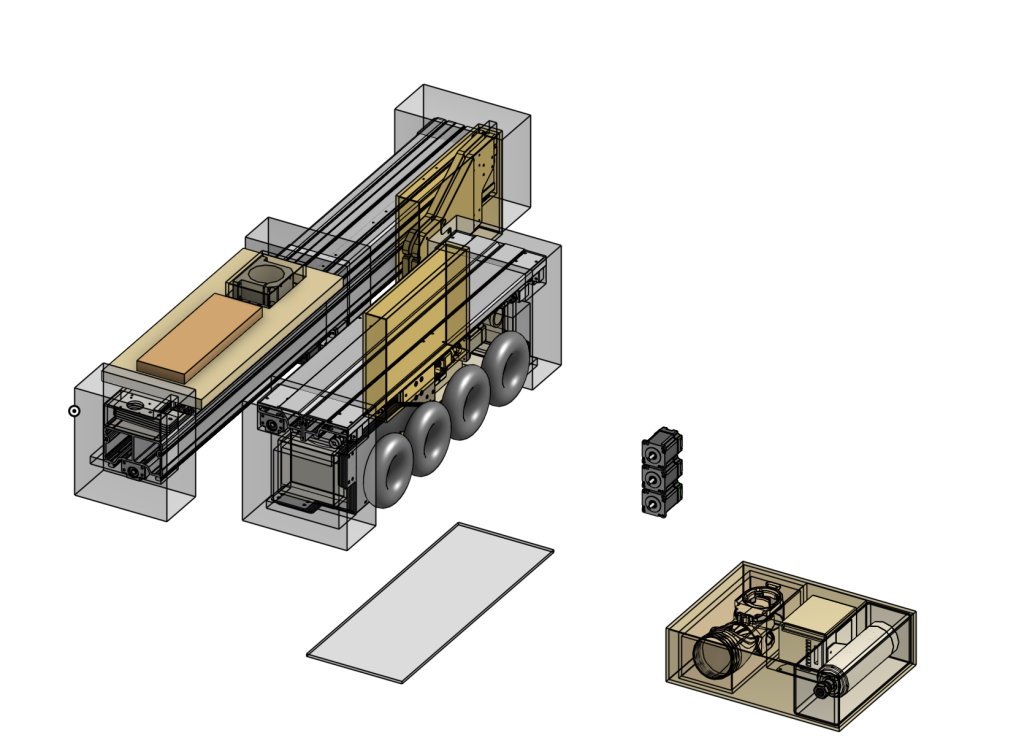

Hi there Johann here. First of all, a lot of the beans are already in the product page of the hybrid router, so go check it out if you haven’t already. Having said that, this is more of a “the rest of the beans” article, so if you’ve been following up on the Sprouter project for the past year and wanted more commentary, read on.

The road to the hybrid router

One day last fall 🍂, Andy came into work, tore open a Makita and asked if any of the engineers were interested in building a replacement. This was not that long after the pandemic and the then recent batches of Makita routers all had overheating bearings due to supply chain issues.

The goal was simple, to build a better (and ideally best) version of the Makita without the overheating bearings, and as a still naive engineer who is looking for something dramatically different after the Vortex project, I signed on to lead this effort. What a rollercoaster it has been since.

Not going to give a full account of the entire process, but here’s a couple twists and turns along the way:

