When will the LaserBeam ship?

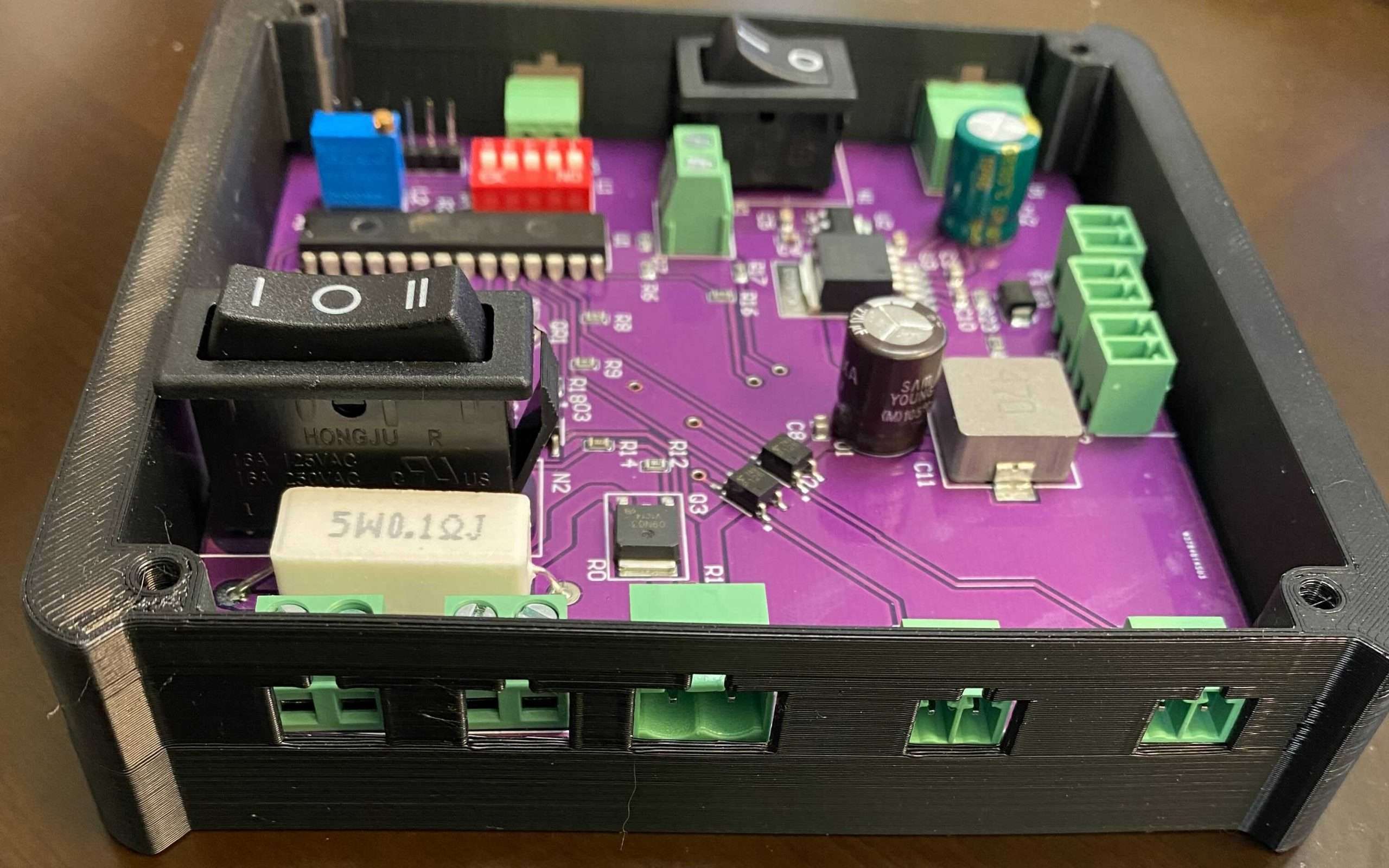

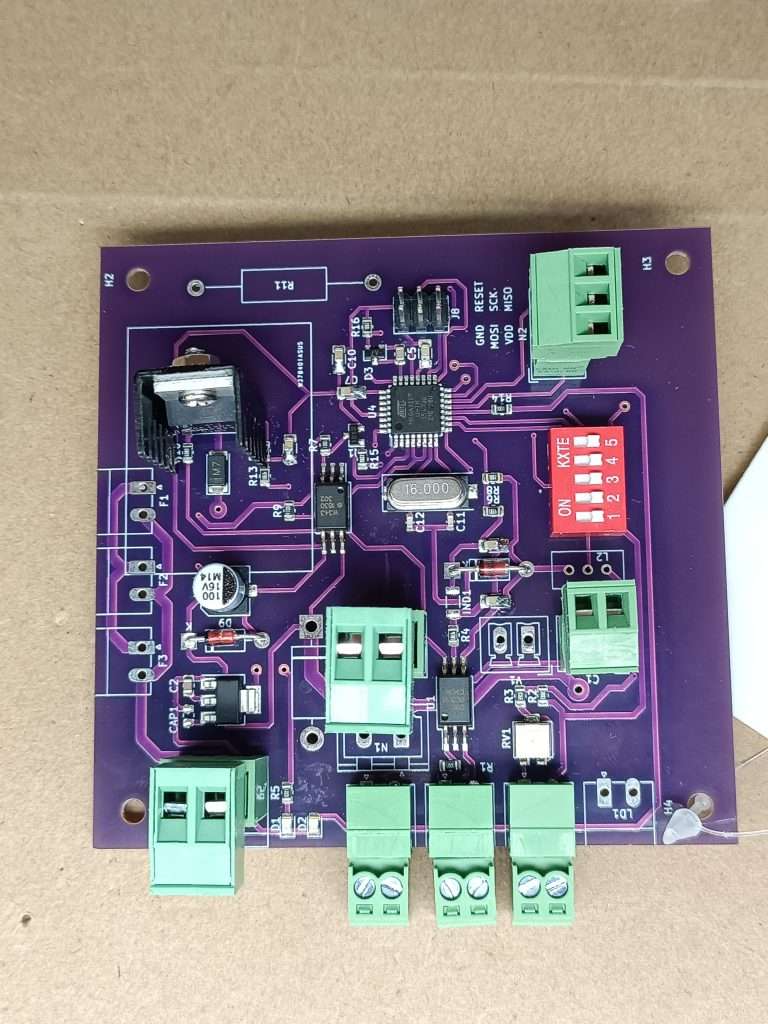

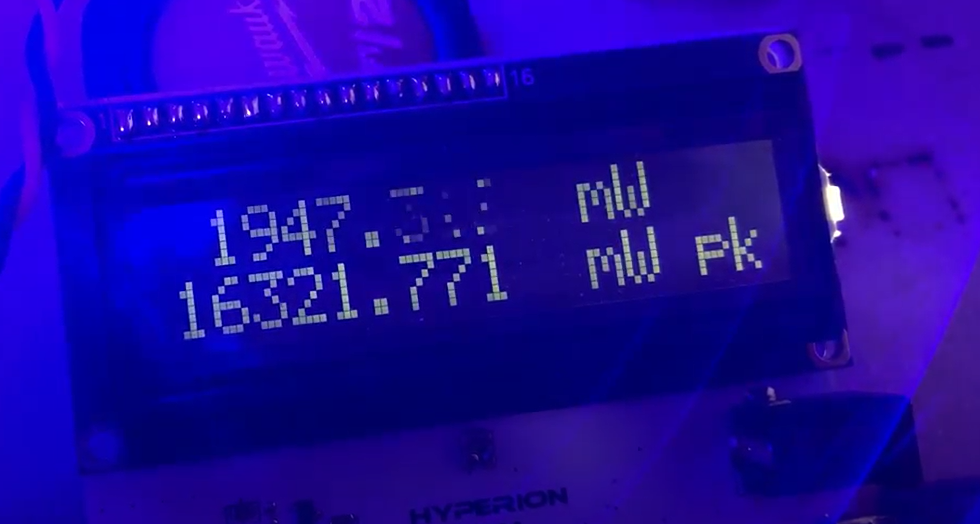

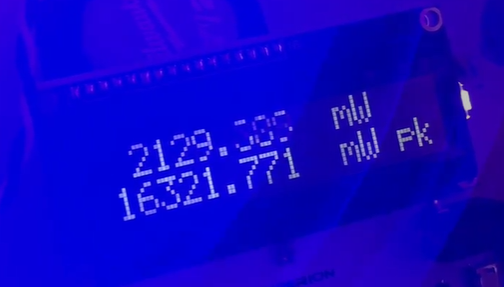

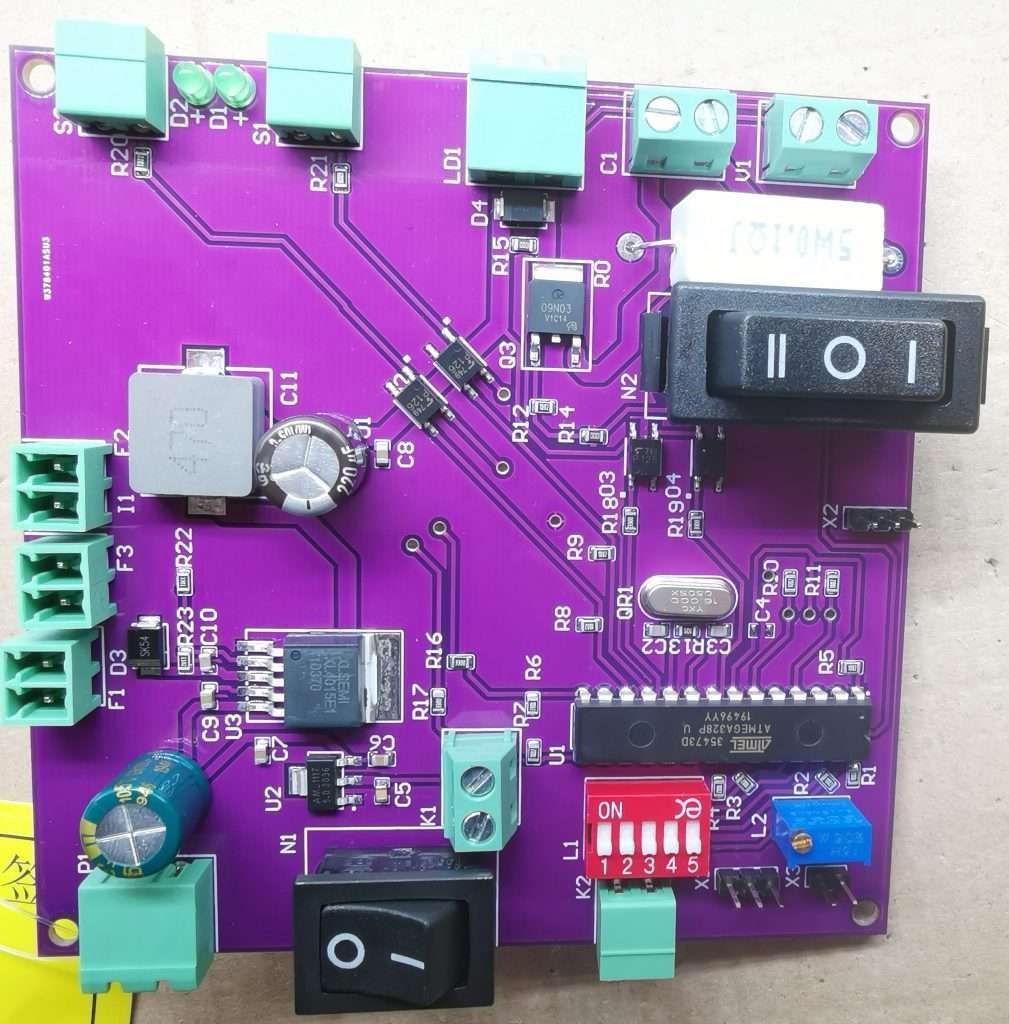

During my time at Sienci Labs, I have learned a lot about rapid prototyping, quality control, and listening and working with our amazing community. Andy & Chris our Founders have always advised me to always give myself more time than needed. It’s a lesson I have not fully taken in until now, I feel like I have learned to set more realistic expectations on the timelines it takes to develop a new product. I do believe for the price, we are developing the best laser diode attachment on the market. The last piece of the puzzle is a 5A laser driver that meets the standards of the company and my own. I have no doubt that we will get there but we need time. The driver needs to work well, be tested independently and then ordered in bulk. That’s all that is left with development. We are currently at version 5 of the driver prototyping, we may need 1-2 more before I am confident enough