Happy June everyone. I am sure the rest of the team shares this sentiment when I say we are enjoying the sunnier weather.

Want to get news like this directly in your email inbox? Make sure to sign up for our mailing list.

You can also read last month’s production update here: https://sienci.com/2023/05/01/may-2023-production-updates/

LongMill and Extension Kit Orders

As we go into the summer season when things start to slow down in terms of orders, we’ve been catching up with the rest of the queue. We also increased staff to speed up our packing. We now have a turnaround time of just a few days. There are a few items we are running low on, such as the Delrin Anti-Backlash nuts and the v-wheels, but our new order should be arriving in the next week or two.

The past half year has been pretty busy, as this is the first time since August/September 2022, or almost 9 months that we’ve been able to get caught up. Even though it seems like a really long time for us to get caught up, during this time, we also experienced orders nearly double over the last few months, which means we’ve been playing catch up.

May has historically been the slowest time of the year for us as well, but we expect things to start to ramp up significantly in August. You can see the trends below.

Last month in May, we mentioned our extrusion die being damaged unexpectedly. The silver lining to this however is that with the fresh die, we are getting better tolerances across the length of the rail. For those not familiar, extrusion dies have to be replaced over time once the die wears and the profile changes shape to enough of a degree that the extrusion it produces is not of the correct dimensions. This means that the quality of the new Y rails should be slightly better than before.

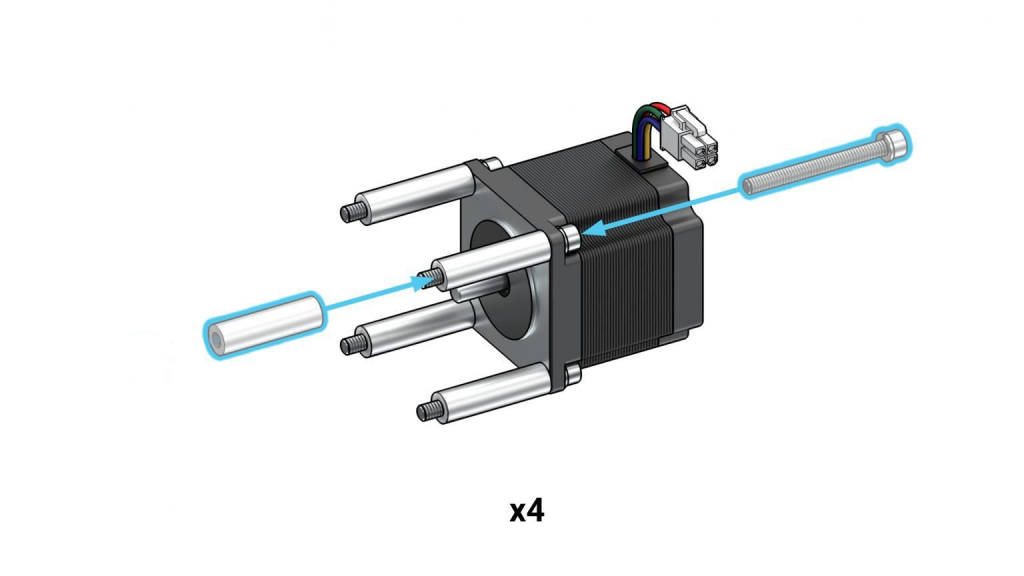

A recent batch of T12 lead screws has arrived, with half of them being out of spec. Due to bends in the screw, we’ve been working on a way to straighten them out. Although in the long run, our priority is to make sure that they are straightened by the manufacturer, due to the large number of bent screws, we wanted to figure out a way to fix them if possible. We expect to receive the full batch of lead screws in the coming weeks, so we’ll have stock available.

While we have some QA issues to tackle, since we have parts stocked up, we expect to be able to go through our existing parts for the time being.

This lull period will allow us to divert energy into the production and assembly of the Rotary Axis, as we expect to see parts start to arrive this month.

Parts for Batch 8 continue to trickle in, with a significant number of parts slated to arrive over the next two months.

We are at the last third of machines in Batch 7, and we expect to go into Batch 8 around August 2023.

LaserBeam Orders

New LaserBeam orders are shipping generally within 2 weeks, but usually faster.

