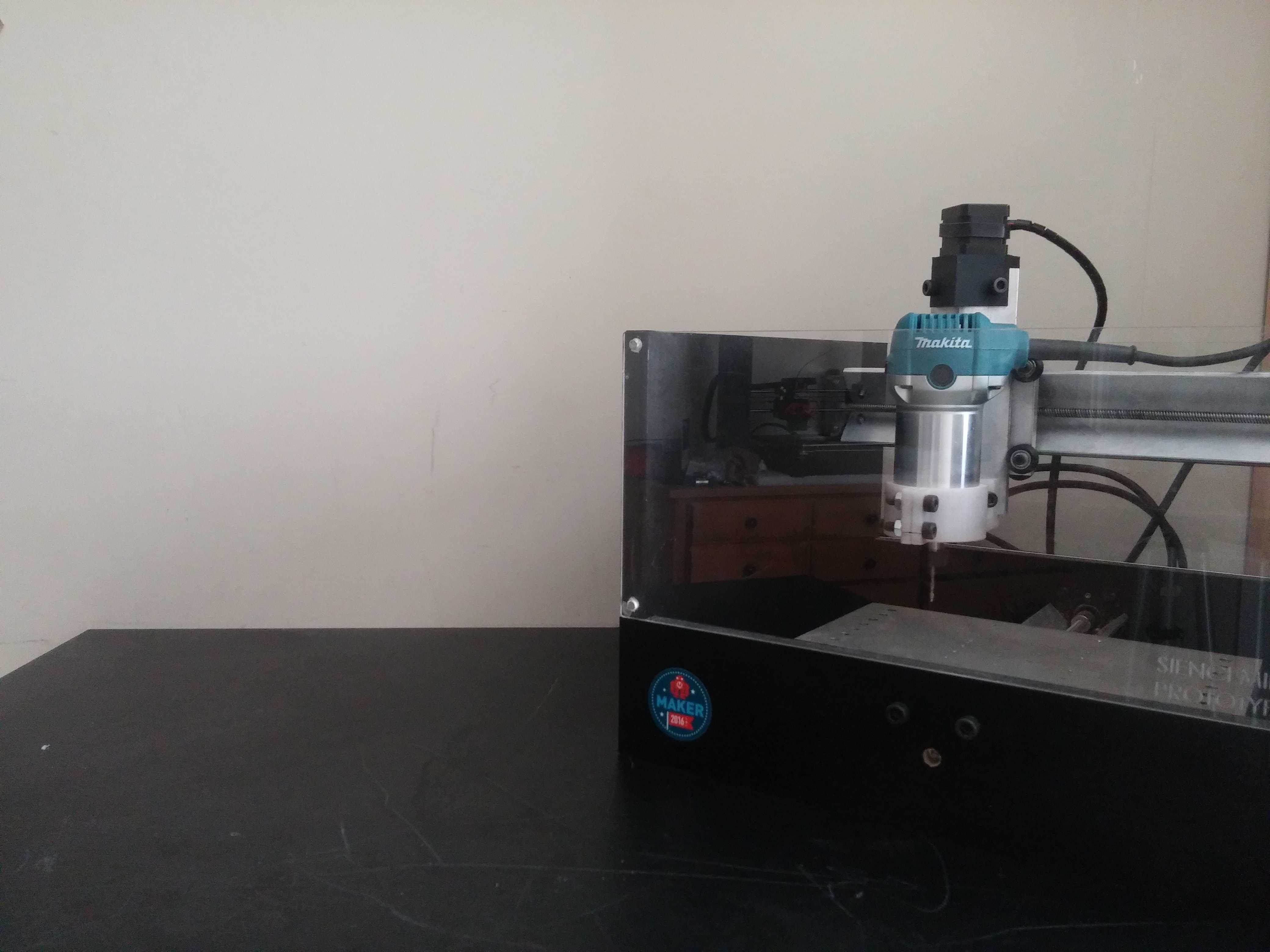

The XZ gantry on the Mill One is one of its core parts and thus requires a high level of rigidity to have an overall high level of performance and precision. This blog post will give a quick look into some of the engineering that goes into the Mill One.

