Hey everyone, Ikenna here with another LaserBeam update. We have made a lot of good progress since the last update. Most significantly we’ve tested our sample production heatsinks with great results, and our prototype LaserBeam drivers will be arriving from the manufacturer in the next week or two.

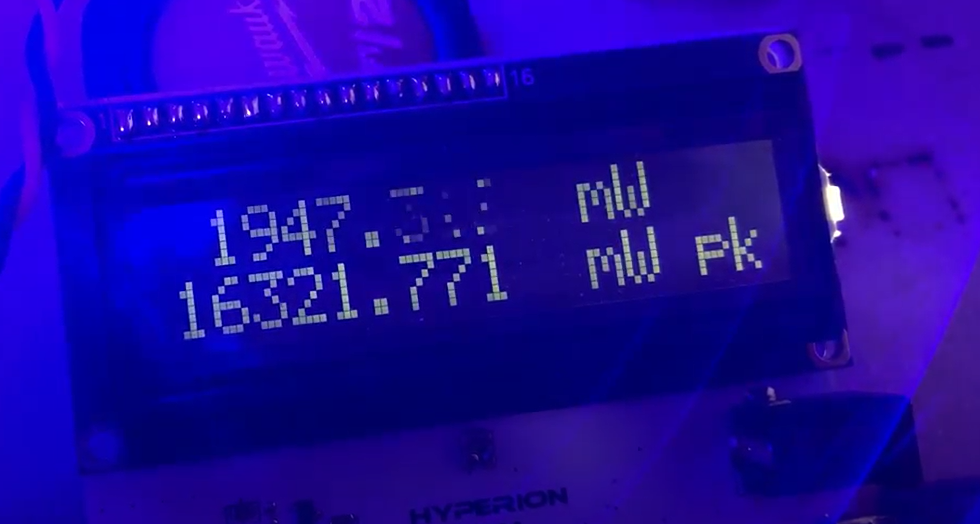

5W Generic Banggood Laser Power Test:

When testing the 5W Generic Banggood laser we were able to confirm that the real continuous optical power of 1.9W-2.2W which is far below the promised 5W continuous power rating. These lasers have their place in the market but if you are looking for high quality at a reasonable price I believe the Sienci LaserBeam is the best offering on the market. In the pictures below the top mW reading is the true optical power reading for this specific laser system. (1.95W, 2.13W)

7W LaserBeam Laser Power Test:

When testing our 7W laser diode we were able to confirm real continuous optical power of between 7.1W-7.2W @ 4.5A (recommended current limit for longevity) which will keep both the diode and driver running for a long time as well as producing the exact power we are promising you, which cannot be said about lower quality laser systems like the one in the previous section. In the picture below the top mW reading is the true optical power reading for this specific laser system. (7.17W, 7.18W)

Sample Production Heatsinks and Lens Focus Ring:

Last week we received some sample production heatsinks and lens focus rings. Good news, the heat dissipation is great and was able to keep the laser system 6 degrees celsius cooler than the generic heatsink when running our max power test file. Everything fits well and was assembled with relative ease. The bad news is that the top of the copper heatsink was just 2.5mm too long for the G2 lens to properly focus, using a very thin 3d printed lens focus ring I was able to get the G2 lens in focus. This confirmed that I needed to reduce the size of the top copper heatsink by 3mm to make everything work, as well as sliding the set screw location down 3mm on the Aluminum heatsink. These changes have been sent to our manufacturer and they have begun production again.

5A Driver Prototype:

I have been working very hard with our PCB designers and our PCB manufacturer to find any potential issues and solve them before we receive the prototypes and begin testing and designing our enclosure. Over the next 2 weeks we will be working with experienced testing labs to produce a comprehensive testing procedure for all LaserBeam 5A drivers. We will also use the prototypes to start creating our safety and assembly manuals.

Safety Glasses:

Our safety glasses are ready and being shipped now. I have been using a these exact glasses to run all our LaserBeam testing and can confirm with my own experience as well as laser power testing that these are great safety glasses and your eyes will be well protected.

Designs:

- Laser Driver Enclosure: I am waiting to receive and test our prototype LaserBeam Driver, I will continue to iterate designs until I can test them with the physical driver boards.

- Magnetic T-mount: The standard T-mount design is finished so I will begin looking into designing a magnetic mount.

- Magnetic Air Assist: The main design is complete, I am now sourcing neodymium magnets to test

- Packaging: I will start playing with packaging ideas, nothing concrete until more production parts begin to arrive.

Testing:

- Power Supply: 12V 7A power supply has been tested successfully, I will continue to test 12V 7A to make sure we get the right power supply for the 5A driver and all the fans.

- PCB Design: Waiting to receive the driver prototypes, in the meantime devising a comprehensive testing procedure.

- Laser Diodes: I am currently testing a secondary supplier for the 7W Laser diodes to ensure that we have a backup if our initial supplier has a shortage.

Supply Chain:

- Lenses: Tested production order successfully, in stock.

- Lens Focus Rings: Tested product samples successfully, currently being manufactured.

- Aluminum Heatsinks: Made one last small change to the copper heatsink set screw location, currently being manufactured.

- Copper Heatsinks: Made one last small change to the top copper heatsink size to make it easier to focus the G2 Lens, currently being manufactured

- Safety Glasses: Production is complete, and has shipped.

- Laser Diodes: Currently have 100pcs 7w Diodes in stock, currently testing a 6W diode to offer a secondary power option.

Ordering Additional Safety Glasses & Lenses:

Check out the link above if you need to order additional LaserBeam accessories that you didn’t order in your original LaserBeam preorder. You won’t be charged any additional shipping and your order will be combined with your LaserBeam Pre-order!

Sienci LaserBeam Pre Order:

Place your Sienci LaserBeam Pre order here: https://sienci.com/product/laser/

Answering your FAQ:

Check out our LaserBeam FAQ video, I take all your unanswered questions from the LaserBeam livestream and try to give you guys more clarity on the LaserBeam add on.

Stay up to date by signing up for

If you missed the last update, check it out here: https://sienci.com/2021/04/12/laser-development-update/