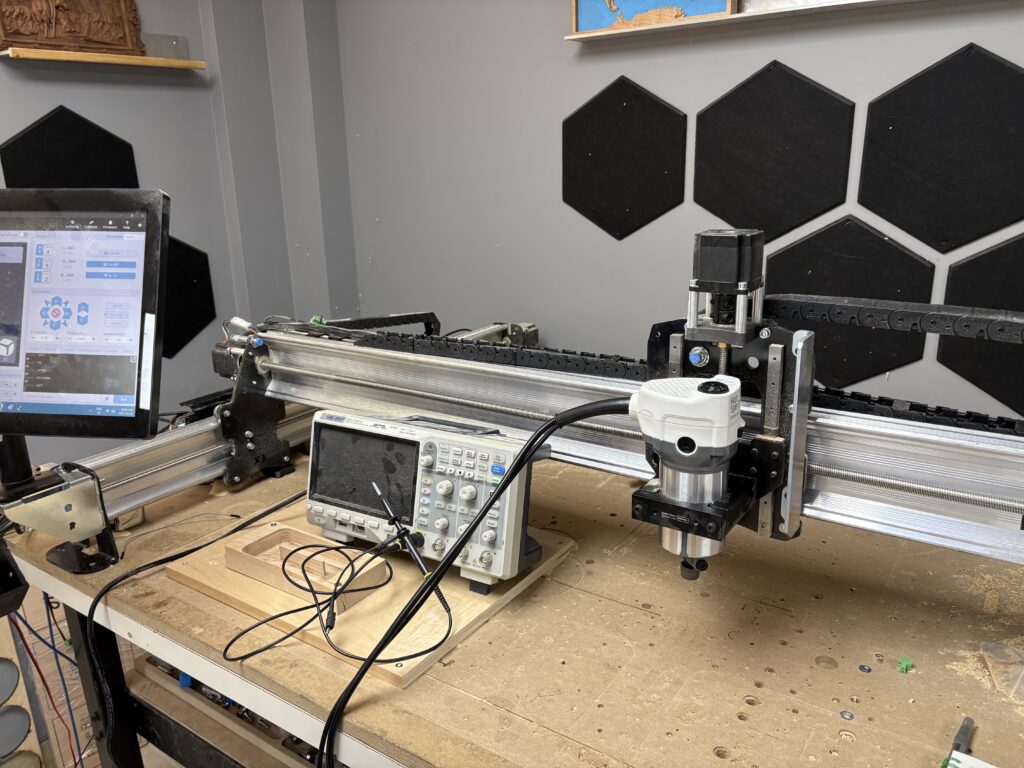

Earlier this year, we were asked by the ESA to restrict the sales of VFDs within Ontario, Canada, until we had received certification. Since then, we have been working on a design of our VFDs to certify their use. We did not have to do any further certifications for the spindle as they were already certified.

The short answer of whether an electrical product needs certification or not is yes, or more officially, complying with CSA standards qualified by UL or equivalent. Certifying a spindle and VFD system ensures:

- The system is tested to be “safe”, which takes into account factors like fire resistance, shock prevention, mechanical durability and more

- Protection against liability in the chance of an issue arising from the device

- Ability to be imported into certain regions

However, in practice, most spindles and VFDs sold in North America for hobby use do not carry a certification. In fact, based on our research, at the current moment, spindles and VFDs from Carbide 3D and PWNCNC, as well as Amazon, don’t have certifications. The only systems that carry the proper certification is Redline CNC, which describe themselves as the “industry’s first and only safety approved plug-and-play spindle kits”.

As far as we understand, there is no specific requirement for hobby or home users to need certified spindle systems for the US*, especially if they are putting together their own systems which is why we have been able to keep selling to the US. For commercial use, insurance companies may require the electronics used to have certifications, either as a field inspection or with the use of certified equipment.

*Somewhat ironically, given that we are restricted from selling uncertified VFDs in Canada, Canadian customers have been purchasing other uncertified (perhaps less safe) spindles and VFDs instead from the US.

As a whole, I believe that it is the responsibility of the manufacturer to design and develop their products to ensure they are safe. Certification is a good representation of compliance of established standards designed by experts in the field. However, certification can cost thousands, if not tens of thousands of dollars, on top of thousands of dollars in yearly inspections needed to keep the certification active. For a full certification of a product like a VFD, we could be looking at spending around $35,000 USD, plus a few thousand dollars per year to upkeep the certification. We believe that the cost restriction is a big barrier for most manufacturers to get full certification for their products. In fact, through this process we learned that our manufacturer of VFDs had received certification for the same VFDs that we currently offer a number of years ago, but due to cost reasons, let the certification lapse. One-time certification at the scale at which we operate also prohibits us from continuously improving our product to meet the changing needs and feedback from users.