What are we looking for?

Appropriate material selection for the Mill Ones XZ gantry is essential. Initial prototypes were made from 1/4″ PVC, but as the design and performance of the Mill One improved, we found a need for a stronger material to replace the PVC.

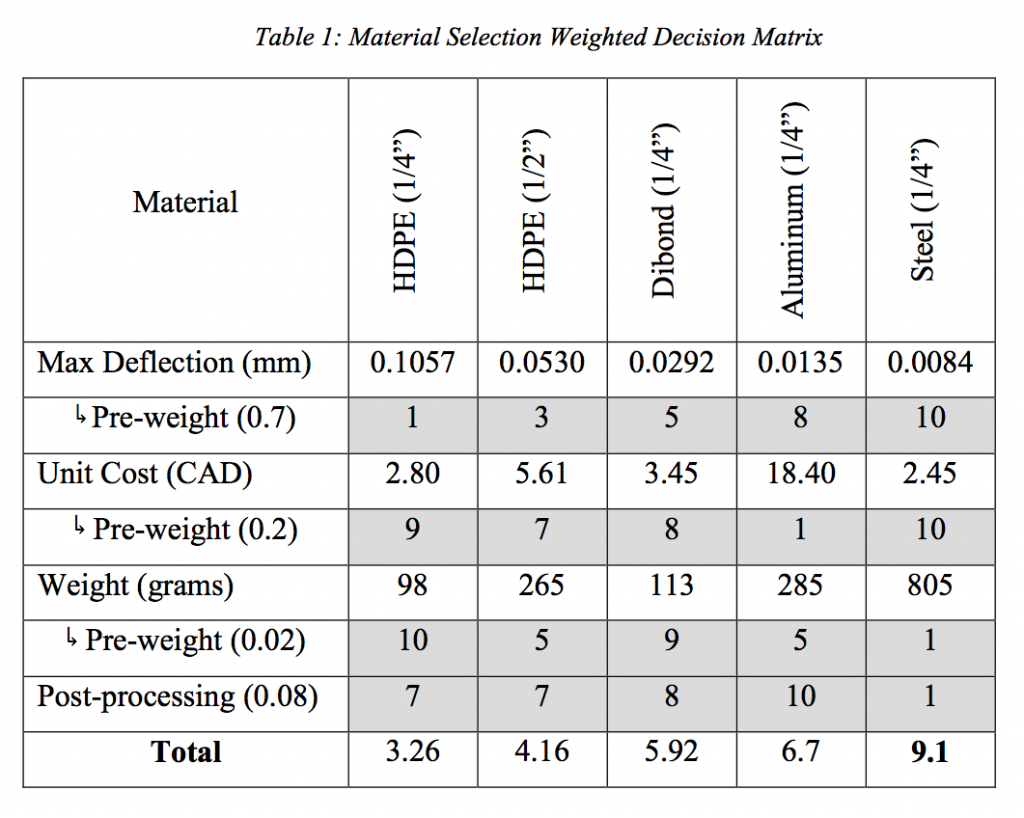

A balance of cost and performance determined the material we’d use for the new XZ gantry.