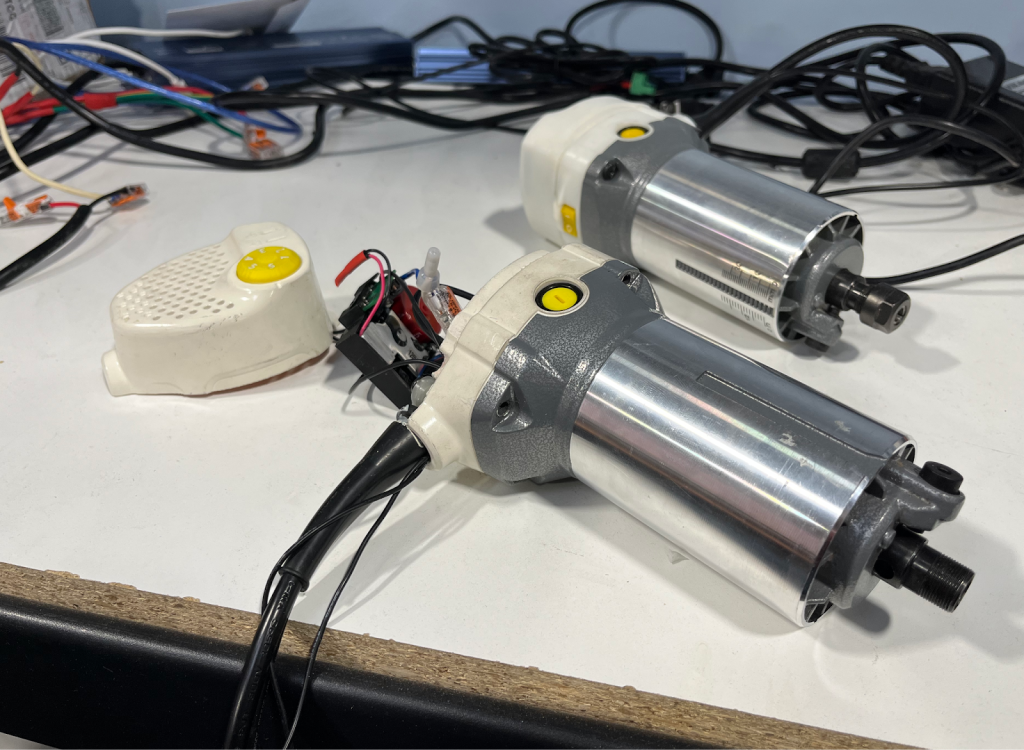

Initially we thought it would be easy to just find a Makita equivalent motor, bond it to a different shaft and off we go. However, after two months of looking, we realized that all power tool motors we can find are mass produced designs, and any substantial customization will require us to spin up a new production line, with a lot of technical and monetary risk that both us and the manufacturers are not particularly keen on.

Next (and partly as a way to give us more design flexibility), we started looking into brushless DC motors. Our initial assumption was that they are going to be way too expensive for this use case, but the prices of new brushless power tools from the big names hinted at the maturation of this technology. We reached out to a few motor suppliers, and we genuinely found a lot of promise, especially around how it can offer spindle-esque performance at a lower price while being more tightly integrated (no VFDs).