There is a secondary option, called SPE-1000, which is a field certification, where an inspector can individually inspect electronics instead. This option is more practical at lower volumes, as we simply need to pay for the inspector’s time, so that the cost to inspect units would work out to only $30 a unit. The cost for this in the short run would be less than getting a full certification.

For the short term, we will offer both certified and uncertified systems to US customers once they are available. Canadian customers will only be able to purchase certified systems. In the long run, we will likely consolidate all of the systems so that all systems will have the same hardware, and have a price difference for models with the certification. In the future when the production volume gets large enough, it may end up being more effective to move from field certification to a different certification standard.

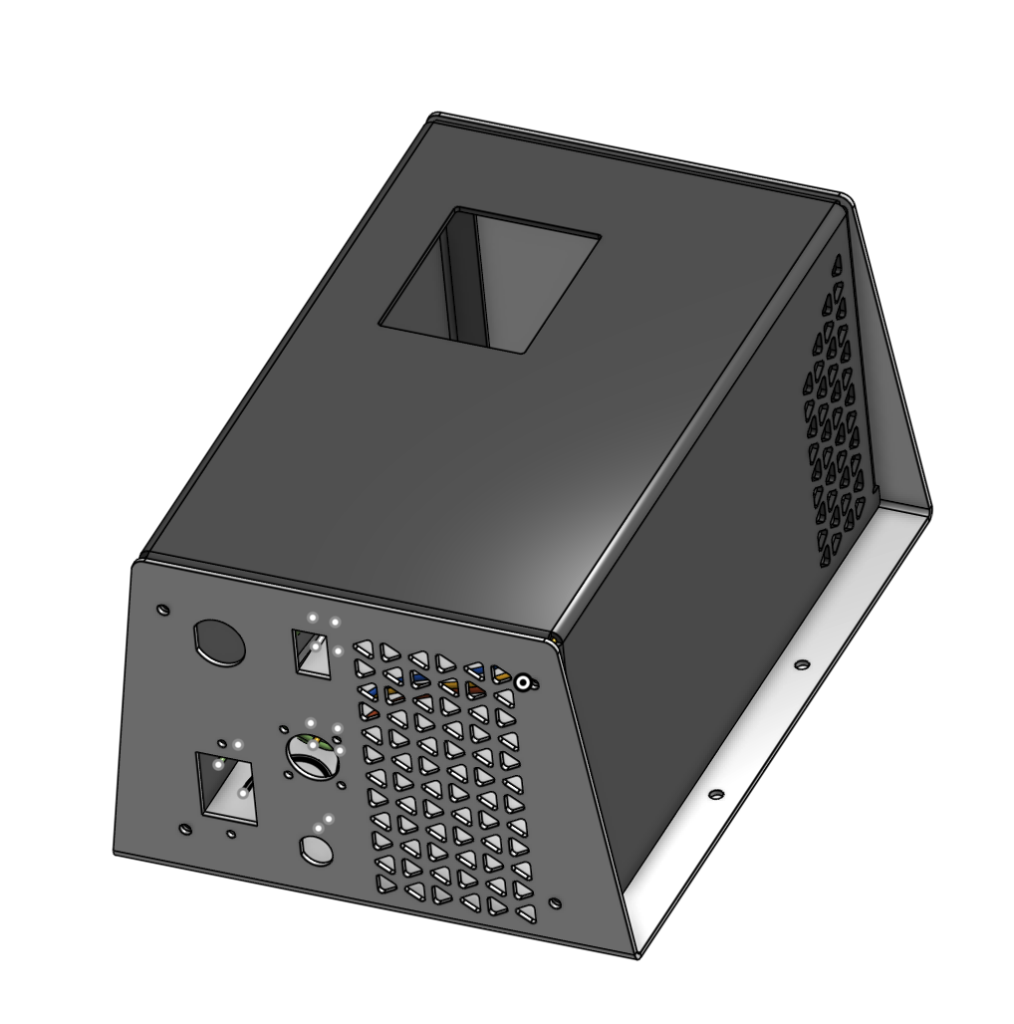

Design Differences

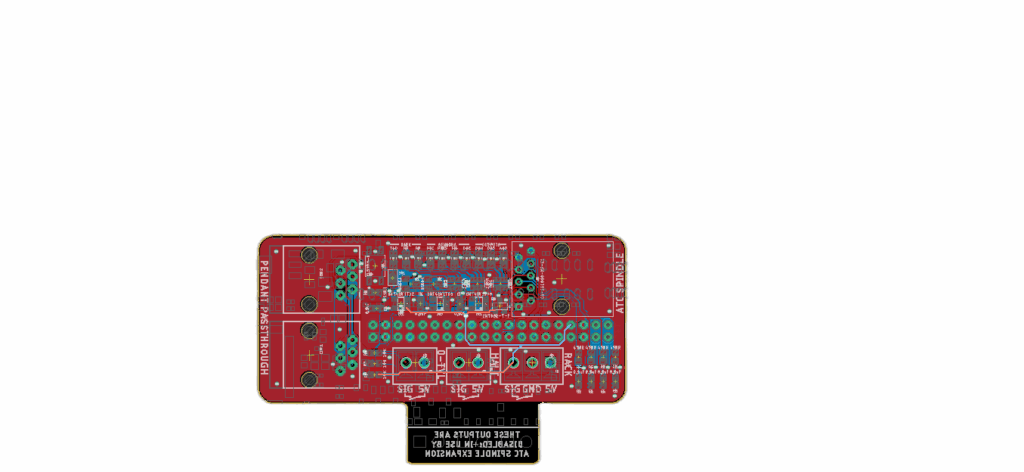

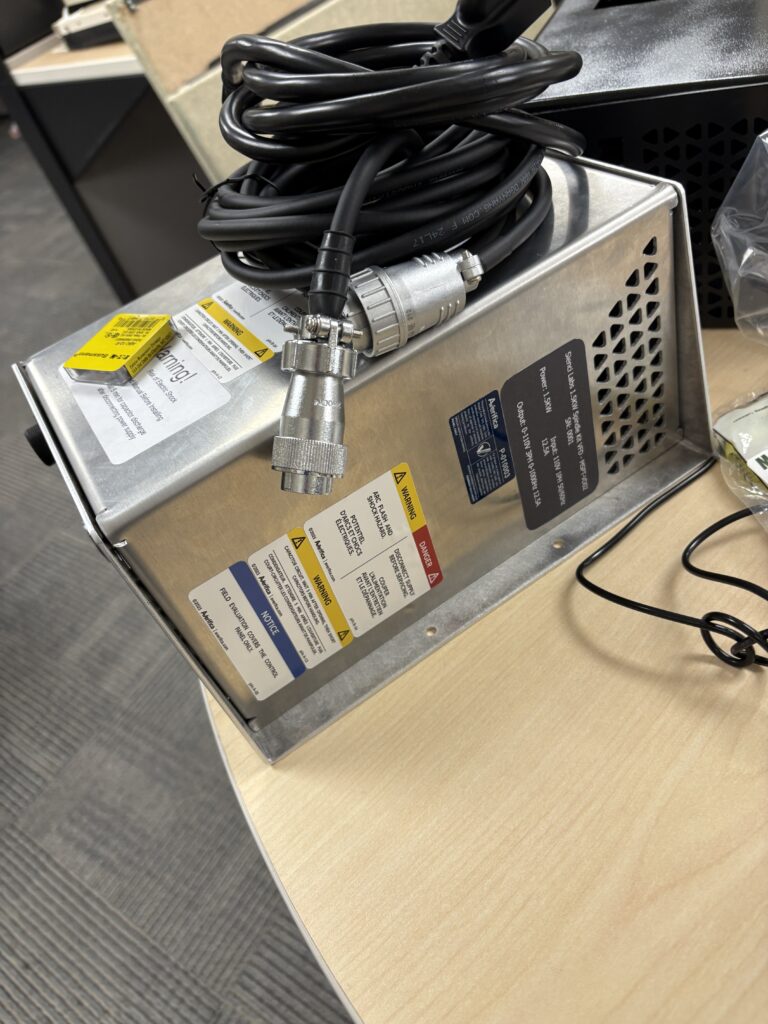

The new VFD comes with several changes considering improved safety and ease of use.