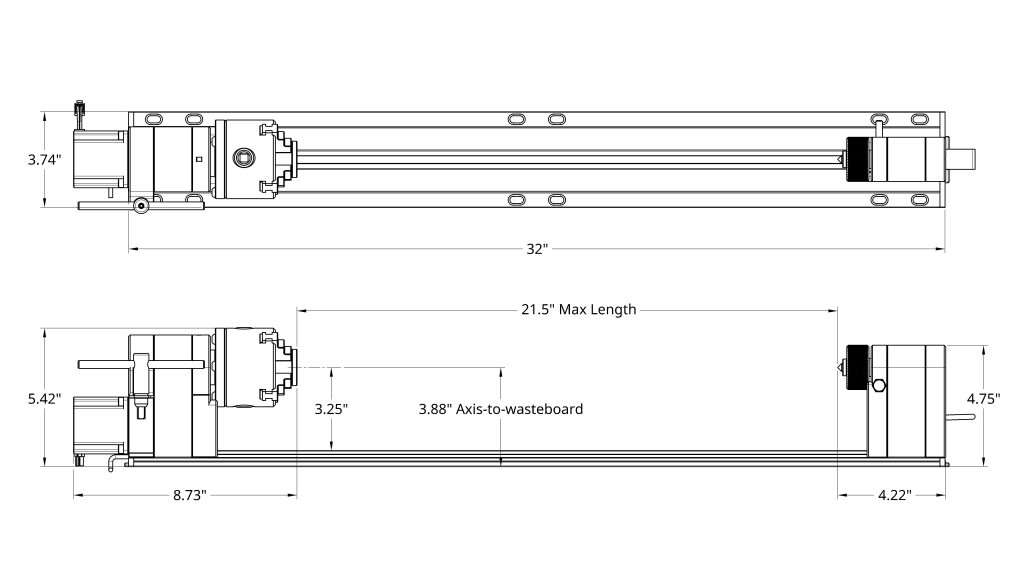

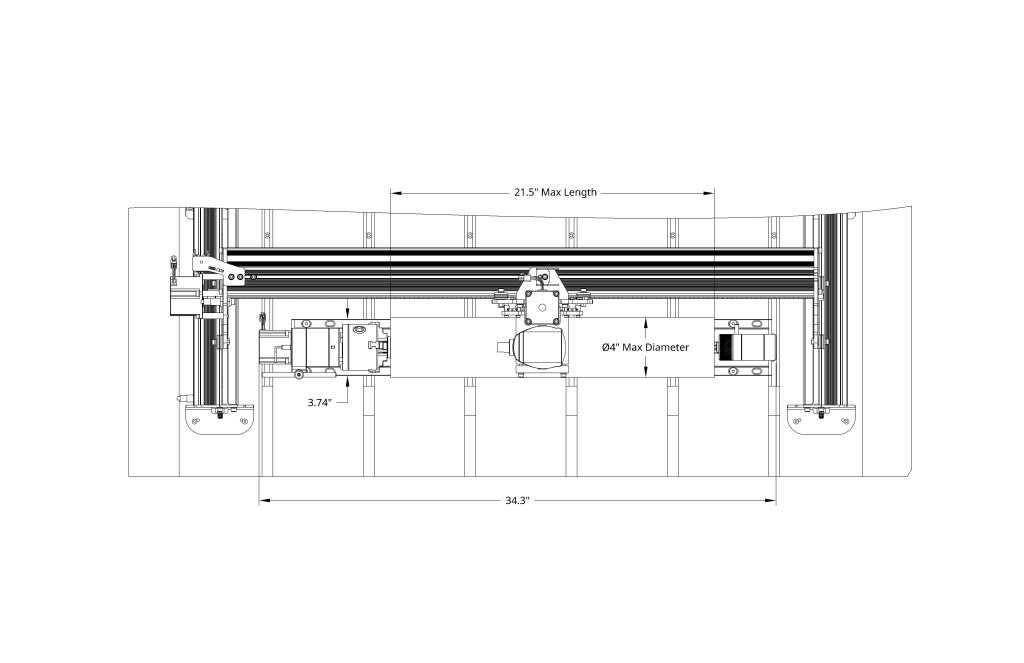

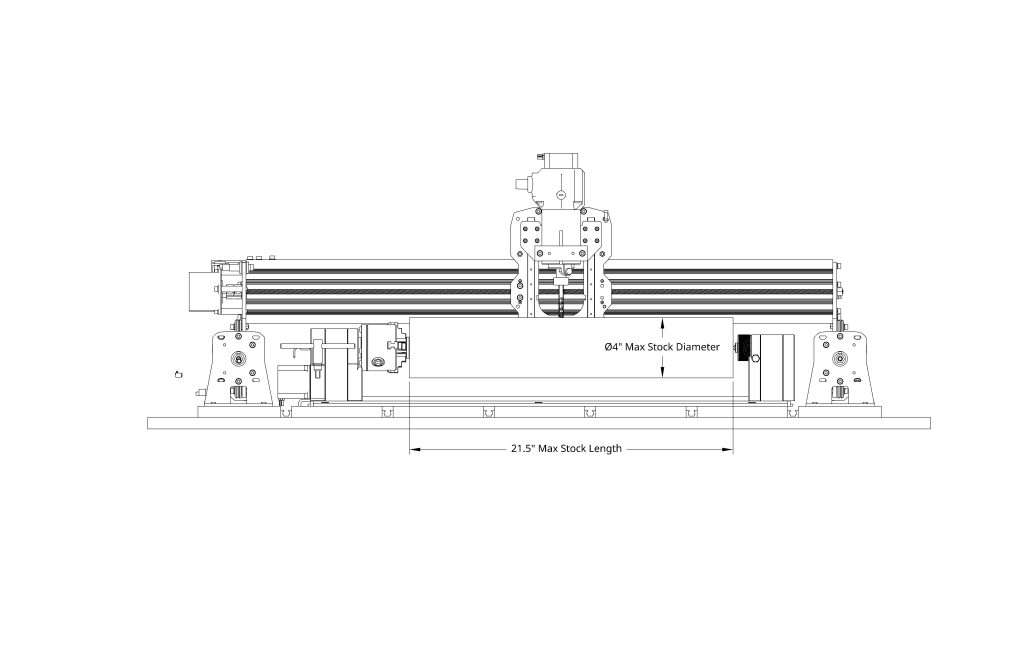

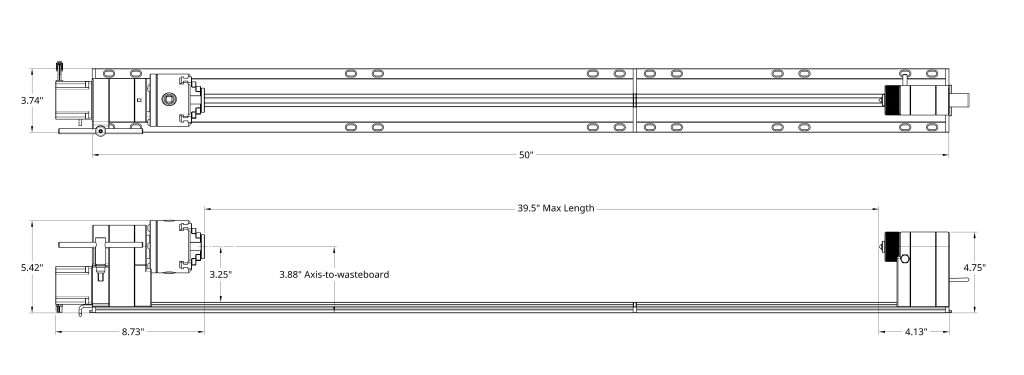

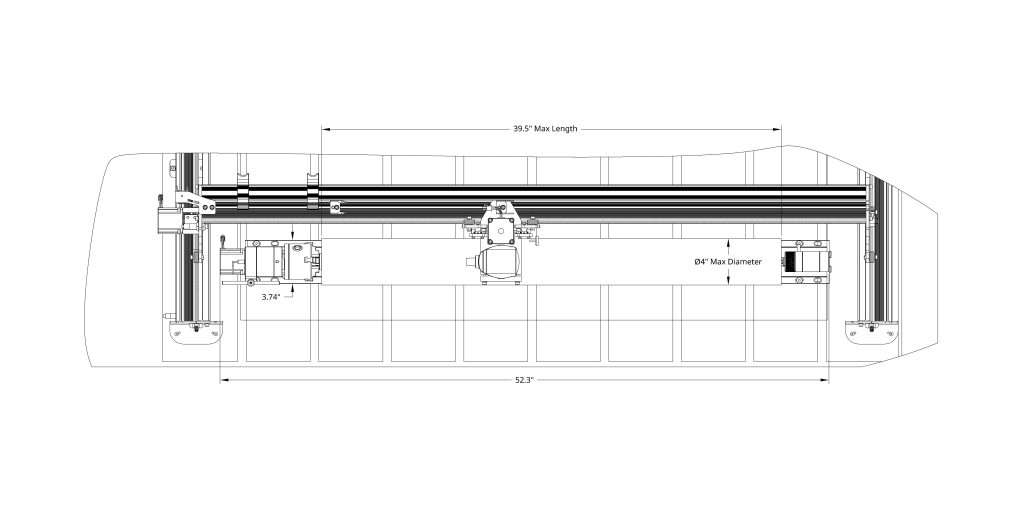

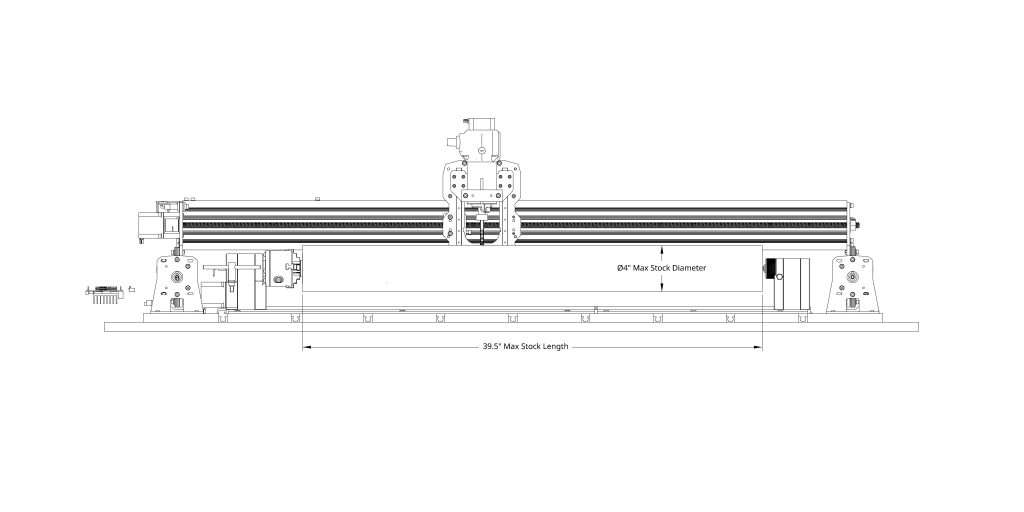

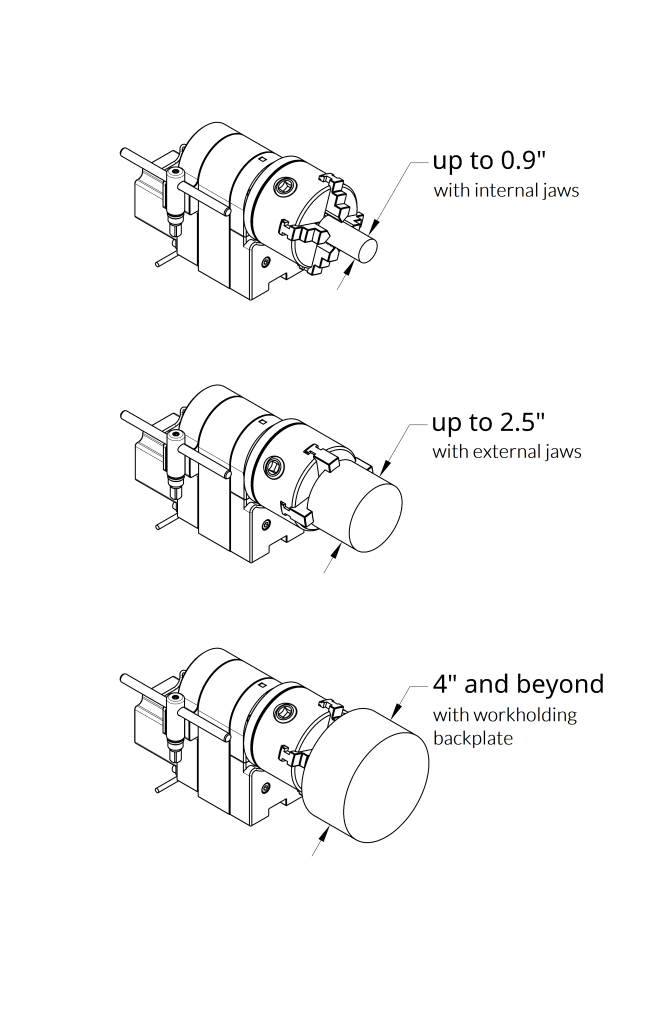

Vortex Rotary Axis

Preorders for the Vortex Rotary Axis will be available for pre-order on June 1, 2023 at 1PM Eastern Standard Time and is expected to ship in August 2023. All important details can be found in this article.

We are expecting parts to start arriving in the coming weeks, and we are prepping assembly and QA for the Rotary units. We’ve started receiving production, and we are expecting the last batch of parts to complete production around mid-July.

Price increase on Makita RT0701 Router

Due to price increases from our supplier earlier this year, we’ve increased the price for the Makita RT0701 from $150CAD to $165CAD.

Shipping Holdups from UPS from Canada to the US

We have now obtained our US EIN number and set up an entity in the US to help facilitate shipments from Canada to the US. Over the last few months, we’ve generally seen fewer holdups, but they are still occurring. Once we get everything set up, we hope that number will drop to zero.

We just set up US bank accounts so that we can also start setting up payment processors in the US. Although for most customers this probably won’t make any impact, this means that we can save on some banking and cross-border fees that happen due to the fact we are doing everything through our Canadian banking network.

There continues to be a bit of friction setting this up, since there are a few extra steps, such as setting up a physical mailing address that can forward mail to us to Canada, learning about the US tax system, and fixing some technical issues with our payment processor as we switch over.