to send off for independent lab testing and bulk ordering. The original ship date I picked was the first week of July, then first week of August then end of August. Instead of telling you we can ship early October. I need to take Andy & Chris’ advice and give myself and those I’m working with enough time to do this right and to not continuously push the date by small increments. Your support on this new product and journey to developing it really does mean the world to me. Thank you Sienci Labs community! We do hope to ship earlier than the new listed date but I think it’s best to allow more time than I believe we need.

*Final shipping update is December 2021 (absolute latest)*

What caused this delay?

- I hired 2 international electronics designers, I misjudged their experience with laser diodes and constant current drivers.

- Neither designer was able to develop something that could perform the tasks we needed v1-v4.

- The best design we received was v4, it had working safety features and delivered current to the diode, only issue was that is was not constant current and was not a high quality design

- Slow design work pace: I hired these designers in April 2021 and only had received designs that could be tested in July. This is the root cause of our 3-4 month delay

- I am now disputing the payments we made to them and working with a new local designer full time and he is working night and day prototyping the new laser driver design.

- I am working between the Sienci office and our new designers office in order to keep the project moving forward and continuously test and debug designs at a much faster pace

- This ultimately stems from my own inexperience hiring electronics engineers and designers. This did teach me a lot

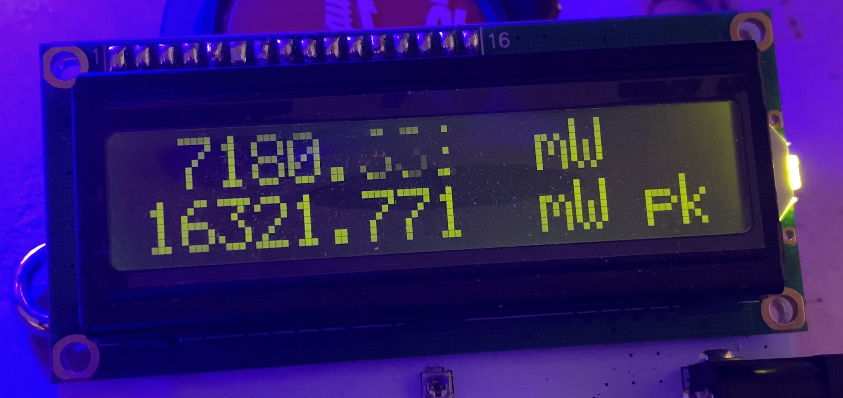

5A Laser Driver Update

- With all that said, version 5 of the driver was tested last night and had some issues

- To much inductance/resistance in the traces leading to the voltage regulator

- Reverse polarity protection was not included

- The way feedback was provided to the mosfet was causing issues with the constant current

- Version 6 is being worked on as we speak and we’ll be placing a new PCB order tomorrow to fix all the issues listed above.