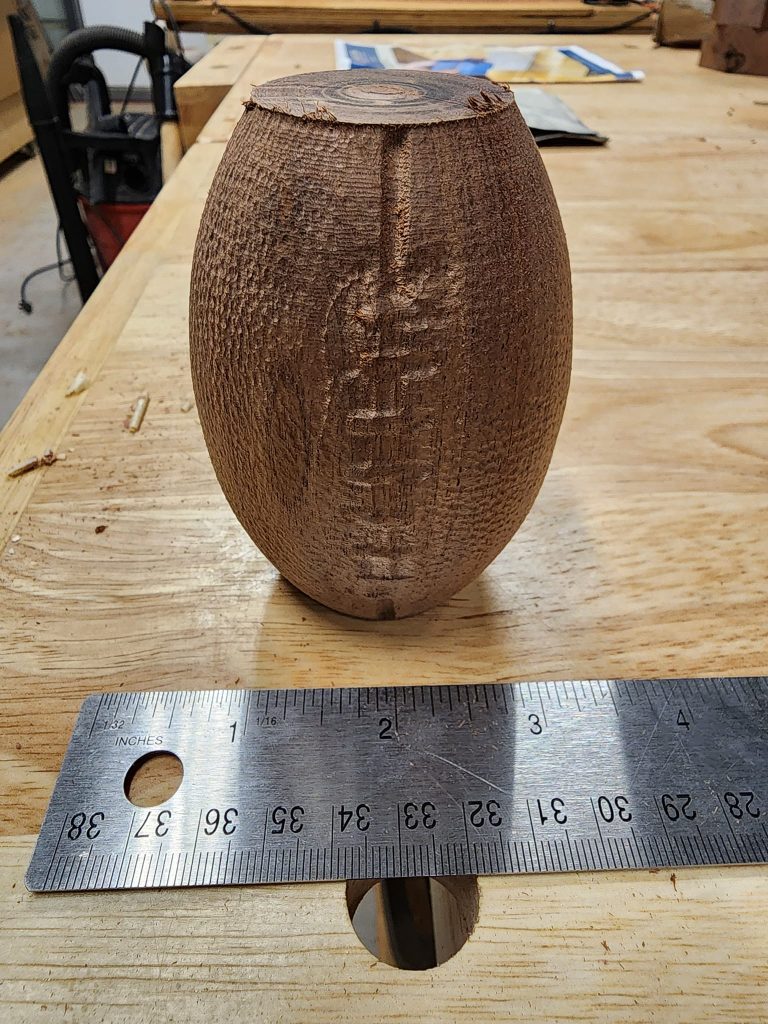

This was a really fun time of the project, where we’re doing a lot of testing to figure out the size and power of the motor we need; getting highly custom samples made, and doing even more testing to validate the samples. A lot of this is probably trivial to a seasoned motor engineer, but to me it was a time of learning and one that is truly enjoyable.

Despite how promising BLDC is, the reality is that we still don’t have a solidified product by May time. So after a trip to China to visit suppliers and a bit of soul searching, I made the following table which made it clear to me that the BLDC cake would require more time in the oven than we have. It also told me that we need to shift the priority to pushing out the LM spindle and work on a speed control version of the Makita clone that has a more assured path to market.

This decision, and another half a year’s work brought us to this point in December 2024, where we have a beautiful product that’s perhaps not the best thing since sliced bread, but a very neat little tool that is in my opinion the best execution of the Makita clone in the industry so far.

What is so special about this router?

I think of this product as a three layered cake.

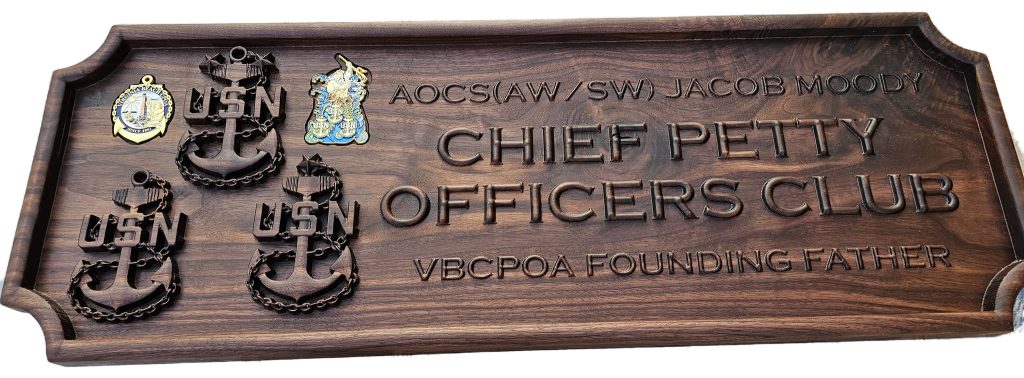

The foundation is a well-tested, finely tuned motor with best-in-class bearings. Getting the motor right wasn’t as easy as we initially thought. After testing what’s on the market, it became clear that many clones are underpowered or poorly tuned. Even with our current supplier, it took three sampling runs to nail down the basics. If you explore the product page, you’ll find detailed speed-torque curves and load responses compared to both the Makita and our 1.5kW spindle. This level of diligence is something I am quite proud of and hope inspires confidence.

The second layer includes all the CNC conveniences we could think of—like ER collets and extra-long cables. While these are not that novel, we made an effort to include them all. Unfortunately, an LED light didn’t make it into the final product, despite our efforts (It still pains me that I asked Jon to design it and it got cut).