Ease of use improvements:

- Pluggable spindle cable: the cable for the spindle is no longer wired in with a screw terminal but instead uses a plug on each end allowing for the user to easily connect and disconnect the cable without tools

- Pluggable AC cable: like the spindle cable, rather than needing to use a screw terminal for the plug, the NEMA 5-15P style cables. Note that this cable must be rated for 15A (these are provided in the kit)

- Pluggable RJ12 connector for controlling the spindle via RS485

- Fuse is easily accessible and swappable

- Switch allows for user to easily turn on and off their VFD

Safety related changes:

- Components are tested for fire resistance, and all bear appropriate UL/CSA safety markings

- Enclosure designed to prevent shock, with proper spacing and mechanical strength to prevent shorting

- Proper safety warnings and stickers

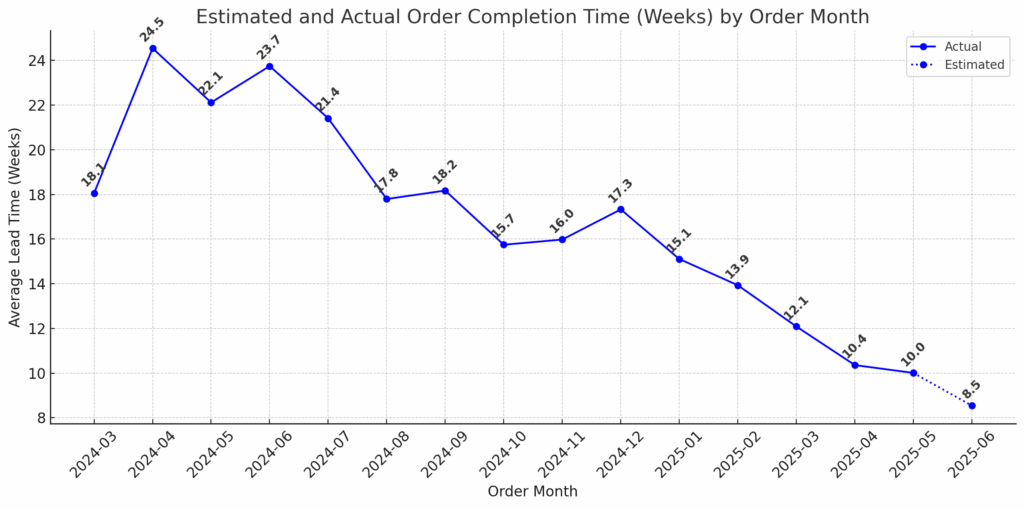

Customers waiting on certified VFDs

Currently we have a small number of users waiting on certified VFDs within Canada. These are either people who ordered and received a spindle kit (uncertified), or ordered but are waiting for their kits to ship, before we took it down from the store. Customers had the option to return their kits for a refund or wait until we provided the certified version.