Production News

- We have finalized the LaserBeam Logo

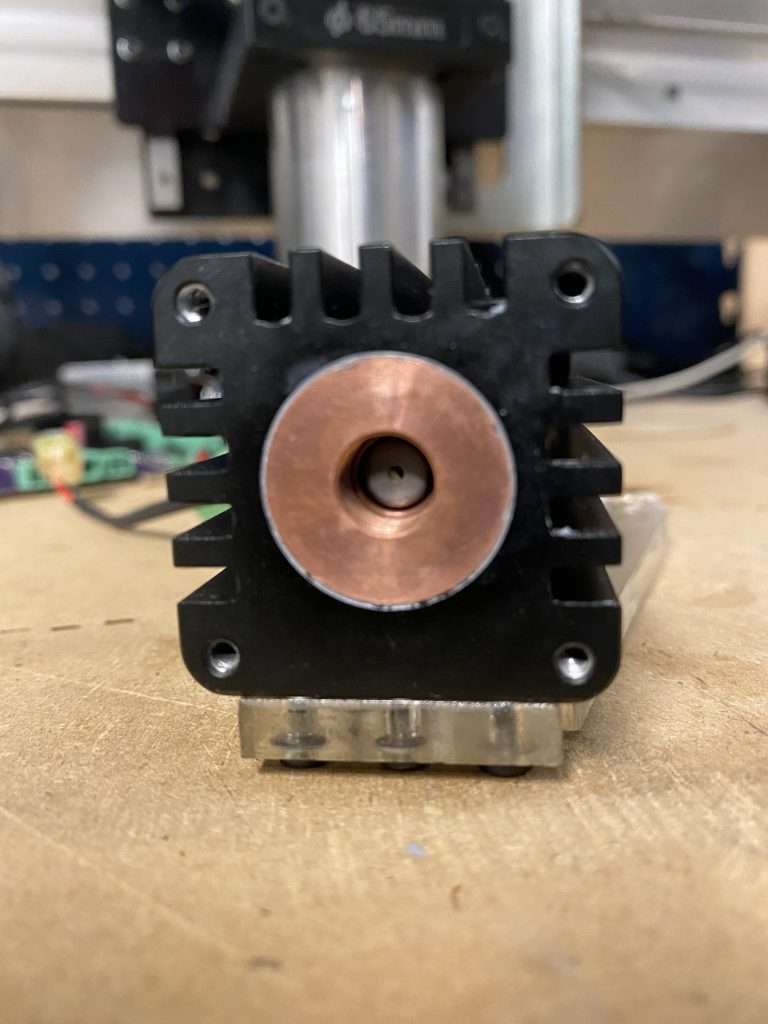

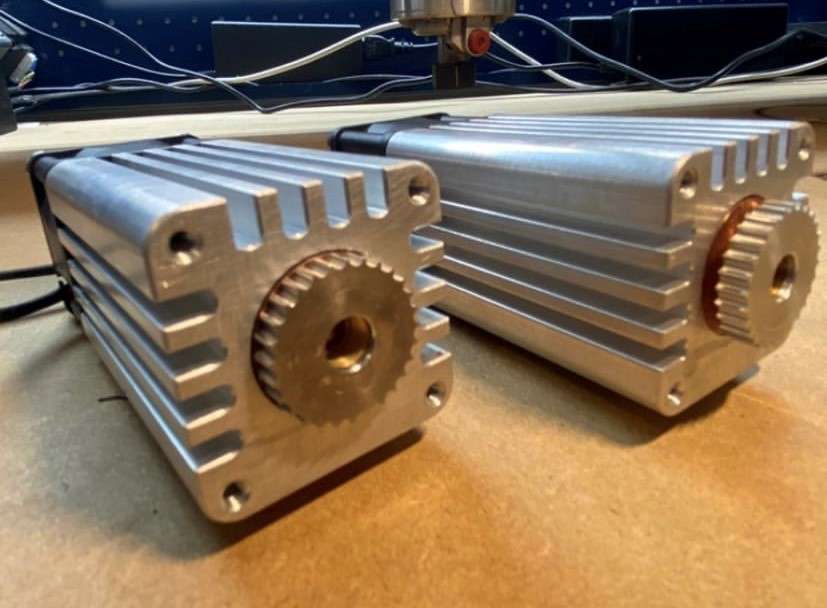

- Both aluminum & copper heatsinks have been tested with great results

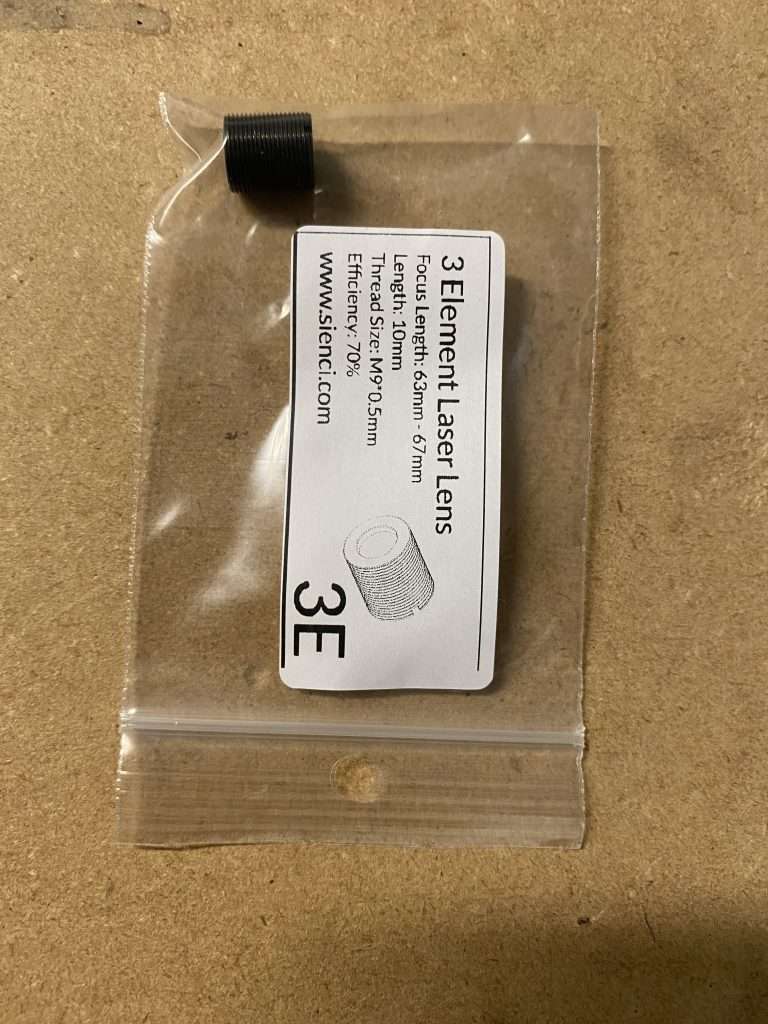

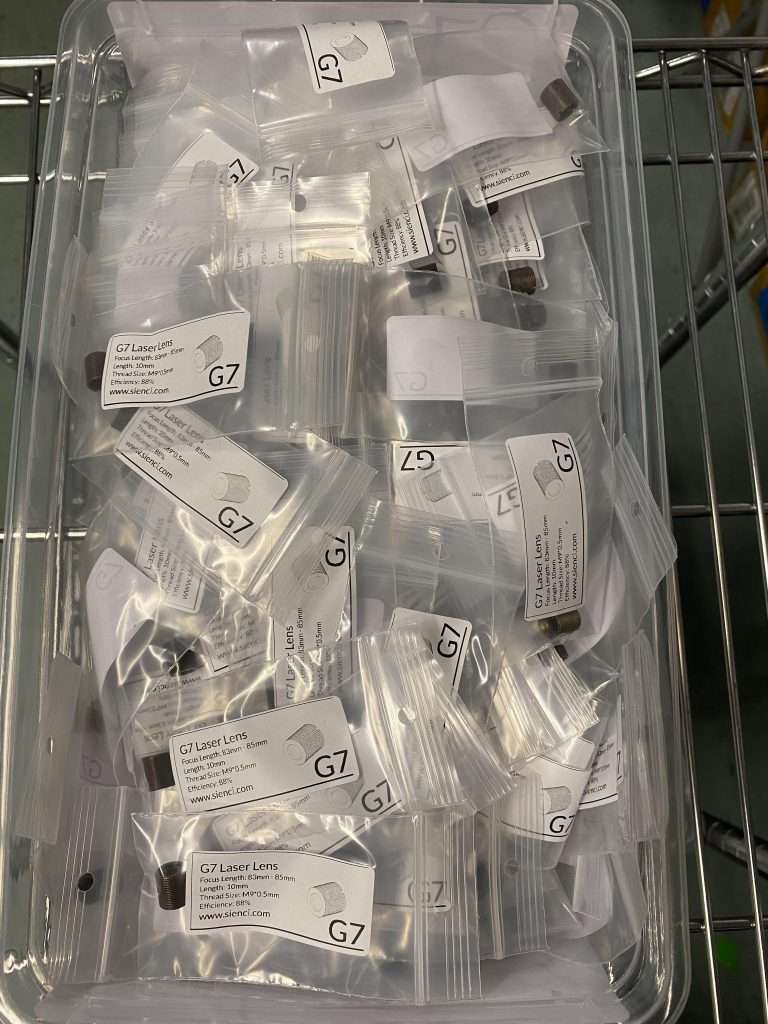

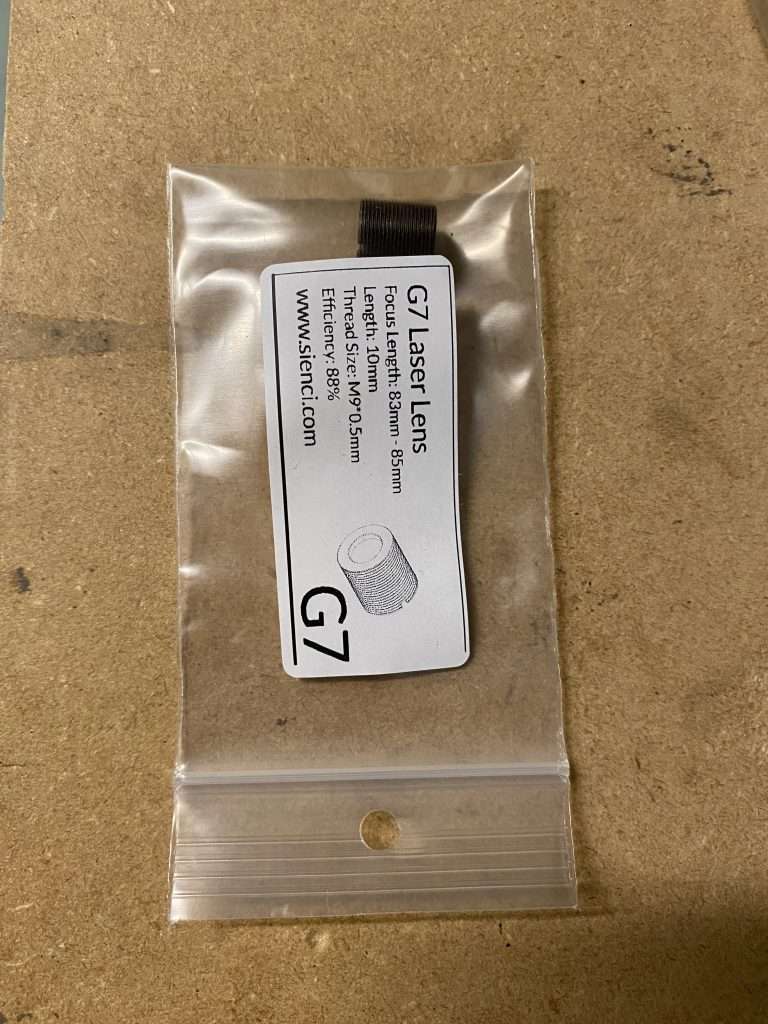

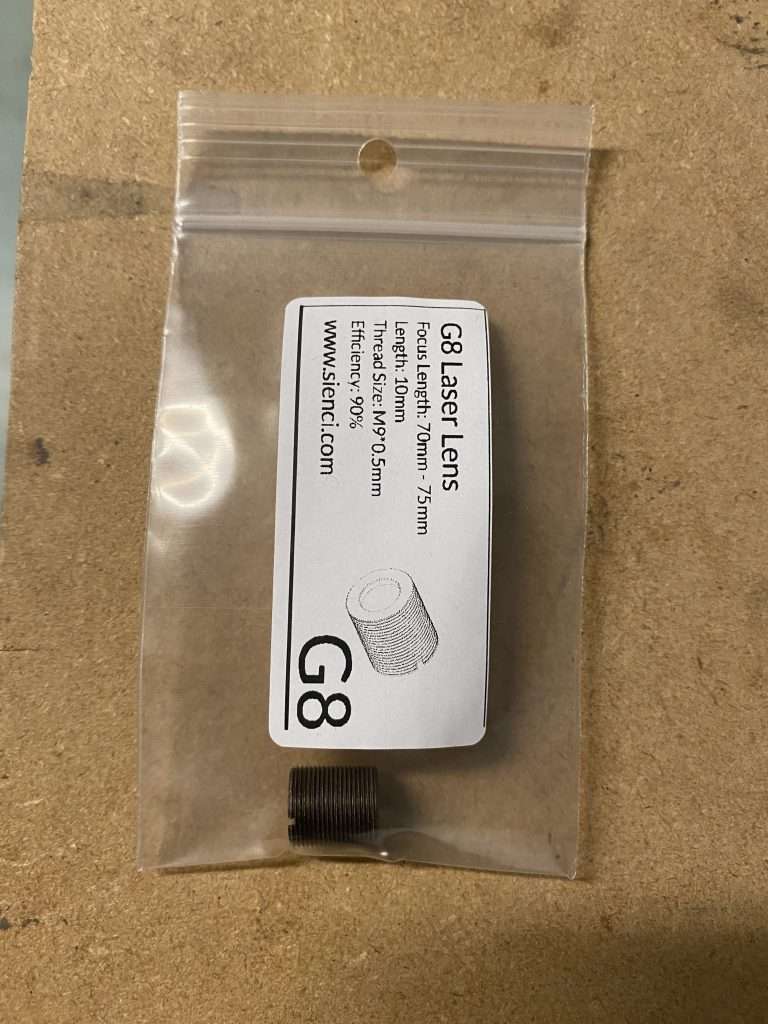

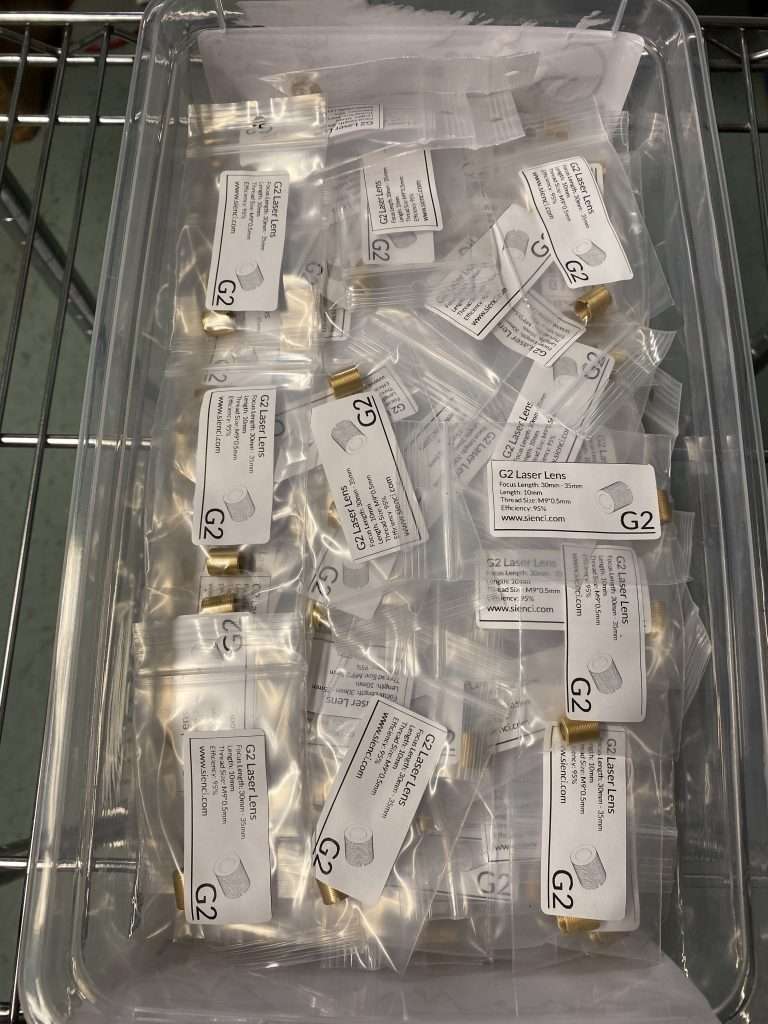

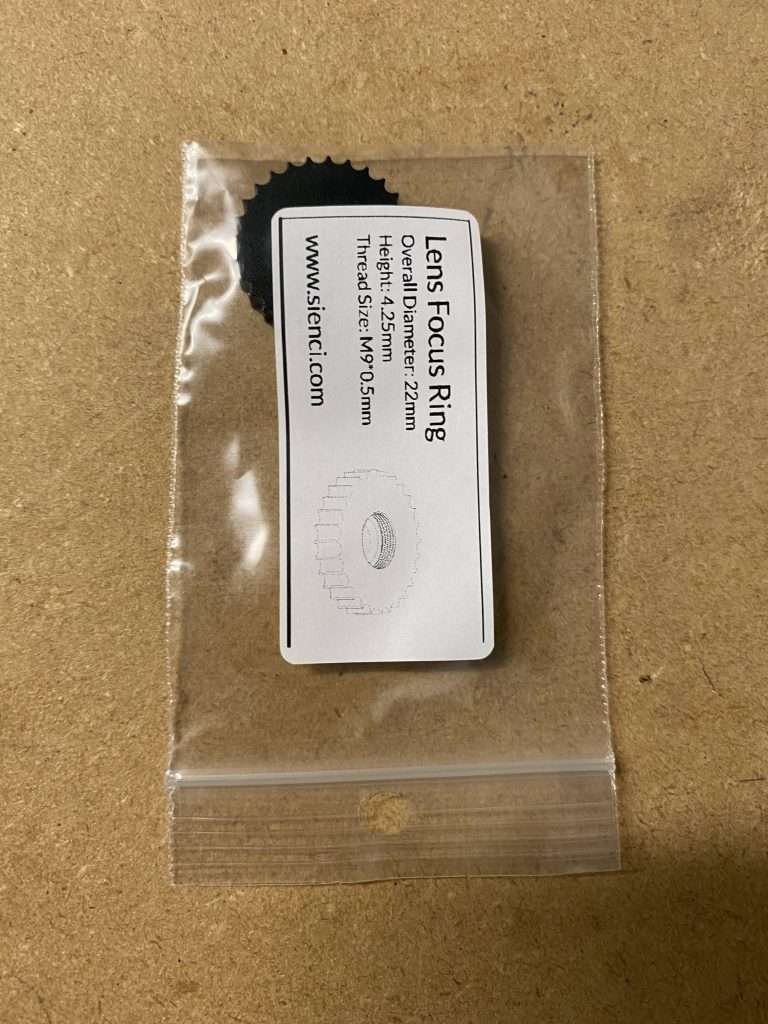

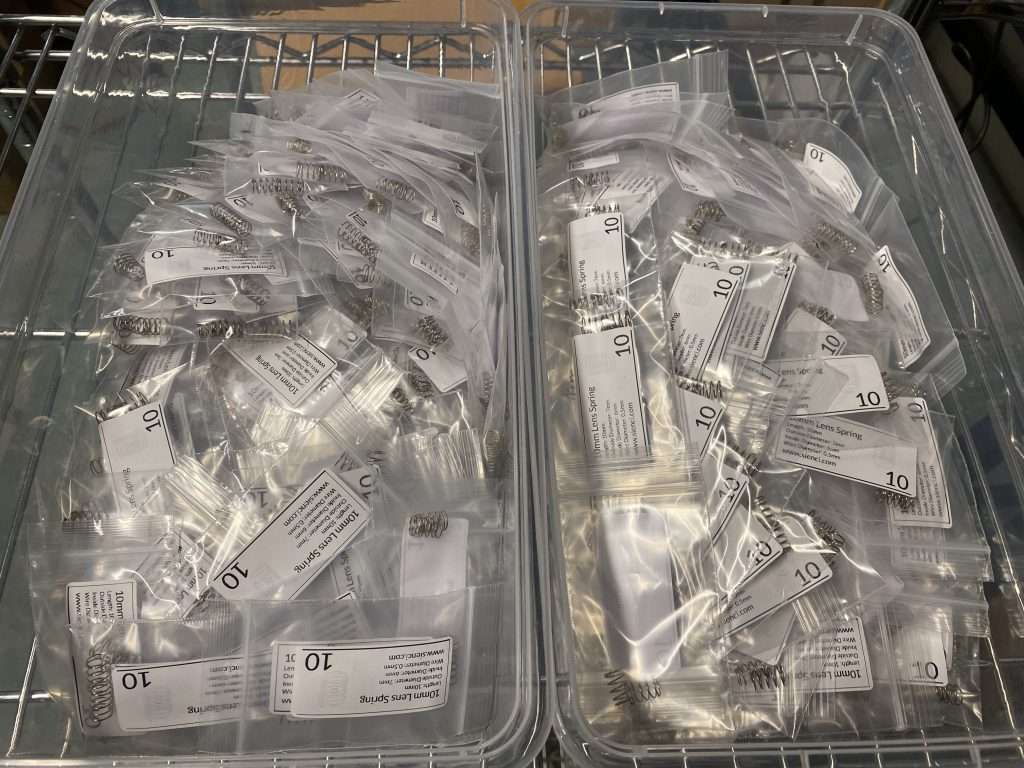

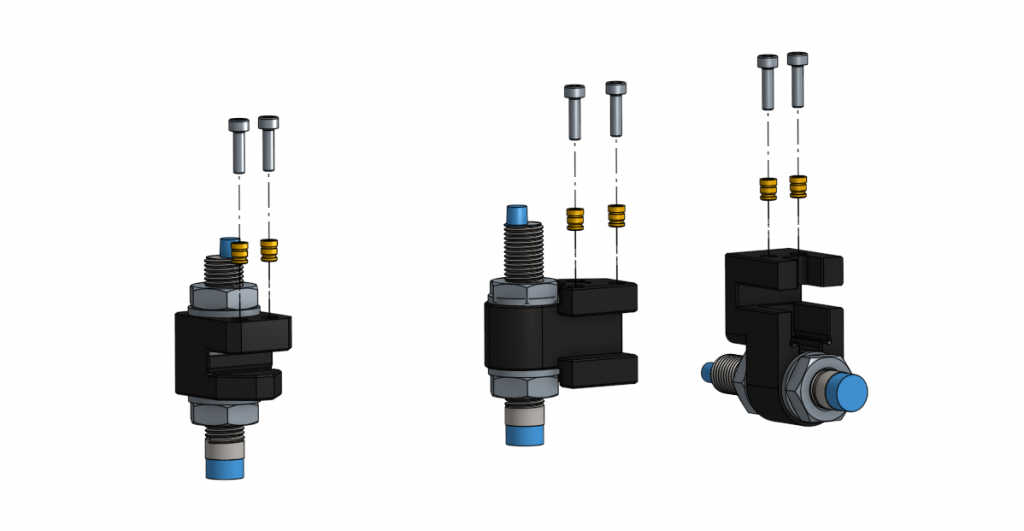