The icing is of course spindle mode. It offers PWM speed control designed for maximum compatibility. While similar features exist in other products (like SuperPID, AMB 1050 DI, and funnily enough a product called the “Sprouter” for Onefinity), our version is by far the easiest to set up and polished. There’s no need for input power or doing potentially dangerous mods to your existing router. My hope is that you’ll find spindle mode such an intuitive feature that you’ll wonder why it wasn’t done sooner.

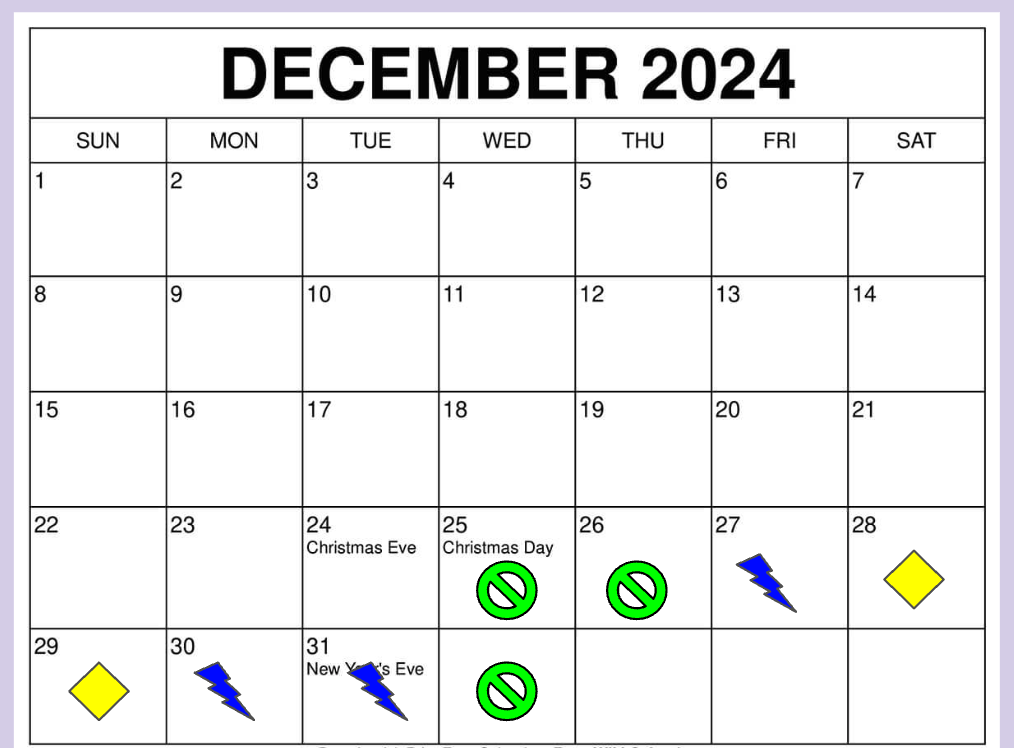

What’s the Plan from Now to Launch?As of November 12, 2024, we’ve paid for a pre-production order of 35 units, with delivery expected in two months (though there’s a 50% chance it could take three). Once the beta units arrive and pass internal testing, we’ll launch a two-week open beta program with 25 units in late January or early February.

If the beta goes smoothly, in February we’ll begin the certification process (~60 days) and production (~30 days) immediately afterward. Pre-orders will likely open around this time.

Our goal is to start shipping by April or May 2025.

I’m sure Andy will keep everyone updated on production progress along the way as well.

Naming Competition?

We’ve never run naming competitions before—probably because we’re not especially fond of Routy McRouteface. However, we’re taking a different approach this time. We’re considering branding this product under a separate company, similar to how Onefinity launched their RedLine spindle brand.

The goal is to reach a broader audience beyond the Sienci ecosystem, which would be difficult with a name like “Sienci Hybrid Routing System.” We’re looking for appealing names that resonate with new users and build the brand around the best fit. Vote for the People’s Choice winner now by submitting the form here (Just for fun)! The winners of People’s Choice and the official name will be announced on December 13, 2024, so stay tuned for that!