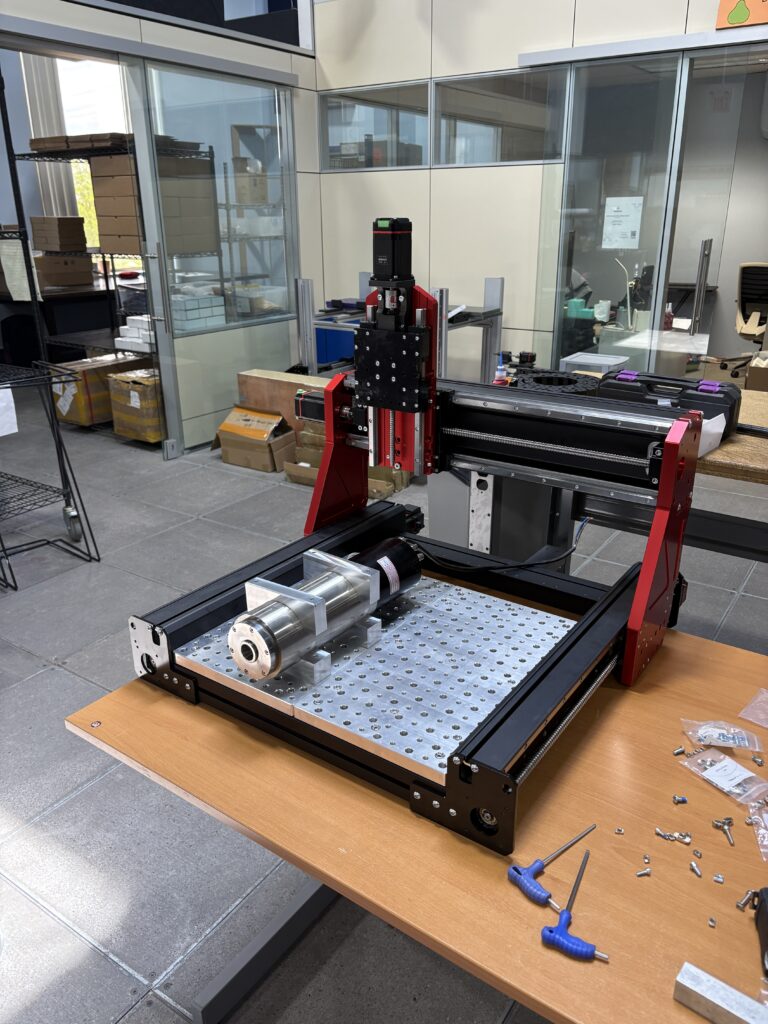

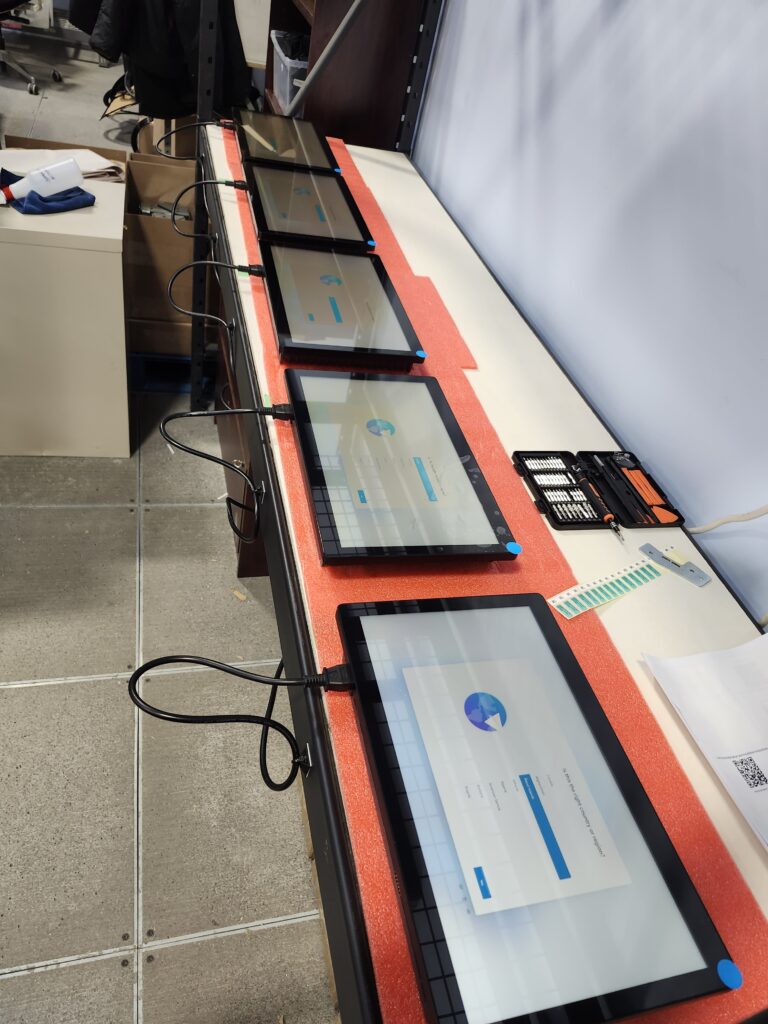

We’re currently assembling the first 100 units for the 110V 1.5KW, some which will go to the initial customers, and the remainder will be available to Canadian customers once the batch is complete.

We are working directly with these customers to issue the replacements.

Current Production

Along with the first 100 units, an additional batch of roughly 300-400 of 110V 1.5KW VFDs, and 300-400 of 220V 2.2KW VFDs are also being lined up for production. Whatever units we have left from the first batch will be available to the general public; the other units will be available once we have an expected ship date for everything else.

Pricing

Here’s a timeline and estimated sale price for each variant. Please note these are estimates only and may change – watch for emails and social posts for formal announcements over the next few weeks

Enclosed VFD refer to the certified versions

Unenclosed VFD refer to H100/uncertified VFDs

1.5kW ER20 with unenclosed VFD – $555 USD

2.2kW ER20 with unenclosed VFD – $700 USD

1.5kW ER20 with enclosed VFD – $650 USD

2.2kW ER20 with enclosed VFD – $790 USD