- Focus ring & springs have been tested and packaged with great results

- We have a stock of 200 7w Diodes

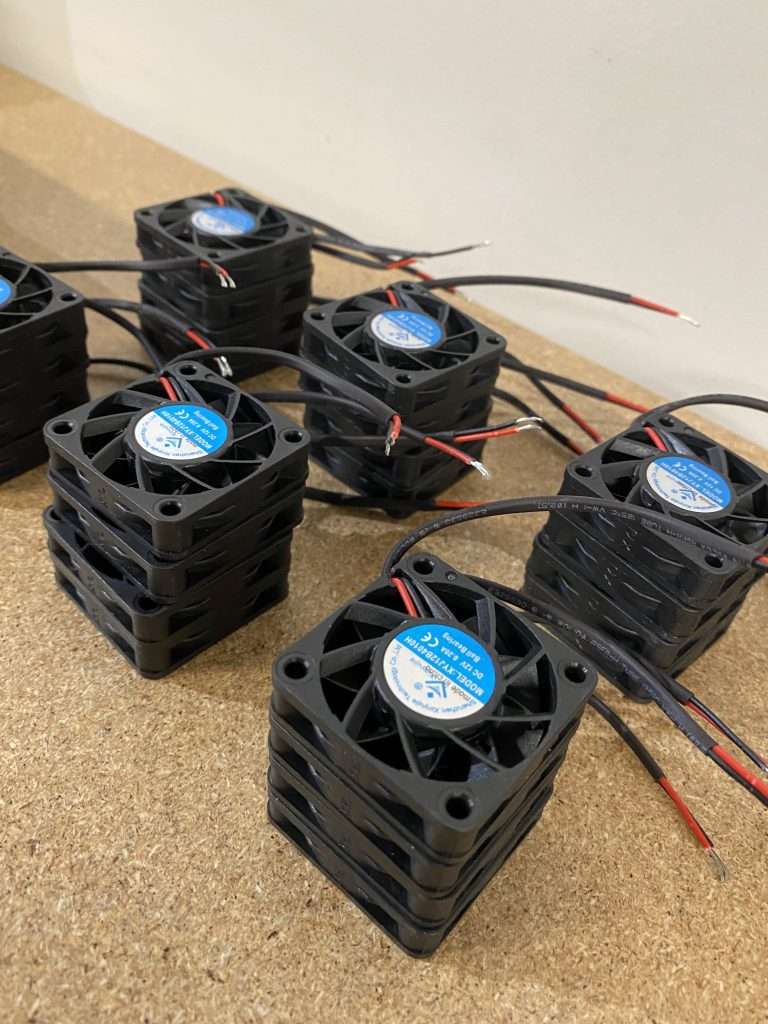

- Fans have arrived and will be tested next week

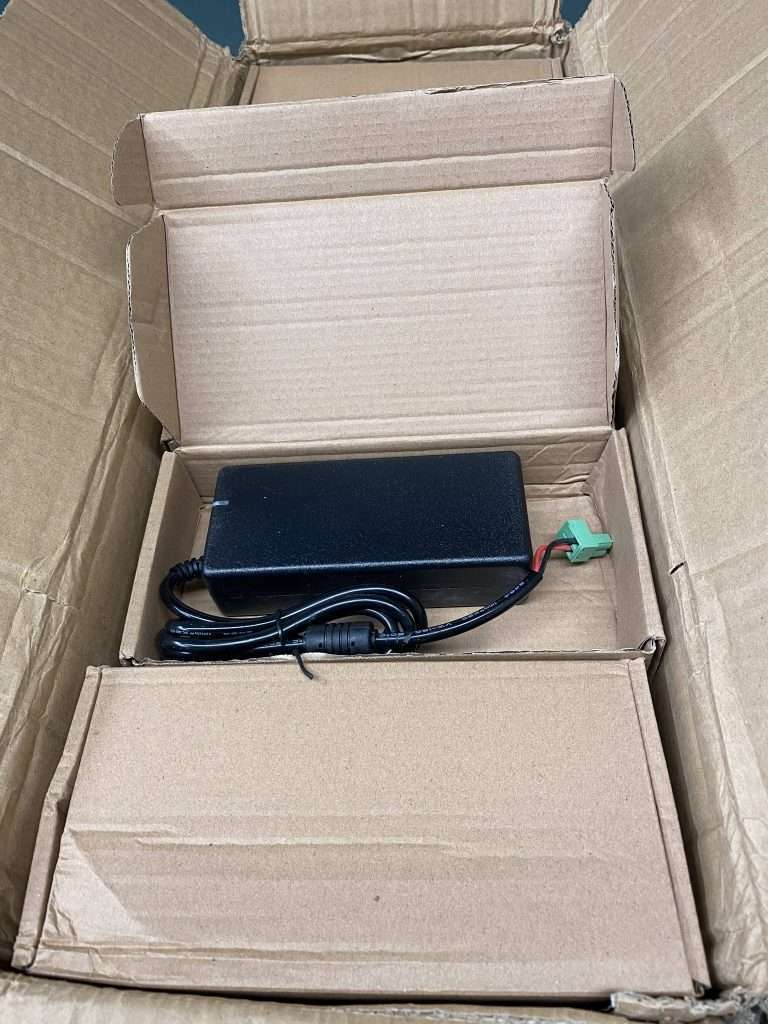

- New batch of power supplies have arrived and will be tested next week

- Extension cables are being prepped for packaging

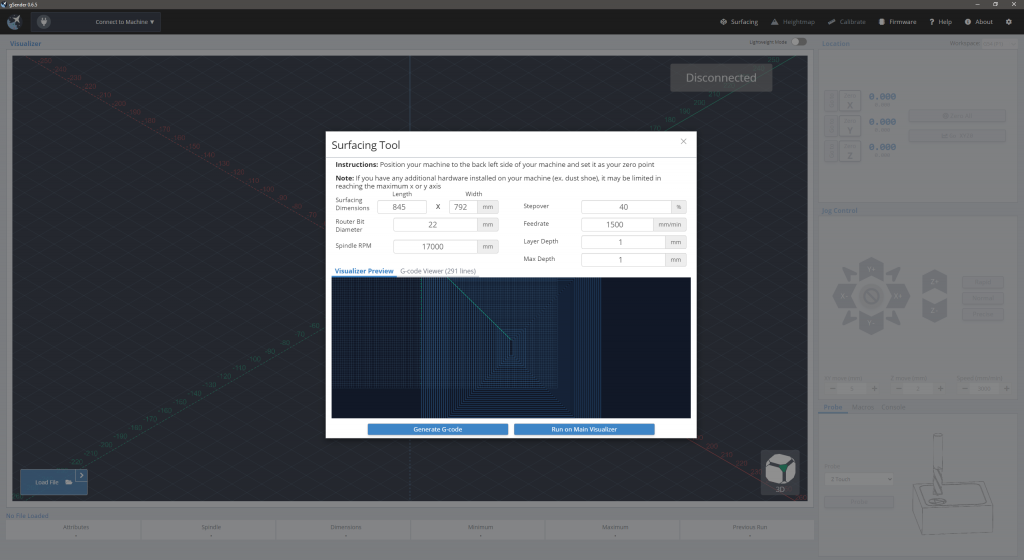

Timeline (8-16 weeks): What needs to be done?

- Driver Development: currently working on v6 of the prototype (1-2 Weeks)

- Testing: send a driver off for testing (1-2 Weeks)