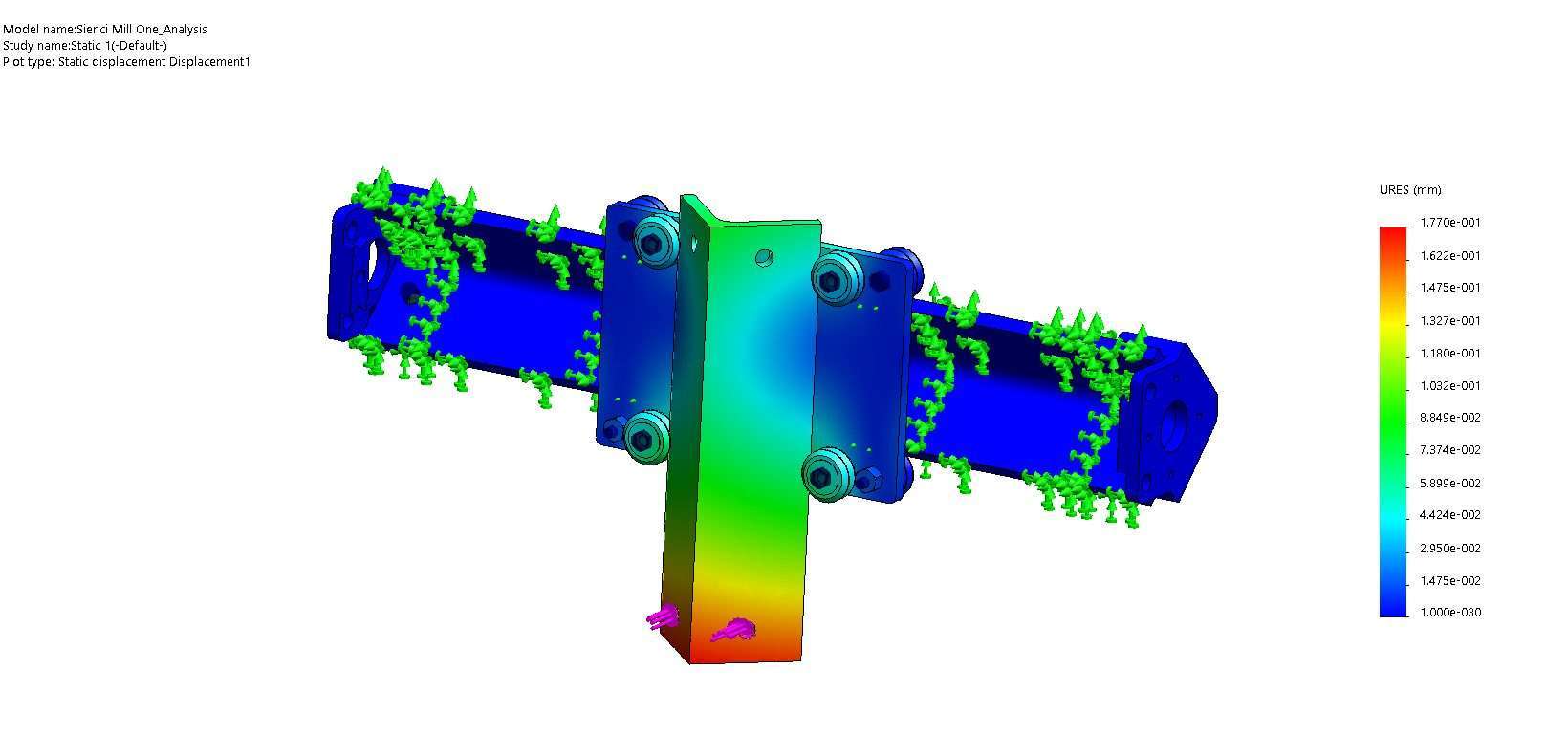

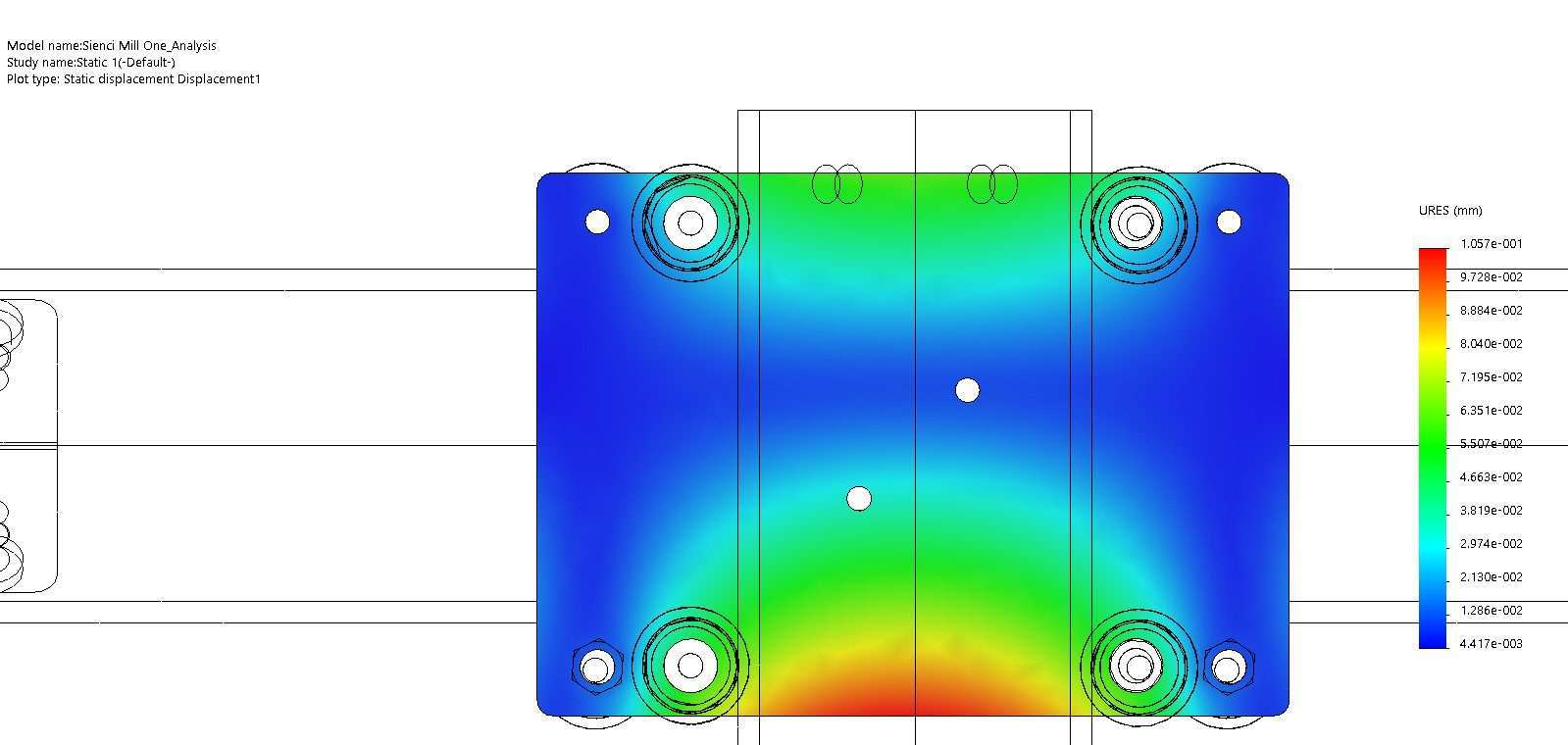

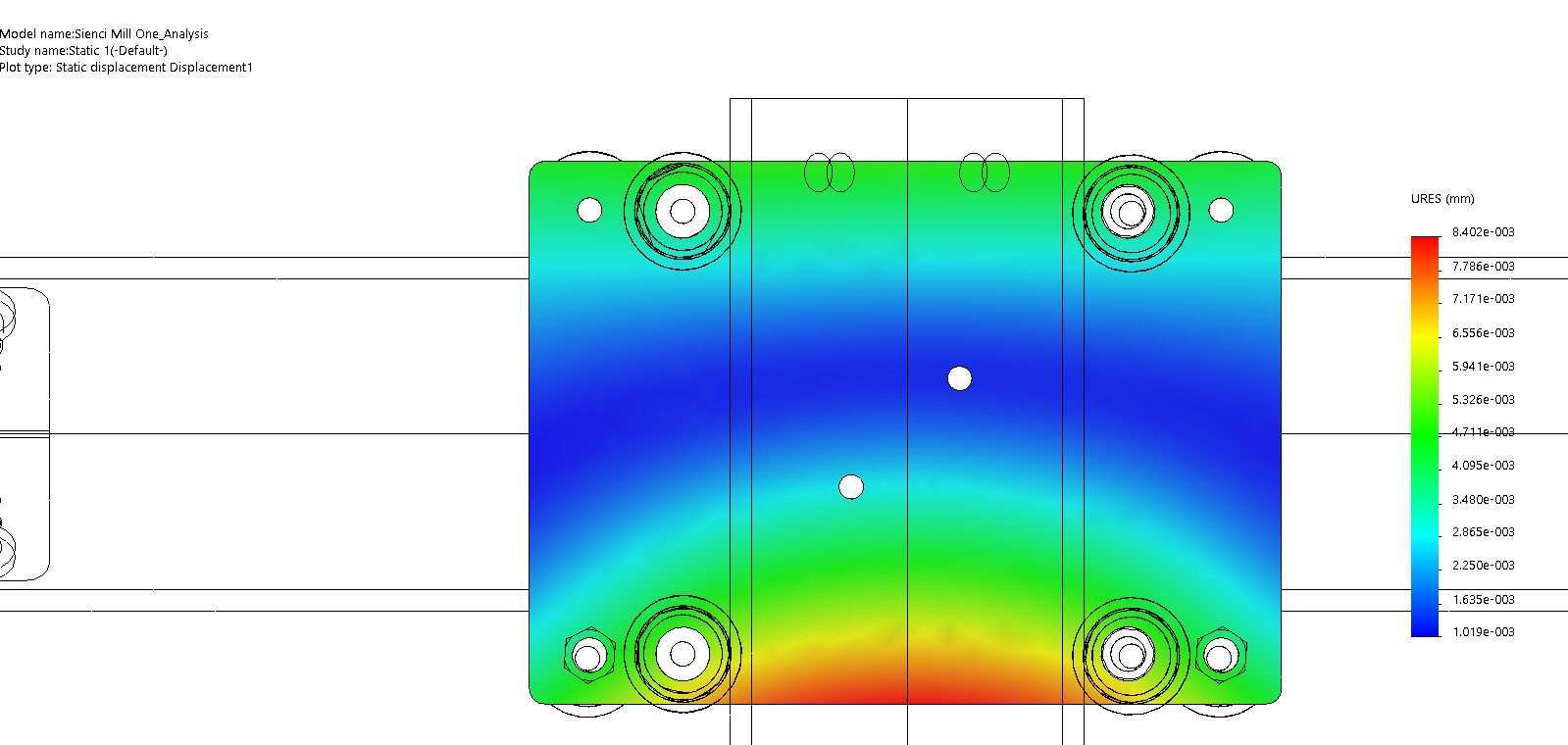

To test for the maximum deflection of the gantry, everything was held steady around the aluminum rails, and a force was applied to the end of the Z axis rail. The red areas have the largest amount of deflection, and we can get an idea of the amount of deflection by taking a look at the legend on the right.

Results

Each material was tested using FEA (finite element analysis) to give us a total max deflection (max deflection occurs at the red areas). Here are some examples:

You can see that the maximum deflection occurs at the bottom of the gantry. If we were to make changes to the design, we know that stiffening up at that area would be the best place to start. Now that we have our results, we could choose the best material.

Conclusion

There are many factors that go into choosing the right material for different parts of a well engineered machine, but this article gives a basic look at how we help make these engineering choices. Every aspect of the Mill One goes through rigorous scrutiny to make it the best machine possible with the constraints we face.