Support for Non-Sienci Machines: A Small Caveat

The CNCs listed on our website should, in theory, all be compatible with this router. We’ve already tested it with many machines on the list, including the Onefinity Elite. However, there are two important caveats:

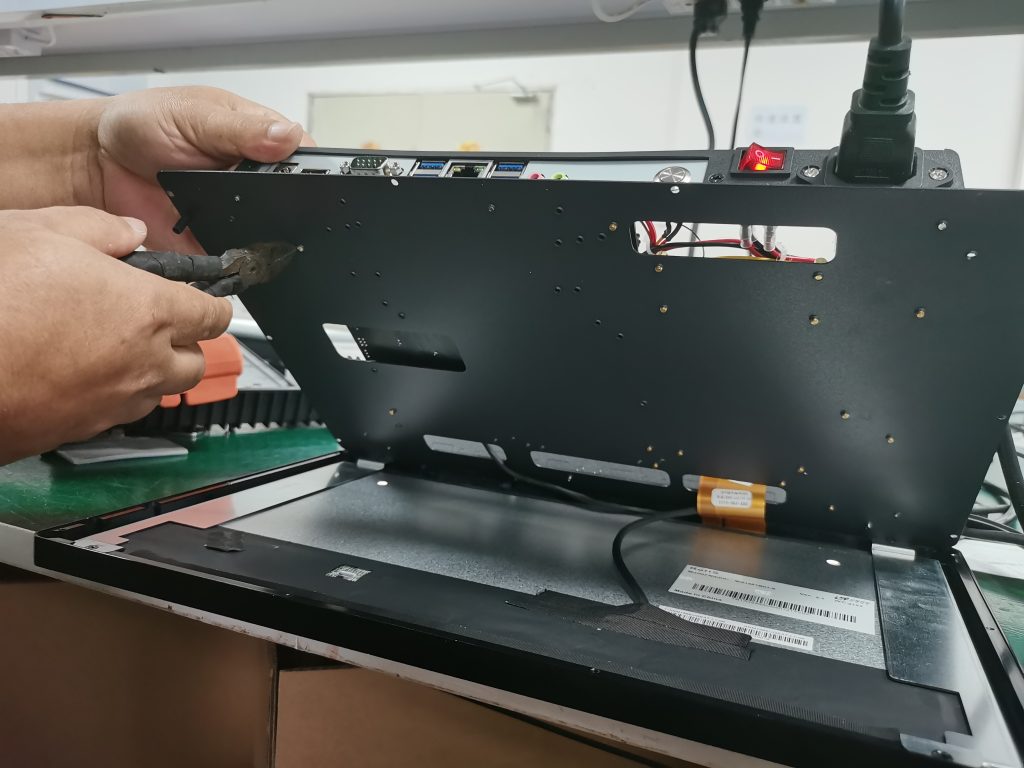

- Shapeoko 5 Pro / HDM: We haven’t tested with the Warthog controller yet. Their PWM implementation is a concern, as their double NAND buffer signal conditioning has caused issues for others, such as for PWNCNC. In the worst case, accessing the headers on the PCB directly may be required—but we will cross that bridge when we get there during beta testing.

- Onefinity Elite: This machine will need a firmware update to an upcoming version. Currently, a bug in PWM control mode causes the spindle to turn on during controller initialization.

Lastly, if your CNC is not on the list, we support 3-5V 0.8-10kHz PWM (nominal), so unless your machine is exclusively 0-10V speed control or has some really high impedance output it should be compatible.

I like what I’m seeing, how do I support this project?

- Join the Beta Program: Help us make absolutely sure we’ve ironed out every kink before we place the big order of 2,000 units. Your feedback is invaluable (especially if you have a non Sienci machine).

- Spread the Word: When the product launches, buy it and share your experience with friends. This is our first custom product in the spindle/router space, and with your support, we hope to bring you even more innovations in the future (cough… BLDC… cough… cough… toolchanging… cough…).

The End 🙂

Feel free to comment below or reach out on Facebook or our forums if you have questions or want to dive deeper into the discussion.