- FDA Compliance: file our test reports with the FDA (1-2 Weeks)

- Order Drivers: order the drivers in bulk (4-8 Weeks)

- Ship: Package and ship LaserBeam Pre-orders (1-2 Weeks)

What If I can’t wait that long?

Please send us an email or give us a call and we will process your refund. I never want to disappoint community members and customers but at Sienci Labs we value transparency over everything. Some of you run your businesses with the Longmill and you anticipated having a Laser for certain projects/jobs, we understand if you need to make different plans and explore other options.

For those of you who still want to wait, first of all thank you. It’s because you guys have supported this project from day one that I get to develop a product that the community will use and hopefully enjoy in the very near future.

Ordering Additional Safety Glasses & Lenses:

Check out the link above if you need to order additional LaserBeam accessories that you didn’t order in your original LaserBeam preorder. You won’t be charged any additional shipping and your order will be combined with your LaserBeam Pre-order!

Sienci LaserBeam Pre Order:

Place your Sienci LaserBeam Pre order here: https://sienci.com/product/laser/

Answering your FAQ:

Send your Laser Questions Here: https://sienci.com/contact-us/technical-help/

Check out our LaserBeam FAQ video, I take all your unanswered questions from the LaserBeam livestream and try to give you guys more clarity on the LaserBeam add on.

Stay up to date by signing up for

If you missed the last update, check it out here: https://sienci.com/2021/07/26/laserbeam-driver-complications/